Influence of nano-TiO2 on mechanical property and hydration characteristic of cement high volume of fly ash system

The influence of nano-TiO2 (NT) on the mechanical properties and hydration characteristics of a cement high-volume fly ash (CHVFA) system were studied in this paper. The compressive strength of CHVFA mortars was tested with different FA and NT contents. Results show that the addition of NT increases the strength significantly, while the degree of enhancement wanes with increasing length of the curing. The mechanism of NT on properties of the CHVFA system was analyzed by X-ray diffraction (XRD), differential scanning calorimetry-thermogravimetry (DSC-TG), scanning electron microscopy (SEM), and nuclear magnetic resonance (NMR). The results reveal that the addition of NT accelerates the hydration of cement and fly ash significantly, but the promotion effect is delayed along with the curing age, thus lessening the facilitating role of NT on the compressive strength of CHVFA mortars.

1 Introduction

China is a coal-fired country. Both at present and for a rather long time to come, coal is and will remain the country’s main source of energy. Fly ash (FA) is an inevitable product of coal-fired power generation, with every 4 tons of coal consumption producing 1 ton of FA. In 2015, according to estimates, FA output in China reached 620 million tons, making it the highest in the world [1]. If such a large amount of solid waste is not put to some rational use, it amounts to a great waste of resources, pollutes the environment, consumes large swathes of farmland and affects the...

1 Introduction

China is a coal-fired country. Both at present and for a rather long time to come, coal is and will remain the country’s main source of energy. Fly ash (FA) is an inevitable product of coal-fired power generation, with every 4 tons of coal consumption producing 1 ton of FA. In 2015, according to estimates, FA output in China reached 620 million tons, making it the highest in the world [1]. If such a large amount of solid waste is not put to some rational use, it amounts to a great waste of resources, pollutes the environment, consumes large swathes of farmland and affects the sustainable development of the industry

Vitreous SiO2 and Al2O3 are the main active components of FA. There are two basic forms of these vitreous bodies, i.e. microspheres and porous vitreous body. Normally, the content of vitreous body in FA ranges from 60 % to 70 %, and these metastable materials tend to shift towards a more stable state, hence imparting a potential for activity on FA.

The use of industrial waste as an admixture in concrete engineering is one of the major options available for the highly efficient utilization of FA. It not only reduces the consumption of natural resources, but also offers advantages that other materials cannot substitute, such as meeting the requirements of green concrete. The advantages of FA can be summed up as four key points: Firstly, fly ash microspheres are conducive to cement-particle dispersion, and they significantly reduce the required content of mixing water while guaranteeing the requisite workability of concrete [2]. Secondly, the secondary hydration reaction of FA mainly occurs in the pores, hence reducing the porosity of the cement matrix, and, by the same token, considerably increasing the compactness and durability of cement-based materials [3]. Thirdly, FA, which does not take part in the pozzolanic reaction, can be used as micro-aggregate to fill the pores between aggregate particles, thereby further improving the density of the concrete [4]. In addition, FA can retard the speed of cement hydration. This lowers the concrete temperature rise caused by hydration heat, thus helping to avoid crack generation [5-8].

However, FA commonly has the combined disadvantage of slow hydration and poor early strength, a fact which greatly restricts its widespread application. Therefore, learning how to improve the early strength of FA-cement systems is the key to FA application research. The incorporation of nano-material can promote the early hydration of cement, thus increasing the early strength of the cementitious composites. At pres-ent, research concerning the impact of nano-material on cement-based composites concentrating heavily on the influence of nano-SiO2 on cement hydration and hardening characteristics. It has been proven that nano-SiO2 not only possesses good pozzolanic reactivity and provides nucleation sites at early ages, but also acts as a pore filler and modifies both the microstructure and the interface transition zone (ITZ) to make the paste become denser [9-11]. Moreover, the higher cement particle dissolution rate caused by the addition of NS at early age would increase the alkalinity of the pore solution, and the silicate or aluminosilicate network formers in FA would break down more easily in a high pH environment, thus accelerating FA hydration [7, 12-14]. However, the addition of NS decreases the mean Ca/Si ratio of the FA coating [7], and it has been reported that C-S-H gel with a low Ca/Si ratio is less permeable [8]. Along with the compacted gel structure, the hydration of fly ash at later age is delayed to a great extent.

As a new functional material, nano-sized titanium dioxide (TiO2) is the most widely used photocatalyst in the field of construction and building materials due to its strong photocatalytic activity. The major applications of TiO2 based photocatalytic cementitious materials include air pollution remediation, self-cleaning and self-disinfection [15-17]. These materials are preferably applied to external building surfaces and concrete pavements, because the relatively flat configurations of such surfaces can facilitate the exposure of the photocatalysts to sunlight. It is expected that buildings coated with photocatalytic cementitious material can maintain their aesthetic appearance and reduce urban air pollution levels at the same time. Beyond that, the effects of nano-TiO2 on the inherent properties of hardened cement pastes have been extensively studied. Chen et al. [18] studied the hydration and properties of nano-TiO2 -blended cement composites. Test results showed that the hydration degree of cement at early age was obviously improved by a small amount of nano-TiO2 (NT) powder. TiO2 was confirmed to be a non-reactive fine filler and had no pozzolanic activity, serving merely as potential nucleation sites for the accumulation of hydration products. Meng et al. [19] showed that the addition of NT decreased and modified the orientation index for the nucleation function, thus improving the strength of mortars. Ma et al. [20] investigated the influence of nano-TiO2 on physical and hydration characteristics of fly ash-cement systems and found that the hydration of fly ash and cement was accelerated simultaneously before 28 days, and the fluidity and setting time were decreased significantly when NT was introduced into the cement-based materials.

The existing research efforts are mainly focused on the influence of NT on cement and fly ash hydration at early ages, while fairly few studies deal with later ages. In this study, the mechanical properties of NT-added high-volume fly ash cement mortar are evaluated at both early and later ages, and the governing mechanisms of NT influence on fly ash hydration are studied. These results may provide a comprehensive explanation of the mechanical behavior of an NT–fly ash cementitious material system.

2 Experiment

2.1 Materials

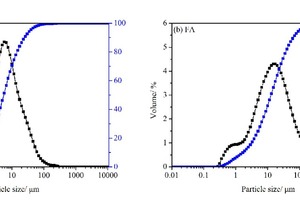

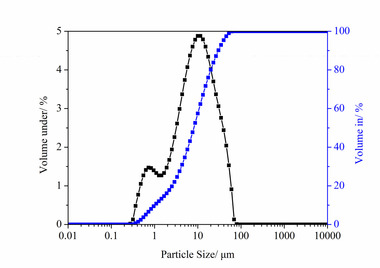

Ordinary Portland cement (OPC) CEM I 42.5 with a specific gravity of 3.13 and a surface area of 350 m2/kg is produced by Huaxin Cement Co. Ltd in China. Secondary fly ash (FA) produced by the Yangluo power plant in Wuhan/China is used as supplementary cementitious material. Nano-TiO2 (NT) with an average particle size of 21 nm and a special surface area of 60.3 m2/g is purchased from Degussa Company. The aggregates are supplied by Xia’men ISO Standard Sand Co., Ltd. and manufactured according to GB/T14684-2011 [21].

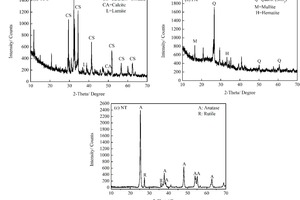

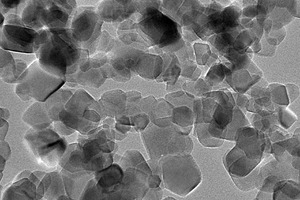

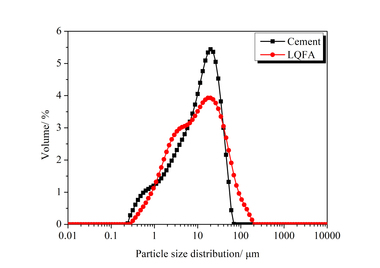

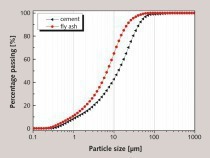

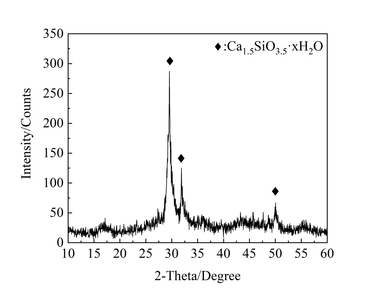

The chemical composition of cement and FA are listed in Table 1. XRD patterns of cement, FA, and NT are shown in Figure 1. The particle size of OPC and FA measured by a Mastersizer 2000 laser particle size analyzer is shown in Figure 2. An SEM image of FA and a TEM image of NT are shown in Figure 3 and Figure 4, respectively. It is obvious from Figure 3 that the FA particles were perfectly spherical in shape.

2.2 Mix proportion and sample preparation

The mix ratios of cement pastes and mortars are shown in Table 2.

All mortars were prepared by blender at an ambient temperature of approximately 25 ° C using a water/binder ratio of 0.5 and a sand/binder ratio of 3. The binder included OPC, FA, and NT. Prior to mix preparation. NT was added to deionized water, then stirred and dispersed by ultrasonication at 325 W for 30 min to obtain uniform suspensions. The mortar samples of size 40×40×160 mm cuboid were cast and demoulded after 24 h. The mortar specimens were cured at (20±2) °C and (95±5) % relative humidity (RH) for 3, 7, 28, 56 and 90 days. In order to prepare the samples for scanning electron microscope (SEM) analysis, the small fragments obtained from the middle part of the mortars at a certain age were immersed in anhydrous ethanol for 3 days and then dried at 50° C for 8 h.

The mix proportions of the cement pastes were similar to those of the mortars except for the exclusion of sand. The water/binder ratio of the pastes was the same as that of the mortars. 40-mm cube samples were also cast for pastes and cured according to a method similar to that followed for the mortars. Small portions were cut from the cubes and then terminally hydrated by anhydrous ethanol to enable X-ray diffraction (XRD), thermogravimetry-differential scanning calorimetry (TG-DSC), and magic-angle-spinning nuclear magnetic resonance (MAS NMR) analysis. The samples for XRD, TG-DSC and MAS NMR should be hand ground in an agate mortar so as to pass the 200 mesh-size sieve and then oven-dried at 50° C for 8 h.

2.3 Test procedure

2.3.1 Mechanical properties

The compressive strength of mortar specimens was tested according to GB/T17671-1999 [22] using a loading rate of 2.4 kN/s. To achieve reliable results, each test was repeated six times and the data averaged.

2.3.2 XRD analysis

A Bruker D8 Advance XRD device with a Cu kα X-ray source at 35 kV and 30 mA was used to determine the phase composition of the samples. The test parameters were step-length 0.02 °, scanning rate 8 °/min and 2-theta from 10 ° to 70 °.

2.3.3 DSC-TG analysis

DSC-TG analysis was conducted using a Netzsch STA449F3 simultaneous thermal analyzer at a heating rate of 10° C /min from 50° C to 1000° C in a nitrogen atmosphere. The CH content, CH (%), can be calculated according to the weight lost between 400-500° C, which is the decomposition temperature of CH, as shown in formula (1) below:

⇥(1)

where WLCH represents the weight loss in percent attributable to CH dehydration; MWCH and MWH represents the CH molecular weight and the H2O molecular weight, respectively.

2.3.4 29 Si MAS-NMR analysis

A Bruker Avance III 400 Solid-state 29Si magic-angle spinning nuclear magnetic resonance (MAS-NMR) spectrometer was used to qualitatively analyze the composition and structure of the Si-based substances. This instrument was operated with a magnetic field set to 120 MHz and a rotation frequency of 10 kHz. A 4-mm zirconia rotor with an accessible volume of 0.115 cm3 was used in all tests. The samples were collected for 2000 scans, each consisting of a single pulse of width 5μs, followed by a relaxation time of 10 s. The hydration degree of cement (aOPC) and FA (aFA) can be calculated by way of the following formula [23-26]:

⇥ (2)

⇥ (3)

where I0(Q0) and I(Q0) represent the integrated intensities of the signal Q0 for the cement before and after hydration, respectively; I0(Q3) and I0(Q4) represent the integrated intensities of the signals Q3 and Q4 for FA before hydration, respectively; I(Q3) and I(Q4) represent the integrated intensities of the signals Q3 and Q4 for FA after hydration, respectively.

2.3.5 Morphology and elemental composition

A Quanta 200 FEG-SEM was used to determine the morphological characteristics of mortars with a 7~15 kV accelerating voltage and 10 mm working distance in low vacuum mode. The spot scanning approach was used to analyze the Ca/Si ratio of hydration products on FA.

3 Results and discussion

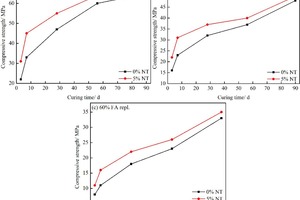

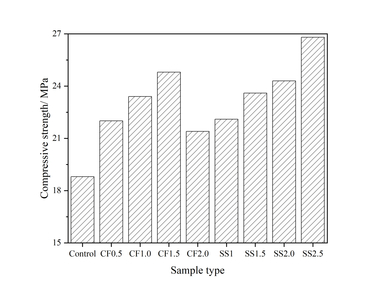

3.1 Effects of nano silica on compressive strength of cement mortar

Effects of NT on the compressive strength of 0 %, 40 % and 60 % fly ash cement mortars are shown in Figure 5. It reveals that, whether or not FA is added, the rate of compressive strength gain of NT-added mortar is enhanced at all ages. However, the magnitude of the increase wanes along with the curing age. As Figure 5 shows, the compressive strength of 0 %, 40 % and 60 % fly ash mortars is higher by 41 %, 38 % and 38 %, respectively, at 3 days for the 5 % NT-added cement mortars. While the corresponding enhancement degrees are 3 % and 4 % and 6 % at 90 days for the 5 % NT-added cement mortars. This trend differs from the research results obtained by Hou et al. [7], who studied the influence of another nano-SiO2 (NS) material on fly ash hydration and found that, at late ages, the addition of NS lowered the strength of fly ash-cement systems. In order to investigate the causes for the strength-gain characteristics of NT-added fly ash system, the hydration characteristics of fly ash–cement pastes at early and late ages were further evaluated.

3.2 XRD analysis

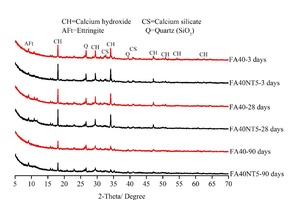

Figure 6 shows the XRD patterns obtained from cement pastes tested after 3, 28 and 90 days of curing, respectively.

Analysis indicated the predominance of cal-cium hydroxide (CH), calcium silicate (C2S/C3S) and ettringite (AFt), with CH being formed in appreciable amount in all samples. As a product of cement hydration, CH is generated in the process of cement hydration; the more CH, the more C-S-H gel. On the XRD scale, the CH shows a strong peak located at 2-theta angles of 18.05. The CH peak was considered to be the main indicator of performance in past cement samples.

The beneficial effect of adding NT to cement pastes is also confirmed by the results of XRD analysis. It is obvious that, at 3 days, the addition of NT increases the intensities of the CH peaks, mainly because the superfine particles of NT possess high surface activity, which can act as potential nucleation sites for the accumulation of hydration products to promote cement hydration and release CH. This view has been fully demonstrated previously [18-20]. At 28 days, the CH intensity peaks of both samples increase remarkably compared to those at 3 days, mainly as a result of constant consumption of clinker and formation of CH along with hydration. Also, the CH peaks of paste with NT are higher than those obtained without NT, most probably due to the fact that NT has no pozzolanic activity and does not take part in chemical reactions in the process of hydration, thus keeping the heterogeneous nucleation effect of NT in continuous effect. From 28 to 90 days, the changes in CH intensity peaks are varied for different samples. For samples without NT, the intensities increase noticeably, while for samples with NT, the degree of increase is slightly lower. This has been closely tied to the accelerating effect of cement hydration and to the filling effect of NT, which together increase the compactness of the C-S-H gel covering the cement particles, perhaps acting as a barrier to ion penetration and thus hindering cement hydration at later ages. These results also correspond to the compressive strength values measured as shown in Figure 5.

So, the effect of NT on cement hydration can be seen as having two sides – one positive and one negative – as summarized below. On the one hand, NT can act as potential nucleation sites to promote the hydration of cement, and because it has no pozzolanic activity and does not take part in chemical reactions in the process of hydration, its heterogeneous nucleation effect will last for a long time. On the other hand, due to the accelerating effect of cement hydration at early age and to the filling effect of NT, the compactness of the C-S-H gel covering the cement particles of paste with NT is more pronounced than that without NT, plus the lesser amount of NT that can serve as nucleation sites. All this accounts for the hindering of ion penetration and further cement hydration. These two factors continuously accompany the entire cement hydration process, and the positive factor predominates at early ages, while the negative factor predominates at later ages.

Figure 7 shows the XRD patterns obtained from cement pastes containing HVFA and combined HVFA and NT, as tested after 3, 28 and 90 days.

As Figure 7 shows, there are four main substances in the hydrated pastes containing HVFA, i.e., calcium hydroxide (CH), calcium silicate (C2S/C3S), ettringite (AFt) and quartz (SiO2), among which CH and quartz account for a considerable quantity in all samples. As a product of cement hydration, CH reacts with silica in a supplementary cementing system and forms C-S-H, hence resulting in improved mechanical properties of mortars. On the XRD scale, the CH has a strong peak also located at 2-theta angles of 18.05, and the quartz at 26.63. The CH peak also can be used to indirectly identify the hydration of cement and the degree of pozzolanic reaction of fly ash.

At 3 days, a significantly higher CH intensity peak of HVFA paste containing 5 % NT can be contributed to the accelerating effect of NT on cement hydration, with only a small amount of FA participating in the secondary hydration reaction. At 28 days, the CH intensity peaks of both samples are conspicuously higher than those at 3 days, mainly becausemore CH is formed along with cement hydration and the low activity of FA leads to the consumption of less CH than the amount being generated. However, the quartz intensity peak of HVFA paste with 5 % NT is clearly lower than of that without NT, which is largely due to the fact that the activity of FA can be stimulated relatively quickly under the higher CH concentration at early age. In addition, because the heterogeneous nucleation effect of NT with no pozzolanic activity can last for a long time, the CH intensity peak of samples with NT is also higher than of those without NT. From 28 to 90 days, the conspicuous decrease in CH intensity peaks of both samples are due more to the higher consumption of CH by FA, as compared to the generation of CH by cement hydration. The analysis of XRD at 90 days also revealed no apparent differences between the CH intensity peaks. This is partly attributable to the compactness of the C-S-H gel on the FA surface, i.e., similar to the hindering effect of NT on cement hydration at later ages.

3.3 Cement and FA hydration degree

The influence of NT on the degree of cement hydration is shown in Figure 8. For samples without HVFA, significant differences in the hydration characteristics of cement are revealed in the NT-added paste when compared with the hydration characteristics of the paste without NT. At different ages, a significantly higher degree of cement hydration is observed in the NT-added paste. However, it is easy to find that the increased degree declines along with the hydration time. Specifically, at 3 days, the degrees of cement hydration in non-NT and 5 % NT cement paste are 36.7 % and 45.2 %, respectively, and an 8.5 % increase is caused by the addition of NT. While at 90 days, the degrees of cement hydration in non-NT and 5 % NT cement paste are 72.3 % and 74.5 %, respectively, and only a 2.2 % increase in cement hydration is observed. This implies that cement hydration is accelerated over the entire age by addition of NT, but the increase degree at early age hydration is greater than that observed at late age, a fact which is in accord with the results of XRD. The effect of NT on cement paste containing FA shows the same trend as that without FA.

Obviously, the addition of FA increases the cement hydration degree to a large extent, which can be explained by the dispersing effect and slow secondary hydration of FA. Firstly, FA particles are virtually spherical (see Figure 3) and play a lubricating role in the whole system, thus making the angular shape of cement distribute more homogeneously [2, 27]. Secondly, FA of slow reaction would provide more water for cement hydration. These two aspects both availably enhance the cement hydration degree to some extent, and the accelerating effect of FA on cement hydration has been experimentally verified by Wang et al. [3].

The influence of NT on the pozzolanic reaction of FA is shown in Figure 9. There are significant differences in the hydration characteristics of FA between NT-added paste and FA-cement paste without NT. At 3 days, the reaction extents of FA in both samples are poor. However, a slightly higher degree of FA hydration is observed in the NT-added paste at all ages. Moreover, the difference in FA hydration degree between pastes with and without NT first increases and then decreases with increasing curing age, and the maximum difference can be obtained at 28 days. This implies that the pozzolanic reaction of fly ash is accelerated in the whole age range, but the increase degree varies for different ages. At first, the activity of FA is not stimulated. Thus, the difference in FA hydration degree is insignificant at 3 days. Then, as the curing age increases, the advantages of NT in terms of accelerating the cement hydration and the accumulation of CH begin to take effect, and the activity of FA in NT-added paste expands more obviously than for paste without NT until the difference between their respective degrees of hydration reaches its maximum at 28 days. Any further increase in curing time narrows the difference, but the FA hydration degree of paste with NT is also higher than that of paste without NT. This differs from results obtained for FA-cement paste with nano-SiO2 (NS) in previous studies by Hou et al. [7]. Their research shows that NS can enhance the pozzolanic reaction of fly ash by increasing the alkalinity of solution at early age, but its later-age hydration may be adversely affected. The different effects of NT and NS on FA hydration may result from their different properties. Nano-SiO2, which has high pozzolanic activity, is almost completely reacted at early age [7], leading to the effect of NS persisting for a shorter period of time. By contrast, nano-TiO2 particles are confirmed to be non-reactive fine fillers having no pozzolanic activity, instead only acting as potential nucleation sites for the accumulation of hydration products. Therefore, their effect on cement and FA hydration can last for a longer time than that of NS.

3.4 Ca(OH)2 content

As mentioned above, pozzolanic reaction is a Ca(OH)2-consuming process. Therefore, the evolution of CH content in pastes is a measure of the reaction characteristics of FA. Results regarding the effects of fly ash and NT on the CH content of cement–fly ash-NT systems are given in Table 3.

As Table 3 indicates, the CH contents in NT-added cement pastes are higher than in pure cement paste at all ages, which is in accordance with the results of XRD in 3.2 and, seen from another side, proves the accelerating effect of NT on cement hydration. Yet there are some interesting signs that the difference value of CH between NT-added cement paste and pure cement paste become less pronounced, that is, from 2.48 % at 3 days to 0.68 % at 90 days. This implies that the promotion role of NT on cement hydration is gradually weakened along with the curing time. All of these findings are consistent with the results of cement hydration discussed in 3.3.

It is also shown in Table 3 that the CH contents of 40 % fly ash cement pastes are higher than the corresponding calculated values before 28 days, suggesting accelerated cement hydration. This may be due to the higher local water-to-cement ratio caused by the ‘dilution effect’ of fly ash [28], as well as to the heterogeneous hydration nucleation effect of fly ash particles [29]. The CH content of the 40 % fly ash replacement paste being lower than the calculated value after 28 days is due to the pozzolanic reaction of fly ash, which points to the generation of less CH by cement hydration than is consumed by FA.

A comparison of the CH contents of the 0 % and 5 % NT-added CHVFA paste reveals that the CH content of NT-added CHVFA paste is higher than that of non-NT-added paste at all ages, mainly because the cement hydration degree in NT-added paste is higher than that in non-NT paste, as shown in Figure 9. However, a higher reduction in CH content of 5.68 % can be observed in non-NT paste from 28 days to 90 days compared to 4.98 % in NT-added paste. Moreover, when the effect of NT on cement hydration is taken into consideration, because the cement hydration degree is nearly the same in both kinds of CHVFA paste. The amount of CH amount by fly ash at later ages can be higher in non-NT paste. The mechanism of this phenomenon is discussed later.

3.5 Microstructure and morphology

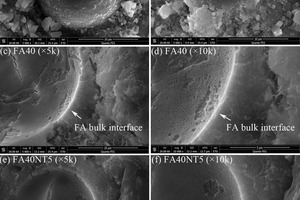

The microstructure of NT-FA-cement pastes was studied under an SEM. Selected secondary electron images are presented in Figure 10 and Figure 11, where the samples are 3 days and 90 days old.

As shown in Figure 10, at 3 days, no matter whether NT is added or not, the fly ash particle surface appears very clean and with small features, indicating a lower degree of FA hydration. The interfaces between the fly ash particles and the bulk pastes are very porous in both samples, mainly because the short crystallization time of hydration products on FA surface does not make the boundary materials densify. In this kind of situation, the hydration of FA occurs with relative ease, as long as sufficient CH is available.

When the curing time reaches 90 days, no matter whether NT is used or not, the FA particles are coated with a significant amount of hydration products, indicating that the degree of second hydration on the surface of FA is improved, as shown in Figure 11. All of these findings correspond to the results in Figure 10. The FA bulk interfaces are also changed from loose at 3 days to dense at 90 days.

Previous studies have proven that C-S-H gel with a low Ca/Si ratio is less permeable, so the hydration rate of fly ash may be related to the chemical composition of FA bulk interface at late ages. To identify the chemical characteristics of the FA bulk interface in the NT-added paste and non-NT paste, EDS analysis was conducted in both the interface and bulk paste regions at 90 days. Figure 12 shows the elemental compositions of the FA bulk interface, where one mark represents one data point obtained from one spot tested. As seen in Figure 12, the mean Ca/Si ratios of the FA bulk interface of NT-added paste and non-NT-added paste are 1.67 and 1.69, respectively. This result indicates that the mean Ca/Si ratio of FA bulk interface of different regions in NT-added paste is somewhat lower than in non-NT-added paste, so to some extent, the delayed hydration of fly ash at late age can be explained by the change of chemical composition. However, the delayed effect of NT is lower than that of NS. The research of Hou et al. [7] showed that the mean Ca/Si ratio of FA coating on NS-added paste and non-NS-added paste are 1.38 and 1.68, respectively, so it can be easily inferred that the compactness of NS-added paste is higher than that of NT-added paste, resulting in a greater delayed effect of NS on FA hydration than that of NT.

4. Conclusion

The main conclusions from this study are shown as follows:

Whether FA is added or not, the compressive strength of NT-added mortar is higher than that of non-NT-added mortar at all ages, while the degrees of increase decline along with the curing age

For paste without FA, the CH content increases along with the curing age, and that of NT-added paste is greater than that of non-NT-added paste at all ages, while the increase rate declines along with the curing age. For paste with FA, the CH content at 28 days is the highest and that of the paste with NT is higher than that of paste without NT at all ages

The hydration degrees of cement and FA increase with the addition of NT, while the increase rate decreases along with the curing age. In addition, the cement hydration degree of paste with FA is higher than that of paste without FA

At 3 days, the hydration degree of FA is relatively low, whether or not NT is added. At 90 days, a substantial amount of FA has been hydrated, and the Ca/Si ratios of the FA bulk interface of NT-added paste and non-NT-added paste are 1.67 and 1.69, respectively. NT has a delayed effect on FA hydration at late ages.

5 Acknowledgment

The financial support from National Key R&D Program of China (2016YFC0701003-5) and open foundation of State Key Laboratory of Silicate Materials for Architectures of Wuhan University of Technology (SYSJJ2018-14) are gratefully acknowledged.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.