The influence of water-repellent admixtures on the water resistance of hardened gypsum-cement-puzzolan paste based on low-grade gypsum

This article examines the influence of a variety of water-repellent admixtures on the water resistance of hardened gypsum-cement-puzzolan paste based on low-grade gypsum and studies special aspects of their application in combination with plasticizers. The required content of the admixtures investigated as a percentage of the binder is measured by experimental mathematical design techniques.

1 Introduction

The widespread use of gypsum-cement-puzzolan binder (GCPB) is a result of its low cost, environmental friendliness and the high performance properties of the products based on it. GCPB is also used during the production of partition panels, floors, three-dimensional utility blocks, finishing materials and other products [1, 2]. It is noted that widespread use of products based on gypsum, which includes GCPB, is limited because of their low water resistance. P.P. Budnikov and V.N. Yung consider that the main reason for the low water resistance is the high solubility of gypsum...

1 Introduction

The widespread use of gypsum-cement-puzzolan binder (GCPB) is a result of its low cost, environmental friendliness and the high performance properties of the products based on it. GCPB is also used during the production of partition panels, floors, three-dimensional utility blocks, finishing materials and other products [1, 2]. It is noted that widespread use of products based on gypsum, which includes GCPB, is limited because of their low water resistance. P.P. Budnikov and V.N. Yung consider that the main reason for the low water resistance is the high solubility of gypsum (2.05 g/l at 20 °C). P.A. Rebinder and other scientists find the reason for the loss in strength to be the wedging action of water films on the internal surfaces of microcracks, causing detachment of separate microelements of the crystalline structure. The current studies are therefore oriented towards improving the water resistance and increasing the scope of use of products based on gypsum.

The water resistance of products based on GCPB can be improved by different methods and techniques that are based on increasing the content of Portland cement (PC) and active mineral admixtures (AMA) in the mix, on decreasing the solubility of calcium sulfate, on compacting the gypsum cement mix, on impregnation with compounds that prevent moisture penetration [3] and also on the introduction of water-repellent admixtures [4, 5].

Analysis of the data in the literature shows the dependence of the water resistance of hardened gypsum-cement-puzzolan paste (GCPS) on the GCPB composition and on the type and quantity of the chemical modifiers in its composition. According to the data from [1] the water resistance measured by the coefficient of softening of GCPB based on the G10 gypsum binder (GB) with a ratio of GB:PC:AMA = 65:23:12 is 0.55-0.8. Introduction of tripoli in amounts of 10, 20 and 30 % to replace 20 % of the gypsum containing PC gives water resistance values of 0.64, 0.76 and 0.80 respectively [6]. These levels of water resistance of the compositions are obtained by using high-grade gypsum and a high AMA content.

The water resistance of a gypsum-cement-zeolitic binder based on G6 gypsum is 0.46-0.59. Thermal activation of powdered marl containing zeolite at a temperature of 600 °C and modification of this binder with a two-component plasticizer gives a water resistance of 0.82 - 0.89 [7]. It is worth noting that the water resistance of these compositions is provided by using a high PC content (minimum of 34 %) and a maximum gypsum content of 55 %. Grinding and thermal activation of marl that contains zeolite also increases the cost of the products.

The effectiveness of the increase in water resistance of GCPB (65:30:5) by the introduction of surface active substances (SAS) with plasticizing effects and organosilicone compounds to the composition has been shown in subsequent studies described by A.V. Ferronskaya [8]. The combined action of plasticizers and redispersible polymeric powder leads to increased hydrophobization of the GCPS and increases its strength and coefficient of softening (to more than 0.85) [9]. It is worth noting that these results are achieved with an increased PC content.

Data analysis [1-9] shows that hydrostable compositions based on GCPB are basically produced by using increased levels of PC and AMA in the composition but in some instances this can be achieved by using higher grades of gypsum. In this respect the studies oriented towards the production of hydrostable GCPB based on low-grade gypsum with reduced contents of PC and AMA are of special interest.

The diversity of new water-repellent admixtures that differ in chemical composition, molecular mass and type of radical [10-13] means that it is necessary to investigate their influence on the properties of GCPB based on low-grade gypsum, especially in combination with effective plasticizers.

These researches are aimed at increasing the water resistance of GCPB based on low-grade gypsum containing reduced levels of PC and AMA, which is achieved by modification of the chemical admixtures. The influence of water-repellent admixtures with different characteristics on the rheological, physical and mechanical properties of GCPB was studied, their required content in the binder composition was measured and special aspects of their interaction with plasticizers were discovered.

2 Materials and methods used in the research

The following materials were used In the course of the investigations:

a) binders:

G6BII gypsum produced by OOO “Arakchinskij gips” GOST 125-79

Portland Cement PC500-D0-N produced by the Belgorod cement plant

b) active mineral admixture (AMA) – metakaolin with a specific surface of 1357 m2/kg

The ratios of the ingredients of the binder used in the studies carried out [14, 15] is as follows (parts by weight): gypsum : PC : AMA – 76 : 20 : 4.

c) mains water that meets the requirements of GOST 23732

d) plasticizers that are the most effective for this GCPB composition, as determined in prior stud ies [16]:

“Odolit-K” superplasticizer based on carboxylates and produced by OOO “Servis-grupp” (TS 5745-01-96326574-08)

“Best-TB” plasticizer produced by OOO “Innovacionnye Tekhnologii” – copolymer based on carboxylic ethers with the addition of a phosphate builder

e) water-repellent admixtures of differing chemi-cal composition, molecular mass, type of radicals and hydraulic activity. The comparative characteristics of the water-repellent admixtures used are shown in Table 1

The standard consistency test, the setting time test for the GCPB and the physical tests for the GCPS were carried out in accordance with GOST 23789-79. The water resistance was measured by the coefficient of softening, i.e. the ratio of the compressive strength of oven-dried samples to the compressive strength of water-saturated samples. Samples of GCPS were saturated with kerosene to prevent the calcium sulphate from dissolving.

3 The influence of water-repellent admixtures on

the properties of the GCPB

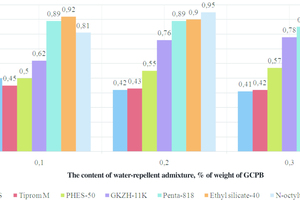

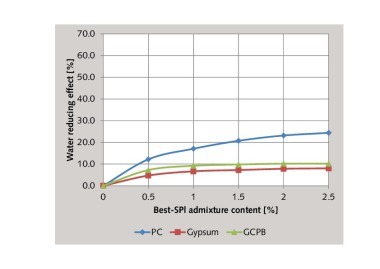

Water-repellent admixtures were added to the mix in proportions of 0.1 – 0.3 % by weight of binder for volumetric hydrophobization of the GCPB. The additive percentage (0.1 – 0.3 %) was chosen on the basis of the results of previous experimental investigations, on the manufacturer’s advice and on review of the literature data. During the production of GCPS samples the water-repellent admixtures were added in the required quantity to the mixing water. The non-water-soluble water-repellent admixtures were dispersed ultrasonically in the mixing water. Their influence on the water resistance of the GCPS is shown in Figure 1.

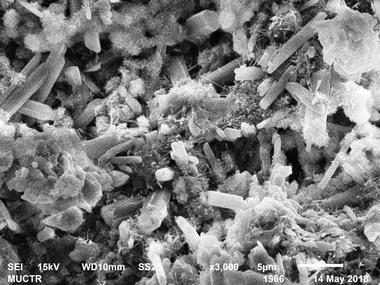

This shows that, depending on the type of water-repellent admixture, the volumetric hydrophobization of the GCPB improves the water resistance of the samples, which results in an increase in the coefficient of softening. The best results were achieved using the “Ethyl silicate-40”, “Penta-818” and “N-octyltriethoxysilane” water-repellent admixtures; depending on their content in the mixture their application leads to an increase in water resistance by 63.3 – 93.9 % while the coefficient of softening is 0.81 – 0.95. It was also found that application of these admixtures leads to a moderate increase in sample density by 5.6 – 12 %. These admixtures were therefore chosen for further study.

4 Production of the complex admixtures

Analysis of the research results and the application of complex admixtures (CA) for modifying the different binders indicate their multi-functional ability to influence several product characteristics, to increase some effects significantly (achieved by the introduction of a one-component admixture) and to sharply decrease or totally eliminate any adverse side effects of the CA.

The effect of the CAs under development is oriented towards increasing the water resistance of the GCPS samples while simultaneously improving their ultimate strength, increasing the setting time of the composition and adding a self-compacting capability. Based on the results of the studies carried out, the most effective water-repellent admixtures (“Ethyl silicate-40”, “Penta-818”, “N-octyltriethoxysilane” ) and plasticizers (“Odolit-K” and “Best-TB”) were used as constituents of the multifunctional CA. The rheological, physical and mechanical properties of the products modified by these new CAs are shown in Table 2.

Table 2 shows that when the CA components under investigation interact there is a synergistic effect that improves the coefficient of softening with a simultaneous increase in the physical and mechanical properties and an increase in the setting time of the composition. The best results were achieved using the following chemical admixtures as components of the CA: “Odolit-K”, “Best-TB”, “N-octyltriethoxysilane” in a ratio of 1.5 : 0.5 : 0.1 respectively. Samples with the following properties were obtained with this CA: ultimate compressive strength (55.9 MPa), ultimate bending strength (19.5 MPa), coefficient of softening (0.98).

In previous studies it was found that during the combined introduction of the superplasticizers (SP) “Best-TB” and “Odolit-K” to the mix the effect of the electrostatic interparticle repulsive forces in the binder that appear during adsorption of the molecules of SP “Best-TB” is accompanied by the steric effect that occurs due to the effect of the hydrophobic side chains of the SP “Odolit-K”. Introduction of the “N-octyltriethoxysilane” water-repellent admixture and adsorption of its molecules on binder particles with side chains leads to further repulsion of the dispersed binder molecules and water molecules. This preserves the hydrophobization effect, which is thought to determine the effectiveness of the CA produced.

5 Optimization of the multifunctional

CA composition

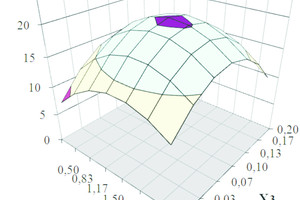

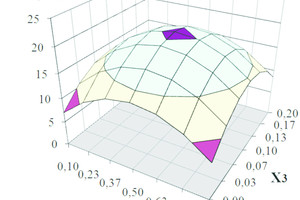

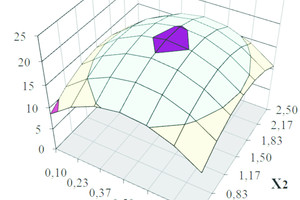

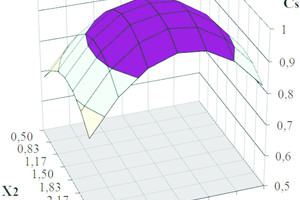

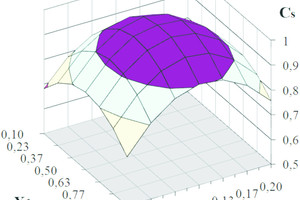

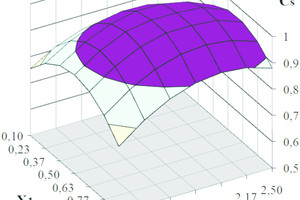

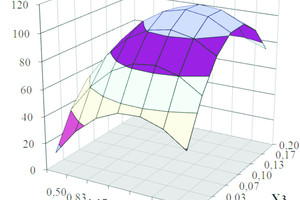

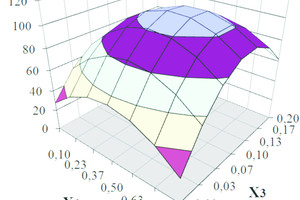

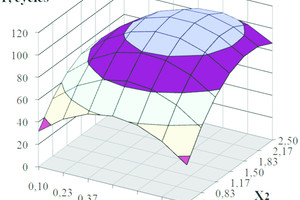

Special studies on optimization of the multifunctional CA composition were undertaken using mathematical experimental design techniques in order to elaborate the influence of the components of the complex modifier. Such factors as the content of SP “Best-TB” (X1=0.1-0.9), which retards the initial structure formation processes, the content of carboxylated SP “Odolit-K” (X2=0.5-2.5) and the content of the “N-octyltriethoxysilane” (X3=0-0.2) water-repellent admixture were determined as initial independent variables. The bending strength of the GCPS samples (Rbend), the coefficient of softening (Cs) and the freeze-thaw resistance (F) were chosen as response variables.

The following mathematical relationships were obtained with the aid of the data reduction process incorporated in the experimental mathematical design techniques:

R = –8.74 + 41.38X1 + 14.45X2 + 143.85X3 – 0.32X1X2 + 6.67X1X3 – 9.21X2X3 – 40.195X21 – 4.29X22 –655.43X23 ⇥(1)

Cs = 0.42 + 0.698X1 + 0.26X2 + 3.26X3

+ 0.063X1X2 + 0.38X1X3 + 0.19X2X3

– 0.77X21 – 0.09X22 – 17.97X23 ⇥ (2)

F = –56.19 + 151.79X1 + 86.52X2

+ 758.97X3 + 15.87X1X2 + 238.096X1X3

+ 79.365X2X3 – 180.27X21 –

27.497X22 – 4506.7X23⇥ (3)

Graphical interpretation of the results of the elaboration of the mathematical models (formulas 1–3) is shown in Figures 2 to 4, from which it can be seen that enhancement of the ultimate bending strength of the GCPS occurs with increasing content of SP “Best-TB” and “Odolit-K” in the mix. A combined increase in the addition levels of the chemical admixtures under investigation leads to gradual enhancement of the strength and then to its reduction. The loss of strength of the GCPS with increased addition levels of SP and water-repellent admixtures can possibly be explained by the blocking action of the above-mentioned admixtures on the particles of the gypsum-cement-puzzolan binder, which clearly appears when they are added to the mix in excess.

The following recommended addition levels of modifying additives in the binder composition were determined on the basis of the experimental mathematical design techniques: SP “Best-TB” (0.5 %), SP “Odolit-K” (1.5 %), “N-octyltriethoxysilane” water-repellent admixture (0.1 %) by weight of GCPB.

6 Conclusions

1. It has been established that the most effective admixtures for volumetric hydrophobiza-tion of GCPB based on low-grade gypsum are the water-repellent admixtures “Ethyl silicate-40”, “Penta-818” and “N-octyltriethoxysilane”. These increase the density of the samples by 5.6 – 12 % and also increase the coefficient of softening by 63.3 – 93.9 % to the level of 0.81 – 0.95.

2. A multifunctional CA based on plasticizers and water-repellent admixtures was produced. The following required levels of the components of the CA in the GCPB composition were determined with the aid of the experimental mathematical design techniques: SP “Best-TB” (0.5 %), SP “Odolit-K” (1.5 %), “N-octyltriethoxysilane” water-repellent admixture (0.1 %) by weight of binder. Samples with the following characteristics were obtained by using this CA: ultimate compressive strength (55.9 MPa), ultimate bending strength (19.5 MPa), coefficient of softening (0.98).

3. The experimental investigations that were undertaken can be summarized by stating that¸ by chemical modification, it is possible to produce hydrostable compositions based on low-grade gypsum binders (G6 gypsum) with reduced levels of PC (20 %) and AMA (4 %). This helps to expand the field of use of the products based on GCPB at a relatively low cost.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.