The spice of gypsum

With approximately 11 billion m2 installed annually, gypsum boards are the most successful gypsum-based construction material [1]. The success of gypsum board is not only due to its excellent physical properties and functional advantages. It is also supported by an efficient, highly automated and continuous production line process which requires high quality raw materials. Besides gypsum binder, water and cardboard, a variety of chemical additives are used during today’s gypsum board production. An overview of the most relevant additives added to the gypsum core is provided based on the literature review and personal experiences. Special attention is given to the topics water reduction and setting time control.

1 Background

Gypsum boards are produced from gypsum plaster, water and additives for the gypsum core as well as cardboard on continuous conveyor lines.

Prior to diving into the chemistry of gypsum additives, a few basic principles of gypsum chemistry have to be recaptured. The chemical reaction of gypsum binder with water is a solution and precipitation process. The crystallization of gypsum follows the law of nucleation and crystal growth. The hydration of calcium sulphate hemihydrate to gypsum can be described with the equation

CaSO4 0.5 H2O + 1.5 H2O --> CaSO4 2 H2O (1)

Numerous partly desired...

1 Background

Gypsum boards are produced from gypsum plaster, water and additives for the gypsum core as well as cardboard on continuous conveyor lines.

Prior to diving into the chemistry of gypsum additives, a few basic principles of gypsum chemistry have to be recaptured. The chemical reaction of gypsum binder with water is a solution and precipitation process. The crystallization of gypsum follows the law of nucleation and crystal growth. The hydration of calcium sulphate hemihydrate to gypsum can be described with the equation

CaSO4 0.5 H2O + 1.5 H2O --> CaSO4 2 H2O (1)

Numerous partly desired and partly undesired factors influence the reaction process and the properties of the final gypsum product:

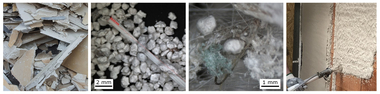

Gypsum binder: Raw material (crystal morphology, impurities) and gypsum processing (thermal & mechanical stress during milling & calcination, storing conditions)

Water-binder ratio

Temperature & pH-value

Other formulation components, in particular chemical additives

Mixing process

Surrounding materials (i.e. absorption capability of plaster base, cardboard)

For the manufacture of gypsum boards, the most relevant process and product properties are rheology/flowability, setting, strength development, cardboard adhesion and drying. A variety of chemical additives are available to adjust these and further properties.

2 Gypsum additives – an overview

The main additives used for gypsum board production are foam, water reducers, set control additives, bond and strength additives as well as moisture and fire resistant additives. Before taking a closer look at additive solutions for water reduction and setting time control, a few remarks on additional additive types and common technologies must be made.

Modern gypsum boards consist of more than 75 % air by volume. Besides the volume of water voids (from evaporation of excess mix water) foam voids of up to 2 mm in diameter come from pre-generated foam which is added to the gypsum slurry. Typically used foaming agents are blends of alkyl ether sulphates (soaps). In the last few years lightweight gypsum board has become the new standard in North America for most internal applications. Compared to standard gypsum boards with approx. 8 kg/m2, the density of lightweight boards is only in the range of 6 kg/m2. Foaming agents play an important, if not the most important role in this future gypsum board trend.

Pre-gelatinized acid modified starch is added to the gypsum core to provide adhesion between gypsum core and paper liner and to increase the strength of gypsum board, in particular flexural strength and nail pull resistance [2].

Adding glass fibres to the gypsum core enables improved fire resistance from 10 to 60 minutes and above. Glass fibres maintain the integrity of the gypsum board during shrinkage and water loss under fire exposure. Glass fibres also increase stiffness, strength and sag resistance, allowing for lighter and longer boards [3]. Further additives improving the fire resistance of gypsum boards are crude vermiculite, clay and microsilica [4].

Gypsum boards are not water-resistant, not waterproof. If the board may be subjected to damp conditions, humidity, and the occasional minor splashes of water, special boards with water-repellent cardboard and hydrophobing agent in the gypsum core are to be used. Commonly used hydrophobing agent technologies are wax emulsions and silicones oils. To prevent mould formation fungicides can also be used.

3 Focus on water reduction

Gypsum binder used for gypsum board production is plaster, also known as stucco, with beta-calciumsulphate hemihydrate as main gypsum phase. Normal plaster needs approx. 4-times the amount of water to flow than necessary for hydration. This excess water must be removed by heating and evaporation from the boards. The drying process has become the main cost-driver of production. Reducing the mixing water by 15 % results in approximately 20 % less water to be dried off from the boards. The reduced amount of water voids from evaporation must be compensated by foam voids from pre-generated foam to keep board density and board weight constant. Since the dryer capacity is often limiting the capacity of the whole production line, additional water reduction may allow for line speed increase to enlarge the plant capacity.

At present, there are four different families of plasticizers used as dispersants in gypsum-based systems:

Lignosulfonates (LS)

sulphonated naphthalene formaldehyde condensates (SNF)

sulphonated melamine formaldehyde condensates (SMF) and

polycarboxylate ethers (PCE)

Lignosulfonates have a robust but extremely slight capability for water reduction, whereas the polycarboxylate ethers are the most effective plasticizers.

Today, SNF is used in the majority of gypsum board plants. Especially in regions with high energy prices or water scarcity, PCE with significantly higher water reduction capability is already increasingly used. Prior to taking a closer look at PCE application during gypsum board production their structure-performance relationship must be explained: PCE are polymers which are similar to a comb in shape. The backbone consists of a polycarboxylic acid (polycarboxylate) and the side chains of the comb are made of polyether chains. Comparable to conventional plasticizers PCE molecules adsorb on solid surfaces via polycarboxylic acid in the backbone. However, side chains do not adsorb but extend into the aqueous solution and prevent the convergence of solid particles. This effect is known as dispersing through steric stabilisation. By varying the polymer structure, the properties of resulting superplasticizers can be adjusted for each desired application [5]. Combinations of different polymers and/or combinations of polymers with other substances, such as clay inhibitors, make it possible to exploit synergy effects, and thus to produce better and more robust performing additives with optimized cost-benefit ratio [5, 6]. Nevertheless, more robust additive solutions tend to be less cost-efficient than high-performance additives for FGD gypsum and natural gypsum without swelling clay contaminations.

The performance of different PCE was compared with the one of SNF in a typical gypsum board formulation. Results from lab-testing are shown in Table 1.

With PCE, comparable consistency was achieved at significantly reduced dosage (>60 % reduction compared to SNF). Nevertheless, the extreme liquefaction performance of the tested PCE 1 is accompanied by more pronounced set retardation. It has been proven that this superplasticizer-induced retardation is caused by the obstruction of the dihydrate nucleation and crystal growth [7]. For the production of gypsum boards it is crucial that this side-effect is compensated by the use of set-controlling additives, since the setting performance determines the rate of production. PCE 2 shows less pronounced set retardation which is at similar slump flow comparable with the one of SNF. The fact that numerous gypsum board plants are successfully running with PCE confirms its suitability. PCE application has the following advantages:

Extremely high water reduction efficiency

Drying energy savings and total production cost reduction

Line speed increase to enlarge the plant capacity

Improved homogeneity of the binder slurry; less cavities

Compatible with FGD and natural gypsum

Compatible with commonly used additives

Odourless and colourless; reduced risk for discolorations

Free of formaldehyde

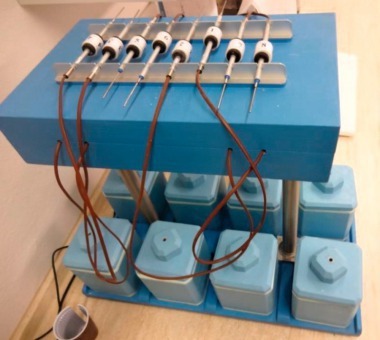

4 Focus on setting time control

The setting behaviour of the gypsum core as well as the length and belt speed of the setting section are coordinated with one another. In modern installations with a high belt speed, the setting distances reach a length of several hundred meters. Quick setting and hardening is of crucial importance to run the gypsum board production at high speed for maximum capacity utilization. The rate of gypsum setting can be precisely controlled by the use of additives. The most effective accelerator is finely ground gypsum, also called ball mill accelerator (BMA), which acts as seed crystals. By adding BMA to plaster slurry the hydration curve can be shifted to earlier time (see Figure 4). The BMA performance depends on the mechanical activation during milling. To improve the BMA performance as well as its storage stability, grinding aids such as sugar, starch or dispersing agent (e.g. SikaGrind GP) are added prior to milling [8, 9].

Another common accelerator is potassium sulphate (K2SO4, also called potash). Its performance is based on providing additional sulphate ions to the solution. Thus the supersaturation of the solution with respect to gypsum is increased which promotes the precipitation of gypsum crystals. As shown in Figure 4, this shifts the gypsum hydration curve to earlier times and increases the reaction intensity. Too high potash dosage can lead to undesired gypsum crystal habit modifications.

During gypsum board production the accelerator dosage is adjusted so that the hydration is nearly complete at the dryer entrance. The higher the accelerator dosage, the earlier not only the end of setting but also the beginning of setting occurs. At high dosage level negative effects are seen immediately after binder contact with water:

Undesired increase of water demand of plaster, resulting in higher consumption of water reducer and/or higher energy cost for board drying

Formation of agglomerations and caking in the mixer, causing undesired production shutdowns for maintenance of the mixer

Hindrance of release of large air bubbles from the plaster slurry prior to closing the cardboard ‘envelope’, resulting in board defects

Less core-cardboard interaction, resulting in bond problems

To avoid these production risks and weaknesses the beginning of setting must be delayed for a few seconds. Modern gypsum board production typically requires the combination of suitable retarding and accelerating additives to achieve the ideal setting curve. This so-called snap-set is characterized by minimizing the setting period (time between initial and end of setting).

The mechanisms of gypsum retardation can be simplified as follows: Commonly used set-retarding additives, such as fruit acids and amino acids, do not affect the dissolution behaviour of the plaster. Rather nucleation and crystal growth are hindered. Adsorption occurs on the surfaces and the gypsum crystal seeds, so further growth is affected. Further accumulation of calcium and sulphate ions on gypsum crystal surfaces can be blocked completely (e.g. by amino acids like Sika Retardan-200 L [10]) or partially (e.g. by fruit acids). In presence of fruit acids the growth rates of the different gypsum crystal surfaces are changed and thus the crystal morphology is influenced towards more compact crystals. This can lead to significant strength losses (esp. citric acid) and extension of the setting period (tartaric acid). Although tartaric acid is not the first choice with respect to its retarding performance, it may be used during gypsum board production as anti-sagging additive. The setting curves of plaster in the presence of various retarders is shown schematically in Figure 5.

The combined use of accelerator and retarder during gypsum board production results in a delay of the beginning of setting for a few seconds to give the required processing time before the accelerated setting occurs. This has the following advantages:

Less production disruptions caused by caking and clumping in the mixer

Improved flow capability

Complete mixing of foam and plaster slurry and homogeneous distribution onto the bottom cardboard

Sufficiently high wet-bond of gypsum to the cardboard layers

Rapid strength development and high final strengths

5 Summary

For the manufacture of gypsum boards, the most relevant process and product properties are rheology/flowability, setting, strength development, cardboard adhesion and drying. A variety of chemical additives are available to adjust these and further properties, including foam, water reducers, set control additives, bond and strength additives as well as moisture and fire resistant additives. The use of foaming agents allows that modern gypsum boards can consist of more than 75 volume-% air and even lightweight boards with densities below 6 kg/m2 could be developed. High-range water reducers are used to reduce large amounts of excess water which is only required to let the plaster slurry flow, but not for hydration. PCE-based superplasticizers provide extremely high water reduction efficiency, allowing for drying energy savings and total production cost reduction. PCE with low retarding effect, similar to SNF-type water reducers, and solutions with improved robustness with respect to changing raw material qualities are available. Highly effective accelerator, most commonly BMA, is used to run the production at high speed and optimal capacity utilization. The combined use of accelerator and in particular amino acid based retarder has numerous advantages.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

![4 Influence of the accelerator type on the plaster hydration [8]](https://www.zkg-online.info/imgs/1/1/6/0/5/7/8/tok_afea0b81e94c58e6ef254044211b0972/w300_h200_x152_y136__305_273.-def2ae90c3533e23.jpg)