Effect of fibers on the properties of gypsum-cement-pozzolanic binder

This article describes the development of compositions, their structure and properties of such composite astringents. The results show that in composite gypsum binders there is no corrosion of basalt fiber. Thus, the study of the influence of various fibers on the structure and properties of the gypsum-cement-pozzolanic binder allows us to recommend compositions with basalt fiber.

1 Introduction

Products and structures made with binding materials are in widespread use nowadays. Meanwhile, modern applications call for the introduction of new structural and composite materials in conjunction with new technologies. Complex environmental conditions and new economic circumstances throughout the country predetermine a new approach to the creation, production and use of building materials of various functional purposes. At the same time, special attention should be paid to resource conservation, maximum use of local raw materials and wastes of various industries, increasing the...

1 Introduction

Products and structures made with binding materials are in widespread use nowadays. Meanwhile, modern applications call for the introduction of new structural and composite materials in conjunction with new technologies. Complex environmental conditions and new economic circumstances throughout the country predetermine a new approach to the creation, production and use of building materials of various functional purposes. At the same time, special attention should be paid to resource conservation, maximum use of local raw materials and wastes of various industries, increasing the competitiveness of construction products, and the use of efficient, science-intensive technologies and materials. The widespread use of gypsum materials in construction is one way to solve these difficult tasks. The preconditions for this include low heat and sound conductivity, fire resistance, high decorativeness and comfort, and ecological safety on the part of such materials. The materials must simultaneously have good performance properties, such as compressive strength and tensile strength, crack resistance, toughness, wear resistance, corrosion resistance and frost resistance. This can be realized by reinforcing the binders. The employed filler allows to obtain a new material that surpasses the traditional binder in terms of economic parameters and strength characteristics.

Fiber reinforcement is based on the assumption that the matrix material transfers the applied load to the fibers by tangential forces acting on the interface and, if the fiber module is larger than the matrix module, then the majority of the applied stresses are received by the fibers, and the full strength of the composition is proportional to the volume content [1]. The prospects of using non-metallic fibers as dispersed reinforcement have been confirmed by studies carried out by foreign and domestic scientists [2-4]. The correct choice of fibers and binder plays a key role in the creation of composite materials by means of fiber reinforcement. In this connection, when choosing a material, it is necessary to take into account not only its manufacturability, strength and economic viability, but also its durability, which is closely related to the resistance of the fibers in the matrix and their adhesion to it.

2 Materials and methods

A gypsum-cement-pozzolanic binder was chosen for use in researching the conception of a gypsum binder G-5 B (II) (Knauf Gypsum, Krasnogorsk) (GV) combined with Portland cement CEM I 42.5 N ZAO Oskolcement (PC) and active mineral supplements – silica gel, metakaolin, triple. The ratio between the components in the binder was determined by a special technique [5].

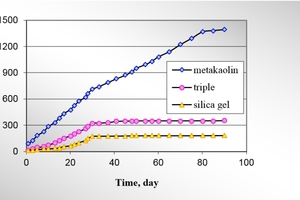

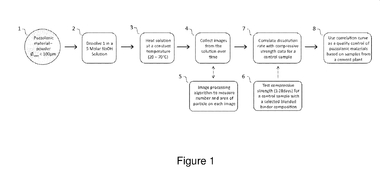

Investigation of the properties of gypsum-cement-pozzolanic binders (GCPV) with silica gel, trefoil and metakaolin showed that the greatest strength and water resistance are typical for gypsum-cement-pozzolanic astringent with metakaolin as active mineral additive. Metakaolin is characterized by 2-3 times more pozzolanic (hydraulic) activity, compared with triple and silica gel

(Figure 1). Therefore, all further research was carried out with a GCPV containing metakaolin, with the following components, wt%: GV – 53.3; PC – 33.3; metakaolin – 13.4.

Since gypsum-cement-pozzolanic binder is found in many dry building mixtures, plasticizers, water-retaining functional additives and polymer dispersions-redispersible polymer powders are necessarily used in their manufacture. The study of the properties of GCPV in the presence of the hyperplasticizer Melflux 5581 F (GP), a water-retaining additive called Hercules 7591 (EC) and re-dispersible polymer powder Vinnapas 8034H (RPP) allowed to determine their optimal contents – 0.2 % GP, 0.5 % EC and 0.5 % RPP (composition 1, Table 1) [6, 7].

Also, the properties of a gypsum-cement-pozzolanic binder with various fibers were studied: polypropylene (d = 10 μm) (PPV, composition 2 according to Table 1), basalt (d = 12 μm) (BV, composition 3), high-modulus glass fiber (d = 10 μm) (CV, composition 4) and polyacrylic (d = 9 μm) (PAV, composition 5). The length of the fibers was 4-5 mm. The fibers were introduced into the GCPV in an amount of 0.4 % by weight of the binder (i.e., in such an amount in which the fibers are generally contained in dry construction mixtures).

3 Results and discussion

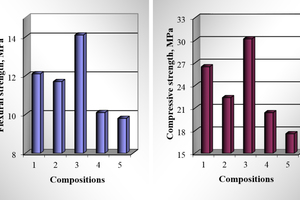

When the fibers are added, the normal density of the binder changes only insignificantly, and the setting time remains practically unchanged. However, the strength parameters of the solidified binder do change (Figure 2). Introduction of polypropylene fiber leads to a reduction in compressive strength from 26.5 to 22.4 MPa, and to a slight decrease in bending strength from 12.1 to 11.7 MPa. The compressive strength increases to 30.2 MPa in the presence of basalt fiber and the bending strength rises to 14.1 MPa. A gypsum-cement-pozzolanic stone with fiberglass is characterized by the lowest durability (strength of 17.6 and 9.8 MPa, respectively).

The introduction of fibers into the matrix of a gypsum-cement-pozzolanic binder slightly increases (from 0.46 to 0.55) the flexural strength/compressive strength ratio that characterizes the reinforcing capacity of the composition. (There was no a priori expectation that this ratio would yield a high value, as the fibers were introduced in low concentration – 0.4 %).

Moreover, the addition of fibers to the gypsum-cement-pozzolanic binder leads to an increase in water resistance, frost resistance and corrosion resistance of the composition (Table 2).

The coefficient of water resistance therefore increases from 0.82 to 0.85 (with polypropylene fiber) and up to 0.86 (with basalt fiber). Lower open porosity (7.4-8.4 %) and lower water absorption (9.0-10.1 %) result from the same compositions. The values of porosity and water absorption are close to those of the composition without fibers for polyacrylic and fiberglass.

The frost resistance of a gypsum-cement-pozzolanic stone with fibers was determined by the accelerated method of freeze-thaw cycling in a 5 % NaCl solution. Twenty cycles of alternate freezing and thawing were carried out, after which the strength values were determined. GCP stone is considered to be frost-resistant, if the strength of the patterns when compressing them is reduced by no more than 10 %. The results obtained (see Table 3) allow us to conclude that, after 20 cycles of freezing and thawing, all formulations are frost-resistant, but the smallest decrease in strength (4.2 %) is characteristic for composition 3 with basalt fiber.

The corrosion resistance of GCPV with fibers was evaluated by two methods: by immersion in a 3 % solution of sodium sulfate and by exposure in a salt fog chamber. The coefficient of corrosion resistance (Kc) of gypsum-cement-pozzolanic stone after hardening for 1 month in a solution of sodium sulfate is equal to 0.92. Kc rises to 0.93 – 0.96 for compositions with polypropylene and basalt fibers. On the contrary, it falls to 0.90-0.88 in the presence of polyacrylic and fiberglass.

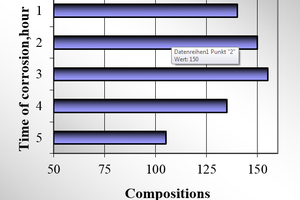

The salt fog chamber is designed for testing materials for corrosion resistance in air. The samples placed inside the test chamber are exposed to salt fog (5 % NaCl solution is sprayed in), at a certain temperature and humidity for a certain length of time. At the end of the tests, the surface of the samples is examined for resistance to corrosion – i.e., the nature and size of defective surface is assessed. It is conventionally assumed that 1 hour of exposure in a salt fog chamber corresponds to the material spending a half-year under normal conditions. The conducted studies showed that the best results in the salt fog chamber were achieved by composition 3 with basalt fiber – the time lapse pending appearance of the first signs of corrosion being 155 hours (Figure 3). The composition with polypropylene fiber (150 hours) showed similar results. However, in the case of polyacrylic and fiberglass, the first signs of corrosion appeared after 135/105 hours.

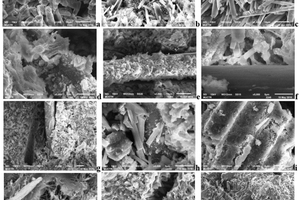

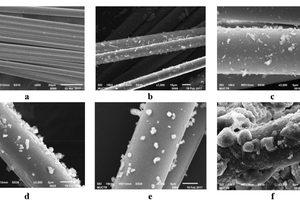

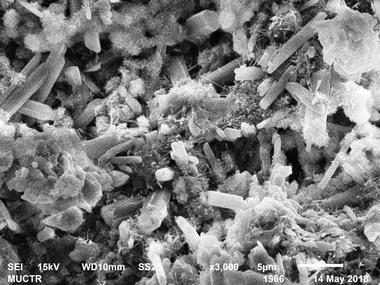

The structure of gypsum-cement-pozzolanic stone, hardened for 7-365 days (Figure 4) was studied. No portlandite was observed, and calcium sulfate hemihydrate crystallized as hexagonal prisms. The crystals of ettringite were very small. Hydrosilicates of calcium crystallized in the form of cellular-spongy films. It should be noted that after 7 days of hardening, the structure of the stone was rather indistinct (Figure 4a), but by 28 days the crystallization of neoplasms was significantly improved (Figure 4b), and by 365 days of hardening, crystals had begun to grow (Figure 4c).

Polypropylene and polyacrylic fibers do not corrode in the GCPV matrix. However, if hydrate neoplasms “sit” directly on polypropylene fiber (Figure 4d), and if after a year of hardening all fiber is densely covered with crystals of hydroaluminates, hydrosilicates and calcium dihydrate (Figure 4e), the polyacrylic fiber remains unchanged (Figure 4f). That is, polyacrylic fiber has no adhesion to the hydrate neoplasms of the binder, and therefore will not “work” in the composite material.

Basalt and fiberglass corrode in a cement stone environment. Electron microscopic images show that after 7 and 28 days of hydration, the fiber is covered by the products of hydration of the astringent (Figure 4g and Figure 4h), and after 3 months, destruction of the basalt fiber surface commences (Figure 4i and Figure 4j). After 365 days, no more basalt fibers are observed (Figure 4h). A similar situation is typical for fiberglass (Figure 4k).

Thus, the study of the influence of polypropylene, polyacrylic, basaltic fibers and fiberglass on the properties of GCPV showed that the best characteristics after 28 days of hardening are achieved by the composition with basalt fiber: bending strength 14.1 MPa, compression – 30.2 MPa, water resistance coefficient – 0.86, water absorption – 9.0 %, open porosity – 7.4 %, corrosion resistance – 0.96, decrease in strength after 20 freeze-thaw cycles (frost resistance) – 4.2 %, the first signs of corrosion in the salt fog chamber appear after 155 hours. However, during further hardening (3 months or more), corrosion of the basalt fiber occurs in the matrix of GCPV (although the strength does not decrease, but increases) Therefore, additional studies of basalt fiber corrosion have since been carried out.

Despite high interest in the degradation of basalt fiber, the mechanisms of hydrolytic and alkaline etching remain poorly understood. Basalt fiber has a multicomponent composition, which entails complex behavior in reaction to external factors, such as oxidative heat treatment or chemical etching. Another reason – common for glass and basalt fibers – is the difficulty of monitoring changes occurring in a micro-object (fiber) of a curved (round) shape under the influence of negative factors [8-11].

According to the literature data [12, 13], alkaline hydrolysis of basalt fibers involves several stages: transition to an alkaline solution of SiO2 from an aluminosilicates matrix, which leads to a decrease in the pH of the solution, and transition to a solution of Na+ and K+ ions, which increases the pH in the initial stage of hydrolysis. In favor of this assumption (taking into account that the dissolution of SiO2 occurs with the destruction of the surface layer and does not change the composition of the remaining fiber), a decrease in the content of sodium and potassium in the fibers after hydrolysis is evident. Together with this, enrichment of the shell with calcium, titanium and iron occurs.

Studies were carried out on its boiling in saturated solutions of various astringents according to the method of A.A. Pashchenko to assess the chemical stability of basalt fiber [14]. The simplest method of preparation of saturated solutions is a prolonged infusion of the solvent with an excess of solute (10:1) with periodic mixing of the mixture. Samples of the basalt fiber were boiled in saturated solutions of gypsum, gypsum-cement-pozzolanic and cement binder for 4 hours. As a comparison, the fiber was also boiled in a solution of calcium hydroxide and in a 5 % solution of NaOH.

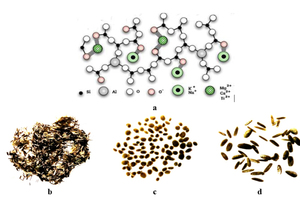

Basalt fiber is an amorphous polymer based on an aluminosilicates backbone. Each silicon or aluminum atom is bound to four oxygen atoms and has tetrahedral coordination (Figure 5a). The ion of Fe3+ plays a glass-forming role. Its presence slows the crystallization process and increases both the softening temperature and the acid resistance of the fiber [15].

The initial basalt fiber had a length of 4-6 mm, a diameter of 10-14 μm and was characterized by a mirror shine (Figure 5b). When interacting with a saturated solution of lime and a 5 % solution of alkali, the Si-O-Si and Al-O-Al bonds are gradually destroyed, which leads to the leaching of the components of Al2O3 and SiO2 from the structure under the action of the OH-group. There is a softening of the structure of basalt fiber, which, in turn, tends to lower its surface energy. Due to destruction of the fiber structure, it changes its shape.

When the basalt fiber is boiled in a saturated solution of lime, the change in shape takes place 3.5 hours after the start of the experiment. Aggregates of a spherical shape with a diameter of 4-6 mm appear (Figure 5c).

When the basalt fiber is boiled in an NaOH solution, the shape change takes place after 30 minutes. Fibers stick together into an elliptical shape 6 mm long and 2 mm thick (Figure 5d). The surface of the fiber is densely covered with neoplasms.

When the fiber is boiled in saturated solutions of gypsum binder, cement and GCPV, the shape of the fibers remains unchanged.

Determination of the pH of solutions of binders with basalt fiber before and after boiling showed that boiling in any of the solutions except the gypsum binder solution, makes the pH value decrease (Table 3). Contrarily, in the latter case, it rises after boiling in a saturated gypsum binder pH solution.

Electron microscopic analysis of the fibers after boiling in various media showed that the initial basalt fiber before boiling was characterized by an even and smooth surface (Figure 6a). After boiling in a saturated solution of gypsum binder, minor defects are visible (Figure 6b), probably caused by the oxidation of Fe2+, which is part of the basalt fiber, to the state of iron Fe3+.

It is known that the resistance of fibers is significantly reduced in matrices having a pH of the medium above 10 [16], as confirmed by a change in the appearance of the fiber boiled in a saturated solution of a gypsum-cement-pozzolanic binder (Figure 6c).

After boiling the basalt fiber in a saturated Portland cement solution, an increase in its dimensions (diameter) to 13-19 μm was established (Figure 6d). According to [17], during the leaching process, a change in the fiber diameter is observed, which occurs cyclically. In the initial period of time, there is an increase in the diameter of the fiber, accompanied by the appearance of neoplasms. Presumably, the process of increasing the diameter of the fiber is accompanied by the absorption of calcium hydroxide from the solution by the latter, and the decrease in diameter is due to transition into the solution of the fiber components. The nature of the interaction of fibers with an alkaline solution can be due to the adsorption of sparingly soluble hydrosilicates and calcium hydroaluminates on the surface of the fiber. These processes lead to an increase in the size of existing surface defects and to the appearance of new ones.

After boiling in a saturated solution of lime, the pH of the solution is reduced to 11.88, while the fiber diameter increases to 11-17 microns (Figure 6e). When boiling in a 5 % solution of NaOH, the surface of the fiber becomes completely defective (Figure 6f). Interaction with NaOH leads to an increase in fiber diameter up to 11-17 microns, while the fiber intensively absorbs sodium hydroxide from the solution, leading to a decrease in pH to 13.02.

The obtained results are well correlated with a certain elemental composition of basalt fiber after boiling in various saturated solutions (Table 4) and with IR spectra of these fibers (Figure 7). Table 4 shows that the largest changes in composition occur after boiling the fiber in a 5 % solution of NaOH. The same confirms the displacement of the bands of valence and deformation vibrations in the region 700-1700 and 3000-3600 cm-1 on IR spectra (see Figure 7).

Thus, the experimental results obtained confirm the position that the fiber resistance is significantly reduced in matrices having a pH of the medium above 10.

There are several ways to improve the alkalinity of basalt fibers. This includes changing the chemical composition of the fiber by adding alkali-resistant components, for example zirconia [18], introducing special additives into the matrix [19], and/or applying protective coatings to the fiber [20].

The method for increasing the alkali resistance of a fiber by introducing alkali-resistant oxides into its composition is less suitable for basalt fibers, as the addition of new components to the molten basalt leads to a change in many properties of the melt: viscosity, melting interval, fiber stretching interval [18].

Increasing the alkali resistance of basalt fiber by applying protective coatings appears most appropriate. The application of a tread substance to the surface of the fiber prevents or limits contact between the fiber and the aggressive matrix environment. Application of this method, however, requires special precautions in the synthesis due to the process of hydrolysis, and it increases the cost of the process due to the high cost of the initial reagents [20].

The simplest solution for increasing the alkali resistance of basalt fiber is to change the composition of the matrix of the binder. But it should be taken into account that the matrix of composite materials determines the basic physico-chemical properties of composites, so the introduction of any new components into its composition can lead to a significant change in the properties of the composite, e.g., to the loss of mechanical or functional properties [21].

To increase the adhesion and durability of the fibers in the matrix, binders should be used with a pH at which the hydraulic activity of the fibers should show up during the first hardening period, and, subsequently, passivation conditions of the fibers are created, which is ensured by lowering the pH. These conditions are best met by mixed gypsum binders, characterized by sufficient water resistance, rapidity of hardening, the ability to regulate both the concentration of calcium hydroxide, and, hence, the pH in different periods of hardening. In order to achieve pH values below 10, it is necessary to reduce the content of Portland cement in the mixed binder and to increase the amount of pozzolanic additive (higher than the minimum according to [5]).

Such conditions are met by composite gypsum binders of low water demand, containing a small amount of cement (10-15 %) and various activity pozzolanic additives, which allow to regulate the concentration of calcium hydroxide and the pH of the medium within the required limits.

4 Conclusion

Compositions are developed, and the structure and properties of such composite astringents are studied. It is shown that no corrosion of basalt fiber takes place in the subject composite gypsum binders. Thus, the study of the influence of various fibers on the structure and properties of the gypsum-cement-pozzolanic binder allows us to recommend compositions with basalt fiber.

The article is based on a paper presented at the third Weimar Gypsum Conference in Weimar,

14.03.-15.02.2017.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.