Investigations on composite cement containing Indian fly ash and granulated blast furnace slag

The paper highlights the performance results of various cement blends obtained, the reaction mechanisms involved vis-à-vis the scope for simultaneous use of these materials in cement. The results indicated that in a ternary blend of fly ash, GBFS and clinker, up to 50 % of the clinker can be replaced gainfully without affecting the performance in a mortar sample. The experimentation on concrete and its durability continues.

The world today faces the gravest challenge in terms of the ever increasing level of greenhouse gas emissions and their impact on global warming coupled with fast depleting natural resources. The use of various kinds of industrial wastes, mine rejects and by-products such as fly ash from thermal power plants, granulated blast furnace slag and other slags from steel plants, low grade limestone from mineral processing industries and cement plants, lead-zinc slag from zinc smelters, copper slag from copper smelters, equilibrium catalyst from refineries, jerosite and kimberlite from the mineral...

The world today faces the gravest challenge in terms of the ever increasing level of greenhouse gas emissions and their impact on global warming coupled with fast depleting natural resources. The use of various kinds of industrial wastes, mine rejects and by-products such as fly ash from thermal power plants, granulated blast furnace slag and other slags from steel plants, low grade limestone from mineral processing industries and cement plants, lead-zinc slag from zinc smelters, copper slag from copper smelters, equilibrium catalyst from refineries, jerosite and kimberlite from the mineral processing industries and so on as blending materials in cement manufacture either singularly or in combination is a significant potential route for their gainful utilization besides reducing the carbon footprints due to cement, construction and building materials relieving thereby the pressure on natural resources. The increased use of BM’s has direct impact on the reduction in clinker content in cement thereby reducing the CO2 emission by reduced fuel combustion and reduced limestone calcinations and at the same time reduced usage of natural limestone.

At present PPC and PSC are being separately used in construction by site mixed as well as ready mix concrete segments but there was no serious attempt to look at a cement or concrete product with the benefits of using GBFS and fly ash complementing each other, as there was no specified standards in India allowing the manufacture of such fly ash – slag, multi-blend composite cement. In order to facilitate the standardization of composite cement in India, systematic investigations have been carried out at the NCB using fly ash and slag along with limestone in varying dosages in line with EN 197.

1 Introduction

Hydraulic cements specified by the Bureau of Indian Standards include OPC (33, 43 & 53 Grades), PPC, PSC and various special purpose cements. Fly ash conforming to IS 3812 (Part 1): 2013 and granulated blast furnace slag conforming to IS 12089: 1987 are used in the manufacture of PPC and PSC respectively. However, the use of both of these materials simultaneously in the manufacture of cement is not employed presently. The blended cements, which are produced using more than one mineral addition, are known as composite cements. The NCB (National Council for Cement and Building Materials) has done some work on composite cements prepared using granulated blast furnace slag and fly ash. Further work on preparation and performance evaluation of composite cements including their long term durability characteristics and effect on the properties of fresh and hardened concrete is required at this stage to enable better understanding of these cements and to enable formulation of national standards on composite cements.

Manufacture of composite cements will permit greater utilization of industrial wastes and enable production of cements with a lower clinker factor leading to resource conservation, enhanced waste utilization and greater sustainability in cement manufacture. Replacement of clinker by slag and fly ash improves the performance of concrete by increasing the resistance to chloride penetration [1]. It was reported that the addition of slag results in a better performance of a concrete containing class F fly ash than one containing class C fly ash [2]. The development of compressive strength in composite cements containing fly ash improves at later ages and is roughly proportional to the content of active silica [3-8]. To facilitate manufacture and use of composite cement in India it is required to formulate the standards for composite cement.

European standards (EN 197-1: 2000) already have specifications on Portland Composite Cement (Cement Type II) permitting simultaneous use of various mineral admixtures, with total additions in the range of 6-20 % (CEM II/A-M) and 21-35 % (CEM II/B-M). European Standards also specify Composite Cement (Type V – CEM V/A and CEM V/B) where simultaneous use of only granulated blast furnace slag and pozzolana / fly ash is permitted. ASTM too has introduced performance-based specifications for hydraulic cements (C 1157-00) with no restrictions on composition of the cement.

Fly ash and slag in combination with OPC are presently not being used for preparing composite cement in our country as there are no national standards on composite cements. However the Indian cement industry has taken up the issue of formulation of standards for composite cements at various forums including the Bureau of Indian Standards (BIS). The physical and chemical properties of composite cement as specified in the European Standards or ASTM are based on material characteristics, testing procedures and product requirement, which are different from those prevailing in India and/or specified by BIS. The values of various properties specified in foreign standards for different types of cements, especially the compressive strength values, are not directly comparable to the values mentioned in the Indian Standards for similar cements, on account of different test procedures. Hence data on composite cements, tested as per BIS procedures, is required for developing these cements for the Indian market. Further, the grinding behavior of different mineral additives are different and the inter-grinding or separate grinding and blending of components can give rise to cements having same composition but differing properties and performance.

The NCB has carried out a study on composite cement wherein combinations of fly ash and granulated blast furnace slag were used for preparing composite cement blends. The results indicated that slag and fly ash could be added simultaneously as the mineral admixture in the preparation of composite cement. However, the properties of composite cement depended on the quality of the clinker and mineral additions, besides fineness and particle size distribution. Further work on preparation and performance evaluation of composite cements including their long term durability characteristics and effect on properties of fresh and hardened concrete is required at this stage to enable better understanding of these cements and to enable formulation of national standards on composite cements.

2 Materials and experimentation

The clinker, fly ash, granulated blast furnace slag (GBFS) and gypsum samples collected from the industries were characterized. Fly ash sample was also characterized for physical properties as per requirements in terms of fineness, lime reactivity, cement index and residue on 45 µ sieve as mentioned in IS:3812.

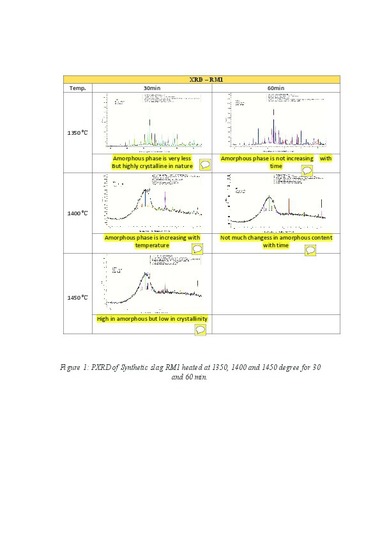

The samples of fly ash and hydrated cements were evaluated for mineralogy and morphology using the X-ray Diffractometer (XRD) and the Scanning Electron Microscope (SEM). XRD studies were carried out using Rigaku International, D-Max 2200 V/PC, Cu Kα radiation, λ=1.5405 Å. The samples were scanned from 2θ= 5 to 65°, with increments of 0.02°. The X-ray tube was operated at an accelerated voltage of 40 kV and current of 30 mA. JEOL 6510 SEM, in the secondary electron mode, was used to carry out morphological studies at an accelerating voltage of 15 kV.

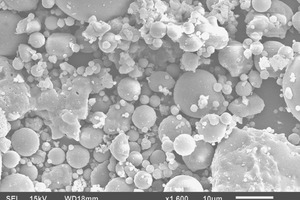

Fly ash has a fineness of 270 m2/kg and 4.6 N/mm² lime reactivity. The glass content in fly ash and GBF slag, estimated by Optical Microscopy, was 43 and 94 percent respectively. The chemical analysis of the above materials is given in Table 1. The purity of the gypsum worked out to be 86.4 %. XRD studies of fly ash indicated the presence of quartz, mullite, hematite phases along with amorphous content. The morphological studies of fly ash by SEM indicated that most of the fly ash particles were in the spherical shape and in agglomerated form besides angular to irregular shaped quartz and hematite particles.

Control ordinary Portland cement (OPC), Portland pozzolana cement (PPC) and Portland slag cement (PSC) were prepared along with cement blends containing OPC clinker (40-60 % by wt.) with different doses of fly ash and GBFS (33-55 %) in various combinations and fineness was maintained at 340+10 m2/kg. The blend compositions are given in Table 2.

3 Results and discussion

Physical performance evaluation of the cement blends was carried out up to 360 days as per relevant Indian Standard and results are given in Table 3. Composite cement samples have shown variation in setting time values, particularly in the initial setting time. However, there was no definite trend observed with respect to increase in fly ash or GBF slag contents. The normal consistency found to be increased with increasing fly ash content in the composite cement samples. The increase in normal consistency may be due to the presence of finer fraction in fly ash, which dominated the ball bearing effect of spherical fly ash particles.

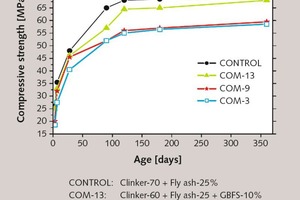

A comparison of the compressive strength values of composite cement samples containing a fixed fly ash content of 25 % and varying GBF slag and clinker content is drawn, given in Figure 1. PPC containing 25 % fly ash content was taken as reference. Reduction in the compressive strength was observed with decrease in clinker content. COM-13, 60 % clinker content, has shown marginally lower compressive strength compared to the reference PPC at initial ages, at later ages the performance is comparable with the reference sample. At 50 % clinker content, COM-9, significant decrease in the compressive strength at all ages is observed. Further reduction in clinker, COM-3 containing 40 % clinker, has not resulted in considerable decrease in compressive strength from compressive strength of COM-9.

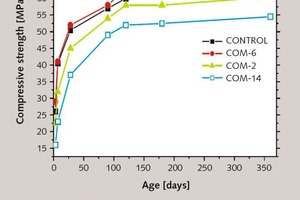

A similar comparison is drawn for the compressive strength of composite cement samples containing fixed GBF slag content of 40 % and varying fly ash and clinker contents, shown in Figure 2. PSC containing 40 % GBF slag was considered as reference. COM-6, containing 50 % clinker and 5 % fly ash, showed better compressive strength development as compared to the reference sample at all ages. Further reduction in clinker content resulted in a decrease in compressive strength. Though the compressive strength development in composite cement samples at initial ages was lower as compared to reference PPC and PSC, there is improvement in the compressive strength at later ages. The reduction in compressive strength values at initial ages may be attributed to the dilution effect, whereas the improvement in strength values at later ages can be due to the synergetic effect of the addition of fly ash and GBF slag together.

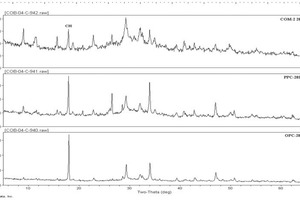

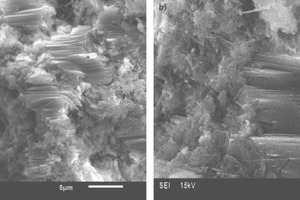

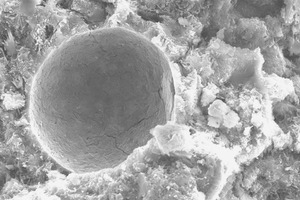

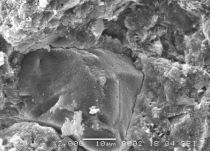

XRD studies of the hydrated samples of OPC, PPC and composite sample COM-2, shown in Figure 3, indicated that the portlandite (CH) content was less in composite samples as compared to OPC and PPC at 28 days of hydration. The factors affecting the CH content in the hydrated samples are the clinker content and pozzolanic activity of fly ash. The broad hump in the XRD patterns of PPC and COM-2 indicated the presence of amorphous content in the samples. The presence of portlandite crystals in 28 day hydrated samples of PPC and COM-2, studied using SEM, is shown in Figure 4. In PPC, portlandite crystals were present as a pack of parallel plate - like structures with preferred orientation.

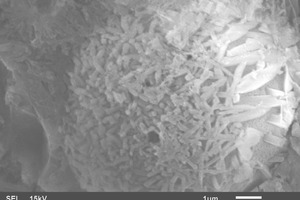

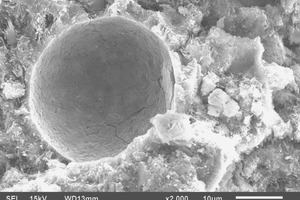

SEM images of fly ash particles at different stages of reaction are shown in Figure 5. Fly ash consists of spherical particles of amorphous nature along with quartz and hematite particles, shown in Figure 5a. Figure 5b shows the partially reacted fly ash, in which the surface of the particle is reacted and needle – like mullite crystals are visible. The completely reacted fly ash particle is shown in Figure 5c, the spherical particle is totally consumed leaving a void space. Dense CSH gel is present around the reacted fly ash particle. The partially or unreacted particles contribute to the filler effect whereas the reacted particles contribute to the formation of additional CSH.

4 Conclusions

Composite cement blends of clinker, fly ash and GBF slag were prepared and evaluated for physical properties and subjected to hydration studies.

The compressive strength values of composite cement blends was marginally lower at the initial ages and improved at later ages compared to the reference samples. The reduction in compressive strength at initial ages may be attributed to the dilution effect and the improvement in strength at later ages was due to the synergetic effect of the addition of fly ash and GBF slag.

XRD and SEM studies of hydrated samples indicated that the portlandite content was less in the composite cement samples compared to reference samples.

Composite cements with a performance equivalent to control PPC or PSC can be prepared by using mix of fly ash and GBFS in the range of 5–35 % and 20–50 % respectively.

Acknowledgement

This paper is based on the R&D work carried out at National Council for Cement and Building Materials (NCB), Ballabgarh, Haryana, India. This paper is published with kind permission of the Director-General, NCB.

//www.ncbindia.com" target="_blank" >www.ncbindia.com:www.ncbindia.com

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.