Experimental study of the effect of water-to-cement ratio on various properties of nano silica concretes with polypropylene fibers

In this study, 420 concrete laboratory samples were prepared according to 20 mixing designs with various water-to-cement ratios and different fiber contents. Three volumes of concrete with 3 % nano silica were prepared according to the relevant ACI standard. Finally, samples of carbon fiber containing nano silica were tested in terms of compressive strength, flexural strength, indirect tensile strength (Brazilian test), abrasion resistance, permeability and porosity, and their mechanical properties were evaluated. According to the results obtained, the optimal amount of fiber used is 0.3% for flexural and tensile strength, but only 0.1 % for compressive strength by volume of concrete, while 0.2 % by volume proved best for hydraulic conductivity coefficient and abrasion strength, with 3 % nano silica mixed in. The bending strength of the samples with optimal fiber weight was shown to be 49 % higher than that of non-fibrous specimens. For test specimens (indirect excitation), this amount is 18 %.

1 Introduction

The use of various additives in concrete and cement products has attracted special attention in recent years. So far, many researches have been carried out on fiber concrete, but researches on the nano silica concrete containing polypropylene fibers have been more limited. Particularly, the effect of nano silica on fiber concrete, especially polypropylene fibers, has been very sparsely investigated.

For this reason, the use of fiber concrete, especially polypropylene fibers with nano silica, was investigated in this study. High-strength fiber-reinforced concrete has a wide range...

1 Introduction

The use of various additives in concrete and cement products has attracted special attention in recent years. So far, many researches have been carried out on fiber concrete, but researches on the nano silica concrete containing polypropylene fibers have been more limited. Particularly, the effect of nano silica on fiber concrete, especially polypropylene fibers, has been very sparsely investigated.

For this reason, the use of fiber concrete, especially polypropylene fibers with nano silica, was investigated in this study. High-strength fiber-reinforced concrete has a wide range of applications in which different types of fiber are used to increase the toughness, flexibility and tensile and flexural strength of the concrete in order to increase the strength of the instrument under static and dynamic loads and to reduce cracking and crushing [5].

[18] documented significant differences between fiber concrete with one type of fiber and concrete containing a combination of types of observed fibers. The finer fibers are activated subsequent to the commencement of micro-cracking in the concrete and can prevent further growth of the micro-cracks.

[12] showed that the silica fume improves the compressive strength at higher ages by improving the conjunction of aggregates with cement paste. Also, the simultaneous use of silica soot and fiber in concrete mixtures leads to an effective increase in the flexural strength of concrete.

An experimental research and analytical study by [6] was done on the behavior of high-performance fiber-reinforced concrete. This study shows that UHPFRC properties such as strain hardening behavior also exist under high strain rates.

[3] investigated nano silica in the process of hydration of cement. Their tests confirm that, by reducing the size of silica particles and increasing the size distribution, calcium silicate hydrates become stiffer, which increases the compressive strength.

[13] provided reinforced concrete with steel fiber with mixing pattern and different lengths of different fibers. They evaluated compressive and tensile strengths, fracture behavior and ductility. The addition of fibers increases the ductility that is associated with energy absorption during fracture. Samples of longer fibers show higher strain than samples with shorter fibers.

[20] investigated crack propagation in cement-based mixtures containing hybrid fibers. They showed that the combination of steel and polypropylene fibers increases the resistance to crack initiation and growth.

[15] performed research on the strength properties of reinforced concrete with polypropylene and nylon fibers in which the resistance strength of reinforced concrete to polypropylene fibers versus concrete reinforced with nylon fibers was compared.

[7] conducted a study titled High Performance Concrete (HPC) containing polypropylene fibers against collapse. These researchers examined the performance of polypropylene fibers in maintaining the integrity of high-resistance concrete exposed to fire.

[2] conducted a study of statistical variation in the impact resistance of polypropylene fiber reinforced concrete. In this research, the ACI-544 Committee’s consistent weight drop test was used to measure the impact strength of reinforced concrete with polypropylene fibers.

[4] conducted a study to find a relationship between tensile strength (Brazilian) and compressive strength of reinforced concrete with polypropylene fibers and glass. The results showed that the tensile strength of reinforced concrete with polypropylene fibers and glass has an increment of about 20 to 50 %, and their tensile strength amounts to about 13 to 19 % of their compressive strength.

[17] added artificial carbon fiber and microsilica to some concrete mixtures to improve their mechanical properties.

[11] analyzed the effect of different modifiers on the properties of concrete mixtures using micro-silicon additive.

[16] have shown that nano silica and micro silica can be successfully used in the preparation of self-compacting concrete (SCC).

[8] measured the compressive strength, tensile strength, water absorption percentage and chloride penetration depth of concrete containing nano silica.

The purpose of the present study is to determine the effect of polypropylene and nano-silica fibers on behavioral properties of concrete under stress conditions due to flexural loads, study the slump as well as the permeability and porosity of the concrete, and obtain their optimal percentage.

2 Experiments performed on samples

In this study, concrete samples have 3 % nano silica with water-to-cement ratios of 0.33, 0.36, 0.4, 0.44, 0.5 and fiber contents of 0, 0.1, 0.2 and 0.3 of concrete volume.

A flexural strength test according to Figure 1 was carried out on concrete beams of 10×10×50 cm at 28 days of age. All stages of testing were performed according to ASTM-C1018 standard. Eq. (1) can be used in order to calculate the flexural strength:

Flexural Strength = [(PL/bd2) x 1000]⇥(1)

An indirect tensile strength test, or tensile strength of halving, was performed on cylindrical specimens of 300×150 mm at 28 days of age. For this, the load needs to be applied continuously and without impact. The load speed of 80 kN/min was selected according to the ACI-C330 standard. Eq. (2) illustrates how to determine tensile strength, and Figure 2 shows the indirect tensile strength test machine.

Tensile strength = [(2P/πdL) x 1000]⇥(2)

Abrasion strength testing of cube samples 150×150×150 mm at 28 days of age was performed using the water sand blast method based on ASTM-C778 standard (Figure 3).

The hydraulic conductivity of the concrete was tested using the penetration method according to ASTM-C1920-5 (Eq. (3)).

Concrete hydraulic conductivity coefficient

= Hp2V/(2TH)⇥(3)

Figure 4 illustrates the machine used for performing the hydraulic conductivity of the concrete tests. The following formula can be used to calculate the porosity of the concrete:

Concrete porosity

= {(w/c) x (100-36.15α)/(W+100/g)}⇥(4)

Compressive strength tests on cube samples of 150×150×150 mm at the age of 7, 28 and 91 days has been performed using a pressure test device with a capacity of 2000 kN (TEKNO test-Italy) at a speed of 2.5 kN/S accordance to ACI-C330 standard. Figure 5 is an illustration of the compressive strength test machine. The compressive strength of samples can be evaluated using Eq. (5) as following:

Compressive strength

= [(P/A) x 1000]⇥(5)

3 The mixture scheme of fiber concrete

containing nano silica

In the mixture scheme of samples, the following points were considered:

The slim test according to ACI Committee 544 is not suitable for fiber concrete, so we should use the reverse slip test according to the setup displayed in Figure 6 (both stone materials broken).

The cement used in these experiments is ordinary Portland cement in accordance with Table 1.

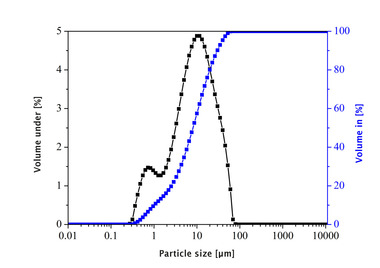

For all samples, the amount of fixed nano silica and 3 % consumption cement have been replaced as shown in Table 2.

The amount of polypropylene fiber varies and is equal to 0, 0.1, 0.2 and 0.3 volumetric percent alternatives of cement used. The properties of the consumed polypropylene fiber are shown in Table 3, and its mixture design with the nano silica is shown in Table 4.

The compressive strength of the 28-day specimen is 40 MPa. The maximum diameter of aggregates is 15 mm. Table 5 summarizes the properties of required materials for sample design.

The super lubricant used in these experiments is Super Plasticizer 400 according to ASTM-C494 type4 standard.

In the production of test specimens, excess water was computed and added to the dry state (S.S.D state) to prevent the concrete from absorbing free water into the empty space of the aggregate.

4 Investigating the results of the flexural

strength test

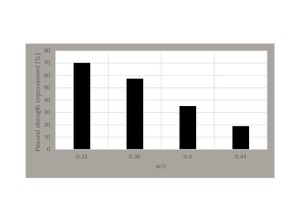

According to Figure 7, the flexural strength is seen to increase with the addition of fibers. As the graphs show, adding fibers up to between 0.3 % and 3 % of nano silica has a significant effect on flexural strength. However, the flexural strength decreases for higher fiber ratios. It is anticipated that by increasing the fiber content more than 0.3 %, the flexural strength will be reduced. In this part, inappropriate distribution of fibers can also result. Non-fibrous samples fractured on failure, a problem that was completely eliminated by the fiber. According to Figure 8, with decreasing water-to-cement ratio from 0.50 to 0.3 in non-fiber samples, the flexural strength improves by 70.17 %. For a water-to-cement ratio of 0.33, adding 0.1, 0.2 and 0.3 % fibers to the samples, as according to Figure 9, improved the flexural strength by 31.81, 37.23 and 39.61 %, respectively.

5 Investigating the results of the tensile

strength test

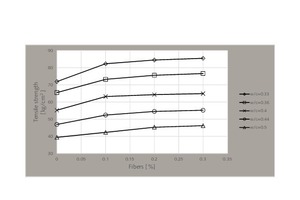

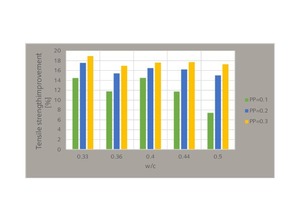

Figure 10 illustrates that the indirect tensile strength increases with the addition of polypropylene fibers. As shown in the diagram, adding 0.1 % fiber has a significant effect on tensile strength. For a fiber ratio higher than 0.1 %, the tensile strength decreases. Also, according to Figure 11, one can see that reducing the water-to-cement ratio from 0.5 to 0.33 in concrete samples without fiber improved the tensile strength by 82.4 %. By adding 0.1, 0.2 and 0.3 % fiber for a water-to-cement ratio of 0.33, tensile strength improves by 11.96 %, 16.13 % and 17.68 %, respectively, compared to non-fibrous samples (Figure 12).

6 Investigating the results of the abrasion

strength test

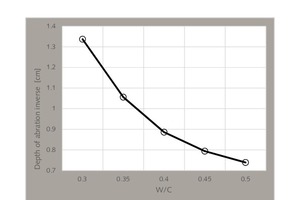

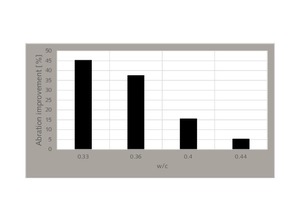

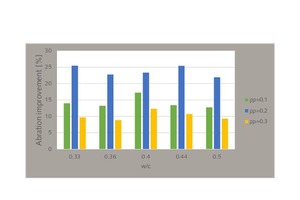

Figures 13 and 14 show the abrasion resistance of reinforced concrete. The changes in the abrasion resistance of the samples resulting from fiber addition are apparent. Increasing the fiber content up to 0.2 % can increase the abrasion resistance. However, increasing the fiber content to more than 0.2 % decreases the abrasion resistance of the non-fibrous samples. The reason for this is that the fiber increases the porosity of the samples. Figure 15 illustrates that, by reducing the ratio of water-to-cement from 0.5 to 0.33, the abrasion resistance of non-fibrous concrete samples is improved by 46 %. Adding 0.1, 0.2 and 0.3 % fiber to the concrete samples for a water-to-cement ratio of 0.33 % improves the abrasion resistance by 14, 25.45, and 9.68 %, respectively, compared to the non-fibrous samples (Figure 16). As the water-to-cement ratio increases from 0.33 to 0.50, the slope of the depth of abrasion curve decreases gradually. This is related to the two-phase nature of concrete in abrasion (phase of mortar and phase of aggregates). As the water-to-cement ratio increases, the abrasion strength of the mortar phase decreases, while the abrasion strength of the concrete tends more towards the abrasion strength of the aggregates.

7 Investigating the effects on hydraulic

conductivity coefficient and porosity of concrete

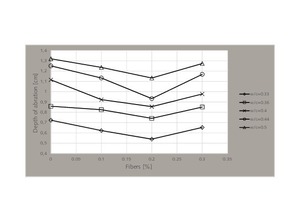

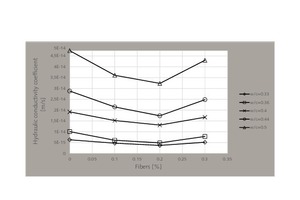

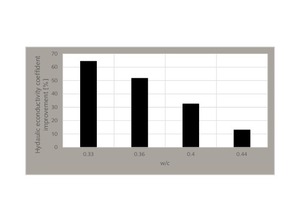

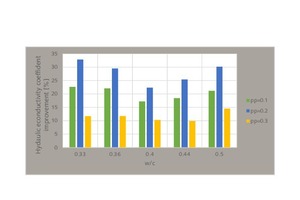

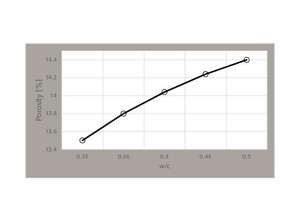

An analysis of Figure 17 to Figure 19 shows that the hydraulic conductivity coefficient is altered by the addition of fibers. Using fibers up to 0.2 % reduces the depth of water penetration and the hydraulic conductivity. Nevertheless, these values increase when more than 0.2 % is added. This behavior of the porosity of most samples is due to the addition of more fiber content. According to Figure 17, it is obvious that, by decreasing the ratio of water-to-cement from 0.50 to 0.33, the hydraulic conductivity of non-fibrous concrete samples decreases from 43.03×10-15 m/s to 6.3×10-15 m/s. this means that the hydraulic conductivity coefficient of samples has improved by about 85.36 %. Figure 19 shows that, for a water-to-cement ratio of 0.33, the hydraulic conductivity coefficient of concrete with 0.1, 0.2 and 0.3 % fibers was improved by 25.08, 41.43 and 17.9 %, respectively. In addition, by reducing the water-to-cement ratio from 0.50 to 0.33, the concrete porosity decreases from 14.4 to 13.5 % (Figure 20).

8 Investigating the results

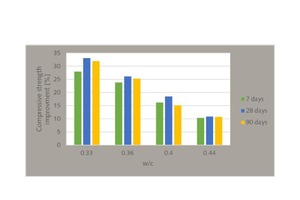

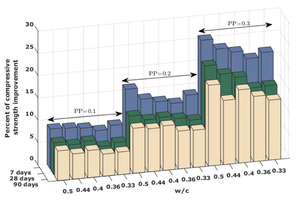

of the compressive strength test

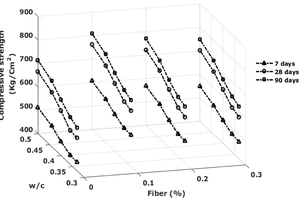

Figure 21 to Figure 23 show the results of compressive strength testing and the percentage of improvement in the compressive strength of fibrous samples (0.1, 0.2 and 0.3) in contrast with non-fibrous specimens. Investigation of the compressive strength of the fiber reinforced concrete shows that the adhesive strength changes with the addition of fibers. Using 0.1 % fiber for a constant water-to-cement ratio of 0.33 causes a relative increase in compressive strength of 7, 28 and 90 days of age. With increasing fiber content to more than 0.1 %, the compressive strength decreases. The reason for this behavior is that, when the amount of fiber in concrete is increased by a certain amount, the compressive strength values are reduced due to poor fiber dispersion.

As to be seen in Figure 22, by reducing the water-to-cement ratio from 0.50 to 0.33, the compressive strength of non-fibrous concrete samples at the age of 7, 28 and 90 days of concrete is improved by 27.92, 33.04 and 31.88 % respectively. Also, Figure 23 illustrates that, by adding fiber at 0.1, 0.2 and 0.3% compared to non-fibrous samples, the compressive strength of the samples at 7, 28 and 90 days of age improves accordingly (21.42, 15.29 and 13.44 %) , (13.52, 8.47 and 35.8 %) and (8.42, 5.9, and 5.71).

9 Conclusion

Concrete samples were tested for compressive, flexural, tensile and abrasion strengths, permeability and porosity, and their mechanical properties were evaluated. The main and most important results are as follows:

For a ratio of 0.1% fiber and 3 % nano silica, an optimal compressive strength state occurs and continues through the end of the experiments. This is due to the inappropriate diffusion of fibers and the reduction of concrete slump, because the super-lubricant remains constant during the test, so that it is better to increase the nano silica in order to achieve higher resistances by increasing the fiber

In samples containing fibers and in non-fibrous samples, about 75 % and roughly 72 % of 28-day compressive strength, respectively, was achieved in the first 7 days. In addition, in fibrous samples, about 80 %, and in non-fibrous samples about 77 % of 90-day compressive strength was achieved in the first 28 days

For a ratio of 0.2 % fiber and 3 % nano silica, an optimal abrasion strength condition occurs. By increasing the fiber content to more than 0.2 %, the abrasion strength is reduced due to the porosity of the samples. The polypropylene fiber prevents the concrete from losing water and prevents the water from moving to the concrete surface. This results in homogenization of the concrete, uniformity of the water-to-cement ratio in all concretes and continuation of the hydration action. This fiber reduces the permeability of the concrete surface, increases the concrete’s life and increases the abrasion resistance of the concrete, while the surface of the concrete neither corrodes nor slips. In addition, the surface of the concrete does not erose or laminate

A sand-blasting test is a good way to evaluate the abrasion strength of concrete against water, because this method can closely simulate the actual abrasion of the concrete

Fibers of 0.3 % produced a significant increase in tensile strength, which is more obvious by the increase of fiber content. The presence of fibers in concrete, which is a brittle body, improves the samples’ ductility and improves tensile strength of the concrete

For a ratio of 0.2 % fiber and 3 % nano silica, an optimal state occurs for the depth of water penetration and the hydraulic conductivity

The reduction in permeability in the presence of fibers is due to the placement of fibers between the porous bonding pathways and their blocking, which results in removal of the capillary property that increases the permeability, and the permeability decreases

For a ratio of 0.3 % fiber and 3 % nano silica, an optimal state of flexural strength occurs. Adding more than 0.3 % fibers decreases the flexural strength as compared to non-fibrous samples. In the appearance of samples with more than 0.3 % fiber, the reduction of flexural strength due to the lack of suitable fibers, the bullet phenomenon, as well as obstruction in concrete, and the line of failure were almost the same as the areas where fiber density was lower

With the presence of fibers in concrete samples, there are two types of main parallel and perpendicular positions between the cracks and the fibers. If the fibers are not perpendicular to the crack’s edges, the fibers bridge (sew) the cracks, the integrity of the concrete is preserved up to a higher level of deformation, and the flexural strength rises accordingly

Mechanical properties such as compressive strength, tensile strength, flexural strength and abrasion of concrete produced improve with an increase in the percentage of nano silica up to 3 %, and then threaten to decrease. This gain in resistance is due to the intense reaction of pozzolanic nano silica, and the reduction in resistance is due to a very high level of nano particles, which, when their amount exceeds a certain percentage (optimal percentage), cling to one physical reaction and create unstable holes. This can also have a negative effect on the motility and efficiency of the concrete. Therefore, in this laboratory test, 3% nano silica is considered to be optimal

Mechanical properties such as compressive strength, tensile strength, flexural strength and abrasion strength of concrete are improved by increasing the percentage of nano silica up to 3 %, after which it threatens to decrease. This increase in resistivity is due to the intensity of the nano silica puzzolan reaction, and the loss of resistances is due to the very high specific level of nano particles. When they increase beyond a certain amount (optimal percentage), clinging together with a physical reaction and causing balling, this also can have a negative impact on the fluidity and efficiency of the concrete. Therefore, in this laboratory test, 3 % nano silica is considered to be optimal.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.