Research on the shrinkage behavior and hydration degree of cement mortars with silane

The silane coupling agent has provided some operational, technical and economic advantages in cementitious materials with the development of science and technology. In this paper, the modified cement mortars were prepared with the incorporation of 1%, 3% and 5% silane coupling agents into ordinary cementitious materials. The influences of γ-Aminopropyltriethoxysilane on the shrinkage percentage, porosity and degree of hydration of cement materials at different curing ages were researched systematically. Non-evaporating water and Differential Scanning Calorimetry (DSC) were used to analyze the degree of hydration of the silane-modified cement pastes. At the same time, the pore structures of cement mortars incorporating different Silane contents were characterized using a porosity test and the X-ray Computed Tomography (X-CT) analysis. The experimental results indicated that the incorporation of silane decreased generally the shrinkage percentage and degree of hydration of modified cement mortars and improved the porosity compared with that of the control cement mortars. In addition, the microscopic analysis of XRD and DSC testings revealed the hydration mechanism, and the pore structure model of cement mortar was set using X-CT.

1 Introduction

With the development of economy, infrastructure construction is in full swing, which has led to the development of structural engineering and the increasing demand for concrete year by year [Aitcin et al, 2000]. The concrete production has exceeded 70000 million m3 in 2022 around the world, which provides a great opportunity for the development of concrete industry and also brings new research topics on the durability of concrete [Medeiros et al, 2008]. The durability of concrete directly affects the service quality and service life of concrete structures, especially the...

1 Introduction

With the development of economy, infrastructure construction is in full swing, which has led to the development of structural engineering and the increasing demand for concrete year by year [Aitcin et al, 2000]. The concrete production has exceeded 70000 million m3 in 2022 around the world, which provides a great opportunity for the development of concrete industry and also brings new research topics on the durability of concrete [Medeiros et al, 2008]. The durability of concrete directly affects the service quality and service life of concrete structures, especially the concrete structural engineering in special environments, such as marine engineering, hydraulic concrete engineering and underground concrete engineering in marine and offshore environments [Zhou et al, 2009]. These concrete structures are subject to exposure to seawater/groundwater, especially the erosion of chloride, magnesium, and sulfate salts, which poses a risk of deterioration [Zhou et al, 2009]. Therefore, several researchers have attempted to incorporate polymers or emulsions into concrete to improve its properties [Aitcin et al, 2003]. The silane coupling agent is a type of waterproof material composed of Si-O bonds as the main chain with good weather resistance, aging resistance and hydrophobicity. Thus, the employment of silane coupling agent in civil engineering field has drawn considerable attentions in recent years [Song et al, 2009; Kuder et al, 2012; Desmettre et al, 2012; Deby et al, 2009; Tamimi et al, 2008].

At present, a large amount of research has been conducted on the employment of silane coupling agent for concrete surface treatment, and many research results have been achieved. For example, a new type of silane cement waterproofing agent was produced. In terms of surface treatment of silane impregnated concrete, a permeable silane waterproofing agent has been developed [Tittarelli et al, 2010]. This silane waterproofing material can penetrate several millimeters into the interior of the concrete, forming a waterproof layer, thereby blocking the passage of water and improving the durability of the concrete [Asthana et al, 1999; Dai et al, 2010]. It is worth mentioning that the concrete deck and pier of the world’s longest Hangzhou Bay Cross Sea Bridge are made of silane materials to resist corrosion and improve the durability of the concrete structure. Looking at the research progress in relevant fields both domestically and internationally, silane materials are used mainly for surface treatment of concrete, that is, in order to achieve impermeability and waterproofing by means of the external coating or impregnation [Liu et al, 2009; Tittarelli et al, 2008; Zhu et al, 2013]. However, there is relatively little research on the method of modifying cementitious material by adding silane materials into the cementitious material. Meanwhile, the corresponding shrinkage behavior, hydration mechanism and pore structure have also been rarely studied.

In this paper, the silane-coupling agent (KH550) was indirectly added to cementitious materials, which is different from the surface protection described in previous papers. The aim of this paper was to better understand the influence of the silane coupling agent on the hydration mechanism and pore structure of cementitious materials which is cured to different ages. Some macroscopic testing methods, including the shrinkage behavior, porosity and hydration degree, were researched systematically in this study. Then, the Differential Scanning Calorimetry (DSC) analysis was employed to supervise the cement hydration procedure. Meanwhile, the X-ray CT analysis was used to establish the structure model of cementitious materials to better understand the cement hydration process.

2. Experimental procedure

2.1 Raw materials

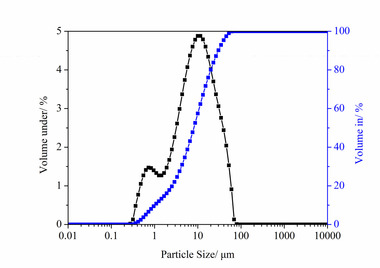

Normal Portland cement (42.5 R type) was used as a binder for mortars with and without silane, which complied with Chinese standard GB175-2007 and was obtained from the Hubei HuaXin Cement Co., Ltd. The chemical compositions and physical of the cement are shown in our previous literature. The natural river sand as required, supplied from Wuhan, Hubei province, with a density of 1.57 × 103 kg/m3 and a modulus of fineness of 2.46, was employed as fine aggregate for the preparation of mortar samples. The specific physical properties of natural sand are shown in in our previous literature. Silane coupling agent, including Aminopropyltriethoxysilane (KH550), was purchased from Diamond material of Chemical Company in China, and its physical and chemical properties are shown in in our previous literature. The molecular structural formula of KH550 is shown in Figure 1. The molecular structure of Aminopropyltriethoxysilane is shown in in our previous literature. Tap water was employed for all experiments.

2.2 Preparation of specimens and curing

conditions

The water/cement ratios of 0.38 and 0.22 were used for cement mortar and cement paste incorporating 0%, 1%, 3% and 5% silane as additives, respectively. Different marks (S1, S2, S3, S4) were used to distinguish modified cement mortar with different silane addition levels, and different marks (S5, S6, S7, S8) were employed for modified cement paste, respectively. The mixture proportions of modified cement mortar and cement paste incorporated with different kinds of silane are shown in Table 1. The prepared fresh cement mortars were poured into a 40 mm × 40 mm × 160 mm prism mold four times. The specific process for cement paste (without sand) specimens was similar to that of cement mortars.

2.3 Shrinkage percentage test

The shrinkage percentage test was used to determine the self-constriction of control and modified cement mortars incorporated with different amounts of silane at 3, 7, 14 and 28 d of curing. The 300 mm × 100 mm × 100 mm beam specimens were prepared using a shrinkage instrument in agreement with ASTM C490 Standard Practice. The test with molded samples was carried out under the condition of constant temperature and humidity to obtain more accurate experimental results [Pozo et al, 2015]. The calculation and treatment of the results of noncontact shrinkage testing were in accordance with the following formula (1):

⇥(1)

Where:

εst = the shrinkage percentage of mortars at the condition of t (h);

L10 = the initial reading value of the noncontact sensor on the left side (mm);

L1t = the T(h) reading value of the noncontact sensor on the left side (mm);

L20 = the initial reading value of the noncontact sensor on the right side (mm);

L2t = the T(h) reading value of the noncontact sensor on the right side (mm) and

L0 = the test gauge distance (mm).

The arithmetic mean of three samples was regarded as the early age shrinkage of the cement mortar specimens, and the calculation should be accurate to 1 × 10-6.

2.4 Porosity test

The porosities of modified cement mortars containing different dosages silane at 3, 7, 14 and 28 d of curing were calculated to research the effect of the different dosages of silane additive on the pore structures of mortars, in agreement with the EN 1015-18:2003. Three cube blocks 70.7 mm × 70.7 mm × 70.7 mm in size were cast in small plastic molds after compaction and vibration. These specimens were demolded after 1 d and were then removed into a standard curing room. The curing was stopped until the corresponding ages were achieved. The specimens were then dried in a vacuum drying oven at a temperature of 105 °C for 24 h, after which they were weighted as M0. These specimens were weighed as Mc after being immersed into water for 24 hours. Equation (2) was calculated as follows:

⇥(2)

Where:

P = the porosity of specimens, %;

M0 = the quality of dry specimens, g;

Mc = the quality of wet specimens, g;

рc =the density of specimens, g/cm3 and

рw=the density of water.

2.5 Degree of hydration test

There are two kinds of water, including none-evaporation and evaporation water, in cementitious materials. The effects of different dosages of silane on the degree of hydration of cement mortar were researched using the nonevaporation water cement measurement. A nonevaporation water substance survey at different curing ages was implemented. The technique was generally employed to estimate the degrees of hydration of mortars with different dosages of silane [Chen et al, 2012; Hou at al, 2013; Schwarz et al, 2007; Neithalath et al, 2009]. A small area was taken from the middle of each specimen and gridded by a porcelain mortar. Ten grams of the powder was placed in porcelain dishes and then dried for 48 h in a vacuum drying oven at 105 °C. The specimens were then ignited in a muffle furnace at 950 °C for 6 h. The mass of these specimens was measured using a balance with a 0.0001 g resolution. The following equation (3) was used to compute the nonevaporable water substance.

⇥

⇥(3)

Where:

Lc = the mass loss of pure cement (g),

C105 = the dry mass of pure cement under the condition of 105 °C (g),

C950 = the ignited mass of pure cement under the condition of 950 °C (g),

Mt = the mass loss rate of pure cement powders at section t (%),

M105 = the dry mass of pure cement powders under the condition of 105 °C (g),

M950 = the ignited mass of pure cement powders under the condition of 950 °C (g),

Wt = the nonevaporable water mass of cement powders at section t (g),

W∞ = the nonevaporable water mass of cement powders under the condition of total hydration (g) and α = the degree of hydration.

2.6 Differential scanning calorimetry (DSC)

Differential scanning calorimetry (DSC) was adopted to research the specific heat capacity (cp) of the geopolymer cement mortar samples containing different types and amounts of silane at different curing ages of 3, 7 and 28 d. DSC is a simple and fast way to determine the heat capacity of small specimens with an extensive range of temperatures and under multiple conditions, such as bulk, powder, film, granular and liquid. In this research, DSC analysis was performed on 8 – 20 mg of powder from the interior of the cement mortar specimens at a scanning rate of 10 °C per minute in the temperature range of 10 °C - 1000 °C.

2.7 X-ray CT

The internal structures of mortars containing different dosages of silane were evaluated using a General Electric (GE) Medical Systems Hispeed CT X-ray scanner. The CT settings were: 200 mA (X-ray tube current), 140 kV(KVP), 9.6 cm FOV (field of view) and 1.2 s full-rotation scan, 1 mm section thickness. The resolution of each element (pixel) was 0.1875 mm ×0.1875 mm. Four silane dosages (0%, 1%, 3% and 5% by weight) were employed to prepare cylindrical samples with a height of 200 mm and a diameter of 100 mm, and X-ray CT measurements were taken for every mixture. A fifth-generation scanner was used, which is different from the third generation X-ray CT scanners used in medical studies, which was controlled to scan approximately 60 slices at most due to excessive warming of the X-ray tube. The space models of all specimens were set up using Mimics 16.0 software according to the CT scanning image.

3 Results and discussion

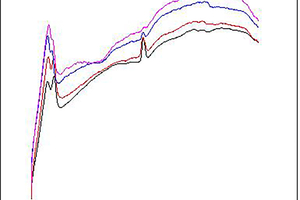

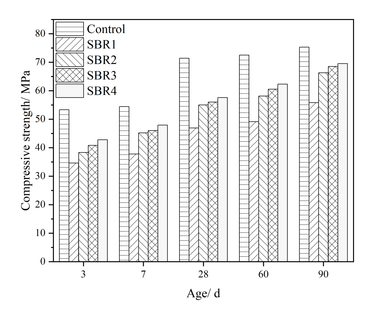

3.1 Variation of shrinkage percentage

The shrinkage percentages of cement mortar containing 0%, 1%, 3% and 5% silane were determined at 3, 7, 14 and 28 d of curing age, and the results are shown in Figure 2. As shown in Figure 2, increasing the curing age improved the shrinkage percentage of the control cement mortar, which was similar to that of modified cement mortar containing different silane contents. The reason for this observation might be that water gradually evaporates with increasing age, leading to an increment of shrinkage percentage in modified cement mortar. Meanwhile, the cement hydration is restricted because of water evaporation, as shown in the following Figure 4.

In an addition, the shrinkage percentage of modified cement mortar was close to the control mortars at all ages from 3 days up to 28 d; however, these results also verified that the shrinkage percentage of modified cement mortars was lower than that of the control cement mortar at all ages. In particular, modified mortar with 5% silane content achieved a shrinkage percentage of 2.83 10-4 at 28 d, which was lower than that of the other mortars. It can probably be concluded that when the humidity of control mortars in the environment is far less than that of the environment itself, the mortars shrink because the water in mortars evaporates from small pores and gel holes. Silane, which is mixed and stirred with cement mortar, is uniformly dispersed in the cement mortars. A polymer cement composite membrane is then formed on the surface between the pores and the aggregate interface of the slurry, in the presence of continuous cement hydration and water evaporation. Due to the formation of a surface composite film, the loss of water from mortars decreases. In addition, cement mortar supplemented with silane polymer can reduce water evaporation and prevent the absorption of dry matrix on water; thus, the shrinkage percentages of modified cement mortars decrease.

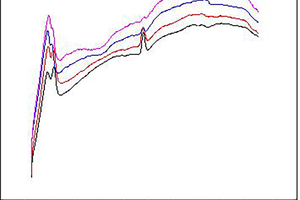

3.2 Variation of porosity

Figure 3 shows the porosity of cement mortars with different wt.% values of silane cured at 20 °C and 90% relative humidity for 3, 7, 14 and 28 d. All experimental results were obtained by averaging the results from the six samples. As shown in Figure 3, the total porosity of mortars increased with increasing age, implying that aging increased the porosity of control and modified cement mortar specimens containing different silane contents. Such an increment caused by aging would become more significant because of the deeper degree of aging. The reason for this phenomenon might be the fact that bubbles caused by cement hydration tend to increase as aging increases, resulting in the formation of porosity.

Additionally, the curve also shows that the porosity of all mortars decreased with silane content; meanwhile, increasing the silane content improved the porosity of modified mortars, which is in agreement with Figures 9, 10 and 11. It is then possible to conclude that the silane has a significant retarding influence on the control cement paste hydration, and strong retardation of cement hydration might delay the setting time and affect construction progress, making hydration products decease and the internal structure of cement mortars incompact [Feng et al, 2016]. Similar phenomena have been reported in publications about polymer-mixed cement powders [Xu et al, 2000; Kong et al, 2015].

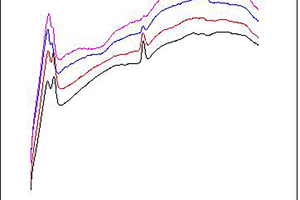

3.3 Variation of degree of hydration

The effect of silane addition on the degree of hydration of cement paste is illustrated in Figure 4. As shown in Figure 4, the degree of hydration of modified mortars supplemented with 1%, 3%, and 5% silane have a decreasing tendency with respect to hydration degree for the blank cement paste, indicating the hydration procedure is inhibited. This may be because the restricting influence of silane might be caused by the absorption and reaction of silane on the surface of cement hydration products. Similar phenomena have been reported in publications about polymer-mixed cement paste. The coupling reaction of silane with cement hydration products might enhance the absorption, with the result that different kinds and dosages of silane have a restricted influence on the cementitious materials. Because of the restriction effect of silane, the porosity of modified cement mortar were lower than those of the control cement mortar, as shown in the above Figure 3.

Another important finding was that increasing the silane addition decreased the degree of hydration of modified mortars. This finding can be explained by the fact that silane rapidly reacts with water and that there were fewer cement hydration products with the development of silane contents, as discussed above. In addition, when the addition of KH550 was 1%, 3% and 5% in the 3-day curing period, in comparison with blank cement paste, the degrees of hydration of modified cement paste were decreased by 0.77%, 1.67% and 2.48%; after a 7-day curing period, the corresponding results were 0.63%, 1.30% and 1.96%; after a 14-day curing period, the corresponding results were 0.51%, 1.59% and 1.73%; after a 28-day curing period, the corresponding results were 0.38%, 0.81% and 1.39%. These results indicate that the amount of non-evaporative water increased with the development of aging in the cementitious materials, resulting in an increase in the degree of hydration. As also shown in Figure 4, the increment speed of hydration degree from 3 to 7 d increased compared to that from 7 to 28 d, indicating that the hydration reaction mainly occurs in the period ranging from 7 to 28 d.

3.4 Differential scanning calorimetry (DSC) of cement paste containing different dosages of silane

Figures 5, 6 and 7 show the endothermic peaks of hydration products of cement paste with different wt.% values of silane cured at 20 °C and 90% relative humidity for 3, 7 and 28 d. The mass distributions of various hydration products in whole cement paste have a significant influence on the working performance, mechanical properties and volume stability of cementitious materials. In the process of hydration heating, the colloids or crystals in cement hydration products reduce the relative mass of the sample due to dehydration, decomposition and gas release. The temperature of each colloid or crystal when dehydrated or releasing gas is a constant value. According to the temperature T value, the type of colloid or crystal in the material can be estimated, and based on the percentage of mass loss during hydration heating, the percentage content of a mineral before decomposition can be calculated. Therefore, the hydration degree of cement incorporated with different kinds and dosages of silane can be judged. As seen in Figures 5, 6 and 7, it can be easily observed that there were two endothermic peaks in the DSC analysis curve of cement paste containing different dosages of silane. The dewatering peak ranging from 85 °C to 90 °C represented C-S-H and AFt, with the corresponding results ranging from 438 °C to 447 °C was Ca(OH)2. Compared with those of the blank cement paste, the dewatering peak of hydration products containing C-S-H, Ca(OH)2 and AFt obviously decreased, indicating that the silane had a significant inhibitory effect on the cement hydration process. As shown in Figure 8, the silane can combine directly with cement paste, that is, a chemical coupling bridge bond is established when the different amounts of silane are mixed in the cement paste, therefore the corresponding shrinkage behaviors is restrained, which is agreement with the result shown in the Figure 2. Meanwhile, the cement particles react insufficiently with water, resulting in that the hydration of cement mortars was restricted, which is related to the result shown in the above Figure 4.

In an addition, as shown in Figures 5, 6 and 7, the dewatering peak of modified cement paste tended to decrease with the increment of silane content, indicating that the restraining influence of the incorporation of more silane content became more evident, which is in agreement with the above results shown in Figure 3 and Figure 4.

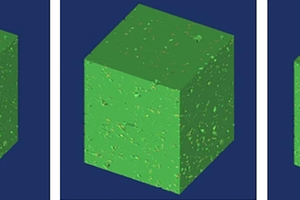

3.5 CT scanning of cement paste containing

different dosages of silane

Some types of techniques are extensively employed to determine pore distribution in cementitious materials. One is image analysis of sample cross-sections, including acquiring images by an optical microscope and cutting samples. However, this method requires a long time for preparing specimens using the typical destructive measurement [Chindaprasirt et al, 2007; Mindess et al, 2003]. Another is X-ray CT imaging technology, which is an application for researching the internal microstructure of cementitious material with three-dimensional (3D) view. The 3D space distribution of pores in a cement paste cylinder can be visualized by X-ray CT measurement, and three typical mixtures are presented in Figures 9, 10 and 11. Figures 9, 10 and 11 represent the control and modified mortars containing 1% and 5% silane at 3, 7 and 28 d, respectively. As shown in the Figures, the yellow color, which indicates the pores and the porosities of modified mortars incorporating silane, was more abundant than that in control mortars, which is in agreement with the porosity results shown in Figure 4. Thus, increasing the silane dosages improved the porosity of cement mortars, verifying the results shown in Figure 2 and Figure 3.

4 Conclusion

Systematic experiments were employed to evaluate the influence of incorporated silane on the mechanical, porosity, shrinkage percentage and degree of hydration of cement mortars. DSC and X-ray CT were carried out to identify the changes in the microstructure of cement paste incorporating different kinds and dosages of silane. Based on the experimental results, the following conclusions could be drawn:

1. The rapid reaction of silane and water makes the hydration of cement incomplete, resulting in a decrease in hydration products and the development of many voids between cement and hydration products. Therefore, the porosity of cement mortars tends to decrease as the incorporation of silane coupling agent.

2. Compared with the blank mortars, the shrinkage percentage and degree of hydration of modified mortars containing different dosages tended to decrease. It can probably be concluded that the polymer cement composite membrane is formed on the surface between the pores and the aggregate interface of the slurry because of the continuous process of cement hydration and evaporation of water. Due to the formation of the surface composite film, the loss of water of mortars reduce.

3. The hydration products of modified cement paste would be reduced compared with control cement paste, which could be verified using the DSC curve. Experimental results also indicated that the Ca(OH)2, AFt and C-S-H of modified mortars decreased due the hydration process was restrained.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.