Investigations into calcined clay cements containing limestone as compared with calcined clay cements containing marble dust

Formulations of blended cements, in which the carbon- and energy-intensive Portland clinker is partially replaced by supplementary cementitious materials, represent a viable strategy for achieving environmental sustainability during cement production. The availability of clay and limestone all over the world means that a new ternary cementitious cement system containing calcined clay and limestone could increase clinker replacement to 50% without significantly influencing the cement performance. This is due to the synergy between the aluminates from calcined clay and the carbonates from limestone. In view of the widespread availability of marble dust, a waste generated by the marble processing industries in India with oxide constituents and a mineral composition similar to those of limestone, a comparative study has been undertaken into the mechanical properties of cement blends containing calcined clay and limestone and cement blends containing calcined clay and marble dust. These were prepared with different clinker/cement ratios of 0.40, 0.45, 0.50, 0.55 and 0.60 and, in the case of calcined clay cement blends containing marble dust, showed better strength development at all curing ages than their counterparts containing limestone. This indicates the potential of marble dust for use as a cementing material in the manufacture of blended cements.

1 Introduction

Worldwide cement demand is increasing continuously due to the increasing population and infrastructural requirements. The annual global cement production is predicted to reach around 4.8 billion t annually by 2030 and 6.0 billion t by 2050 from the current level of 4.1 billion t [IEA-WBCSD, 2018]. The cement industry is facing major challenges associated with the cement production. These include rapid depletion of natural resources and carbon emission into the atmosphere, which accounts for about 7-8% of global CO2 emissions. Every tonne of OPC produced releases an equivalent...

1 Introduction

Worldwide cement demand is increasing continuously due to the increasing population and infrastructural requirements. The annual global cement production is predicted to reach around 4.8 billion t annually by 2030 and 6.0 billion t by 2050 from the current level of 4.1 billion t [IEA-WBCSD, 2018]. The cement industry is facing major challenges associated with the cement production. These include rapid depletion of natural resources and carbon emission into the atmosphere, which accounts for about 7-8% of global CO2 emissions. Every tonne of OPC produced releases an equivalent amount of CO2 into the atmosphere. Not only the CO2 released from cement plants but also the SO2 (sulphur dioxide) and NOx (nitrous oxides) contribute to the greenhouse gases (GHG). The Indian cement industry has recognised these problems and has therefore adopted various best available technologies (BAT) and environmental practices that can help reduce the industry’s carbon and energy footprints. These include investment in more efficient kiln technology, increased use of alternative fuels, clinker replacement, control of heat consumption during clinker production and exploration of innovative technologies, such as novel cements and carbon capture, storage and utilization (CCS/U). It is estimated that these efforts will reduce the CO2 emission in India to 0.58 t CO2/t cement by 2030 and 0.35 t CO2/t cement by 2050 [WBCSD-CSI-2018].

Clinker replacement, where some of the Portland clinker in cement is replaced by supplementary cementitious materials (SCMs), such as fly ash, granulated blast furnace slag, limestone, etc., in the manufacture of blended cement is one of the most promising approaches for mitigating carbon emissions. On average, the production of 1 kg of ordinary Portland cement (OPC), the most common type of cement used with >90% of its composition made up of Portland clinker, generates 0.93 kg CO2. By comparison, blended cement, i.e. cement with a low proportion of Portland clinker and a high proportion of SCMs and fillers, can result in a carbon figure as low as 0.25 kg CO2/kg [Hammond and Jones, 2011]. The production of blended cements by lowering the clinker content could play a significant role in achieving an average global clinker ratio of 0.60 by 2050 against the present level of 0.65, as set out by the 2018 Technology Roadmap, and has the potential to mitigate almost 0.29 gigatonnes (GT) of CO2 in 2050. Clinker replacement has currently contributed, on average, a 20-30% reduction in CO2 emissions per t of cement produced, when compared with the 1980s [Oliver et.al, 2015]. Fly ash and granulated blast furnace slag are the most proven SCMs worldwide in the production of blended cements but it is estimated that the production of slag and fly ash will account for around 16% of cement production in 2050 [Miller et.al, 2018]. Cement-grade limestone in India will last for another 35-40 years (assuming 100% pet coke utilization as fuel) with an anticipated clinker production of 500 million t by the end of 2020. In view of the future scarcity of cement-grade limestone, the marble wastes, that are generated by the marble processing industries to the tune of 5-6 million t per year and are compatible with the cement system, could be a potential material for the production of blended cements. The limited future availability of proven materials means that continuous efforts are being made to explore other innovative compatible materials and industrial wastes/by-products such as marble waste, clay, red mud, steel slag, etc., as mineral constituents in the development of blended cements in India other than the traditional PPC, PSC and composite cements.

Much research has recently focussed on calcined clays as alternative sources of SCMs. They are produced by thermal treatment of clay minerals so they have the immediate advantage that they are naturally abundant in very large quantities almost all over the world. The total reserves/resources of clay in India are estimated to be around 2941 million t, of which 2039 million t falls in the mixed grade/unclassified class [IBM, 2017]. The clay deposits in India are spread over in a number of states, of which Kerala holds 26%, followed by Rajasthan (19%), West Bengal (14%), Odisha (10%) and Karnataka (9%). The thermal activation of clays takes place at between 500 and 900 °C and, in contrast to the de-carbonation of limestone in the production of Portland clinker, does not normally involve direct release of CO2 from the raw clay. Due to the extensive availability of clay and limestone all over the world, a new ternary cementitious cement system containing calcined clay and limestone could increase clinker replacement to 50% without significantly influencing cement performance. This is due to the synergy between the aluminates from calcined clay and the carbonates from limestone [Antoni et.al, 2012]. The global reserves of raw clays are considered effectively unlimited when compared to the volume of global cement production. It is thought that cement based on ground limestone and calcined clay will penetrate the market to 27% of global cement production by 2050 [IEA-WBCSD, 2018] and that, in a global average assessment of cement compositions, calcined clay will contribute 8% to the overall cement composition by 2050 in comparison to the negligible proportion in 2014.

In view of the wide availability of marble waste in India the present paper therefore highlights the performance characteristics of limestone calcined clay and marble dust calcined clay cements and their comparative evaluation. Marble dust is chemically and mineralogically similar to limestone and could be a potential material in the manufacture of blended cement, namely marble dust calcined clay cement.

2 Experimental procedure

Chemical analysis of the Portland clinker, limestone, marble waste and raw clay samples was carried out in accordance with the test procedures described in various Indian standards. The amount of kaolinite present in raw clay is measured by DTA/TGA. The morphology and granulometry of calcined clay was investigated by optical microscopy (NIKON). The lime reactivity of calcined clay was determined in accordance with test procedure IS: 1727 (Method of Tests for Pozzolanic Materials).

Different limestone calcined clay and marble dust calcined clay cement blends were prepared with different clinker/cement ratios of 0.40, 0.45, 0.50, 0.55 and 0.60 (Table 1) by an intermixing procedure. They were investigated for oxide constituents, particle size distribution, heat of hydration using isothermal calorimetry, and physical characteristics such as Blaine fineness, consistency, setting times, compressive strength development at different ages, soundness, etc., determined in accordance with various testing procedures described in the Indian standard IS:4031.

3 Characterization of materials

3.1 Raw and calcined clay

The mineralogy of the raw clay showed a predominance of kaolinite [Al2Si2O5(OH)4], with diffraction lines at 12.4 and 24.8° (2θ), α-quartz [SiO2], muscovite [KAl2(Al,Si3O10)(F,OH)2] and haematite [Fe2O3] (Figure 1). The raw clay was calcined at a temperature of 800 °C and the diffraction pattern of the calcined clay showed the presence of amorphous material, indicating a loss in crystallinity of the kaolinite.

The amount of kaolinite in raw clay was determined by measuring the mass loss between 450 °C and 700 °C; complete dihydroxylation of pure kaolinite mineral results in a mass loss of 14%. In this way the percentage of kaolinite in raw clay was found to be 59% (Figure 2a) and the TGA curve showed no further mass loss indicating, complete dihydroxylation of kaolinite (Figure 2b). The lime reactivity of calcined clay was determined as 8.0 MPa. Chemical analysis of the calcined clay sample showed the presence of 0.53% CaO, 49.50% SiO2, 41.52% Al2O3, 1.88% Fe2O3 and 41.48% reactive silica (Table 2).

An optical micrograph of the calcined clay showed the presence of quartz, calcite, opaque minerals and iron oxide, with a glass content of 54%. Glass grains with both sharp angular and rounded grain margins were uniformly distributed (Figure 3) and varied from 2 to 75 µm with an average of 14 µm. However, the majority of glass grains were in the size range of 2 to 15 µm. Subhedral to anhedral quartz grains with sharp grain margins were randomly distributed and micro globular calcite grains were observed as clusters. Opaque minerals with rounded grain margins were also detected. Anhedral to subhedral iron oxide grains were randomly distributed.

3.2 Limestone and marble dust

Chemical analysis of the limestone showed the following oxide constituents: 28.11% CaO, 30.03% SiO2, 8.93% Al2O3, 4.66% Fe2O3, 1.69% MgO. This was categorized as low grade limestone with ~50% CaCO3, which did not fulfil the requirement of CaCO3 ≥ 75% for limestone to be used as a mineral constituent for ordinary Portland cement as specified in the Indian standard IS:269-2015. The limestone sample was ground to a fineness of about 6% retention on 90 μm. The oxide constituents present in marble dust were: 34.77% CaO, 15.07% SiO2, 2.73% Al2O3, 11.86% Fe2O3 and 12.34% MgO. The fineness of marble dust in terms of percentage retention on 90 μm was found to be 2-3%, indicating its greater fineness than the ground limestone.

3.3 Ordinary Portland Cement (OPC)

The chemical analysis of ordinary Portland cement (OPC) (95 wt.% Portland clinker and 5 wt.% gypsum) showed 61.54% CaO, 21.78% SiO2, 5.20% Al2O3, 4.84% Fe2O3, 1.35% MgO and 2.25% SO3 as the major oxide constituents (Table 2). The clinker parameters and potential clinker phases according to the Bogue calculation were estimated as: LSF 0.88, SM 2.17, AM 1.07, C3S 44%, C2S 29%, C3A 5.60%, C4AF 14.73%. The Blaine fineness of the OPC was 315 m2/kg. The compressive strengths of the OPC at 1, 3, 7 and 28 days were determined as 23.0, 27.5, 33.0, 50.5 MPa respectively.

4 Results and discussion

4.1 Chemical analysis

Chemical analysis of limestone calcined clay and marble dust calcined clay cement blends indicated a comparatively high value of loss on ignition due to the presence of carbonaceous components in the cements (Table 3a and b).

4.2 Particle size distribution

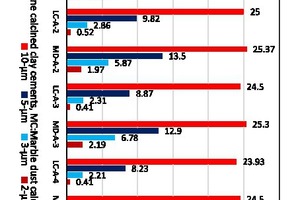

Comparative evaluation of the particle size distributions of limestone calcined clay and marble dust calcined clay cement blends indicated the greater fineness of the marble dust calcined clay cements. The percentage fractions passing through 10, 5, 3 and 2 μm were found to be higher for the marble dust calcined clay cement blends (MD-A-1 to MD-A-5) than for the limestone calcined clay blends (LC-A-1 to LC-A-5) at all clinker/cement ratios (A1-0.40, A2-0.45, A3-0.50, A4-0.55 and A5-0.60) (Figure 4). This could be attributed to the greater fineness of marble dust than limestone. The percentage of particles below 2 μm was found to be greater in marble dust calcined clay cements (in the range of 1-2%) when compared with limestone calcined clay cements (<0.60%), indicating the finer nature of marble dust cement blends.

4.3 Physical characteristics

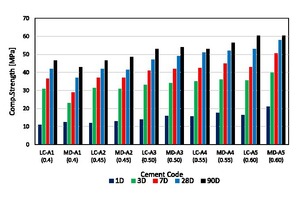

Limestone calcined clay and marble dust calcined clay cement blends, prepared with clinker/cement ratios of 0.40, 0.45, 0.50, 0.55 and 0.60, were evaluated for their various physical characteristics such as fineness, consistency, setting times, compressive strength development up to 90 days and soundness. The Blaine finenesses of the limestone calcined clay and marble dust calcined clay cement blends were 400-450 m2/kg and 550-600 m2/kg respectively when measured using the Indian test procedure IS: 4031(2)-1999 (Table 4a and b). The water requirement for preparing cement paste of standard consistency, as per IS:4031(4)-1998, was found to be higher in the case of marble dust calcined clay cement blends than for limestone calcined clay cements owing to their greater fineness. It was found that the water demand increased with increasing percentage mineral addition, both for limestone and for marble dust. The initial and final setting times, measured as per IS:4031(5)-1988, of the marble dust calcined clay cement blends were substantially lower than with the limestone calcined clay cements, indicating the accelerated hydration reaction with the addition of marble dust. The compressive strength development of marble dust calcined clay cement mortars (IS:4031(6)-1993) was found to be marginally increased at all curing ages and clinker/cement ratios when compared with their counterparts containing limestone (Figure 5). Comparative evaluation of the strength development of the two cement blends, LC-A5 and MD-A5, prepared with a clinker/cement ratio of 0.60 showed a substantial gain in strength for the marble dust calcined clay cements, i.e. 28% at 1 day, 13-15% at 3 and 7 days and 10% at 28 days in comparison with the limestone calcined clay cement blends, whereas the 90 day compressive strengths were approximately similar in both cases. These cement blends were dimensionally stable when tested in accordance with IS: 4031(2)-1988.

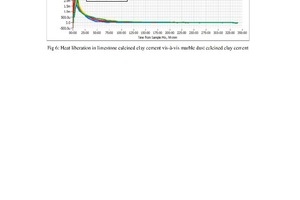

4.4 Heat liberation through isothermal calorimetry

Cement hydration is a strongly exothermal reaction that takes place in various stages. The heat liberation is a result of the hardening processes in the cement paste. Isothermal calorimetric measurements can therefore be used to assess the rate of the hydration reaction and the accompanying heat release. The heat evolution by the marble dust calcined clay cement showed a high heat evolution with early reaction when compared with the limestone calcined clay cements (Figure 6).

5 Conclusions

1. The raw clay with a kaolinite content of 59% was calcined at a temperature of 800 °C and the diffraction pattern of the calcined clay indicated a loss in crystallinity of the kaolinite.

2. The glass content in the calcined clay was estimated to be about 54%, with a lime reactivity of 8.0 MPa.

3. The oxide constituents of the limestone showed it to be low grade limestone with a CaCO3 content of 50%, which did not fulfill the requirement of CaCO3 ≥ 75% specified in the Indian standard for limestone to be used as a mineral additive in cement.

4. The marble dust used was dolomitic in nature with an MgO content of 12.34%.

5. Different limestone calcined clay and marble dust calcined clay cement blends were prepared by intermixing all the constituents while maintaining clinker/cement ratios of 0.40, 0.45, 0.50, 0.55 and 0.60.

6. The particle size distributions showed the finer nature of marble dust calcined clay cement blends when compared with their counterparts containing limestone.

7. The compressive strengths of the limestone calcined clay and marble dust calcined clay cement blends prepared with clinker contents as low as 0.40 met the minimum strength requirements specified in the Indian standard for blended cements.

8. Comparative evaluation of the physical characteristics of limestone calcined clay and marble dust calcined clay blends showed:

– Higher water demand for the marble dust calcined clay cements

– Faster setting times for the marble dust calcined clay cements due to the more rapid hydration, indicated by the greater heat liberation

– Marble dust calcined clay cement blends showed better strength development at all curing times when compared with limestone calcined clay cements

9. The study reveals that marble dust could be a potential candidate in the manufacture of limestone calcined clay cements.

Acknowledgement

The work reported in this paper forms part of an R&D study entitled “Development of Low Carbon Multi-Component Cement Blends (CRT-WAU-15)” and the authors would like to express their sincere thanks and gratitude to the Director General, National Council for Cement and Building Materials for granting permission to publish this paper.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

![1 X-ray diffraction pattern of raw clay and calcined clay (K: Kaolinite, M: Muscovite, Q: Quartz, H: Haematite) [1, 2]](https://www.zkg-online.info/imgs/1/6/9/8/9/7/7/tok_1ffb4333d5b65a2cea8de57320b26f72/w300_h200_x600_y349_Materials_Agarwal_Figure_1-9f57b6742a6551c3.jpeg)

![2 DTA/TGA curve of clay [1, 2]](https://www.zkg-online.info/imgs/1/6/9/8/9/7/7/tok_cfe37cd125339b0505fad9a8b798e359/w300_h200_x600_y359_Materials_Agarwal_Figure_2a-79fd72dddc2d43af.jpeg)

![3 Distribution of glass grains in calcined clay (20x, x-nicols) [1, 2]](https://www.zkg-online.info/imgs/1/6/9/8/9/7/7/tok_8aa65a614e3c6c9f6ac9d26a6eb74168/w300_h200_x347_y264_Materials_Agarwal_Figure_3-6e23b3cb3c90b534.jpeg)