Structure and formation properties

of a water-resistant compound binder based on calcium sulfate β-hemihydrate

This article discusses some special aspects of the hydration and structural formation of water-resistant gypsum-cement-pozzolan composite binders based on calcium sulfate β-hemihydrate modified by a group of mineral and chemical admixtures. The pore structure factors of the products based on these binders were measured and the phase compositions of the new hydration growths were studied.

1 Introduction

The main problem when mixing gypsum binder (GB) and Portland cement (PC) lies in enabling a stable structure to form during their co-hardening. Another important aspect is the problem of obtaining the required water resistance value without an appreciable increase in PC content in the mix or its dilution by means of excessive addition of active mineral admixture (AMA). It is impossible to produce competitive and durable materials based on these binders without solving these major problems.

A large body of research in this field [1-6] carried out by Volzhenskij A.V., Fischer...

1 Introduction

The main problem when mixing gypsum binder (GB) and Portland cement (PC) lies in enabling a stable structure to form during their co-hardening. Another important aspect is the problem of obtaining the required water resistance value without an appreciable increase in PC content in the mix or its dilution by means of excessive addition of active mineral admixture (AMA). It is impossible to produce competitive and durable materials based on these binders without solving these major problems.

A large body of research in this field [1-6] carried out by Volzhenskij A.V., Fischer H.-B., Babkov V.V., Petropavlovskaya V.B., Bur‘yanov A.F., Sreenivasa R.L. and other scientists shows the effectiveness of a number of methods that increase the technical properties of products based on gypsum-cement systems. These include: the application of AMA to create the conditions for stable structure formation; stiff raw mix pressing; volumetric and surface hydrophobization; introduction of modifying admixtures and their complexes [7-9]; dispersed reinforcement [10, 11]; self-reinforcement through new growths of fibrous crystals.

The articles [12-17] are concerned with the effectiveness of the application of natural and synthetic AMAs as mineral admixtures in compound gypsum binders to improve the water and freeze-thaw resistance of the products based on them. In this case the water resistance of these products is no more than 0.6-0.7. The paper [18] describes the composition of hydration products of a hardened cement paste compound that has been modified by a complex agent based on thermally-activated polymineral clay and limestone.

Application of alpha gypsum in the GCPB composition helps to achieve an ultimate compressive strength 30-40 MPa at 7-15 days during normal hardening. However, the application of high strength GB increases the cost of the products.

With due respect to the results of the studies reviewed above, it can be noted that the application of the compositions based on GCPBs with high water resistance is achieved by an increase in the content of AMA and PC in the mix. In some instances it is achieved by using alpha gypsum. In this respect the studies that are oriented towards the development of water-resistant GCPB based on low-grade calcium sulfate β-hemihydrate with a reduced content of PC and AMA for which there is stable structure formation during hydration will be of particular interest. So far there has been little investigation of some of the issues connected with the study of the structure formation of such systems.

2 Development of a water-resistant gypsum-

cement-pozzolan binder based on calcium

sulfate β-hemihydrate

The ultimate purpose of the present paper is achieved by the application of AMA with high hydraulic activity and multifunctional complex admixtures (CA).

The first stage in the previous studies [19, 20] was to choose, from a wide range, the AMAs that were most active after 5, 7 and 30 days of hardening. This explains their low required content in the GCPB composition and enables stable structures to form. A GCPB with the following composition was prepared: GB:PC:AMA – 76:20:4 (gypsum G6BII, Portland cement PC500-D0, metakaolin with a hydraulic activity of 1238 mg/g).

The technical properties of this composition were improved by modifying it using a multifunctional CA that contained a mixed polymer that retarded the set and was based on carboxylic esters with the addition of a phosphate element, polycarboxylate superplasticizer and a homogeneous mixture of oligoethoxysiloxanes [21, 22].

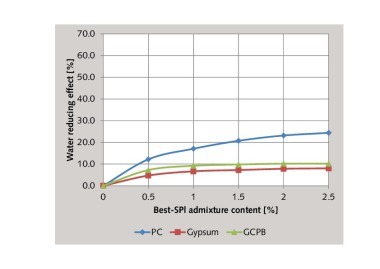

The mechanism of the synergistic effect of the components of the multifunctional CA is based on the fact that during the combined use of modifying mixed polymers based on carboxylic esters and polycarboxylate superplasticizer in the composition of a mix, the repulsion effect of the electrostatic forces between the particles of the binder that occurs during the adsorption of molecules of the first element is complemented correspondingly by the steric effect that arises as a result of the influence of the hydrophobic side chains on the second element. This increases the dispersion of the particles of the binder, resulting in a reduction in the water requirement of the products by 34 % and an increase in the ultimate bending strength by 22 % and in the ultimate compressive strength by 34 %. Introduction of a homogeneous mixture of oligoethoxysiloxanes and adsorption of its molecules on the binder particles with side chains orientated towards the water voids leads to further dispersion of the binder particles while retaining the hydrophobization effect (the water requirement decreases by 40 % and the water resistance doubles). This causes an extension of the initial set and final set of the mix (to 21 min and 22 min respectively).

Special aspects of the hydration and structure formation were measured by examining the pore structure factors of the original and the modified hardened gypsum-cement-pozzolan pastes (GCPP) in accordance with GOST 12730.4-78 (Table 1) and studying the phase composition of the new hydration growths by scanning electron microscopy (SEM), X-ray diffraction analysis and differential thermal analysis at 90 days.

3 Influence of the multifunctional complex admix-

ture on the pore structure factors of hardened

gypsum-cement-pozzolan paste and special as-

pects of the hydration and structure formation of

gypsum-cement-pozzolan binders

Research has shown that modification of the composition by multifunctional CA helps to reduce total porosity and redirect the space of closed pores, open capillary pores and non-capillary pores.

Analysis of Table 1 points to a decrease in total pore space by 23.9 % and in open capillary pore space by 73.4 %, and to an increase in closed pore space by 43.3 % with an increase in microporosity index from 0.18 to 1.51. This indicates the formation of a more compact grain structure of the hardened GCPP that has been modified by multifunctional CA.

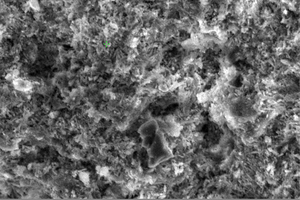

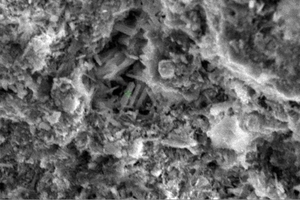

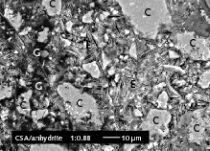

The final composition of the hydration products was investigated by SEM at the endpoints stated on the electron micrographs (Figures 1 and 2).

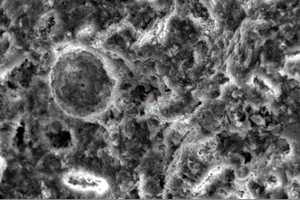

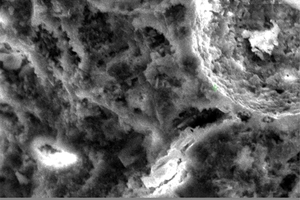

Analysis of the microrelief of the original hardened GCPP (Figure 1 – A, B) shows its stepped structure formed by flaky particles; needle crystals in the areas close to cracks can be observed. The final composition of samples at stated points shows the existence of small needle-like ettringite inclusions that occupy less than 0.2 % of the space under observation.

Randomly oriented crystals with dimensions of 60-70 µm can be seen in the mass of modified hardened GCPP (Figure 2 – A, B). The surfaces of the pores covered by granular phase are responsible for the different stages of crystallization of the sample while hardening. Analysis of the final composition of the sample at the endpoint B stated in Figure 2 shows that the granular phase is present in the form of hydrated calcium silicates (3CaO-2SiO2-3H2O) and also in a low-basicity form of hydrated calcium sulfoaluminate (3CaO-Al2O3-3CaSO4-12H2O).The formation of a more homogeneous finely-crystalline structure can also be seen. This is responsible for the observed decrease in porosity of the sample.

Analysis of the X-ray diffraction patterns of the hardened GCPP samples shows that the qualitative composition of the new hydration growths does not change appreciably during the introduction of multifunctional CA into the GCPB composition. In this case the improvement in the performance properties of the products is linked with changes in their quantitative indexes. Modification of the GCPB by multifunctional CA leads to a decrease in the intensity of the diffraction peaks of ettringite (d=2.68 Å), of calcium hydroxide Ca(OH)2 (d=4.92 Å) and of hydrated calcium aluminate (d=7.7 Å), which indicates that the binder is more fully hydrated than with the original composition. The observed increase in the intensity of the diffraction peaks of the hydrated calcium silicate CSH(B) (d=3.07; 2.80 Å) and the low-basicity hydrated calcium sulfoaluminate (d=9.54 Å) is responsible for the improvement in the mechanical and physical properties of the modified matrix.

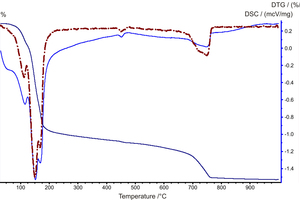

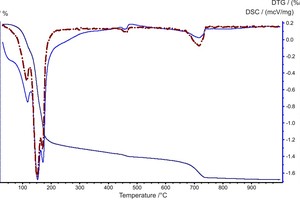

Analysis of the thermograms of the original and modified hardened GCPPs (Figures 3, 4) shows that introduction of multifunctional CA into GCPB leads to more complete hydration of the mixed binder, resulting in a decrease in the amount of water. This causes an increase in the mechanical and physical properties of samples modified with multifunctional CA.

The endoenergic effect at a temperature of 420-480° C, which characterizes removal of chemically combined water from the calcium hydroxide (Ca(OH)2 → CaO + H2O), indicates a low content of calcium hydroxide in the matrix due, resulting in high alkalinity of the liquid phase of the GCPB. This does not appreciably change the endoenergic value of the compounds being studied. A decrease in the endoenergic effect at a temperature of 700-800°C, which characterizes the removal of chemically-bound water from hydrated calcium silicates, was observed during introduction of multifunctional CA. This is linked with a decrease in the quantity of high-basicity hydrated calcium silicates with formation of low-basicity hydrated calcium silicates that contain less chemically-bound water.

4 Conclusions

1. The article states that there has been little research into the issues connected with the development of water-resistant GCPB based on low-grade calcium sulfate β-hemihydrate with a low content of PC and AMA for which stable structure formation conditions are provided during hydration. The special aspects of structure formation of such systems are of particular interest.

2. It has been found out that modification of a GCPB based on calcium sulfate β-hemihydrate using multifunctional CA produces a decrease in total porosity of hardened GCPP by 23.9 %, in open non-capillary pores space by 91.7 % and in open capillary pores space by 73.4 %, and it increases the closed pore space by 43.3 % and the microporosity index from 0.18 to 1.51.

3. The studies undertaken into the hardened GCPP structure and the hydration processes of GCPB using SEM, X-ray diffraction analysis and DTA provided the opportunity to obtain fresh information about special aspects of the formation of the microstructure of modified hardened GCPP. This consists of a low content of free calcium hydroxide and ettringite, a high content of hydrosulfoaluminates and low-basicity hydrated calcium silicates and the formation of a more homogeneous and compact grain structure of the hardened GCPP with improved mechanical and physical properties and water resistance.

4. Based on the results obtained by X-ray diffraction analysis, DTA and SEM it can be concluded that a rational choice of AMA for gypsum-cement mixtures based on calcium sulfate β-hemihydrate with a low content of PC and modification of these compositions by multifunctional CA makes it possible to form stable structures and to achieve high strength and water resistance of the products that are based on them.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.