Limestone requirements

for high-limestone cements

Tests performed on mortars permit the conclusion that, within the scope examined here, neither chemical composition nor mineral-phase type and content have significant effects on workability, 2-, 7- and 28-day cement compressive strength and durability. The tests described here were performed on blended cements containing 19%, 24% and 34% ground limestone by mass, and demonstrate the importance of the fineness of the limestone and clinker particles for cement properties and concrete durability. If the differences in the granulometric parameters of the limestones are excluded, not only limestone content but also BET surface area are critical for the cements’ subsequent working properties. Tests on concrete in the laboratory indicated that, apart from the cement’s limestone content, only the w/c-ratio is definitive for the durability of concretes. Even concretes based on blended CEM II/B cements (using CEM I 52.5 R as the initial cement) containing 24 % limestone by mass exhibited high internal and external frost resistance (CDF/CIF and cube test).

1 Introduction

Among endeavours for reduction of climate-relevant CO2 emissions in the cement industry, particular importance is attached to the replacement of Portland cement clinker by other main constituents. Around the globe, only fly ash and ground granulated blast furnace slag (GGBFS) are currently available in significant quantities. Both of these materials are by-products, and are subject to significant cyclical economic and seasonal fluctuations, unlike limestone, which is available in adequate quantities at numerous locations.

Natural occurring limestone is a non-homogeneous mixture of...

1 Introduction

Among endeavours for reduction of climate-relevant CO2 emissions in the cement industry, particular importance is attached to the replacement of Portland cement clinker by other main constituents. Around the globe, only fly ash and ground granulated blast furnace slag (GGBFS) are currently available in significant quantities. Both of these materials are by-products, and are subject to significant cyclical economic and seasonal fluctuations, unlike limestone, which is available in adequate quantities at numerous locations.

Natural occurring limestone is a non-homogeneous mixture of a range of different minerals. The European cement standard EN 197, Part 1, therefore specifies certain minimum requirements for limestones for the production of Portland limestone cement:

CaCO3 ≥ 75 % by mass

Clay content ≤ 1.2 g/100 g, measured using the methylene blue adsorption method

Organic carbon (TOC) ≤ 0.2 % by mass for Type LL limestone and ≤ 0.5 % by mass for Type L limestone

European cement standard EN 197, Part 1, permits the use of 5 to 35 % by mass of limestone in Portland limestone cements (CEMII/A-L, -LL and CEM II/B-L, -LL).

The addition of up to 5 % by mass as a minor constituent to all other cements is also possible. Limestone as a minor constituent is generally ground together with the clinker and possesses a lower hardness than Portland cement clinker, and therefore accumulates in the fines fraction [1, 2].

Within certain limits, these extremely fine limestone particles can increase packing density and thus workability and durability. Optimisation of packing density is a complex process, however, and depends inter alia on parameters such as cement fineness and ground limestone volume.

Calcite can, in addition, react in small amounts with the aluminates from the clinker, forming carboaluminates [3], which subsequently enhance the stability of the ettringite. At high limestone contents, the dilution of the reactive clinker content predominates, however. Giergiczny [4] shows, by way of example, the loss of strength as limestone content rises. Locher describes, in [5], a limestone content of approx. 15 % by mass as the limit for joint grinding. Up to this content, it is possible to compensate for the fall in compressive strength by means of finer grinding of the Portland limestone cement.

Only relatively few studies documenting the properties of Portland limestone cements as a function of limestone quality are available [6].

2 Performance of tests

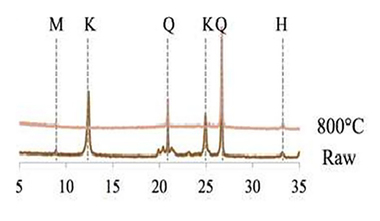

Thirty-two limestone specimens from twenty-four different deposits were firstly dried at 105 °C. A representative subset was ground in a vibratory disc mill to approx. 5000 cm²/g for the subsequent analyses. Figure 1 shows the differences here compared to the requirements of EN 197. Not only these normative requirements, but also other parameters were analysed, such as BET surface area, for example, as a measure of the external and the internal surface area of the ground limestone.

Ten limestones were separately ground by way of example in a laboratory-scale mill and mixed with works-ground Portland cement, in order to determine their influence on the most important cement properties. This cement was specially produced for this purpose without any addition of minor constituents (OPC-A1).

The particle-size distribution of the ground limestone must approximate as closely as possible the particle-distribution curve of the Portland cement used in order to reduce as far as possible the potential effects arising from a change in the particle-size distribution of the blended cement. The limestones were therefore ground for 20 minutes in a laboratory ball mill. The particles of > 90 µm screened out were subsequently also ground for a further 15 minutes and then homogeneously mixed with the screen underflow.

The Portland cement : ground limestone mixing ratios were selected to accordance with the limits stated in EN 197: 19 % and 34 % by mass. Four limestones were additionally tested at a rate of 24 % by mass. The sulphate content of the blended cements was adjusted to a constant 3.0 % via the addition of a separately refined calcium sulphate anhydrite.

A second series of tests illustrates the influence of clinker fineness via the combination of a ground limestone (L2) with four Portland cements from one production facility, which differ essentially in their fineness (OPC-B1, -B2, -B3 and -B4).

The third series of tests compares two ground limestones of differing fineness but identical composition (L2, L2-G) in combination with a Portland cement (OPC-C1). Finally, a Portland limestone cement (PLC-D1) with a limestone content of 28 % by mass produced using joint grinding was tested with varying w/c ratios.

The individual results for the Portland cement and the limestone are shown in Table 1 and Table 2.

3 Results and discussion

3.1 The influence of limestone quality

The yield point of a mortar was selected as the criterion for assessment of working properties. The yield point of the Portland cement used was 18 Nmm. In this test apparatus, the decrease in the reactive clinker particles did not, in principle, result in an improvement in working properties.

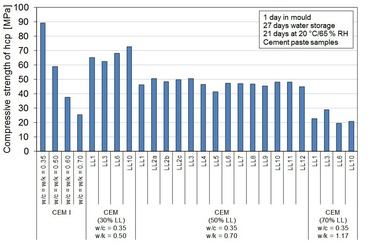

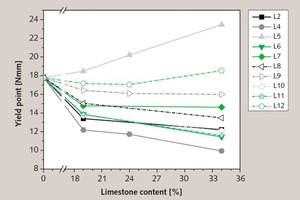

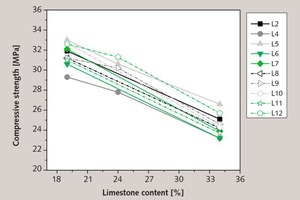

The influence of the limestone on the yield point becomes more and more pronounced as limestone input increases (Figure 2). As expected, the decrease in the reactive clinker particles results in a reduction in compressive strengths (Figure 3).

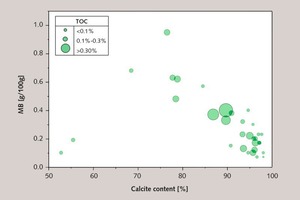

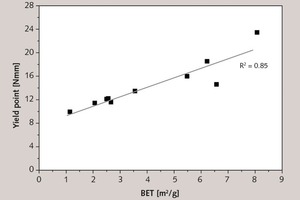

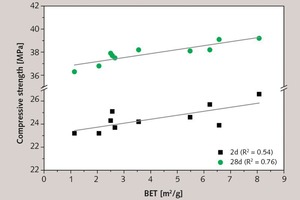

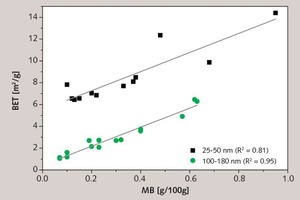

The BET surface area of the prepared ground limestones was identified in this study as a critical factor for performance properties (Figure 4). With approximately identical fineness and particle distribution in the feed materials, the workability of the resultant blended cements declines significantly as the BET surface area of the ground limestone increases. A slight increase in compressive strength as BET surface area rises is also simultaneously observable (Figure 5).

The differences in the BET surface area at identical fineness can in part be explained by the differences in clay content as determined using the methylene blue adsorption method. A clear correlation becomes apparent only in combination with the crystallite size of the calcites (Figure 6).

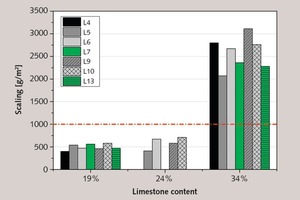

The durability of concretes produced from cements with a high limestone content are also of significance for assessment of performance properties. The method specified in CEN TS 12390-9, Part 5 (slab test) was used for assessment of resistance to freeze-thaw cycles. The composition of the concrete is orientated around the limits for Exposure Class XF3 as per DIN EN 206-1/DIN 1045-2. Testing was performed on a concrete mixture with no artificial air pores. The air content of the fresh concretes is in the 1.4 % vol. to 1.8 % vol. range.

The Portland limestone cements containing 19 % and 24 % by mass ground limestone meet the requirements for frost resistance (Figure 7). Scaling with 24 % by mass ground limestone differs only slightly from the results for 19 % by mass ground limestone. Frost resistance declines over-proportionally when the ground limestone content is raised to 34 % by mass. Scaling then more than doubly exceeds the limit. A correlation between the quality parameters of the limestones and scaling is not apparent in this study.

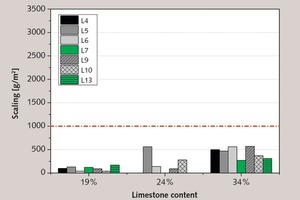

For testing for de-icing salt resistance, the concretes were adjusted by means of air-entraining agents to an air content of 4.5 ± 0.5 % vol. in the fresh concrete. Scaling in the de-icing agent resistance test on air-entrained concrete is well below the limit, at 570 g/m² (Figure 8). This permits the supposition that porosity and the transport processes in the concrete play a more important role (see also 3.4 on this).

3.2 The influence of clinker fineness

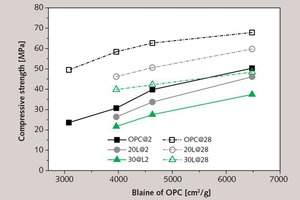

The influence of clinker fineness was determined using mixtures of a ground limestone with three Portland cements of differing fineness and identical origin (see Table 1, OPC-B1, -B2, -B3 and -B4). A ground limestone was added at rates of 20 % and 30 % by mass to these Portland cements. Sulphate content was adjusted to 3.0 % via the addition of refined calcium sulphate anhydrite.

The strength level of the cements increases when the fineness of grind of the clinker is raised. This is observable equally in both Portland and Portland limestone cements (Figure 9). In this system, a fineness of ~ 3400 cm²/g is adequate in a Portland cement to achieve a compressive strength in the mortar after 2 days of, for example, 26 MPa. A clinker fineness of no less than ~ 4000 cm²/g is necessary for a Portland limestone cement containing 20 % limestone by mass. At 30 % limestone by mass, the necessary clinker fineness rises to ~ 4600 cm²/g. The clinker fineness requirements at high limestone contents rise significantly as

hydration time progresses. After 28 days, the Portland cement with ~ 3400 cm²/g achieves a compressive strength of ~ 53 MPa. A clinker fineness of no less than ~ 5000 cm²/g is necessary to attain the same compressive strength level in a Portland limestone cement containing 20 % limestone by mass, while the necessary clinker fineness rises to > 6500 cm²/g for 30 % limestone by mass.

3.3 The influence of ground limestone fineness

As noted above, high clinker fineness is necessary in order to meet compressive strength requirements. This generally has a detrimental effect on working properties. This was to be counteracted by means of systematic combination with a ground limestone with a reduced fine particles content. A works-ground Portland cement was combined for this purpose with two ground limestones which differed only in their fineness (Table 3).

As a result of the process used, the Blaine measuring method does not supply repeatable measured data for ground limestone L2-G. The BET surface area of these two ground limestones differed only insignificantly compared to the bandwidth of the BET surface area determined for limestones of various origins (Table 2). This is indicative of a comparatively slight influence by fineness of grind on the BET surface area of the ground limestones.

As expected, variation of the fineness of the ground limestone affects the performance properties of the cements produced from it. The use of the coarse ground limestone improves workability significantly. The main reason for this may be found in the widening of the particle size distribution. This correlation between particle size distribution and water demand is also correspondingly described, for example, in [7]. The lower compressive strength observed simultaneously when ground limestone L2-G is used corresponds to the correlation between the BET surface area of the limestone and compressive strength in the mortar shown in Figure 4.

3.4 The influence of w/c ratio on freeze-thaw

resistance

Resistance to freeze-thaw cycles is influenced very greatly by porosity and strength. It is known that porosity also increases as limestone content rises [3].

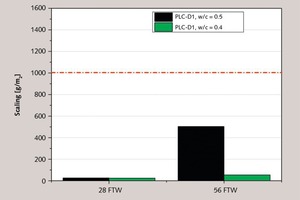

A Portland limestone cement (PLC-D1) with a limestone content of 28 % by mass and produced by means of joint grinding was also tested with a w/c ratio of 0.40. Testing was performed on a concrete mixture with no artificial air pores. At a w/c ratio of 0.40, an air content in the fresh concrete of 1.2 % vol. stabilised, compared to 2.1 % vol. air at a w/c ratio of 0.50.

Scaling after twenty-eight freeze-thaw cycles is extremely low in both concretes (24 to 26 g/m²). Significant differences become apparent after fifty-six freeze-thaw cycles, however. Scaling was 504 g/m² for a concrete with a w/c ratio of 0.50. At the reduced w/c ratio, this figure increased only marginally, from 24 g/m² to 55 g/m².

Drilling cores for determination of porosity in accordance with SIA 262/1, Appendix A were taken after 28-day conditioning of the test objects. As was to be expected, porosity declined significantly, from 12.2 % vol. to 9.8 % vol., as a result of the reduction in the w/c ratio. This difference is equally apparent in water absorption in accordance with SIA 262/1, Appendix A. This is 1960 g/m² at a w/c ratio of 0.50, but 1130 g/m² at a w/c ratio of 0.40.

4 Summary

Limestone used for the production of Portland limestone cements must conform to the requirements of EN 197, Part 1. These normative criteria cannot be used for any prediction of cement quality, however.

BET surface area is a useful parameter, since it correlates to the performance properties of the cements produced. The workability of the cement declines significantly, and compressive strength increases slightly, as BET surface area increases.

In addition to clinker properties, the granulometric parameters of the limestones as a function of limestone content in the cement were responsible for the cement properties determined during testing.

At a limestone content of ≥ 19 % by mass, compressive strengths decreased in this study in accordance with the dilution of the clinker content. Such a decline in compressive strength can be adjusted only by increasing the fineness of the clinker. Finer grinding is achieved only at the cost of workability, however. In cements with a high limestone content, workability can be improved by using ground limestones with a lower ultra-fine particle content. Compressive strength is affected simultaneously only very slightly.

The cements with a limestone content of 19 %/24 % by mass tested here exhibit high resistance to freeze-thaw cycles. The scaling rate is in this context unrelated to the purity of the limestone and its BET surface area. All mixtures containing 34% limestone by mass manifest inadequate resistance to freeze-thaw cycles. Concrete making provisions, such as the reduction of the w/c ratio or the incorporation of artificial air pores, nonetheless, do make it possible to produce from such high-limestone cements a concrete with adequate resistance to freeze-thaw cycles [8].

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

![10 Calculated phase volume for Portland limestone cement as a function of limestone content;Cc – CalciteCH – PortlanditeEt – EttringiteM$ - MonosulfoaluminateHc – HemicarboaluminateMc – MonocarboaluminateHt – HydrotalciteFe-H – Iron-containing hydrogarnetPor – PorosityA description of the modelling concept is provided in [3]](https://www.zkg-online.info/imgs/tok_32991a5b9ada19fb1006472b5fe1f6e3/w300_h200_x400_y395_101550373_5732934c10.jpg)