Milieu-dependent effect of retardants on hydrating calcium sulphate binders

To meet technical and economic requirements, calcium sulphate binders must exhibit varying properties. Especially in respect of the open processing time and the setting time, the binders must be adjustable in a time period from a few minutes to several hours. To meet these requirements, the use of additives to regulate setting is necessary [1]. Objective of this work was to characterize the effect of selected retardants on a plaster of Paris paste as a function of the pH value (adjusted with NaOH).

1 Introduction

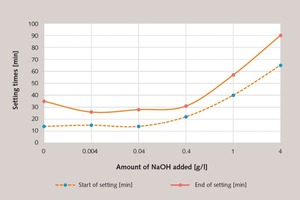

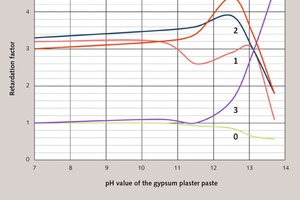

Mallon [2] has defined the retardation factor as the quotient of the start of setting of gypsum plaster paste containing a retardant to the start of setting of a gypsum plaster paste without a retardant. The corresponding pH value was adjusted with an alkali or acid. The milieu-dependent effect is illustrated in Figure 1.

Reul [3] established in his investigations that selected retardants (application concentrations 0.03… 0.1 % relative to the binder mass) have a different effect with different calcium sulphate binders. For instance, DL malic acid, citric acid and mesotartaric...

1 Introduction

Mallon [2] has defined the retardation factor as the quotient of the start of setting of gypsum plaster paste containing a retardant to the start of setting of a gypsum plaster paste without a retardant. The corresponding pH value was adjusted with an alkali or acid. The milieu-dependent effect is illustrated in Figure 1.

Reul [3] established in his investigations that selected retardants (application concentrations 0.03… 0.1 % relative to the binder mass) have a different effect with different calcium sulphate binders. For instance, DL malic acid, citric acid and mesotartaric acid retard setting both in the case of plaster of Paris and machine-applied gypsum plaster. L(+)-tartaric acid and racemic acid, on the other hand, only have an effect on machine-applied gypsum plaster.

Schmidt [4] determined clear differences in the setting behaviour of plaster of Paris retarded in neutral and basic milieu with citric acid.

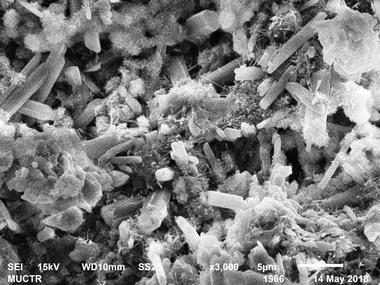

Forg [5] also discussed with reference to the milieu the effect of malic, citric and tartaric acid. In particular, he investigated the interaction of lime hydrate and tartaric acid amounts. With a higher addition of lime hydrate, the setting curve becomes steeper. At the same time, changes in the crystal microstructure can be observed, which leads to a reduction in the strengths: from fine crystalline to coarse crystalline with simultaneous reduction of crystal intergrowth.

The retarding effect of different inorganic and organic compounds on the setting of calcium sulphate binders has long been described in the literature. Representative here are: Budnikoff (1928), Graf and Rausch (1951), Koslowski and Ludwig (1999) [6–16].

2 Materials and test methods used

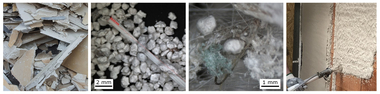

For the tests, a plaster of Paris from maxit Baustoffwerke GmbH, Krölpa, was used.

The setting behaviour of the gypsum plaster pastes was characterized by means of the knife-cut and thumb impression method.

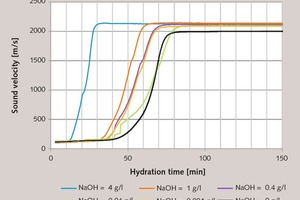

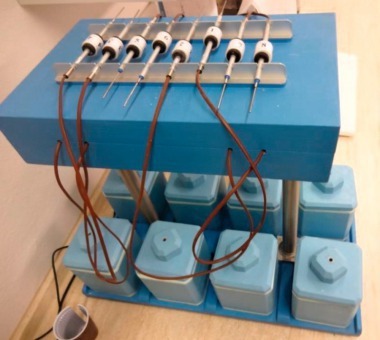

For continuous description of the setting behaviour of the assessed gypsum plaster pastes, the ‘Ultrasonic-Multiplex-Tester IP 8’ from the company Ultratest was employed.

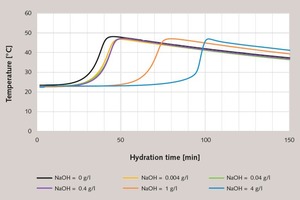

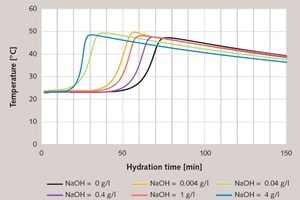

The hydration progress was described based on temperature measurement with the ‘gyp-labo’ measurement system developed by boldtechnoconsult.

The pH value of the gypsum plaster pastes, suspensions and solutions was determined by means of a ‘HI 2215 pH/OPR Meter’ from Hanna Instruments using an HI 1043 glass electrode (pH: 0… 14).

Prescribed were six different pH values in the range from 7 to 13.7. These values were obtained with different quantities of NaOH in the mixing water. The pH values measured in the gypsum plaster pastes were much lower (see Table 1).

The following substances were used as retardants:

citric acid

tartaric acid

retardant on amino acid basis (Retardan–200 P)

phosphate retardant

The amounts of the retardants added were based on the results from preliminary experiments. Here a start of setting after around 45 min at a pH value of 13.1 was the objective.

3 Test results

3.1 Influence of tartaric acid

The preliminary tests have shown (Table 3) that to achieve an open time for the gypsum plaster paste (approx. 45 min), the amount of tartaric acid added must be 0.03 %, prescribed was a pH value of 13.1 (corresponding to 1 g/l NaOH).

In the following, the setting behaviour was determined for the addition of 0.03 % for different pH values.

The effects of the tartaric acid on the retarding of the plaster of Paris paste as a function of the amount of NaOH added were described by means of three test methods. The corresponding descriptions (Figures 2-4) permit identical conclusions.

A significant retarding of the setting behaviour only occurs with additive amounts of NaOH above 0.4 g/l (i.e. a pH value higher than 12.5, in the paste higher than 11.1).

3.2 Influence of Retardan–200 P

The preliminary experiments have shown (Table 5) that to reach an open time of the gypsum plaster paste (around 45 min), the amount of Retardan-200 P added must be 0.0016 %, prescribed was a pH value of 13.1 (corresponding to 1 g/l NaOH).

Similar tests were realized with the other above-mentioned retardants. The determined setting times are listed in Table 7.

If the determined setting times of the pastes with additives are put into relation with the start of setting of the gypsum plaster paste without additives, a relative value is derived that enables comparison of the effect of various additives, termed the influencing factor IF (SS) in the following.

IF (SS) = setting start of the sample with additive/setting start of the sample without additive

Values IF (SS) > 1 reflect the effects of the retardants, it is therefore possible to refer to a retardation factor.

The retardation factors calculated in this way for the different additives are listed in Table 8. Figure 8 illustrates the results obtained.

4 Summary

The objective of this work was to describe the effect of selected retardants on a plaster of Paris paste as a function of the pH value. For this purpose, the setting behaviour (start of setting and ultrasonic measurement) and the hydration progress (temperature measurement) were characterized. The amounts of retardants added were derived from the results of preliminary tests, in which an onset of setting after around 45 min at a pH value of 13.1 was the objective. On the basis of the start of setting, to quantify the effect of the additive, a retardation factor was determined. For the retardants used, a pronounced milieu-dependent effect at pH values > 10 was established. For an optimum retarding effect of additives, one characteristic are narrow basicity ranges.

The article is based on a paper presented at the 3rd Weimar Gypsum Conference in Weimar, 14.03.-15.03.2017.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

![1 Effects of different substances on the onset of setting of a hydrating alabaster gypsum (plaster of Paris) (according to Mallon [2])](https://www.zkg-online.info/imgs/1/1/7/8/2/4/9/tok_5f4f4080dd989b0a44c31449656c03c4/w300_h200_x400_y260__800_521.-ebf3caa7a95cdaad.jpg)