Set-retarding plasticizers for improving the effectiveness of gypsum-cement-pozzolan binders

The studies that were undertaken have made it possible to establish the influence of plasticizers and their complexes on the rheological, physical and mechanical properties of gypsum-cement-pozzolan binders based on low-grade gypsum and to measure the content required in the mixes.

1 Introduction

Materials and products based on gypsum-cement-pozzolan binders (GCPB) have not become widely used in the construction industry at present because it is necessary to use expensive input products with high contents of Portland cement (PC) and active mineral admixtures (AMA) to provide the required performance properties. The use of GCPB based on calcium sulfate hemihydrate with reduced contents of PC and AMA helps to increase competitiveness but there is a need for studies that are oriented towards improving its effectiveness by modifying the composition with chemical admixtures.

A...

1 Introduction

Materials and products based on gypsum-cement-pozzolan binders (GCPB) have not become widely used in the construction industry at present because it is necessary to use expensive input products with high contents of Portland cement (PC) and active mineral admixtures (AMA) to provide the required performance properties. The use of GCPB based on calcium sulfate hemihydrate with reduced contents of PC and AMA helps to increase competitiveness but there is a need for studies that are oriented towards improving its effectiveness by modifying the composition with chemical admixtures.

A new GCPB with reduced contents of PC (20 %) and AMA (4 %) was produced that helps to stabilize gypsum-cement-pozzolan systems [1]. The low strength properties and water resistance of these compositions are their main disadvantages. A solution to the problem in relation to improving the effectiveness of GCPB can be provided by modifying the composition with chemical admixtures and their complexes.

The article reviews the results of the first stage of research into the influence of plasticizers on GCPB properties; a plasticizer that reduces the setting times has also been produced.

A great many superplasticizers are currently being introduced into the Russian market. These are the admixtures produced by firms such as BASF, Glenium, Melflux, Sika ViscoCrete, etc.

The effect of modifying additives depends significantly on the binder composition and on the quantity and quality of the chemical compounds that appear during its hydration [2] as well as on the alkalinity of the medium. This means that in compositions based on gypsum binders and GCPB with reduced PC content the expected result is not always achieved.

It is well known that GCPB based on calcium sulfate hemihydrate has a short setting time, which in most cases excludes the possibility of using it without admixtures that retard the hardening kinetics of the mixture. V.B. Ratinov [3] classifies admixtures that control the setting time and curing time of binders into three classes.

The first class covers admixtures that do not react with the binder but promote a change in solubility. In the second class there are agents that form barrier films made from low-solubility mixtures on the surface of the hemihydrate when interacting with binders, as a result of which the setting of the gypsum and of binders based on it is retarded. However, application of the agents of this class does not allow the setting time to be controlled over a wide range and in some cases it also leads to a reduction of the strength properties of the end products [4-6].

The third class includes surface-active substances (SAS). Through adsorption by the gypsum particles they reduce the rate of formation of seed crystals, increase the flowability of the paste and reduce the quantity of mixing water required. Their retarding effect is determined by the thickness and strength of the solvate shell that forms on the surface of the solid particles of the binder.

In the authors’ opinion, the third class of admixtures is to be preferred as according to the data analysis in the literature these admixtures do not have a negative effect on the physical and mechanical properties of gypsum-cement-pozzolan stone (GCPS) while providing highly effective retardation of the kinetics of structure formation and hardening. Moreover, it is not necessary to use a large amount of admixture of this type to achieve a result.

In this respect the studies focusing on the production of plasticizers that retard the kinetics of the initial structure formation of the binder but do not affect the hardening kinetics and strength of products based on them are highly interesting [7]. For this reason, the investigation of plasticizers in gypsum-cement-pozzolan compositions and the production of retarding plasticizers that increase the product strength while retarding the kinetics of initial structure formation is currently a topical issue. This will make it possible, for example, to expand the field of use of low-grade gypsum and of the GCPB based on it in the production of effective gypsum materials for constructing internal partitions [8] or gypsum-fibreboard for external finishing of buildings and structures [9].

The purpose of the present study is to determine the effect of different types of plasticizers on standard consistency, setting time and strength of GCPB based on low-grade gypsum and to produce set-retarding plasticizers that have a high water-reducing effect and retard the kinetics of initial structure formation in order to improve the strength and water resistance of the products based on it.

2 Materials and methods used in research

The following constituents were used for preparing the binder:

gypsum binder G6BII, produced by OOO

”Arakchinskij gips”

Portland cement PC500D0, produced by the Belgorod cement plant

a mineral admixture called metakaolin with a hydraulic activity of 1238 mg/g

that was chosen from a wide range of natural and synthetic AMA in the light of previous studies [10].

The ratios of the constituents in the binder are as follows – gypsum: PC : AMA – 76 : 20 : 4 parts by weight.

The admixtures used as plasticizers were: superplasticizer (SP) “Odolit-K” produced by OOO “Servis-grupp” (TS 5745-01-96326574-08); “Glenium Sky 591”, “Glenium Mix sky 323”, “Glenium 115”, “Glenium Ace 430” produced by “BASF Stroitel’nye sistemy” and SP “Best-TB” and “Best-SPl” produced by OOO “Innovacionnye Tekhnologii”.

The standard consistency test and setting-time tests were carried out in accordance with GOST 23789-79 and the tests of the physical and mechanical properties were carried out on standard samples (4 cm x 4 cm x 16 cm) made in moulds with a standard consistency using the methods described in GOST 23789-79. The water resistance was measured by the coefficient of softening, i.e. the ratio of the compressive strength of oven-dried samples to the compressive strength of water-saturated samples. Water saturation was carried out over 24 hours. The influence of the set-retarding plasticizer and its components on the formation of the GCPS pore structure was measured by the methods described in GOST 12730.4-78. Samples of GCPS were coated with kerosene to prevent the calcium sulfate from dissolving.

3 Structure and properties of modified gypsum-

cement-pozzolan stone

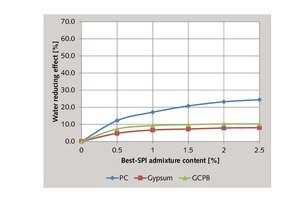

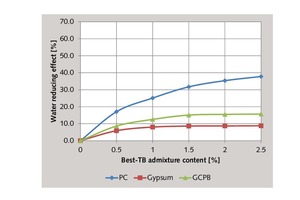

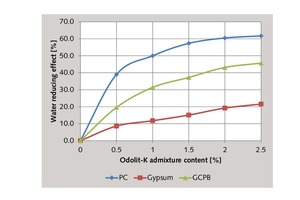

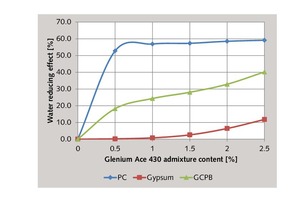

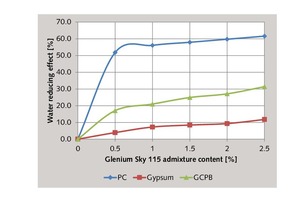

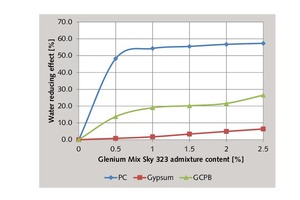

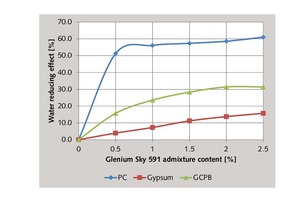

The influence of the plasticizer on rheological properties of cement, gypsum and gypsum-cement-pozzolan binders was studied in the first stage of the investigations. All of the studies were undertaken in accordance with GOST 23789-79 so that the results could be compared. The research results are shown in Figure 1.

It can be seen from Figure 1 that the best water-reducing effect in the cement binder was given by plasticizers:

“Odolit-K” (61.7 %)

“Glenium Sky 115” (61.6 %)

“Glenium Sky 591” (61 %)

“Glenium Ace 430” (59.1 %)

in the gypsum binder by plasticizers:

“Odolit-K” (21.6 %)

“Glenium Sky 591” (15.7 %)

and in gypsum-cement binder by plasticizers:

“Odolit-K” (45.7 %)

“Glenium Ace 430” (40.2 %)

The research results into the effect of the plasticizer on the setting time of gypsum-cement-pozzolan binders and on the physical and mechanical properties of GCPS are shown in Table 1.

As can be seen from Table 1, SP “Odolit-K” and “Glenium Ace 430” accelerate the setting time slightly. Plasticizers “Best-SPl”, “Glenium 115”, “Glenium Mix sky 323”, “Glenium Sky 591” retard the initial set and final set by 1-25 min, depending on the addition level.

The additive “Best-TB” had the most obvious retarding effect on the kinetics of the initial structure formation; it is a copolymer based on carboxyl esters with the addition of a phosphate builder. Depending on the content (0.5 – 1.5 %), the initial set was retarded by 26.5 – 190.5 min. and the final set by 28 – 213 min.

The most effective plasticizers for increasing the final compressive strength were SP “Glenium Ace 430”, which increased the final compressive strength by 42.8 – 82.7 % depending on the addition level, SP “Glenium Sky 591” by 35.8 – 71.6 % and SP “Odolit-K” by 39.1-53.1 %.

The plasticizers investigated also had a substantial influence on the relative bending strength of the GCPS samples. Depending on the addition level, SP “Glenium Ace 430” increased the final bending strength by 42.8-70.5 % and SP “Odolit-K” by 12.4-23.8 %.

The most effective additives for increasing the coefficient of softening are as follows (in decreasing order): SP “Odolit-K”, SP “Best-TB”, SP “Glenium Ace 430”, SP “Glenium Mix sky 323”.

4 Production of set-retarding plasticizers

The studies that were carried out showed that plasticizers improve the physical and mechanical properties of GCPS; however, GCPB has a short setting time, which makes the product-forming processes more difficult. Set-retarding plasticizers were produced to deal with this problem. SP “Odolit-K” and SP “Best-TB” were used as the chemical admixtures for the research. There is a synergistic effect during the interaction that helps to retard the kinetics of structure formation while increasing the product strength [11].

Molecules of SP “Best-TB” are adsorbed onto the surfaces of the binder particles and form a thin layer that increases the zeta potential on their surfaces. This prevents adhesion bonding under the action of electrostatic forces that reduces the viscosity of suspensions. The phosphate builder that forms part of SP “Best-TB” promotes the formation of a protective film of sparingly soluble compounds on the surfaces of the gypsum particles. This retards the setting of the gypsum. The molecules of SP “Odolit-K” have both main and side chains. The main chain is adsorbed on binder particles and the side chains are directed away from them towards the water. They create the effect of repulsive inter-action between particles known as the steric effect. This is responsible for the dispersion of the floccules of binder and plasticizer and the water-reducing effect of the admixture.

It is thought that the mechanism of the synergistic effect of the chemical admixtures under investigation is based on the electrostatic repulsion forces of the binder particles that occur during the adsorption of SP molecules complemented by the steric effect that arises as a result of the influence of the hydrophobic side chains of the SP. This increases the dispersion of the binder particles, resulting in a significant reduction in water demand and an increase in the product strength properties.

The set-retarding plasticizer was added to the gypsum-cement-pozzolan mixture with the mixing water in amounts of 1 – 1.5 % by weight of binder. The gypsum-cement-pozzolan mixtures modified by the above-mentioned plasticizer have slower kinetics for the initial structure formation, resulting in an increase of the initial set (by 2 – 56.5 min) and of the final set (by 1.5 – 59.5 min). Depending on the content of set-retarding plasticizer in the GCPB and on the mixture rating the final bending strength increases by 7.6–21.9 % and the final compressive strength by 6.6 – 34.7 % while the softening coefficient increases to 0.54 – 0.59.

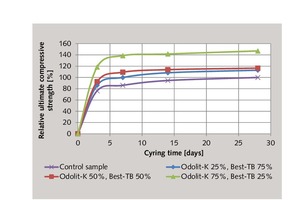

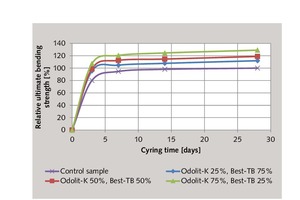

The kinetics of hardening of the gypsum-cement-pozzolan mixture with the set-retarding plasticizer in amounts of 1.5 % by weight of binder are shown in Figures 2 and 3. The strength of the concrete cube test specimens at the age of 28 days is taken as 100 %.

It can be seen from Figures 2 and 3 that, depending on the ratio of the components in the composition of the set-retarding plasticizers, the relative final bending strength at the age of three days is increased by 9.8 – 42.2 % and the compressive strength by 15.4 – 27.1 %.

The increase in the bending and compressive strengths of the samples based on GCPB with added set-retarding plasticizer is an indication of the formation of a denser pore structure. The influence of the set-retarding plasticizer and its components on the pore structure formation of GCPS is shown in Table 2.

Table 2 shows that the highest porosity occurs in the sample without any admixture. The following changes were observed on addition of the set-retarding plasticizer: there is a reduction of total pore volume by 21.3 %; the open non-capillary pore volume decreases by 83.3 %, the open capillary pore volume decreases by 70.9 % and the relatively closed pore volume increases by 50.9 %. This results in an increase in the microporosity index from 0.18 to 0.56 and is evidence of the formation of a denser pore structure.

5 Conclusions

The influence of the plasticizers under investigation on the rheological properties of cement, gypsum and gypsum-cement-pozzolan binders was examined. The most effective one was SP “Odolit-K”. Its introduction substantially reduced the water demand of all the different types of binders being examined.

The influence of the plasticizer on the physical and mechanical properties of GCPS was also studied. It was found that the most effective admixtures among the plasticizers investigated were SP “Glenium Ace 430” and SP “Odolit-K”. Depending on the addition level, SP “Glenium Ace 430”, for example, increased the final compressive strength by 42.8-82.7 % and the final bending strength by 42.8 – 70.5 % while SP “Odolit-K” increased the final compressive strength by 39.1 – 53.1% and the final bending strength by 12.4 – 23.8 %.

It was also found that the “Best-TB” plasticizer had the effect of retarding the kinetics of the GCPS structure formation and, depending on its content (0.5 – 1.5 %), helped to increase the initial setting time by 26.5 – 190.5 min. and the final setting time by 28 – 213 min. while maintaining a high rate of strength generation of the hardened binder.

A new set-retarding plasticizer was developed that helps to increase the GCPS strength during the retardation of the initial structure formation processes. For example, depending on the ratio of the set-retarding plasticizer, the initial set increases by 2 – 56.5 min., the final set by 1.5-59.5 min, while the relative compressive strength of the samples at three days increases by 9.8 – 42.2 % and the final bending strength by 15.4 – 27.1 %. Application of the set-retarding plasticizer promotes an increase in the GCPS final strength after hardening for 28 days. The compressive strength is increased by 6.6 – 34.7 and the bending strength by 7.6 – 21.9 % while the coefficient of softening increases to 0.54 – 0.59.

Application of the set-retarding plasticizer promotes the formation of a denser pore structure of the samples based on GCPB. A decrease in the void volume by 21.3 % was observed on addition of the set-retarding plasticizer that had been developed. The non-capillary pore space decreased by 83.3 %, the open capillary pore space decreased by 70.9 % and the closed pores space increased by 50.9 %, with the result that the microporosity index increased from 0.18 to 0.56.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.