Physical and mechanical properties of composite cements

Summary: This paper reports on the results of an experimental study conducted to evaluate the physical properties and strength development of composite cements manufactured with a steel slag (SS) and blast-furnace slag (BFS) combination. The influence of the proportions and fineness of the slag on the compressive strength of the cement blends are presented. Test results showed that the physical properties of the composite Portland cement series were affected by the BFS-SS substitution. The BFS-SS combination used for replacement gave better results when they were ground finer than the Portland cement clinker. The increase in Blaine fineness of the BFS-SS combination had a positive effect on the compressive strength. The substitution ratio can be raised to 60 to 80 % provided the slag fineness value is 4600 cm2/g.

Reuse of some industrial waste materials has become very important during the past decade because of environmental regulations that require waste disposal minimization [1]. Granulated blast-furnace slag (GBFS) and fly ash can be accepted as important materials for this type of utilization [2].

Blast-furnace slag cement has been traditionally produced by intergrinding cement clinker with slag in tube mills or grinding clinker and slag separately [2]. This concept also brought with it the possibility of using various slags with different mix ratios. Basic oxygen furnace (BOF) slag...

Reuse of some industrial waste materials has become very important during the past decade because of environmental regulations that require waste disposal minimization [1]. Granulated blast-furnace slag (GBFS) and fly ash can be accepted as important materials for this type of utilization [2].

Blast-furnace slag cement has been traditionally produced by intergrinding cement clinker with slag in tube mills or grinding clinker and slag separately [2]. This concept also brought with it the possibility of using various slags with different mix ratios. Basic oxygen furnace (BOF) slag results from the steel-refining process in a conversion furnace. In general, BOF slag is also called steel slag (SS) and it can be used to substitute partially as clinker for producing Composite Portland Cement (CPC) [3].

Reports on the utilization of both BFS and SS for producing CPC are not very frequent. SS consists of calcium silicates and ferrite with oxides of aluminium, manganese, calcium and magnesium [4]. The mineralogical composition of SS changes with its chemical composition. Olivine, merwinite, C3S, C2S, C4AF, C2F, RO phase (CaO-FeO-MnO-MgO solid solution) and free-CaO are common minerals in steel slag. The presence of C3S, C2S, C4AF and C2F endorses steel slag cementitious properties [5].

Chemically SS is a very inert material. Geiseler [6] and Motz and Geiseler [7] have concluded that the release of elements from BOF slag have insignificant environmental impact. On the other hand, chromium is a redox active metal that persists as either Cr(III) or Cr(VI) in the environment. These two oxidation states have opposite toxicity and mobility properties. Hexavalent chromium is very toxic and readily transported. Trivalent chromium is an essential nutriment at low amounts and a marginally toxic element at higher content and is mostly insoluble in water [1]. The EU Directive, 2003/53/EC, restricts the marketing and use of cement and cement-based preparations, when hydrated, to more than 0.0002 % chromium VI of the dry weight of cement. Therefore there is a need to reduce the contribution to chromium levels in the cement [8]. The addition of ferrous sulfate is currently the most widely used technology available to achieve a content of chromium VI less than 0.0002 %. BFS can be used in the stabilization of heavy metals such as chromium. Giergiczny and Krol [9] have stated that immobilization of heavy metals (Pb, Cu, Cr, Zn, Cd, Mn) is effected by the composition of solidifying binder and time of maturing. Especially the binders with high ground GBFS content (85 %) is as effective as Portland cement itself. They concluded that the level of Cr+6 ions immobilization varies from 91.32 % to 99.46 %.

Many investigations were performed using SS as an industrial raw material [10–13]. SS was mainly used as a bulk material, asphalt aggregate, filling material, cement raw feed, railroad ballast, and in agriculture worldwide. Today about 65 % of the SS produced are used in qualified fields of application. The remaining 35 % of these slags are still dumped.

It will need further intensive research work to decrease this rate as far as possible [7]. The SS used in this study is a by-product of BOF. 100-150 kg slag is co-produced during 1000 kg steel production [14]. 12 million t BOF slag per year is produced in Europe [7]. Alone 8 million t steel slag was stored at the Ereg˘li Iron & Steel Plant in Turkey. This huge amount of slag storage should be evaluated for sustainable development. It was known that when BOF slag was used alone in cement as a mineral admixture, it caused unwanted expansions and cracks in concrete. However a combined usage of BFS and SS could reduce such harmful expansions and cracks.

Ground granulated blast-furnace slag, a kind of industrial by-product, has been used since the 1940s either as a component of blended cement or partial replacement of Portland cement. Researchers have been investigating various properties of concrete containing some by-products and waste materials such as granulated blast-furnace slag, FA, bottom ash (BA), silica fume (SF), waste glass (WG) as a mineral admixture, aggregate replacement or binding material [15]. Ground BFS is used as an admixture in concrete or as an additive in the manufacture of Portland slag cements in countries where large amounts of BFS are available as a by-product. A great deal of research work has been carried out to date on the hydraulic binding properties of ground BFS and the durability of concrete containing BFS. Alkali silica reactivity, resistance to chloride penetration, freezing and de-icing salt resistance can be shown as examples of such durability characteristics [16].

The overall objective of this work was to determine whether a combination of SS and BFS might be processed into a sufficiently cementitious material to produce CPC. Some physical properties and strength development of CPC manufactured with a combination of SS and BFS were evaluated. The influence of slag proportions and fineness of slag on compressive strength of CPC were presented.

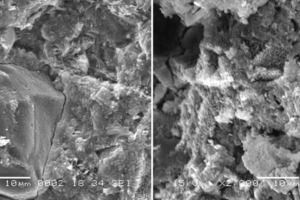

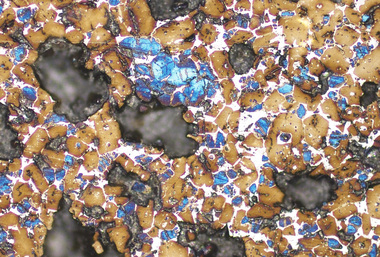

Ordinary Portland cement (CEM I 42.5 N) complying with TS EN 197-1 was used throughout the investigation. SS and BFS were obtained from the Ereg˘li Iron & Steel Works Factory (ERDEMIR) in Turkey. SS was obtained in the non-ground form and BFS was in the granulated form. The hardness of SS is about 6.5-7.0 in the Mohs scale. Chemical compositions of these materials were shown in Table 1. A magnetic separation process was applied on SS in the ERDEMIR to reduce the iron content. XRD pattern of an SS sample after magnetic separation process was shown in Figure 1 [17]. CEN standard sand was used to produce mortar specimens. The chemical composition and particle size distribution of the standard sand were presented in Table 2.

BFS and SS were ground separately in a ball mill to a specific surface area of about 2500 cm2/g Blaine fineness. Since the grindabilities of BFS and SS are different to each other BFS was ground for 4 h and SS was ground for 3 h. In one case, a 10 kg specimen was ground with a 30 kg ball. Subsequently, 70 % BFS and 30 % SS were blended and ground for about one hour until the combination reached 3400–3500 cm2/g Blaine fineness. Finally, an intergrinding process was applied to the PCC, BFS and SS. As a result the S1, S2 and S3 series were ground to 3800, 4200 and 4600 g/cm3 Blaine fineness respectively. Photographs of the ground materials are shown in Figure 2.

A combination of 30 % SS and 70 % BFS was used as cement replacement in the production of mortar specimens. Four main groups of composite cement were prepared. The first main group (S0) was the reference group and consisted of normal Portland cement at 3400 cm2/g fineness value. The second group (S1) has 3800 cm2/g, the third group (S2) has 4200 cm2/g

and the fourth group (S3) has 4600 cm2/g Blaine fineness value and all of them consist of a BFS-SS combination. The Portland cement clinker was replaced by a slag combination at proportions of 20 %, 40 %, 60 % and 80 % in every main group, except the reference group. The mixture details are shown in Table 3. Cement: sand: water proportion was chosen as 1:3:0.5. For a compressive strength test, three specimens were produced for each test according to the procedure given in TS-EN 196-1. The size of the specimen was 40 x 40 x 160 mm originally. After these specimens had been kept in their moulds for 24 h at 20 °C room temperature, they were then removed from the moulds and placed in water at 20 ± 2 °C temperature.

Compression tests on the 7., 28. .and 90. day were conducted on the mortar specimens. The specimens which were prepared for the 7. and 28. day tests were removed from the water bath on the day of the experiment. Since the bending test was not included, each specimen was cut into three equal sections for the compression test. The average value of the compressive strength obtained from these 3 prisms was taken into consideration. The specimens were loaded uniaxially until failure. The specimens which were prepared for the 90. day tests were kept in a humidity room with relative humidity of 60–70 % after the

28. day until the 90. On the 90. day the compressive strength was determined as with the other specimens. The specific weights of the cements produced were determined in accordance with TS-EN 196-6. Setting times and the volumetric expansion values of the cements were determined in accordance with

TS-EN 196-3.

The specific weights, setting times and the expansion values of the cements were shown in Table 4. As an expected result, the specific weights of the cement groups showed a gradual decrease trend with the increases in BFS-SS replacement in all series. The bulk unit weight of the SS was changing between 2000 and 2800 kg/m3. Also the specific weight of the BFS was smaller than that of Portland cement clinker. Therefore, as the replacement ratio increases the specific weight of the CPC series also decreases. The effect of the BFS-SS replacement on the initial and final setting times can be clearly observed. Initial and final setting times were greater than those of the S0 group which was the reference group. However, there were no considerable changes among the S1, S2, and S3 series. The mix proportions of these series were the same, but the Blaine fineness values were different in these series. Therefore 20 % BFS and SS combination is sufficient to retard setting times with respect to the S0 series. The MgO and Al2O3 content of the replacement materials may be the reason for the slowing of the reaction [18–19]. It was observed that the SS increases volumetric expansion of mortar specimens.

The amounts of free CaO and MgO in the SS were of immense importance for the volumetric expansion. The reaction of both oxides with water has an effect on the volume fixation [18–19]. Furthermore it was also observed that the cement fineness also increased the volumetric expansion. Özkan [19] showed that the composite cement including 70 % PCC and 30 % SS has a maximum of 2 mm volumetric expansion. However the maximum allowable volumetric expansion value in TS EN 196-3 was 10 mm. Therefore composite cements incorporating granulated BFS and SS mixtures conform to TS EN 196-3. The influence of the SS on the colour of mortar specimens was insignificant. The mortar specimens are shown in Figure 3. Since the colour of the clinker and the BFS-SS combination are similar, then the colour of the mortar series is also similar to the colour of mortar series produced with the clinker.

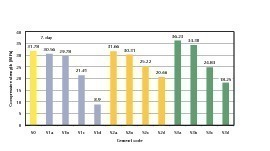

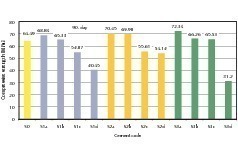

Compressive strength values of the mortar specimens on the 7. day are shown in Figure 4. The general tendency observed in the S1, S2 and S3 series was that as the Portland cement clinker proportion reduced, the compressive strength reduced. Although the decrease ratios were very low for the high values (60–80 %) of the Portland cement clinkers, dramatic decreases were observed for the low values (20–40 %) of the Portland cement clinkers. High decreases of strength in the early ages such as the 7. day should be considered normal for the low values (20–40 %) of the Portland cement clinkers (especially in the S1 series). SS and BFS are known to be slower than Portland cement clinker for showing their pozzolanic effect. While the compressive strength in the S1d group was only 28 % of the reference group, these ratios increased to 65 % and 57 % in the S2d and S3d groups as the fineness values increased. This proves that the fineness of cement has a significant effect on the strength of the mortar specimens. While the results obtained from the S1 group with 3800 g/cm2 fineness are lower than the reference cement, the results of the S2 group with 4200 g/cm2 fineness are close to the reference cement values and also the 40 % BFS-SS replacement in the S3 group with 4600 g/cm2 fineness has given higher results than the reference cement.

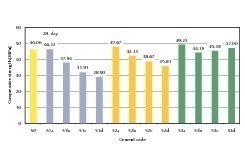

The compressive strength of the 28. day mortar specimens

are shown in Figure 5. A 45 % increase was observed in the 28. day strength in the reference mortar as compared to the 7. day strength result. The S1d group which had very low compressive strength on the 7. day was observed to progress to an increase of 225 % on the 28. day when compared with the seven day compressive strength. As BFS-SS content increases, compressive strength reductions of the S2 and S3 series on the 28. day were not very high as compared to strength reductions observed on the 7. day. However 37.5 % strength reduction was observed in the S1d group with respect to the S1a group in the S1 series. The reason for this result is related to the Blaine fineness of the cement. The S1 series has a relatively low fineness value as compared with the S2 and S3 series. Although the strength reduces until the Portland cement clinker ratio reduces to 40 % in 28. day strength of S3 series a re-increase in the strength was observed for 40 % and 20 % clinker ratios. Since the fineness value was the only difference between the S3 series and the other series, consequently, it should play a role in the appearance of this outcome. As the fineness value increases, losses in compressive strength reduce or partial increases were observed. As a result, the S3 series showed the best performance of all the series for the 28. day compressive strengths of mortars. In the ratios (S3b and S3c groups) of 60 % and 40 % Portland cement clinker, the strength was detected to be lower (4.1 % for S3b) than the compressive strength of the reference mortar. However in the S3a and S3d groups the compressive strength reached higher values when compared to the strength of the reference mortar. The strength of the S3a group is 6.9 % higher than the strength of the reference mortar. Similar results were reported in the literature. Al-Rawas and others [20] concluded that higher strength values were obtained at 14 and 28 days curing periods for 20 % replacement ratio when incinerator ash with a Blaine fineness of 4300 cm2 /g was used as a substitute for cement. Xuequan and others [3] also concluded that the fineness of cement is an important factor for utilization of SS for producing composite Portland cement.

The compressive strengths of the 90. day mortar specimens are shown in Figure 6. The compressive strengths measured on the 90. day underline the effect of the Blaine fineness of cement and the age of mortar. There are only 2 groups with higher strength than S0 in Figure 4 which shows the 7. day compressive strength. The number of groups having higher strength than S0 (reference group) are 4 and 7 for the Figure 5 and Figure 6. Although the compressive strength progressed slowly at an early stage (7. day), in the long term (90. day) this situation altered. The reason was that the cements with BFS and SS react slowly and their compressive strength increases as the mortar age progresses. In general, the pozzolans require calcium hydroxide while they are reacting chemically. They use the calcium hydroxide that is a hydration product of Portland cement clinker. In the composite cements the existing clinker reacts chemically at first, and then the pozzolans react by using the calcium hydroxide generated by the clinker reaction. This is the reason why the advantages of the pozzolans appear so late in comparison to normal cement.

The physical properties of the CPC series were affected by the BFS-SS substitution. As the BFS-SS combination replacement ratio increases the specific weight of the CPC series decreases. As the BFS-SS combination replacement ratio increases, the volumetric expansion of the CPC series increases. However the increased values are still below the allowed limits given in the standard. Similar results were observed as regards the setting times.

The fineness of the BFS-SS combination was found to be more critical than that of the PCC. As the fineness of the BFS-SS combination was kept constant, the increasing amount of BFS-SS combination had a detrimental effect on the strength development of the mortars. However, grinding BFS-SS combination finer than the PCC was shown to have a positive effect on the compressive strength development of the mortars. The early strength development of the composite cement mortars was not good enough as compared to mortars produced with Portland cement. However this temporary situation was eliminated when the strength developments at 28 and 90 days were considered. Regarding the compressive strength, the PCC ratio can be reduced to 60 % and the BFS-SS combination can be substituted in the remaining portion of 40 % for fineness values of 4200 cm2/g or lower. The substitution ratio can be raised to 60 % to 80 % provided the slag fineness value is raised to 4600 cm2/g. The required compressive strength can be maintained by raising the BFS-SS replacement, with the increase in the setting times, and the decrease in specific weight.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

![1 XRD pattern of SS after magnetic separation [17]](https://www.zkg-online.info/imgs/tok_416f0beaad5d90f2f8e7211c8c601ce0/w293_h175_x146_y87_101521483_dd37599967.jpg)