Additive-dependent effects

on plaster hydration

The purpose of this work was to illuminate the effects of certain additives or of combined additives on a hydrating gypsum plaster. The changes in hydration and the strength development process are described in particular.

1 Introduction

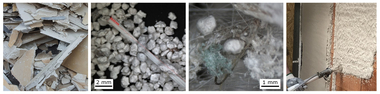

Among calcium sulphate binders, building plasters in particular, plaster of Paris, or gypsum plaster, is the most well-known and often used. Plaster of Paris is a partially calcined product of raw gypsum (CaS04 · 2 H2O) resulting from exposure to temperatures of 120-180 °C in a firing system. In comparison with other calcium sulphate binders, plaster of Paris is relatively inexpensive to produce and is therefore turned out at high tonnage rates. The main constituent of plaster of Paris is calcium sulphate hemihydrate (CaS04 · 0.5 H2O [HH]) in its β form. β-HH has a...

1 Introduction

Among calcium sulphate binders, building plasters in particular, plaster of Paris, or gypsum plaster, is the most well-known and often used. Plaster of Paris is a partially calcined product of raw gypsum (CaS04 · 2 H2O) resulting from exposure to temperatures of 120-180 °C in a firing system. In comparison with other calcium sulphate binders, plaster of Paris is relatively inexpensive to produce and is therefore turned out at high tonnage rates. The main constituent of plaster of Paris is calcium sulphate hemihydrate (CaS04 · 0.5 H2O [HH]) in its β form. β-HH has a characteristically jagged morphology and an accordingly high water requirement. Individual and combined additives can be used to achieve the desired working properties and solid-state parameters.

Schneider [1] summarized the topic of additive employment as follows in her dissertation:

“Additives can be used to reliably control, e.g. delay, the setting process [Mall1988; Bade1999]. However, the resultant crystals may be somewhat coarser, particularly if a carbonic acid is employed, usually leading to higher porosity and a loss of strength [Kosl 1983; Midd1994]. On the other hand, additives introduced in low concentrations can enhance the intercrystalline interaction [Smit1970] such as to yield gypsum products with superior mechanical properties. If, however, the introduction of additives alters the crystal habit so strongly that the porosity increases, a negative effect may result [Amat1986]. No correlation has yet been established between the kinetics of hardening and the mechanical properties. The nature and strength of the bond between the crystallites remains the most important parameter with regard to mechanical strength [Amat 1987]. The ppm-range introduction of polymers (e.g. Retardan P) pronouncedly delays the initial stiffening point while reducing the total porosity and, hence, increasing the strength [Midd 1994].”

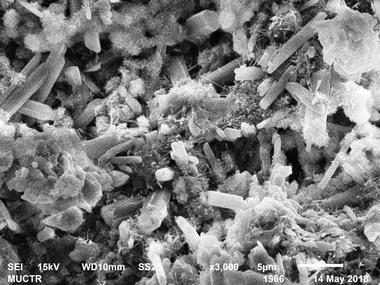

The setting and hardening/curing processes are strongly dependent on the water requirement of the plaster and/or on the defined water/binder ratio. Additives can influence the size and morphology of gypsum crystals, hence altering the rheological behaviour of the binder slurry. If the gypsum crystallizes out as long needles, the setting time is shorter than it would for more compact crystals. This context is of importance when additives are used to control the setting process. For example, when citric acid is used as a retarder, it results in preferential additive attachment to the heads of the gypsum crystals, yielding mostly short-prismatic, compact gypsum crystals [2]. Forg determined that the microstructural changes thus generated are evidenced by, inter alia, lower strength of the hardened material [3].

2 Employed materials and methods of analysis

2.1 Plaster of Paris

The employed plaster of Paris was calcined in a kettle. The phase composition was determined as follows by wet-chemical means: A III – 1.6 %, A II – 0.6 %, HH – 87.6 %. The water/binder ratio ascertained via the mixing ratio was 0.76. The initial and final stiffening times amounted to initial stiffening – 09:30 min and end of stiffening – 25:30 min.

2.2 Additives

Five different plasticizers were used for reducing the water/binder ratio:

G-1: plasticizer 1 based on a polycarboxylate ether

G-2: plasticizer 2 based on a polycarboxylate ether

G-3: plasticizer 3 based on a polycarboxylate ether

G-4: plasticizer 4 based on a sodium-naphthalene sulfonate

G-5: plasticizer 5 based on a melamine sulfonate

The plasticizers were dosed in dependence on the water/binder ratio so as to obtain gypsum slurries of comparable consistency. For plasticizers G-4 and G-5, retarding substances (Retardan [G-X.1], fruit acid [G-X.2]) were included in the tests.

2.3 Applied methods of analysis

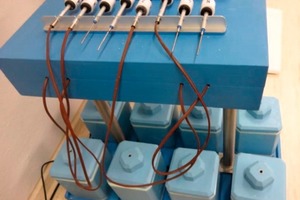

The progress of hydration was described by means of the “GYP-LABO” measuring system (Figure 1) developed by Bold-Technoconsult.

The linear changes taking place in a shrinkage drain in the course of setting were continuously registered and recorded by a position sensor. A type FIB/WdB shrinkage drain with 250-mm gauging section (Figure 2) was used.

Strength testing was performed on standard prisms using a Toni Technik Toni Comp III test instrument. The prisms were demoulded after 24 h, stored under laboratory conditions (65 % rh, 20 °C) until the 7th day and then dried at 40 °C up to constant mass solids content.

3 Test results

3.1 Course of hydration

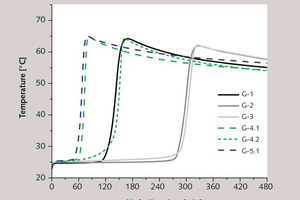

Figure 3 illustrates the fact that the employed plasticizers/combined additives actually did retard the progress of hydration to a greater or lesser degree. The PCE plasticizers (delayed onset of hydration) showed a major retarding effect. The intensity of the hydration process (temperature gain per unit of time = slope of curve), however, changed only marginally.

In departure from the other curves, the use of a combined additive (G-4.2) with a fruit acid serving as retarder led to a characteristically continuous, if minor, initial gain in hydration intensity. The retarding agent Retardan (G-4.1) did not alter the characteristic course of hydration/kinetics of setting under the prevailing conditions.

3.2 Linear change

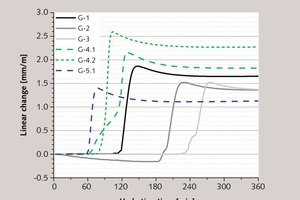

As is generally known, additives, in particular those which retard hydration, can have a considerable impact on crystal morphology. It therefore comes as no surprise that the additives discussed in this analysis bring about differentiated changes of volume. The measured linear-change behaviour leads to the following conclusions.

The expansion behaviour displayed by all assessed specimens is characteristic of calcium sulphate binders (Figure 4). As to be expected, expansion set in at the beginning of the hydration process (cf. Figure 3). For all specimens considered, the rate of expansion remained recognizably comparable. Thus, the specimens’ expansion can be presumed as having been directly linked to the progress of hydration.

The most rapid expansion was observed for plaster containing fruit acid as retarding agent and a plasticizer based on sodium-naphthalene sulfonate (G-4.2). When Retardan was substituted for fruit acid, the change of volume was significantly lower (G-4.1). The least expansion was observed on addition of the plasticizer based on melamine resin in combination with Retardan as retarding agent. The change of volume observed during the setting of plaster containing PCE-plasticizers was in the medium range. Differences in change of volume were noted between the individual PCE plasticizers.

3.3 Strength

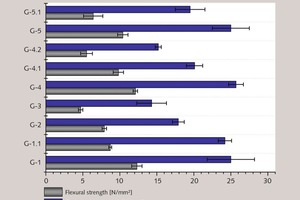

Compared to the other plasticizers, the addition of PCE plasticizers cause a more or less pronounced loss of strength, depending on which plasticizer modification was used.

Adding a retarder in combination with the subject plasticizers also yielded lower strengths. The loss of strength caused by the addition of fruit acids exceeded that which resulted from the addition of the polymer Retardan.

4 Conclusions

Within the scope of this work, the effects of certain additives and combined additives on a hydrating plaster of Paris were illuminated. The plasticizers were dosed in dependence on the water/binder ratio so as to obtain gypsum slurries of comparable consistency. The intensity of the hydration process (temperature gain per unit of time = slope of curve), however, remained comparable for all specimens tested. As to be expected, expansion is linked to the beginning of hydration and, hence, to setting. All tested specimens showed a mutually comparable rate of expansion. The specimen expansion process is therefore directly coupled to the hydration rate.

Addition of a retarder in combination with the subject plasticizers caused a loss of strength, whereas the addition of fruit acid caused a greater loss than did the addition of polymer Retardan.

The article is based on a paper presented at the 3rd Weimar Gypsum Conference in Weimar, 14.03.-15.03.2017.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.