Composite gypsum binders with

improved water resistance

Compositions of composite gypsum binder with various active mineral additives have been developed by the authors. It is revealed that the introduction of additives in an optimal amount increases the performance characteristics of composite gypsum stone, such as flexural and compressive strength, water resistance, and also reduces the porosity and water absorption of the binder. Based on the conducted research, the optimal compositions with various active mineral additives were selected, which can be used for dry building mixes for interior and exterior decoration of premises, as well as for creating elements of load-bearing structures of low-rise buildings.

1 Introduction

In recent years the domestic industry has been in need of environmentally friendly and safe construction materials that can be produced at minimum energy consumption. These materials include gypsum-based binders. They have a number of advantages in comparison with the other binders: the environmentally friendly materials do not contain toxic components. In comparison with cement production neither pollutants nor greenhouse gases are released into the atmosphere during the production of gypsum-based binders. They have superior thermal and sound insulation properties. However...

1 Introduction

In recent years the domestic industry has been in need of environmentally friendly and safe construction materials that can be produced at minimum energy consumption. These materials include gypsum-based binders. They have a number of advantages in comparison with the other binders: the environmentally friendly materials do not contain toxic components. In comparison with cement production neither pollutants nor greenhouse gases are released into the atmosphere during the production of gypsum-based binders. They have superior thermal and sound insulation properties. However insufficient water resistance restricts their field of application.

Up to date it has been proven that in order to improve water resistance properties of a binder it is required to mix it with such substances that would lead to the formation of water-resistant new growths. Such new growths include Portland cement and active mineral additives (AMA) [1-5].

One of the materials containing these components is a composite gypsum binder, the advantage of which in comparison with the other binding materials is its high water-resistance that allows it to be used for the production of various types of concrete, cast-in-place elements of wall structures and dry mix mortars for the interior and finishing work [6-7]. This material retains its properties that are typical for gypsum binders: decorativeness, low consistency and good insulation properties.

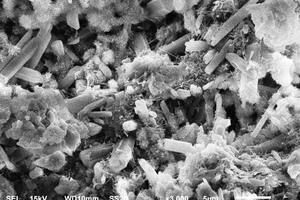

Composite gypsum binders were developed in the early 1990s. They are an activated homogeneous mixture of any gypsum binder with a hydraulic component that is an organomineral modifying additive obtained by combined mechanical activation of Portland cement, an active mineral additive and a functional additive. The hydraulic component improves the rate and degree of Portland cement hydration and the activity of silica components, enhances the reactivity of tricalcium aluminate and the other minerals, that contributes to the formation of ettringite in the initial period of hardening. The organomineral modifier may also be composed of the other additives: setting retardants, foaming or air-entraining agents, antifoaming and water-proofing agents, pigments, fibrous dispersed materials, etc., depending on the required characteristics of the finished gypsum material.

At different times Chernysheva N.V. [8], Rakhimov R.Z. [9], Voitovich E.V. [10], Korovyakov V.F. [11-12] and others were engaged in the research and development of new compositions of composite gypsum binders in Russia. The peculiarity of each research work was the use of new materials as an active mineral additive to produce an organomineral modifier. Thus, Voitovich E.V. developed the compositions of composite gypsum binder based on nanostructured raw materials [10]. At the Dmitry Mendeleyev University of Chemical Technology of Russia, Potapova E.N. with the colleagues studied the effect of modifying additives on composite gypsum binder properties [13-15].

The issues of making water-resistant gypsum binders were given great attention at the 3rd Weimar Conference on Gypsum [16-18] and the 20th International Conference on Building Materials “20. Ibausil” [19-21].

In the literature there are quite a number of publications devoted to the study of composite gypsum binders with silica. Compositions with the other active mineral additives have been studied much less. Therefore, the purpose of this research work was to expand the range of composite gypsum binders for production of dry mix mortars and for their use in low-rise residential construction by developing compositions with various active mineral additives of both natural and artificial origin.

2 Materials

The following materials were used for making the composite gypsum binder (CGB): ЦЕМ I 42.5 H of OOO “HeidelbergCement Rus”; Г-6 Б II gypsum binder of ‘Peshelansky Gypsum Plant’; active mineral additives: metakaolin (‘MetaRus’), microsilica (Lipetsk), tripolite (Bryansk region) and zeolites (Khonguruu, Yakutia); modifying additives – tartaric acid, Sika ViscoCrete 510 plasticizer. For chemical composition of the studied additives see Table 1.

As seen from Table 1, all additives contain a large amount of silica, however they contain SiO2 in different states. In microsilica SiO2 is in a glassy state, in metakaolin – in an amorphous state, in tripolite the silicon oxide is watered (SiO2 ∙ nH2O), and in zeolites it is bound both to H2O and to various oxides in aqueous framework aluminosilicates. On the other hand, these additives are characterized by different pozzolanic activity [15] that should have an impact on the composite gypsum binder properties.

3 Study results

At the first stage of the research work the optimal content of components in a CGB was experimentally determined.

Pursuant to TU 21-53-110-91 [22], a CGB contains 60-85% of gypsum binder (GB) and an organomineral modifier (OMM) consisting of Portland cement (PC), an active mineral additive (AMA) and a plasticizer. The analysis of publications devoted to gypsum binders of improved water resistance [23-24] showed that the ratio of PC and AMA in such binders is ≈ 1.5. Therefore, the studies for selecting the proper composition of a composite binder were conducted for each active mineral additive.

As an example, see below the study results of CGB with metakaolin AMA (compositions 1.1-1.6 – see Table 2).

An increase of gypsum binder percent share in the range from 60 to 80% resulted in a decrease of paste normal consistency (NC) from 53.0 to 49.6% and to certain acceleration of setting processes. However, irrespective of the compositions, all setting times were very short, therefore the addition of setting retarders was required.

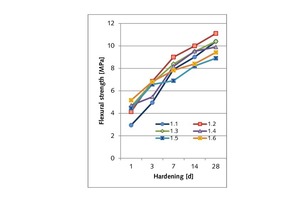

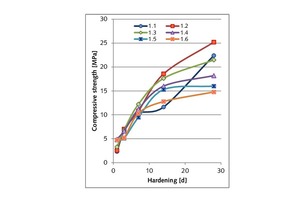

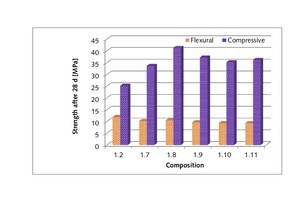

At the beginning of setting, the compositions with a high content of gypsum binder were characterized by the greatest strength (composition 1.6), but at a further hardening, the greater strength was already typical for the compositions with a higher content of Portland cement (Figure 1, compositions 1.1 and 1.2).

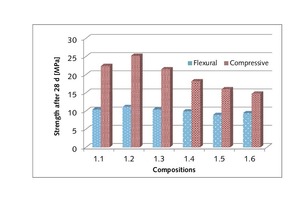

The strength analysis results showed (Figure 2) that the highest strength was demonstrated by composition 1.2. After 28 d of hardening its flexural strength was 11.0 MPa and compressive strength – 25.2 MPa.

The hardened binder of composition 1.2 was characterized by less open porosity (6.4%), less water absorption (15.0%) and greater water resistance (Cs=0.82), compared to other compositions (see Table 3).

So, based on the obtained data, composition 1.2 was chosen for further studies that was composed of gypsum binder (65%), Portland cement (21%) and metakaolin AMA (14%).

The similar studies with microsilica, zeolites and tripolite active mineral additives made it possible to choose the CGB compositions (see Table 4).

As can be seen from the data of Table 4, all composite binders illustrate similar strength characteristics (with the exception of the composition with tripolite) but different water resistance. If the composite binder with metakaolin can be referred to the water-resistant one, the binders with microsilica and zeolites – to binders of improved water resistance, and the binder with tripolite cannot be regarded as a water-resistant binder.

Since the composite gypsum binders were characterized by very short setting time (beginning – 1.5-2.5 min, end – 2.0-3.0 min), at the next stage of the research the effect of setting retardant additives on CGB properties was studied.

Citric acid, tartaric acids and Plast Retard PE were chosen as setting retardants. The best results were obtained with tartaric acid.

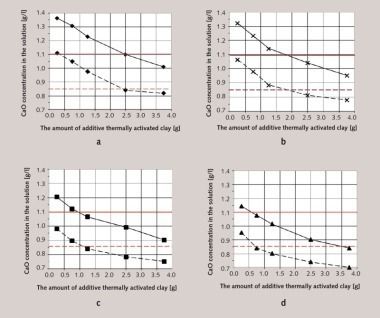

In Tables 5 and in Figure 3 the results of the tartaric acid effect on the properties of composite gypsum binders with metakaolin AMA are shown.

The addition of even a small amount (0.05%) of tartaric acid led to a decrease of normal consistency (NC) from 52.5 down to 44.0%. But the further increase of tartaric acid content did not have such a significant effect on NC. However, the setting time of the binder increased with an increase in tartaric acid concentration: the beginning from 2.0 to 10 min, the end – from 2.5 to 23 min.

A decrease in NC resulted in higher compressive strength both in the early and later periods. On the contrary, flexural strength practically didn’t change. Composition 1.8 that contained 0.07% of tartaric acid was characterized by the highest strength – 41.3 MPa (Figure 3).

The results of determining the porosity, water absorption and water resistance of the matured composite binders with tartaric acid (see Table 5) correlate well with the strength indicators. Therefore, composition 1.8 was chosen for further studies (0.07% tartaric acid content).

When studying the mixed gypsum binders with the other active mineral additives, the best results of the tartaric acid effect were obtained: for microsilica AMA – 0.07% (composition 2.8), zeolite AMA – 0.05% (composition 3.7) and tripolite AMA – 0.07% (composition 4.8).

A composite gypsum binder composition obligatory includes a plasticizing additive. In this research work the Sika ViscoCrete 510 additive was used as a plasticizer that, according to the manu-facturer data, works well both in gypsum and

cement systems.

The addition of a polycarboxylate plasticizer in the amount of 0.1-0.6% led to a decrease in water demand of pozzolanic gypsum-cement paste, however the degree of water demand decrease for the binders with different active mineral additives varied significantly (see Table 6). In compositions with metakaolin, NC decreased from 44.5 to 33.0%; with microsilica – from 44.0 to 20.0%; with zeolites – from 42.0 to 27.0%, and with tripolite – from 50.0 to 36.0%. Such different effects of polycarboxylate plasticizer can be explained, on the one hand, by the different effect of the additive on Portland cement and gypsum components [25-29], and, on the other hand, by the different specific surface area and consistency of the additives themselves.

Similar changes can be observed with the setting time. The most noticeable lengthening of the setting time is in CGB compositions with metakaolin: the beginning of setting varies from 3.5 to 12.5 min, and the end – from 7.5 to 19 min respectively. And in the compositions with tripolite, on the contrary, not an increase but a decrease of both the beginning and the end of setting time was observed. At the same time, the obtained values are very close (see Table 6). It should be noted that the setting time of the compositions with tripolite is very short that makes it difficult to use such compositions.

Such an integrated mutual effect of tartaric acid and Sika ViscoCrete 510 plasticizing additive on the properties of pozzolanic gypsum-cement paste of binders various by their compositions also led to different strength properties of the hardened binders. An increase in a plasticizer content in the system led to a higher normal consistency of the pozzolanic gypsum-cement paste that, in turn, led to a higher strength. Binders with metakaolin (composition 1.16) and with microsilica (composition 2.16) after 28 d of hardening demonstrated the compressive strength of 48-49 MPa, CGBs with zeolites (composition 3.16) – 36 MPa, and with tripolite (composition 4.16) – 26 MPa.

Harder compositions were characterized by lower open porosity and water absorption and higher water resistance (see Table 6). In the case of composite gypsum binders with metakaolin, all the studied compositions had a softening coefficient, Kr > 0.8. For CGBs with microsilica and zeolites, water-resistant compositions were those in which the content of the plasticizing additive was in the range of 0.3-0.6%. All CGB compositions with tripolite had a Cs coefficient from 0.71 to 0.79 that allowed us to attribute these compositions to ones with improved water resistance.

4 Conclusion

The study of the CGB composition effect on its properties showed that the ratio of CGB components is determined, on the one hand, by the activity of the mineral additive and, on the other hand, by the kind and amount of the modifying additives used.

The study of the individual and complex effect of the plasticizing additive (Sika ViscoCrete 510) and the setting retarder (tartaric acid) on CGB properties allowed us to develop water-resistant compositions of CGBs with various active mineral additives, i.e. with metakaolin, microsilica and zeolites, which properties are in line with the requirements of the regulatory documents.

The developed composite gypsum binder compositions of improved water resistance can be used for production of dry mix mortars and for structural elements in low-rise housing construction.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.