Development of composite cements characterized by low environmental footprint and appreciable performance

This contribution reports on the optimization of the multicomponent CEM II/C-M (S-LL) cement, a cement type which is intended to be introduced with a revised version of the EN 197-1. The replacement of Portland cement clinker has been maximized by a combination of granulated blast-furnace slag and limestone while meeting an adequate cement performance and minimizing its environmental impact.

1 Introduction

The partial replacement of Portland cement clinker by supplementary cementitious materials (SCM) is more and more in the focus of cement research. The main reason for this development is the potential to limit the CO2 emission associated with the production of Portland cement clinker [1]. The availability of highly reactive main constituents in accordance with EN 197-1, e.g. of granulated blast-furnace slag, are limited to meet the demand of only about 20 wt.-% of global cement production and are unlikely to increase [1]. The application of another well-known SCM, limestone, is...

1 Introduction

The partial replacement of Portland cement clinker by supplementary cementitious materials (SCM) is more and more in the focus of cement research. The main reason for this development is the potential to limit the CO2 emission associated with the production of Portland cement clinker [1]. The availability of highly reactive main constituents in accordance with EN 197-1, e.g. of granulated blast-furnace slag, are limited to meet the demand of only about 20 wt.-% of global cement production and are unlikely to increase [1]. The application of another well-known SCM, limestone, is limited because of its small contribution to the cement performance [2]. However, the smart combination of several SCMs provides the possibility not only to limit the clinker content in the composite cement but allows for further improvement of the cement and concrete performance. Following that road, the European Commission funded a research program [16] aiming at understanding of the parameters that allow maximization of the cement clinker replacement by combinations of slag and limestone while meeting both adequate cement performance and minimizing its environmental impact. Based on the understanding of the cement hydration and performance development, a modelling tool was developed for this purpose allowing predictions of the compressive strength evolution depending on the starting cement composition and curing time. Furthermore, the tool allows the calculation of the effective global warming potential of the composite cements. This finally enables definition of the optimal cement composition characterized by high performance and at the same time with low environmental impact.

This paper reports on the modelling framework, its basic fundaments and assumptions. Furthermore, the modelling results are verified by the laboratory testing of composite cements.

2 Materials and composition

Composite cements with a broad range of compositions from 50 – 100 wt.-% of cement clinker, 0 – 50 wt.-% of granulated blast-furnace slag (GBFS) and 0 – 50 wt.-% of limestone (Figure 1) were virtually investigated. Composite cements were obtained from cement clinker, GBFS and natural limestone. All these materials were characterized by compositions typical for the European markets [3]. For the calculations it was assumed that the slag and limestone contain only glassy phase and calcite, respectively. The overall SO3 level was set to 2.75 % by adding calcium sulphate (anhydrite).

3 The model

The optimization procedure applied within this work comprises several models. Results obtained at each calculation step provide the input for the next step.

The modelling of the compressive strength evolution as a function of the cement composition and time is based on the following [4, 5]:

Definition of the composite cement composition, including the composition of the clinker and supplementary cementitious materials

Calculation of the reactive phases dissolution kinetics

Thermodynamic calculations using a consistent thermodynamic dataset to predict the porosity

Calculation of the compressive strength based on the predicted porosity

Consequently, the global warming potential of the investigated composite cements was compared to the calculated compressive strength to verify the “environmental efficiency” of the investigated systems. The details of the modelling approach are provided in [6].

3.1 Results of the modelling

The modelling approach adopted enables establishing of the correlation between the cement performances, kinetics of the hydration, formed microstructure and resulting performance.

When reacting, multicomponent composite cements are characterized by complex interactions between their constituents. The cement clinker reacts as the first cement component. The reaction produces several hydrates that are filling the space initially occupied by mixing water and the cement clinker itself. Additionally, the reaction releases alkalis and calcium to the pore solution that in turn activates the reaction of the slag. The reaction of slag results in the precipitation mainly of the C-S-H phase, the AFm phases and hydrotalcite. This reaction modifies further the porosity of the system. It is important to notice that the reaction of slag has a significant back-impact on the reaction of clinker. At later hydration times the clinker reaction is slowed down. Furthermore, calcite from limestone reacts with the available alumina from the clinker and slag to form monocarboaluminate phases instead of the monosulfoaluminate phase present in cements without limestone. This results in ettringite stabilization and decrease of total pore volume.

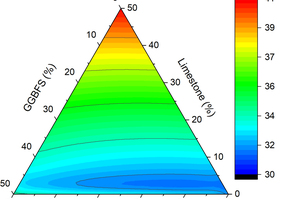

The adopted modelling method fully describes these interactions and correctly describes the phase assemblage at different hydration times. Consequently the prediction of the pore volume is possible (Figure 2).

The resulting porosity is plotted in Figure 2. The lowest porosity is calculated for the systems rich in clinker and slag. The positive effect of calcite and alumina bearing phases [3, 7, 8, 9] is visible; the lowest porosity is registered for the samples characterized by about 5 wt.-% of limestone and up to 30 wt.-% of slag. Increasing the slag content to more than 30 wt.-% results in an increase of the porosity. This indicates that the increasing C-S-H volume is not able to compensate for the decrease of other hydrates.

3.2 Compressive strength

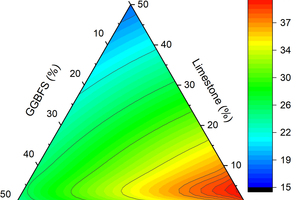

The predicted compressive strength at 7 and 28 days of hydration is shown in Figures 3 and 4. The compressive strength at early times is depending mainly on the cement clinker while other cement components have little impact: the higher the clinker content in the cement, the higher the compressive strength. This phenomenon is related to the kinetics of the reaction of the different materials. The clinker phases (particularly C3S and C3A) react faster than slag. Thus, at early hydration times, mainly the reaction of the clinker contributes to the formation of the microstructure and resulting compressive strength. However, it is noticeable that already at that time some small presence of limestone has a positive impact on the compressive strength according to the mechanisms described above [8]

At 28 days of hydration, the contribution of slag is clearly pronounced. The highest compressive strength is visible for the cements containing up to 30 wt.-% of slag. A further increase of slag content results in a reduction of the compressive strength since the relatively low reaction degree of slag at 28 days is not able to compensate for the dilution of the cement clinker.

3.3 CO2 balance (global warming potential)

The potential to reduce the CO2 emission associated with the cement production was evaluated using a simplified analysis. The CO2 emissions associated with the materials were taken from The Cement Sustainability Initiative WBCSD-CSI [10] tool for EPDs of concrete and cement (v1.4) [11], based on Eco invent (v3.3) [12].

The emission associated with the clinker production was calculated to be 799 kgCO2/tclinker. For the slag, assumptions for granulation, transport, drying and grinding were made. The emission associated with the ready-to-use slag was calculated to be 85 kgCO2/tslag. In the case of limestone ready to use for cement production, process related emissions from transport and grinding (10 kWh/t) were calculated to be 8 kgCO2/tlimestone. The mixing of components as well as the quarrying and grinding of the calcium sulfate were not assumed in the calculation.

The graph shows the principle concept of the CO2 reduction in relation to the clinker replacement by SCMs. Since the global warming potential for the clinker is significantly higher than for the slag and limestone, the replacement of the clinker by the both SCMs enables a significant reduction of the emissions.

The effective global warming potential was calculated as the global warming potential in kg of CO2 that needs to be emitted to produce the cement of a given compressive strength:

where GWPEff is the effective global warming potential, GWP is the warming potential of the cement of a given composition (Figure 5) and Rc(t) is the calculated compressive strength for a given cement composition at a given hydration time (Figure 3 and 4). The results of these calculations are shown in Figure 6.

From the result in Figure 6 it is noticeable that the effective global warming potential is the lowest for systems characterized by a high slag and limestone content at all hydration times.

Slag is associated with a low global warming potential and contributes to the compressive strength significantly. Despite the fact that limestone does not contribute significantly to the strength, it significantly reduces the GWP of cement. Consequently, it has a substantial impact on the GWPEff.

A very high limestone content (> 25 %) results in a very strong reduction of the compressive strength and the GWPEff is similar to the pure Portland cement or even higher.

Consequently, there is an optimal content of the limestone from the perspective of GWP over strength evolution. Increasing the slag content at the adopted scenarios always results in the reduction of the GWPEff.

4 Performance of the optimal cement compositions in concrete

In order to verify the performance of the composite cements the laboratory blended cements were tested in concrete. It is noticeable that the currently available modelling tools do not allow preditction of the concrete durability properties. Consequently, the purpose of this part of the work was to experimentally verify if the composite cements described above are characterized by a satisfactory performance in concrete.

The tested cements are characterized by a clinker replacement ratio of 60 and 50 wt.-%, respectively, and contain 10 wt.-% of limestone. These blends are the most effective with respect to the effective global warming potential (Figure 6) at 28 days and have an appreciable performance (Figures 3 and 4).

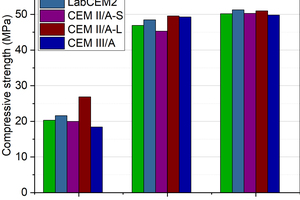

In order to prepare these cements, industrial CEM I 52.5 R was mixed with ground slag, ground limestone and calcium sulfate. Additionally, commercially available reference composite cements, which are well established in the European market, were investigated (e.g. for Germany [13] CEM II/A-S, CEM II/A-LL and CEM III/A). The composition of the tested cements is given in Table 1. The target strength class of the cement was 42.5 as defined by the EN 196-1 norm and comparable to the average strength level in the German market.

The compressive strength evolution of the concretes is given in Figure 7. The compressive strength of the two investigated LabCem is similar to the currently commercially available CEM II/A-S and CEM III/A. However, the strength is initially lower when compared to the cement CEM II/A-LL. At 90 days from mixing with water all the cements are characterized by the same compressive strength.

The resistance of the concretes to freeze-thaw resistance without de-icing salt was examined. The results of the scaling (CIF) after 56 freeze-thaw cycles are given in Table 2. The concrete samples based on the cement containing slag are characterized by a similar performance and fulfill the acceptance criterion according to German requirements [14]. The scaling during the CIF test was significantly below the limit of 1000 g/m2 after 56 freeze-thaw cycles.

The resistance of the concretes to freeze-thaw with de-icing salt was tested according to the CDF test. The results are given in Table 2. All the tested concretes are characterized by significantly lower scaling than 1500 g/m2 after 28 freeze-thaw cycles as required by [15].

The results of rapid chloride migration tests on mortars are given in Table 2. The penetration of chloride is lower for the cements containing slag when compared to the limestone cement. This proves that slag generally improves the resistance of the cement mortars and concretes to the chloride migration.

Overall, the investigation of the mortar and concrete performance reveals that LabCem1 and 2 are characterized by a performance which is generally comparable or superior to the cements currently available in the market such as CEM II/A-S and CEM III/A.

5 Conclusions

The production of Portland cement clinker is associated with significant CO2 emissions. The cement industry has already reached considerable reductions of its CO2 emissions. The available quantities of highly reactive SCMs are limited and are unlikely to increase. Recent research work revealed that the use of granulated blast-furnace slag in combination with limestone may lead to a further increase of the clinker replacement level while keeping the granulated blast-furnace slag content relatively low in cement.

Multicomponent cements make it possible to minimize the effective global warming potential of cements. This research revealed that composite cements characterized by approximatively 50 wt.-% of Portland cement clinker, 40 wt.-% of granulated blast-furnace slag and 10 wt.-% of limestone provide on the one hand an appreciable performance and on the other hand a low effective and general global warming potential.

This investigation showed that the optimized cements are characterized by a durability performance comparable or superior to commercial composite cements.

It is important to note that the developed model is flexible with respect to the cement composition and its kinetics of hydration. Any composition of the Portland cement clinker, granulated blast-furnace slag and limestone with known hydration kinetics can be modelled and the performance predicted.

Acknowledgements

This project has received funding from the European Union’s Horizon 2020 research and innovation program under grant agreement No 760639 “EnDurCrete”. This publication reflects only the author’s view. The European Commission is not responsible for any use that may be made of the information contained.

//www.heidelbergcement.com" target="_blank" >www.heidelbergcement.com:www.heidelbergcement.com

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.