A review of tertiary cementitious systems: Limestone and fly-ash-based composite cements

The purpose of this literature review is to assist the development of composite cements for better understanding of the state of the art of the use of Portland/limestone/fly-ash cement (PCC). In order to appreciate the environmental benefits of this product, the review was to distill, capture, and summarize the performance characteristics when Portland

Composite Cement is studied. In the finishing mill, the limestone portion is generally more finely ground than clinker, since it has a lower hardness. This results in a higher overall Blaine rating for the product, a typical broadening of the gradation, and a uniform distribution of the limestone particles, resulting in better particle packing. Note that even though the Blaine rating is typically higher, this does not mean that water demand is increased. Early hydration products nucleate on the limestone particles. Additional hydration products above and beyond the calcium-silicates, i.e. carbo-aluminates, form due to reactions between limestone and aluminates, and can provide a synergistic effect when used with supplementary cementitious materials such as fly ash and slag cement. The finishability of concretes made with PLC may be improved due to the improvement in the overall particle packing.

1 Introduction

The construction industry is one of the largest sources of GHG emissions. Around the world, more concrete is used than any other material. About 10 billion t of concrete are laid each year [1-2], with demand expected to rise even further, especially in the developing countries. The production of this enormous quantity of concrete results in a huge environmental impact, primarily due to the cement consumed. The production of one ton (907.185 kg) of Portland cement emits on average 0.87 t of CO2 [3], and the cement industry is thus responsible for around 7% of total current global...

1 Introduction

The construction industry is one of the largest sources of GHG emissions. Around the world, more concrete is used than any other material. About 10 billion t of concrete are laid each year [1-2], with demand expected to rise even further, especially in the developing countries. The production of this enormous quantity of concrete results in a huge environmental impact, primarily due to the cement consumed. The production of one ton (907.185 kg) of Portland cement emits on average 0.87 t of CO2 [3], and the cement industry is thus responsible for around 7% of total current global man-made CO2 emissions [4]. For this reason, the International Energy Agency (IEA) and the World Business Council for Sustainable Development (WBCSD) in 2009 established a Cement Technology Roadmap [5]. Along with thermal and electric efficiency, waste-heat recovery, the use of alternative fuels and carbon capture and storage (CCS), clinker replacement is one of the cement industry’s five main strategies for reducing CO2 emissions. Replacing clinker with supplementary cementitious materials (SCMs) is a compelling solution; it is technically feasible and is (unlike CSS technology) immediately practicable to reduce the environmental impact of concrete production. Clinker is usually replaced with byproducts such as ground granulated blast-furnace slag (GGBFS; from the iron and steel industry) and/or fly ash (from coal-fired power stations). Other substitutes include: natural pozzolans (e.g. volcanic ash), rice husk ash, silica fume, artificial pozzolans (e.g. calcined clay) and limestone. It should be noted that there are large regional variations. In most European countries, clinker substitutes are directly blended into the cement, whereas in the US and Canada they are typically added at the concrete-making stage [6]. The development of binary and ternary cements has progressed rapidly in recent decades. There is a trend to increase the replacement levels of clinker and to optimize different combinations of cementitious materials [7]. Limestone filler is readily available, whereas there is uncertainty concerning the future availability of slag and fly ash. As highlighted by Snellings [8], supply concerns about conventional high-quality SCMs are rising and alternative sources of SCMs, such as calcined clays, are now subject to increasingly more research [9]. Slag and fly ash are characterized by pozzolanic reactivity which contributes to long-term strength, while small additions of limestone filler could have a beneficial effect on the early-age properties of mortar and concrete [10, 11]. Ternary mixes are particularly interesting, since they potentially combine these contradictory properties of limestone filler at an early age and of slag or fly ash at a later age [12]. The objective of this literature review is to understand the properties of composite cement in cement mortar and concrete in the presence of limestone and fly ash together with clinker.

1.1 Limestone in international cement standards

The use of up to 5% ground limestone in Portland cement has been permitted by the Canadian cement standard since the early 1980s. Limestone is also permitted in European standard EN 197, Part 1 (CEN 2000), which allows cements to contain limestone at three different input levels. CEM I, “Portland cement”, may contain up to 5% minor additional constituents, limestone being one possibility. CEM II/A-L and CEM II/B-L, both designated “Portland-limestone cement”, contain 6% to 20% and 21% to 35% ground limestone, respectively. Roughly 19% of all cement sold in Europe contains between 6% and 35% limestone (Cembureau 2001). A review of “Cement Standards of the World”(Cembureau 1991) shows that more than twenty-five countries allow the use of between 1% and 5% limestone in their P (“Portland”) cements. Many countries also allow up to 35% replacement in PB (“Portland composite”) cements. Since 1991, the date of the latest edition of “Cement Standards of the World”, several countries, including Australia, Italy, New Zealand and the United Kingdom, have modified their standards to permit a limestone content [13].

2 Literature review

Syad Ali Rizawan et al. [14] studied the optimum replacement level of OPC by fly ash & limestone powder in self-consolidating paste systems (SCP). They observed that the limestone-powder-based SCP systems exhibit high early strength but lower twenty-eight day strengths. Blended FA and LSP complemented each other with the enhancement of flow properties in SCPs, yielding significantly higher twenty-eight day compressive strengths. According to this study, up to 20% by mass of OPC can be replaced when limestone powder and fly ash are used separately in SCPs, while the combination of limestone and fly ash can replace OPC up to 30% in SCPs without sacrificing initial and later-age strengths.

Bülent Yılmaz and Asım Olgun [15] investigated the effects of low-calcium fly ash (FA), limestone (LS) and dolomitic limestone (DLS) on the properties of cement and mortar. The binders were prepared by Portland cement (OPC), fly-ash/Portland cement (FA-OPC), FA-LS-OPC, and FA-DLS-OPC with a maximum PC replacement level of 40%, FA level of up to 40%, LS and DLS levels of up to 15%. Yılmaz and Olgun report that FA, LS and DLS prolong the setting time of the cements. The FA-OPC system shows decrement in the expansion as the fly-ash content of the cement increases with the comparison of OPC. In ternary systems, FA-DLS-OPC causes a marked decline in the expansion of the specimens tested.

Nastasia Saca and Maria Georgescu [16] investigated the behavior of ternary blended cements containing limestone filler and fly ash added to 5% magnesium sulfate solution. They noted that the presence of both limestone and fly ash in cement appears not to decrease the vulnerability of cements to magnesium sulfate attack at 5 °C in comparison with limestone filler or fly-ash cements. After 90 d, compressive strengths decrease in all specimens (from 33.5 MPa to 16.4 MPa in Portland cement mortar and from 35 MPa to 13.8 MPa in 10% fly-ash cement mortar) as a consequence of higher amounts of deterioration products which exert pressure in the capillary pores.

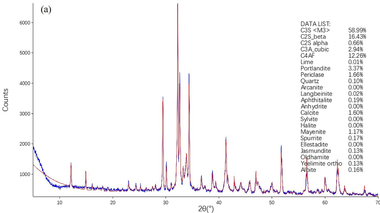

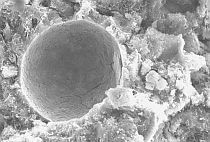

Klaartje De Weerdt et al. [17] studied the hydration mechanisms of ternary Portland cements containing limestone powder and fly ash and report the effect of minor additions of limestone powder on the properties of fly-ash-blended cements. The investigations were performed using isothermal calorimetry, thermogravimetry (TGA), X-ray diffractometry (XRD), scanning electron microscopy (SEM) and pore-solution analysis. According to their investigations, the presence of limestone powder resulted in the development of hemi and mono carboaluminate and in stabilization of ettringite as against cement with no addition of limestone, in which part of the ettringite is converted to monosulphate. Thus the presence of 5% limestone results in the expansion of the volume of the hydrates, as is apparent in the increase in chemical shrinkage and a rise in compressive strength. This effect was enhanced in the fly-ash/limestone blended cements, due to the additional alumina supplied by the fly-ash reaction.

Maria Georgescu, Nastasia Saca [18] studied the properties of blended cements with limestone-filler and fly ash contents. They reported a significant shortening in setting times in the blended cements compared to Portland cement. The reductions in setting times were greater in cements with higher fly-ash contents (20-30%). The presence of the limestone filler in the cement causes significant loss of mechanical strength compared to the control mix, especially as time progresses (28-360 d), as a consequence of the dilution effect of the active component in the binder. These researchers conclude that the decrease in mechanical strength associated with the presence of the limestone filler in the cement is, after 360 d, similar to that resulting from contents of 20-30% fly ash; this was ascertained by comparing the mechanical strengths of the cements with same levels of clinker replacement.

I. Elkhadiri et al. [19] studied the mechanical behaviour of various mortars prepared using both fly ash and limestone in Moroccan Portland cement and reported that the fly ash acts as grinding agent with comparison of grinding time at constant residue on a 80-mm sieve. The intergrinding of clinker with fly ash and limestone indicates that there is an optimum input level at around 77% clinker, 2% gypsum, 7.5% fly ash, 13% limestone, which produces a packing structure for mixtures and good mechanical properties.

K. De Weerdt et al. [20] studied the hydration mechanisms of ternary Portland cements containing limestone powder and fly ash and report that up to 5% limestone powder can have a beneficial effect on the compressive strength of OPC. They observed that the positive effect of limestone powder cannot be attributed only to a physical effect resulting from the presence of 5% limestone (additional nucleation sites and higher effective water-to-cement ratio), as after longer hydration times no significant differences in the amount of clinker or fly ash consumption were observed between limestone-containing and limestone-free blends. The effect of limestone powder on the hydration of OPC and limestone-containing OPC-FA systems indicated that this was mainly caused by its interaction with the hydration products formed. Initial days, (At 1) the hydrates products for OPC and OPC-FA are similar, those are C-S-H, Portlandite, ettringite. OPC-FA and limestone contain OPC-FA system shows difference in the amount of AFm and AFt phases. The hydration products clearly show that, in the absence of limestone powder, ettringite decomposes to monosulphate, and on the other hand, in the presence of calcium carbonate - the main constituent of limestone powder - the decomposition of ettringite to monosulphate is prevented because monosulphate is rendered unstable and instead, as is observed, calcium mono- or hemicarboaluminate is formed.

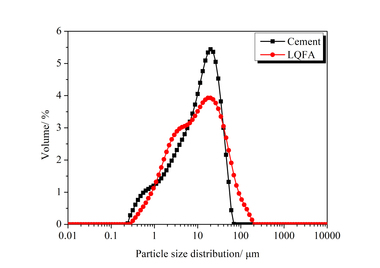

Kirk Vance et al. [21] studied the hydration and strength development in ternary Portland cement blends containing limestone and fly ash or metakaolin. Their investigations indicated that limestone particle size and the type of material used for partial replacement influences hydration and the mechanical properties of cement pastes. Limestone powders with a median particle size of 0.7, 3, and 15 μm, at OPC-replacement levels of between 0% and 20% (by volume), and two other replacement materials of differing reactivity (i.e. Class F fly ash or metakaolin) at replacement levels of between 0% and 10% (by volume), are used to prepare ternary blends. They observed that the fine limestone accelerates early-age hydration, resulting in comparable or better one-day compressive strengths, and higher calcium hydroxide (CH) contents as compared to pure cement pastes. The assimilation of metakaolin in conjunction with limestone powder influences the heat-release (i.e. kinetic) response significantly. It is shown that the synergistic effects of limestone and metakaolin assimilation result in improved properties at early ages, while retaining later-age properties comparable to that of traditional OPC systems.

Yong Zhang and Guang Ye [22] studied the effects of limestone powder on the microstructure of ternary cementitious systems and report that limestone powder reacts with aluminate-containing phases and results in the development of carboaluminate in the cementitious system; monosulfoaluminate was not found as expected The porosity and pore size of hydrated cement pastes were expanded compared to control cement pastes. They observed that the reactivity of carbonate is extremely dependent on the content of alumina phases in cementitious systems. The addition of limestone powder may enhance the pozzolanic reaction of fly ash due to the accelerated generation of CH at an early age. In view of these characteristics, the better mechanical behaviour in the presence of limestone powder at 28 d could be attributed more to the filling effect of unreacted limestone and the reaction products of carboaluminate which filled the large capillary pores of cementitious systems.

Kim-Séang Lauch et al. [23] studied the use of ternary cements to reduce the environmental impact of concrete and report that concretes made with ternary cements, up to 30% limestone filler and 20% slag or fly ash, exhibit good accordance regarding resistance to chloride diffusion and sulfate attack. For carbonation and freeze-thaw tests, and also for compressive strength, the presence of limestone filler has a negative effect when its percentage exceeds 25%. The investigations conducted by Kim-Séang Lauch et al. suggest that curing has an influence on the performance of ternary cements and the authors recommend a long curing period for such composite blends.

Barbara Lothenbach et al. [24] studied the influence of limestone on the hydration of Portland cements and report that blending of Portland cement with limestone not only accelerates the initial hydration reaction but also influences the hydrate assemblage of the hydrating cement pastes. Barbara Lothenbach et al. performed their study on the basis of thermodynamic calculations and experimental products and concluded that the presence of limestone causes the formation of monocarbonate rather than monosulfate at room temperatures.

Krittiya Kaewmanee and Somnuk Tangtermsirikul [25] studied the properties of binder systems containing cement, fly ash and limestone powder as unary (“simple”), binary and ternary binder systems. Researchers noted that the gain in early strength is observable when 10% of the limestone powder has an average particle diameter (d50) of 2 mm. In addition, the combination of fly ash and limestone powder in a ternary binder system exhibits performance of a satisfactory level and superior performance to that of a single-component binder system containing only cement. The use of more than one type of cement-replacing material in concrete is highly attractive because this is the optimum way to fully exploit the benefits of each particular type of cement-replacing material.

Pailyn Thongsanitgarn et al. [26] studied the hydration and compressive strength of blended cement containing fly ash and limestone as a cement replacement and report that the heat of hydration of binary cement containing fly ash is delayed and lower compared to the control cement. However, they also observed that the hydration rate of fly-ash cement can be accelerated when limestone is incorporated to make a ternary blended cement. Thermogravimetric analysis confirmed the improved reactivity of ternary blended cement. DTG curves of all blended cement pastes hydrated indicated at 28 d hydration products such as mono-carboaluminate, ettringite, calcium silicate hydrate, and Portlandite. They correlated the hydration products of the ternary cements for higher compressive strength in PC-FA-LS ternary blended cement mortars when compared to binary fly-ash cement mortar.

3 Observations

The production of composite cements, of combined Portland cement / limestone / fly-ash type, i.e. ternary blended cements, promises in particular the following benefits:

Ecological – the reduction of toxic-gas emissions, as a result of the diminution of the “clinker factor” and of the recovery of the fly ash

Economic – reduction of cement production and marketing costs

Technical – improvement of certain properties of pastes, mortars and concretes

Due to the complex action – both physical and chemical – the limestone filler and the fly ash, added either separately or together, induce changes in the hydration/hydrolysis processes, in physical and mechanical properties and in concrete durability.

Limestone is a readily available material

The benefits of limestone for the engineering properties of cement and concrete are widely acknowledged

In China, mixtures of lime and fly ash have been widely used as masonry cement and for the production of blocks since the late 1950s

The EU standard (EN 197, Part 1) permits ternary cement compositions containing fly ash and limestone

Ternary mixes are particularly interesting, due to their combination of contradictory properties, of limestone filler at early age and fly ash at later age

Minor replacements of fly ash by limestone powder appear to have a beneficial effect on the strength development of the ternary blended cements tested whether there is also chemical effect; limestone powder was replaced with crystalline quartz powder of a similar particle-size distribution to simulate the physical effect of the limestone

Ternary compositions containing fly ash and limestone demonstrate the feasibility of reducing CO2 emissions

Several studies have investigated the synergetic action of fly ash and limestone

OPC can be replaced by limestone and fly ash

Fly-ash and limestone-containing exhibit packing structure and good mechanical properties

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.