Gypsum (not) only for construction

Under this motto, some 120 attendees from 14 different countries gathered in Weimar for the latest biennial Weimar Gypsum Conference. Now, for the third time around, the event was hosted in the tried-and-tested fashion by the F. A. Finger Institute for Building Material Science (FIB) at Weimar Bauhaus University and Bauhaus Academy of Professional Development in cooperation with the business associations of the German and Russian gypsum industries.

In his welcoming address, Hans-Bertram Fischer pointed out that gypsum has a very wide range of applications. One of the organizers’ prime concerns, therefore, was to create a forum for a broad exchange of ideas in the field of calcium sulphate binders and their applications.

The conference addressed researchers and practicing experts as well as consultants, appraisers and sworn experts. In particular, the conference was intended to bring researchers from East and West closer together. With the presented papers being simultaneously interpreted from and to German and Russian, the resultant...

In his welcoming address, Hans-Bertram Fischer pointed out that gypsum has a very wide range of applications. One of the organizers’ prime concerns, therefore, was to create a forum for a broad exchange of ideas in the field of calcium sulphate binders and their applications.

The conference addressed researchers and practicing experts as well as consultants, appraisers and sworn experts. In particular, the conference was intended to bring researchers from East and West closer together. With the presented papers being simultaneously interpreted from and to German and Russian, the resultant exchange of expertise was of a rare quality.

The program of lectures – some scientific and some more application-oriented – covered a broad spectrum of topics. The East European peers outlined their ongoing work and research findings on subjects like:

aerated gypsum

insulating mineral plaster/render

use of industrial waste

hydration of calcium sulphate-hemihydrate

modified gypsum systems

use of fibre in gypsum-cement-pozzolanic binders

use of various additives, e.g., retarders

special-purpose gypsums

More than 30 papers and a spate of posters dealt with a plethoric range of gypsum topics and presented the most recent research findings along with practical examples of implementation.

Raw material gypsum

In his opening speech, Horst-Michael Ludwig, Weimar, stressed the fact that gypsum actually does disserve a conference all of its own. In addition, gypsum will also be a major topic at the 20th Ibausil, International Conference on Building Materials in Weimar from 12.09.-14.09.2018. In his contribution entitled ‘The raw material gypsum and its importance for Germany’, he spoke of the German Association of Gypsum Product Manufacturers and its 12 member companies. Each year, some 4 million t of gypsum-base raw materials (natural gypsum and anhydrite) are mined in Germany. Of that, 2.8 million t goes to the plaster industry, 1.2 million t to the cement industry, and another 0.1 million t to various other users. Recycled plaster has not gained much importance to date, but that will change. Ludwig stressed the importance of FDG gypsum for the industry as a very effective, high-quality material – 7.2 million t of which accrued in 2013. Due to the clean-energy transition mandated by the German government, FDG gypsum production will be halved over the next 10 years. That presents a problem, of course, because more, not less, gypsum will be needed, both for expanding construction volumes and for increasing use in the cement industry. Appropriate research will be necessary to develop equivalent, innovative products. Ludwig assured his audience that the importance of natural gypsum mining will grow significantly again in the future.

Then, Ferdinand Pavel, Berlin, illustrated ‘The economic importance of the gypsum industry in the Southern Harz’. Gypsum mining, he said, is an expressly regional industry, i.e., roughly 50 % of its overall employment impact is confined to the region. That makes a good argument in discussions about gypsum mining.

‘Do good and talk about it! The gypsum industry and its socio-political responsibility’ is what Michael Rutz, Berlin, had to say. Nowadays, he observed, no company can afford to concentrate solely on production – and that applies in particular to the mining and raw materials processing industry. Such companies have a wide range of responsibilities. For one thing, the benefits of domestic raw material resources must be made clear to the public. This includes calling attention to the sustainability of gypsum mining. Corporate social responsibility (CSR) plays a decisively relevant role.

Hans-Ulrich Hummel, Iphofen, thanked the conference’s organizers for bringing the gypsum community together. In his baseline paper entitled ‘Gypsum and water – as thick as thieves’, Hummel explained how gypsum can be found nearly everywhere in the world, and then gave a rundown on five major deposits in Europe. Following an overview of gypsum production, he also explored gypsum’s structures and crystallographic properties.

Gypsum in all its diversity

Igor Chartscheno, Moscow, reported on the ‘Sulphatic activation of slag binder in soil stabilization’. The results of the study outline the strength of composite binders based on ground blast furnace slag activated by calcium sulphate and investigate the optimum ratio of components providing the active solidification of slag, based on a mixture of gypsum and anhydrite of calcium hydroxide.

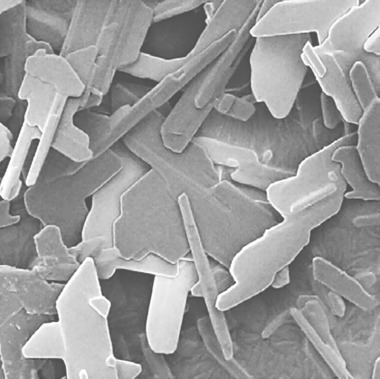

Reinhard Trettin, Siegen, surveyed his own company’s test findings in his paper called “Phase transitions in the calcium sulphate-hydrate system – an overview of in-house studies”. In the production of calcium sulphate-based binders, the gypsum is first converted to hemihydrate. Then, when the hemihydrate is concentrated in a calcining kettle, small, large-surface crystals of hemihydrate appear. Put through an autoclave under saturated steam conditions or in a suspension, the crystals grow larger while their surface area decreases. The nucleation process involved in the formation of dehydrate is also influenced by the nature of the employed hemihydrate.

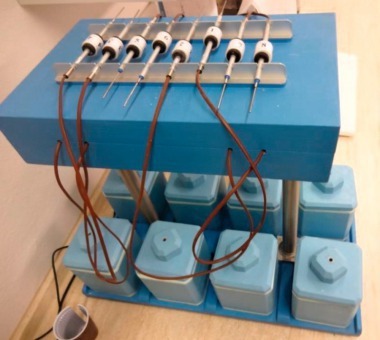

Andreas Hübner, Ellrich, spoke on “Aerated plaster – foamed calcium-sulphate-base materials for producing porous insulation and grouting materials”. In a cooperative project, a porous lightweight building material based on calcium sulphate (aerated plaster) was successfully developed for use as horizontal insulation or for grouting multiple-leaf, sulphatic masonry. The aerated material is produced in situ by mixing foamed material with a calcium sulphate emulsion glue.

Markus Ehrhardt, Weimar, reported on an “Innovative insulated mineral plaster/render based on glass microspheres”. This newly developed plaster/render features low thermal conductivity, good frost resistance and high adhesion/cohesion. Consisting of 85 vol.% glass microspheres and 15 vol.% gypsum-based compound, it is suitable for use both as render and as plaster.

“Modified composite zeolite containing gypsum binders with increased water resistance” was the topic discussed by Miroslav Sanytsky, Lviv. Solving the problem of increasing water resistance of gypsum binders is largely achieved by the way of optimizing а fractional composition of plaster and composite cements containing active mineral additives as natural zeolite tuff, and by their modification with additive superplasticizers of a new generation.

Christin Riechert, Weimar, put forward “Pozzolanic calcium sulphate-composite binders for use in panel-shaped products”. Her findings serve as a foundation for developing panel-shaped products based on calcium sulphate-composite binders. In comparison with pure plaster of Paris mixtures, these mixed binders can achieve (up to five times) higher strength for the same water/cement ratio. Moisture-induced, calcium sulphate-typical loss of strength can be significantly reduced as a formulation function to the same level as that of cementitious systems. By way of suitable formulation, ettringite-related expansion can be timed to stop within seven days.

Ekaterina Potapova, Moscow, elucidated the “Effects of different fibres in the application of gypsum-cement-pozzolanic binders”. Good results were achieved with metakaolin. Using glass fibres reduces the strength of the end product, promotes corrosion and lowers the chemical resistance.

The subject of a paper by Alexander Panchenko, Moscow, was the “Use of industrial waste for improving the stability of gypsum binders with water exposure”. It was shown that a gypsum binder with a complex additive containing carbide mud and bio-silica has high water resistance – 1.8 to 2.2 times higher in comparison with the initial gypsum and a softening factor value within the range of 0.85 to 0.91. The hardened multi-component gypsum binder has 2.5 to 3 times less open porosity and greater compressive strength (1.4 to 1.6 times higher for the dry state and 2.6 times higher in the water-saturated state).

In his lecture entitled “The spice of gypsum”, Markus Müller, Zurich, looked at the use of additives. In the manufacture of gypsum boards, the most relevant process and product properties are rheology/flowability, setting, strength development, cardboard adhesion and drying. A variety of chemical additives are available to adjust these and further properties, including foam, water reducers, set-control additives, bond and strength additives, as well as moisture- and fire-resistant additives. For example, high-range water reducers are used to reduce excess amounts of water, which is only required to let the plaster slurry flow, but not for hydration.

Hans-Bertram Fischer, Weimar, explained the ‘Milieu-dependent effect of retarders on hydrating calcium sulphate binders’. He described the impact of certain retarding additives in plaster slurry as a function of pH and characterized both the setting behaviour and the hydration progress. Based on the point of initial stiffening, a retardation factor was used to help quantify the impact of the additive. The applied retarders were found to have a pronouncedly milieu-dependent efficacy at pH >10. Occasionally, narrow basicity ranges are characteristically necessary to optimize the retarding effect of additives.

Christian Pritzel, Siegen, shed light on the “Effects of mixed additives on the bonding reaction and morphology of alpha-hemihydrate”. He analyzed and discussed the impact of mixing retarders and accelerators as an example of mixed additives. Commonly employed retarders include citric acid and Retardan, while potassium sulphate is a commonly used accelerator. Consequently, mixtures of Retardan and potassium sulphate, and of citric acid and potassium sulphate, were prepared for use in influencing the hydration of alpha-hemihydrate.

Victoria Petropavlovskaya, Tver, addressed a “Binder based on gypsum wastes from the ceramic industry”. The mathematical model for calculation of structures of disperse systems on the basis of a calcium sulphate dehydrate is considered. Such systems are necessary for receiving materials, which exclude roasting of raw materials on the basis of gypsum waste for the receiving binders. For them, a certain composition of raw mix is used. Selection of structure by means of a model allows intensification of the properties of materials. Such materials are characterized by high strength. Other properties have good indicators, too.

Wolfgang Hans, Vienna, lectured on the “Effectiveness and application properties of alternative setting retarders for gypsum plasters”. He introduced various additives, including sodium gluconate/glusono-delta-lactones and blends with tartaric acid and their respective properties. Some of them allow higher concentrations with which to achieve the same setting behaviour as when tartaric acid is employed.

Grigorij Jakovlev, Izhevsk, explained the “Properties of gypsum binders modified with mechanically activated microsilica”, one advantage of which is that such additives allow a reduction in feed quantity.

“Repair materials for sulphatically and hydraulically bound masonry” was Weimar-based Angela Eckart’s topic. Two research projects devoted to finding alternative materials for the rehabilitation of masonry that has suffered damage by expanding minerals were implemented at Weimar Bauhaus University The project findings attest to a very positive tendency. The mortar system provides an option for future restoration measures. However, no general recommendation can yet be given for this system in all its potential applications, because damage due to expanding-mineral formation is time dependent. Hence, long-term observation of the model masonry and objects is planned.

Gerd Srocke, Halberstadt, reported on a “Gypsum forming at high temperatures in historical buildings”. In his practice-oriented report, he examined both the wall rock and the building materials, i.e., the sulphate of lime referred to as gypsum in its hydrate form. Srocke elucidated the high-temperature gypsum plaster produced in Hundisburg and related its potential range of applications.

Klaus Rietschel, Weimar, had lots of practical examples of potential applications to offer for “Gypseous high-gloss plasters in Thuringia: investigations – re-creations – repairs – reconstructions”. He called attention to the knowledge needed in order to recognize region- and era-typical appearances of “high-gloss” mineral wall finishes in heritage structures dating from the late 18th and early 19th centuries in terms of general appearance, employed materials and applied technologies. By way of several examples, he showed how replication can yield the desired results.

“Microstructure and properties of modified gypsum systems” was the topic of a report by Natalya Kondratieva, Lviv. The results of studies of the adsorptive modification of gypsum matrix with micro- and nano-scale additives in the presence of a polycarboxylate plasticizer were presented. The features of the hydration process, the formation of structure and the relationship between the direction of crystal growth and changes in the matrix characteristics were revealed. Thus, targeted regulation of the physical and mechanical properties of dihydrate gypsum can be realized.

Burhan Murati, Debar, introduced “Special-purpose gypsums”. The aim of his project was to self-produce a choice of plasters and grouts in Macedonia. Following a successful series of laboratory experiments and shakedown testing of the products by qualified regional artisans, one grout showed positive results: smooth surfaces, stability, little wear, no cracking and low water absorbency. Positive results were also obtained for gypsum-base plasters.

An introduction to modern X-ray fluorescence analysis was given by Stefan Hoffmann, Kassel, in his contribution entitled “From raw material to quality product – X-ray analysis systems (XRF/SRD) in the gypsum industry”. Modern, compact systems for use in analysing gypsum products are important tools for assuring quality. They enable closer control of individual steps of production and better characterization of the physical and chemical properties of the end products.

Kai Siewert, Weimar, highlighted the ‘Damage potential of sulphate and sulphide in undisturbed soil’. Earthmoving work in road construction often includes the use of binders in the form of cement, building lime, hydraulic stratum/base-coarse or mixed binders. If the soil contains sulphate or sulphide, it may react with the binder to form ettringite. Secondary evolution of ettringite in soil involves volume expansion with resultant lifting of the ground surface. Siewert explained the formation mechanisms of secondary ettringite evolution in soil, described the factors of influence and outlined the limiting values for sulphate content as a tool for estimating the risk potential of soils.

“Application of pulverized waste from production of basalt fibre as part of gypsum composites and its influence” was elucidated by Kirill Petropavlovskij, Tver. He showed the results of studies of gypsum dispersed systems with the addition of waste from basalt production. Introduction of basalt dust improves the physical and mechanical properties of the modified gypsum material. The effect of additives on the strength, density and water absorption of gypsum dispersions promotes hydration hardening. The strength of composites reinforced with basalt dust increases the packing density of the particles, hence contributing to a more optimally matched grain composition and elevating the chemical affinity of gypsum and basalt. It also improves the efficiency of the composites, primarily through optimization of their internal structure.

Yilmaz Sakalli, Siegen, interpreted an “Investigation of the effects heterogeneous nucleation on the hydration of calcium sulphate hemihydrate” and of various heterogeneous nuclei on the nucleation mechanisms of various hemihydrates. Anhydrite, sand, calcium carbonate and barium sulphate have very little impact on the reaction process. Addition of dihydrate affects both nucleation and the reaction process. Mineral hydration was significantly accelerated and the induction period suppressed by dihydrate seed crystals in the course of hydration. Microscopic investigations show that two generations of crystals evolve. Even small amounts of dihydrate have a strength-enhancing effect, while more than roughly 5 % causes a loss of strength. Large individual crystals in the microstructure apparently have a stabilizing effect.

The effects of specific additives and combinations of additives on hydrating plaster of Paris were dealt with by Tibia von Bronk, Sulzheim, in her lecture with the title “Additive-dependent effects of stucco hydration”. The intensity of the hydration process was comparable for all subject specimens. The beginning of expansion is linked to the initial hydration and, hence, to stiffening. All subject specimens exhibited comparable expansion rates, i.e., expansion within the specimens progresses as a direct function of the hydration rate. Adding a retarder in combination with the subject plasticizers has a strength-reducing effect. The loss of strength is higher in reaction to fruit acid than to the retarding polymer Retardan.

Nigmadjan, Talipov, Tashkent, spoke on the “Production and use of gypsum binders in Uzbekistan”. In Uzbekistan, demand for building materials is on the rise. Present consumption is running at approx. 7.5 million t cement/year, or some 2.5 million t more than in 1990. The mining and application of gypsum has also been expanding markedly. As of this writing, cement production accounted for 140 000 t and gypsum production for 4 million t. Most processing is attended to on Chinese-built equipment with an output of 900 t/d. Nineteen plasterboard plants turn out more than 20 different products for interior masonry/drywall. Hemi- and dihydrate products, in addition to gypsum-based thermal insulating materials are under development.

In the closing lecture, Alexander Gawrisch, Kiev, looked into the situation of the construction sector and plasterboard industry in the Ukraine. The Ukraine market is dominated by two large producers and a few small importers. While some 90 million m² plasterboard was installed in 2008, that figure was down to about 45 million m² in 2015. It should also be noted, that the share of high-mass walling material, e.g., cellular concrete and normal concrete, is increasing, because drywall construction, for historical reasons, has a poor reputation in the Ukraine.

Be seeing you

Hans-Bertram Fischer closed out the conference with a word of thanks to all speakers and facilitators for their contributions. At the next event in three years, even more experts and consultants will be invited to speak. First, though, the 20th International Conference on Building Materials – Ibausil is coming up in 2018 and also will be focusing on gypsum.

//www.uni-weimar.de" target="_blank" >www.uni-weimar.de:www.uni-weimar.de

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.