Pre-hydration of cement: global survey and laboratory results

Cement pre-hydration degrades the performance of concrete, particularly strength and set times. Testing performed on 181 cements showed that more than one quarter had suffered enough pre-hydration to significantly affect performance. The study also showed that cements manufactured in vertical roller mills are much more likely to be affected by pre-hydration than cements made in ball mills. A controlled laboratory study of selected cements demonstrates that even mild pre-hydration causes measurable performance loss.

1 Introduction

Cement pre-hydration occurs when cement comes into contact with a source of moisture – moist air or water – before its final use. Depending on the degree of pre-hydration, deterioration of relevant engineering properties of the cement may take place, the most noticeable being:

Reduced powder flowability

Loss of workability and set retardation during mortar or concrete production

Reduction of compressive strength

In addition, the effectiveness of chemical admixtures such as accelerators and retarders can be compromised, and their performance rendered less predictable.

Exposure of...

1 Introduction

Cement pre-hydration occurs when cement comes into contact with a source of moisture – moist air or water – before its final use. Depending on the degree of pre-hydration, deterioration of relevant engineering properties of the cement may take place, the most noticeable being:

Reduced powder flowability

Loss of workability and set retardation during mortar or concrete production

Reduction of compressive strength

In addition, the effectiveness of chemical admixtures such as accelerators and retarders can be compromised, and their performance rendered less predictable.

Exposure of cement to moisture may occur for multiple reasons, including water applied during finish grinding, gypsum dehydration during silo storage, and exposure to moist air or water at any point during transportation and storage of the finished cement. Several authors have discussed the subject, and information on the most common causes of pre-hydration is available in the literature [1-4].

The use of vertical roller mills (VRMs) is increasingly common in the production of finished cement. Due to their operating principles, VRMs are prone to vibrate if one or more production parameters deviate from a narrow specification. The intensity of vibration can quickly increase to the point of requiring interruption of the operation of the mill. Water is typically added to address vibration issues; anecdotal information from the field indicates that up to 4 % water (% of cement weight being ground) is commonly added to reduce vibrations of VRMs.

The article gives a brief review about previous studies on pre-hydration and its effects on cement properties. A discussion about the results of a global survey of the pre-hydration levels of commercial cements made in both ball mills (BMs) and VRMs follows. Finally, the results of laboratory tests in which three commercial ordinary Portland cements (OPCs) were pre-hydrated under controlled conditions are presented, and their properties such as strength and setting time are discussed.

´

2 Mechanisms of performance loss due

to pre-hydration

The negative impact of pre-hydration on the performance of cements is generally known in the industry, but only recently have the mechanisms of pre-hydration become better understood. The development of deeper knowledge on the interactions of cement and water over the past 10 years from the use of more sophisticated analytical equipment and modelling is allowing a better understanding of the phenomena involved in pre-hydration.

In 1975, Theisen and Johansen [5] investigated the relationship between pre-hydration and compressive strengths of cements and introduced the parameter Wk to quantify pre-hydration. Wk is defined as a specific part of the chemically bound water and can be measured by thermogravimetry. The authors suggested that below a threshold Wk value of about 0.35% there is little or no change in properties. Above this threshold, their data suggests loss of compressive strengths at all ages.

Dubina et al. [6] studied the interactions of individual clinker phases and different forms of calcium sulfate with water vapor. By measuring the mass change of samples exposed to different relative humidities at 20oC and 40oC, they concluded that free lime reacts quickly with water vapor to form portlandite, while the silicate minerals (alite and belite) undergo only physical adsorption of water with little chemical reaction. Orthorhombic C3A sorbed much more water than cubic C3A, but less than half of the adsorbed water reacted chemically with this clinker phase. They concluded that while water adsorbs readily onto bassanite (plaster), it undergoes very little chemical reaction to form gypsum. This is contrary to the observations of Whittaker et al. [7]; the difference may be the longer pre-hydration times used in that study. Table 1 summarizes the results from Dubina’s research on the threshold relative humidities at which individual phases initiate rapid water uptake at 20oC.

In 2014, Dubina et al. [8] detected the formation of ettringite following the exposure of blends of C3A and gypsum to humid air. Since ettringite forms by a dissolution-precipitation mechanism, this implied that liquid water was present. They therefore concluded that under certain humidity and temperature conditions water can condense into the voids between the cement grains, resulting in pre-hydration that is similar to a normal hydration process. This is particularly relevant to storage of hot cement in silos; water released by thermal decomposition of gypsum can condense as the cement cools, leading to cement pre-hydration.

In 2015, Stoian et al. [9] compared the pre-hydration of an ordinary Portland cement when exposed to water vapor and when sprayed with liquid water. They found evidence of dissolution/precipitation reactions when the cement was exposed to liquid water, such as relatively large amounts of calcium hydroxide. However, this pre-hydration had negligible impact on set times or on the growth rate of C-S-H. While the calcium silicate minerals are not expected to undergo significant pre-hydration at RHs lower than those shown in Table 1, Stoian et al. speculated that physical adsorption of water might cause structural changes to the surface of the silicates that would reduce their reactivity to liquid water. They also suggested that a thin carbonation layer could form on silicate surfaces exposed to water vapor, which would further reduce the reactivity of the particles to water.

It should be noted that the studies discussed above do not directly correlate to the conditions encountered during cement grinding because they utilized lower temperatures than those present in ball mills and VRMs. However, they provide a basis for the understanding of the types of pre-hydration reactions that may occur.

3 Incidence of cement pre-hydration in the field

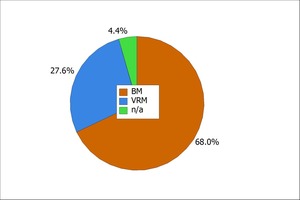

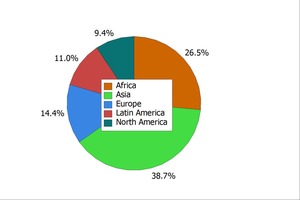

To investigate the prevalence of cement pre-hydration in commercial cements, samples of 181 different cements from around the world were collected and tested. These were all cements that had been submitted to GCP laboratories for the development of customized cement additives. Figure 1 shows the distribution of the database in terms of mill type, general cement composition, and manufacturing location. About two thirds of the cements were produced in ball mills and the rest in VRMs. About 35% were ordinary Portland cements (OPCs), while the remaining were interground or blended with one or more types of supplementary cementitious material. The geographic distribution of the cement sources covers all world regions.

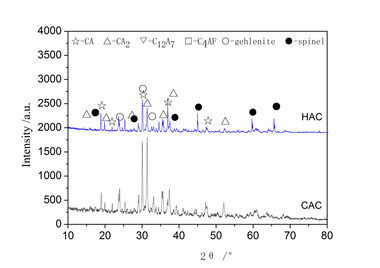

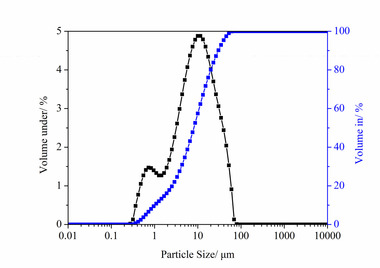

To determine the degree of pre-hydration of the cements, a Netzsch STA 449 thermogravimetric analyzer (TGA) was used. Samples were heated at a constant rate of 10oC per minute from room temperature to 1000oC in a stream of dry nitrogen, while being continuously weighed. The pre-hydration level of the cements was determined by the Wk parameter as the percentage weight loss between the temperatures that correspond to the end of the dehydration of the gypsum and the beginning of the dehydration of calcium hydroxide. This definition differs from that of Theisen and Johansen as it does not include the physically adsorbed water that is lost before the decomposition of gypsum [5].

Cements with Wk higher than 0.30 % were considered have a problematical level of pre-hydration for the purpose of statistical analysis. Table 2 shows that 26% of all cements have Wk ≥ 0.30 %. The proportions of OPC and blended cements with pre-hydration were quite similar. Most notably, the proportion of VRM cements with pre-hydration was much higher than that for ball milled cements: 48% vs. 19%.

There are a number of factors that make VRMs more susceptible to causing cement pre-hydration as compared to ball mills. The most important of these is the practice of spraying water onto the grinding bed of a VRM in order to stabilize the bed and reduce mechanical vibrations.

4 Laboratory study of pre-hydration of OPC

under different conditions

To better understand the relationship between Wk and cement performance, and to provide additional insight into the findings of the pre-hydration survey described above, new laboratory experiments were designed and performed. In this study, three commercial OPCs were pre-hydrated by exposing them to different controlled conditions of temperature and relative humidity using environmental chambers. The exposure temperature ranged from 25o C to 70o C, which is a wider range than was used in previous studies. Also, the cement was exposed while contained in two types of containers, to investigate the impact of the exposed surface area to volume on the amount of pre-hydration. After the prescribed exposure, the Wk value was determined using TGA and then the cement performance was evaluated through mortar strength and set time evaluation via isothermal calorimetry. Table 3 summarizes the testing conditions applied in this investigation.

Table 4 lists the compositional and physical characterization of the three cements. All cements have some measurable pre-hydration, as evidenced by the Wk values and the presence of small amounts of portlandite, which forms readily when free lime is exposed to moisture. For OPC 1 and OPC 2, the initial pre-hydration levels are low (0.15-0.16%). For OPC 3, which is the only VRM-produced cement, the as-received pre-hydration level is more significant (0.28%).

After undergoing the pre-hydration treatment described in Table 3, the cement samples were removed from the environmental chamber, homogenized via mechanical blending, and then vacuum-sealed in plastic bags until TGA or mortar testing.

TGA was performed using a Q500 thermo-balance from TA Instruments. The instrument was operated in high resolution mode in which the heating rate is automatically decreased when phases are decomposing to avoid overshoot of decomposition temperatures. This mode provides more accurate determination of decomposition temperatures and allows better separation of reactions occurring at similar temperatures, such as the dehydration of gypsum and plaster.

For evaluation of mortar properties, the EN-196 Part 1 standard was followed for the compressive strength measurements at 1, 7 and 28 days. In addition, 50 g samples of each freshly mixed mortar were placed in an isothermal calorimeter at 21oC to monitor the early hydration kinetics.

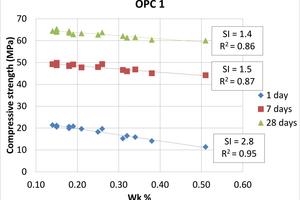

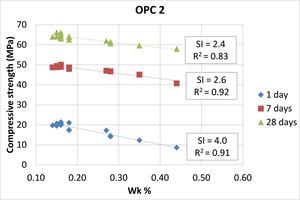

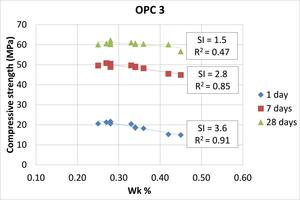

Figure 2 plots all of the mortar strength results for each cement exposed to the pre-hydration conditions listed in Table 3, as a function of Wk. These plots confirm previous findings that pre-hydration has a negative effect on compressive strength. Interestingly, the results showed the threshold to be less than 0.30 % Wk and are more in line with the recent results of Caput and Theisen [10]. This is an important result, as it indicates that even mild pre-hydration can negatively influence cement performance. It also suggests that the conclusions from the global pre-hydration survey may be too conservative, as many of the cements with Wk < 0.30 % likely had undergone some loss of compressive strength.

The slopes of the linear trend lines in Figure 2 can be used to estimate the degree of strength reduction for each cement type and age, in units of MPa of strength lost per 0.1 % increase in Wk, which we will refer to as the strength index (SI). Those values, together with the R2 values of the trendlines, are shown in the plots. For all cements, the SI values are largest at early ages, indicating that younger mortars are affected more strongly by pre-hydration. By 28 days some of the initial strength loss appears to have been recovered. The SI values suggest that the magnitude of the correlation between strength and Wk is cement-dependent.

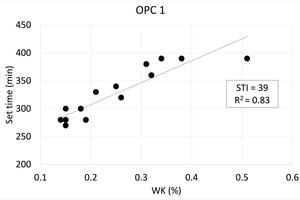

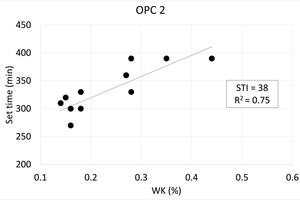

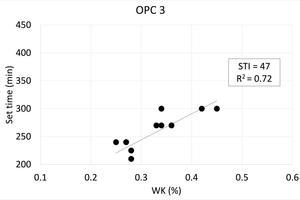

The cement hydration kinetics in the first 24 hours of hydration are also greatly affected by pre-hydration. As an example, Figure 3 shows the isothermal calorimetry curves of EN-196 mortars prepared with OPC 1 exposed to 50oC, 75 % RH for up to 24 hours in trays. Set times can be estimated from such curves by determining the midpoint between the end of the induction period and the maximum of the main hydration peak. Figure 4 shows the set times plotted as a function of Wk for the three OPCs submitted to the exposure conditions listed in Table 3. Similarly to the approach taken to determine the SI values, a set time retardation index (STI) and R2 values are shown in these plots. Set times extension of 30 - 50 minutes for every 0.1 % increase in Wk were observed.

5 Conclusions

Based on a large testing survey of cements produced around the world, we conclude that at least a quarter of all cements are pre-hydrated to the extent that concrete compressive strengths and set times are negatively affected. Importantly, the survey also showed that cements produced in VRMs are more than twice as likely to be pre-hydrated as those ground in ball mills.

Laboratory pre-hydration experiments with three ordinary Portland cements showed that cements are likely to experience strength reductions of 3.5 MPa per 0.1 % increase in Wk at 1 day, and 1.8 MPa/0.1 % Wk at 28 days, on average. Extended set times by around 30 – 50 minutes for every 0.1 % increase in Wk were measured. We also observed strength decrease at Wk values as low as around 0.20 %, suggesting that even mild pre-hydration can negatively affect performance.

Acknowledgements

We are grateful to Joseph Accime and Joshua Detellis for performing the laboratory experiments described in this article.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.