Research on the interface and microstructure of thin layer mortar

Rapid water loss is one of the important characteristics of thin layer mortar. The testing methods, such as the velocity of water migration, the strength of interfacial bonding, XRD, SEM, FTIR and TG-DSC-DTG were used to research the interface and microstructure of thin layer mortar with continuous moisture migration from the thin layer mortar to aerated concrete. The results show that the rate and the amount of water migration on the interface from mortar to substrate dropped significantly with the increase of viscosity of mortar. There was also a good corresponding relation on the tensile bond strength of the interface and mortar viscosity, which means that the interface bonding strength increased with the increase of the viscosity of mortar.

1 Introduction

Thin layer mortar has been mostly considered as a special mortar, which possesses high water-cement ratio and high area/volume ratio [1].The common problem of the thin layer mortar system is that the a high proportion of water in thin layer mortar will be absorbed by the super absorbent matrix materials [2], then the thin mortar hardens rapidly in a short time due to the rapid loss of water, so the hydration degree is less, even less than 30 %; this has serious effect on the use and service life of construction.

Cellulose ethers (CE), with properties of water retention, thickening...

1 Introduction

Thin layer mortar has been mostly considered as a special mortar, which possesses high water-cement ratio and high area/volume ratio [1].The common problem of the thin layer mortar system is that the a high proportion of water in thin layer mortar will be absorbed by the super absorbent matrix materials [2], then the thin mortar hardens rapidly in a short time due to the rapid loss of water, so the hydration degree is less, even less than 30 %; this has serious effect on the use and service life of construction.

Cellulose ethers (CE), with properties of water retention, thickening and so on, are widespread admixtures introduced into mortar formulations to improve the workability, the process of cement hydration, harden microstructure and other aspects [3-4]. The viscosity of thin layer mortar modified with cellulose ether is increased, which contributes to good flowability of paste and enhanced mechanical strength of the final hardened paste. The well-known cellulose ethers applied in practice are hydroxyethyl methyl cellulose (HEMC) and hydroxypropyl methyl cellulose (HPMC) [5-6]. Many researchers studied the effect of cellulose ethers on mortars from different aspects. Pourchez [7] et al analysed the influence of HPMC and HEMC on cement hydration by adding different dosages of admixtures. Wyrzykowski [8] et al investigated the microstructure of porosity variety of the cementitious matrix with addition of cellulose ethers through mercury intrusion porosimetry.

The previous work showed different results on the hydration process. Ma [9–11] et al researched the early stage hydration process of cellulose ether modified mortar mainly through analyzing the hydration heat, the content of Ca(OH)2 and XRD of the mortar with different dosages and kinds of CE. Based on the above views, this article deals with the study of the properties of interface thin layer mortar modified with cellulose ether with different viscosities, which are rarely reported in the early researches, by dehydrating velocity, FTIR, DTG and SEM.

2 Experimental

2.1 Raw materials

The cement used in this work was Portland cement produced by the HuaXin Cement Company of Hubei province, in accordance with the Chinese standard GB 175 Type II (PII42.5). It has a mean grain size of 16.17 µm and mass density of 3.15 g/cm³. The physical properties and chemical composition of cement are given in Table 1 and Table 2.

The HPMC was an America Hercules Group Company product. The viscosity of HPMC is 1 000 000 m Pa•s in a concentration of 2 % at 25 °C. Aerated concrete was used as the super absorbent matrix material. The physical properties are given in Table 3.

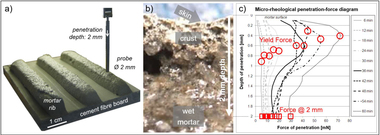

2.2 Experimental process

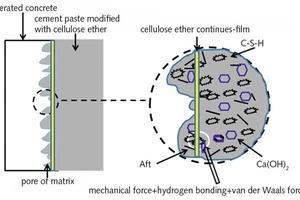

The samples for the experiments were modified cement paste material to add different dosages of HPMC with a water-cement ratio of 0.4. Samples were formed with self-made mould. The size of mould are 40 mm x 40 mm x 6 mm. Preservative films were put on the surface of samples to prevent water evaporation. The curing temperature of cement ingredient was (20±5) °C and humidity 65 % R.H. Samples were maintained for 3, 7 and 28 days respectively before being tested. The structural sketch is given in Figure 1.

2.2.1 Tensile strength

Tensile adhesive strength between interface and modified thin layer cement mortar was measured at 3, 7 and 28 days according to standard JCT985-2005 “Cementitious self-leveling floor mortar” by a testing machine.

2.2.2 Dehydrating velocity

Dehydration velocity of interface thin layer mortar is based on Equation 1:

P=(Mt1-Mt2)/(t2-t1) ? S⇥(1)

P: dehydration rate (g min-1 m-2)

Mt1: sample quality of t1 (g)

Mt2: sample quality of t2 (g)

S: sample area (m2)

2.2.3 Slurry viscosity

The viscosity of thin layer mortar was tested by the R/S.SST paddle rheometer. Shear stress ranged from 6 to 200 Pa, the test date processing used Rhe02000 software.

2.2.4 Chemical combined water content

Configured cement paste samples were sealed in plastic bags and maintained in a temperature and humidity conservation box for a defined period. Next, the samples were hydrated in ethanol. The paste block was then comminuted to particles of less than 1mm in diameter, after which 5 g samples were dried for 2 hours at 105°C to eliminate the physically bonded water. Finally, the samples were fired to constant weight at 1050°C. Chemical combined water content based on Equation 2:

M1 – M2 – vsM1

W = [ (100–v1) – v1] x 100 % ⇥(2)

M1

W: chemically combined water content (%)

M1: hardened cement paste quality before ignition (g)

M2: hardened cement paste quality after ignition (g)

v1: loss on ignition of cement paste (%)

vs: dosage of admixture (%)

2.2.5 Micro measurements

Qualitative analysis of phases was carried out by a Japan D/Max-RB X-ray diffractometer. FTIR spectra were taken in a Perkin Elmer Nexus spectrometer. Powdered samples were mixed with KBr and pressed into pellets. The analyses were carried out in the frequency range of 400–4000 cm-1, using 4.0 resolution and 128 scans. For the thermal analyses, a Netzsch STA 449PC, a simultaneous Thermogravimetry (TGA) and Differential Scanning Calorimetry (DSC) system, was used. The samples were heated from room temperature to 1000 °C with a heating rate of 10 °C/min in a N2 atmosphere (60 ml/min). The microstructure of the cement pastes was investigated with a Japan D/Max-RB Scanning Electron Microscope (SEM).

3 Results and discussion

3.1 Viscosity and dehydration of interface

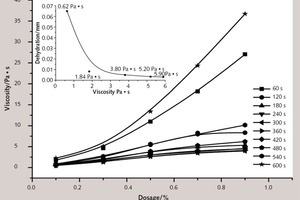

The relationship of thin layer cement paste viscosity, dehydration and cellulose ether dosage are shown in Figure 2. It can be seen that the viscosity of thin layer modified mortar gradually increased and the dehydration decreased with increase of cellulose ether dosage.

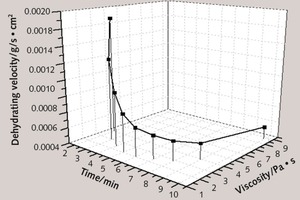

The thin layer cement paste modified with cellulose ether between dehydration velocity and hydration time is shown in Figure 3. With the hydration continuing, the dehydration velocity of thin layer cement paste modified with cellulose ether at the interface gradually slows down. During the first six minutes after mixing, the dehydration velocity is decreased linearly and the latter flattens. The viscosity of thin layer cement paste decreased to the bottom at six minutes after mixing, and then increased rapidly. Because the water retention of cellulose ether did not completely work in early hydration, after six minutes, on the one hand, the matrix absorbed lots of water from the thin layer cement paste; on the other hand the cellulose ether function enhanced the viscosity of the thin layer cement paste to retain the water. Studying the relationship between viscosities and dehydration velocity can find that the variation trend of the dehydration velocity of thin layer cement paste modified with cellulose ether at the interface decreased first and then increased.

3.2 Viscosity and tensile bond strength

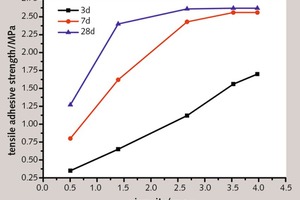

The dependence of tensile bond strength on viscosity and ages is given in Figure 4. The tensile adhesive strength between the aerated concrete matrix and the thin layer mortar increased with both viscosities and times increased. According to analyzing curve of 3 days, the tensile adhesive strength linearly increased with the increasing of the viscosity, while after 7 days and 28 days, the trend stabilized to 2.62 MPa.

3.3 Micro-analysis

3.3.1 XRD analysis

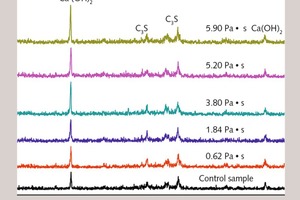

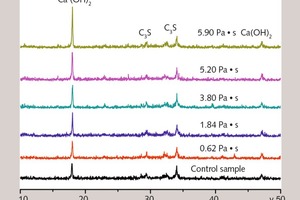

Figure 5 shows the XRD analysis of thin layer cement paste with different viscosities and times. It can be seen that the main minerals in hardened cement paste include Ca(OH)2 and C3 S; the diffraction peak of Ca(OH)2 in 18°and the diffraction peak of C3 S appear in 34° and 29° respectively. Compared to the XRD diffraction of the same period and different viscosities, the diffraction peak intensity of Ca(OH)2 decrease with the increase in viscosity. Due to the dosages of HPMC increased, which delayed the hydration process, the viscosity of the thin layer mortar increase, but the production of Ca(OH)2 and C3 S decrease.

However, compared to XRD diffraction of 3 d, 7 d and 28 d, with the extension of age, the thin layer cement paste hydration could fully, thus the intensity of the diffraction peaks of ettringite, Ca(OH)2 and C3 S all increase.

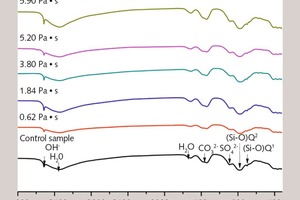

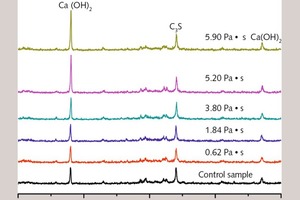

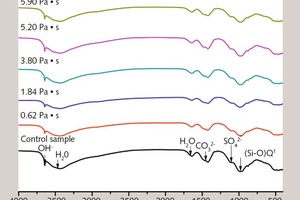

3.3.2 FTIR analysis

Figure 6 presents FTIR analysis of thin layer cement paste. The most remarkable feature of the FTIR spectrum is its peak changes. With the extension of age, the characteristic peak of Si-O shifted from a high wavenumber to a low wavenumber(874 cm-1 to 978 cm-1), due to the polymerization of SO42- units during C-S-H formation. The characteristic peak of OH- which are associated with the formation of Ca(OH)2 appeared at 3640 cm-1. Because of the Si-O stretching vibrations in Q1 sites, all cement paste samples had a characteristic peak around 850 cm-1 and the intensity of the characteristic peak increased gradually. The position of S-O band appeared at 1150 cm-1, due to early formation of ettringite. The characteristic peak of CO32- was at 1450 cm-1.

Compared to the same age and different viscosities of samples, with the viscosity increased, the positions of Ca(OH)2 and Si-O characteristic bands shifted to higher wavenumbers and the intensity of these peak decreased, then these peaks gradually decreased. When the viscosity is 5.90 Pa•s, the vibration peaks of OH at 3640 cm-1 and (Si-O)Q1 at 850 cm-1 were not obvious. This showed that thin layer cement paste modified with cellulose ether not only delayed the process of cement paste hydration, but also changed the structure of C-S-H during cement hydration. The larger the viscosity, the more it decreases obviously.

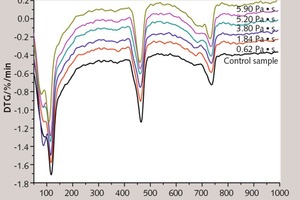

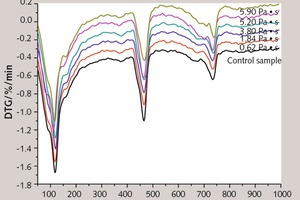

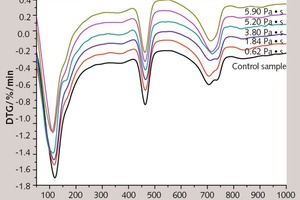

3.3.3 Differential thermal analysis

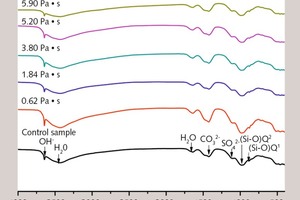

The thermal analysis results of thin layer cement paste are given in Figure 7. Applying thermal analyses for the assessment of the Portland cement hydration processes has proved very useful [12-13]. It is known that tricalcium silicate (C3S) and dicalcium silicate (C2S) are the main mineralogical components of Portland cement [14]. With the mortar hydration, endothermic effects with the maximum at 462.9 °C correspond to portlandite decomposition which was generated by Ca(OH)2 heating. Endothermic effects accompanied by the mass loss which occurs with the maximum at 737.9 °C correspond to the decarbonation of CaCO3 [15-16].

By comparing DTG curves of samples with different viscosities, it can be seen that the trend is similar. There was only a small difference in the intensity of the endothermic peaks, this decreased with the increase of the viscosity of mortar. The addition of cellulose ether showed an effect of slower hydration processes and lesser Ca(OH)2 content compared with the control sample. According to the mass variation of TG curves between 420 ~ 460 °C and 105 ~ 1000 °C, the proportions of Ca(OH)2 and chemically combined water are shown in Table 4.

The results of the measurements of content of Ca(OH)2 and chemically combined water of thin layer cement paste are shown in Table 4. With the viscosity increasing, the content of Ca(OH)2 in cement pastes and chemically combined water gradually decreased. The higher the viscosity of the cement paste, the greater its impact on the setting time and initial hardening rate. After 3 days of hydration, the cement paste viscosity of 5.90 Pa•s, in which 4.83 % Ca(OH)2 was 60 % less than the 7.78 % Ca(OH)2 in the control sample and the content of chemically combined water was 10.58 % in the viscosity of cement paste which was 5.90 Pa•s less than that in the control sample with 11.30 %. After 7 days of hydration, the Ca(OH)2 content had decreased by 43 % (control samples) to a viscosity of 5.90 Pa•s. After 28 days of hydration, the decrease amounted to 46 %. It can also be seen that the content of Ca(OH)2 and chemically combined water obviously increased as the mortar hydration continues. Compared to the 3 days ,7 days and 28 days of hydration, there are big differences of content of Ca(OH)2 and chemically combined water. The contents of Ca(OH)2 of the control sample are 7.78 %, 8.05 % and 8.35 % respectively and the contents of chemically combined water are 11.30 %, 13.55 % and 15.40 %. Moreover, the increasing range diminished gradually as the viscosity of mortar increased, which can be explained by the fact that increasing viscosities can retain more water and the processes of hydration can be prolonged. Therefore, the change of content of Ca(OH)2 and chemically combined water decrease.

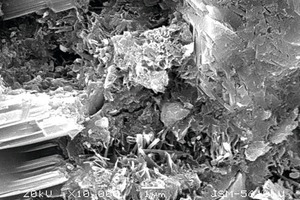

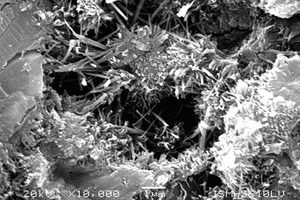

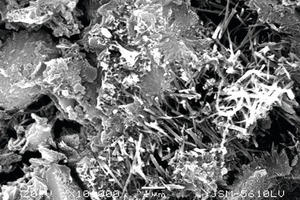

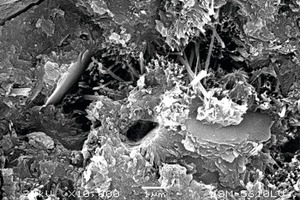

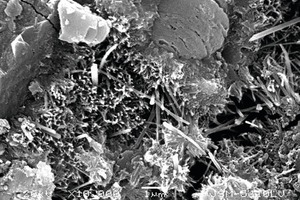

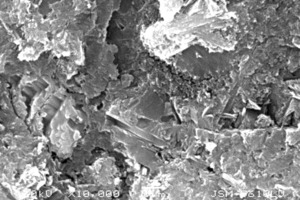

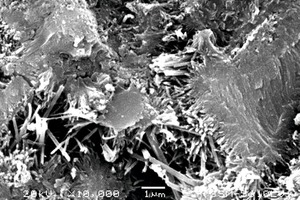

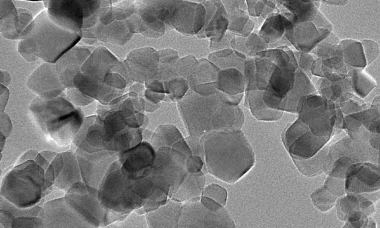

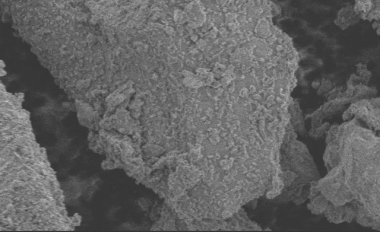

3.3.4 SEM investigation

The above results are in good qualitative agreement with the results of the SEM measurements in Figure 8, where substantial changes in the crystalline structure can be observed as the samples gradually hydrate. There are quite a few holes in all thin layer mortar samples due to the air-entraining function of cellulose ethers. The density of the sample structure increased along with the viscosity of the thin-layer mortar [17]. When aerated concrete which was a high water-absorbing matrix contacted with thin layer cement paste, it would absorb lots of water from cement paste rapidly and block the hydration process. The mortar viscosity modified with cellulose ether can be hydrated fully at the interface of aerated concrete [18]. On the other hand, the effect of cellulose ether on thin layer cement paste seems to be a significant advantage to the strength of hardened cement paste which could generate a greater amount of C-S-H gel, Ca(OH)2 and ettringite. These hydration products formed a network for improving the compactness of structure.

4 Discussions and conclusions

Based on related analysis, the microstructure model of the interfacial transition zone is shown in Figure 9 [19]. Previous research has shown that the water and ions of hydration products concentrated in interface between thin layer mortar and high absorbed matrix (aerated concrete), at the same time, the water and ions (Ca2+, OH-, SO42- and Al3+) have strong migration behavior and penetrated into the pores of the matrix materials surface, which hydrated first and formed hydration of Ca(OH)2 and C-S-H [20-21].

The stacking density of cement particles in the interface transition region is increased. Porosity and crystals decreased from modified cement paste to aerated concrete interface and formed interface enhancement region due to crystal preferential [22-24]. The contents of C-S-H gel of modified mortar interface are more than control samples. A continuous film of cellulose ether formed at the interface of the transition region due to hydration-induced interaction between mechanical force, hydrogen bonding and van der Waals force [25].

Based on this research, it can be concluded that gradual effects of viscosity on thin layer cement paste dehydrating was clearly observed. The results demonstrated that the viscosity of mortar is crucial to the tensile adhesive strength and dehydrating velocity. It was noted that, as the viscosity of thin layer cement paste modified with cellulose ether increased, the adhesive strength of the interface was increased, the dehydration was diminished and the microstructure of harden was densification.

In summary, cellulose ether modified the viscosity of the cement paste as a tool to control flow properties and hydration processes. Therefore, higher viscosity of thin layer mortar can be optimized by using the production process.

Acknowledgements

The program was funded by the Youth Fund of the National Natural Science Foundation of China (No.50902107) and the National Science and Technology Supporting Program (No. 2012BAJ20B04-02).

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.