Measurement of the velocity ratio

of solids and gas in vertical pneumatic conveyor lines

This report describes systematic measurements of the velocity ratio C = uS/uF in a vertical pneumatic conveyor line. Two limestone fractions of the same base material were analysed, which had mean particle diameters of dS,50 = 13,2 μm and dS,50 = 9638 μm. During the measurements, the load μ was varied in different test series, which were carried out with approximately constant delivery pressure/length unit (∆pR ⁄ (∆LR), from very small to values of μ ≅ 125 kgS ⁄ kgF. As the load μ increases, the solids/gas velocity ratio rises as expected and progresses asymptotically towards the limit value C = 1. The solids velocity uS was determined by means of a capacitive transit time measurement using cross-correlation of the measurement signals. From the measurements with the fine-grained limestone powder, the settling velocities wT,ε of the particle clouds forming in the vertical conveyor section can be back calculated. These show some special characteristics that are insufficiently considered/covered by the wT,ε-calculation equations proposed in the literature. Although the different flow forms that obviously occur in the measuring section are recorded numerically by the measuring method used, they cannot be assigned to a defined flow formation.

1 Introduction

To calculate the pressure loss, respectively to dimension the different sections of a pneumatic conveying line, the local ratio of the velocities of solid and conveying gas, C = uS ⁄ uF ≤ 1, is always required [1,2]. This ratio changes in the course of the conveying path. Measurements [3] of the C values of a fine-grained and a coarse-grained bulk material in vertical pipe sections up to the range of very high loads μ = ṀS ⁄ ṀF are reported below. Given a steady state flow at the measuring point, the settling velocities wT,ε of particle clouds can then be back-calculated from...

1 Introduction

To calculate the pressure loss, respectively to dimension the different sections of a pneumatic conveying line, the local ratio of the velocities of solid and conveying gas, C = uS ⁄ uF ≤ 1, is always required [1,2]. This ratio changes in the course of the conveying path. Measurements [3] of the C values of a fine-grained and a coarse-grained bulk material in vertical pipe sections up to the range of very high loads μ = ṀS ⁄ ṀF are reported below. Given a steady state flow at the measuring point, the settling velocities wT,ε of particle clouds can then be back-calculated from the determined data and compared with the individual particle settling velocities wT,0.

The following specifications apply: True velocities are designated by „uX“, so-called empty pipe velocities by „vX“. For the gas phase in pneumatic conveying lines, the following then applies, for example, vF = εF ∙ uF, with εF = relative gap volume of the gas. Since εF in such systems has values εF >~ 0,90, it is generally reasonably accurate to set uF = vF. The evaluation of tests in actual practice is normally always based on this assumption.

2 Testing technique

2.1 Test system configuration and test procedure

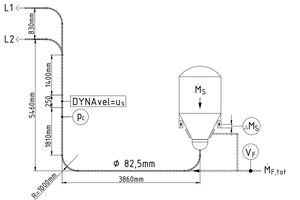

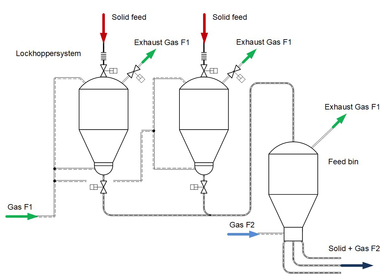

The measurements were conducted on two conveying lines with the inner diameter DR = 82.5 mm and lengths LR = 159 m and LR = 50 m. After injection of the solids, both lines run through the same conveyor pipe to the end of the vertical section in which the measured value acquisition device is installed to determine the C value. The pipes then separate. In the tests presented here, the bulk solids were injected through a downward-discharging pressure vessel with VB = 2,0 m3 net volume and a large-area gas supply to the cone that assists discharging of the solids. The main part of the conveying gas is fed directly to the beginning of the conveying line. Figure 1 shows schematically the course of the common conveying section of both pipes up to their division and the position of the measuring arrangement contained in it for determination of C.

The pressure vessel feeds the bulk material flow to a horizontal conveying pipe, which is deflected after approx. 3.86 m by a 90° bend with the radius RU = 1.0 m into a vertical line with the total height HR ≥ 5.5 m. The arrangement of the installed measuring devices is shown clearly in Figure 1. Their inlet pipe section has an undisturbed length/diameter ratio of (Lzu ⁄ DR) ≅ 22, while that of the outlet pipe section is (Laus ⁄ DR) ≅ 17. The conveyor section itself consists of a drawn mild steel pipe.

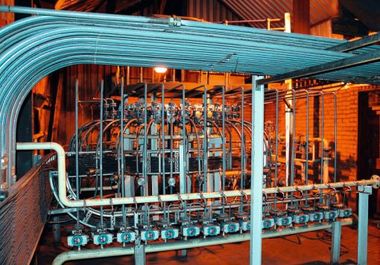

For determining the true solids velocity uS, the DYNAvel measuring system from DYNA Instruments [4] including the necessary peripherals was used. DYNAvel determines uS without calibration by means of a transit time measurement. For this purpose, the local capacities that build up due to the bulk material friction in the conveying process are recorded at two measuring points with a defined distance ∆x between them, are compared using a cross-correlation calculation and the resulting transit time difference ∆t is used to calculate the solids velocity uS = ∆x⁄∆t.

The local gas velocity uF,C at the measuring point was determined by measuring the gas mass flow

.MF,tot supplied to the conveying system minus the so-called top/displacement gas flow .MF,O by means of the absolute conveying pressure pC measured directly upstream of the DYNAvel device using the ideal gas law. Details are provided in section 2.3.

The solids throughput .MS is determined by means of load cells on the basis of both the increase in weight over time of the receiving container at the end of the conveyor section and the decrease in weight of the injecting pressure vessel.

With a constant conveying line pressure difference ∆pR in each case, the initial conveying gas velocity vF,A was gradually reduced from high vF,A-values into the range of the conveying ability limit. The pressure differences ∆pR were varied in pressure stages of ∆pR ≅ (1,0 - 2,0) bar. Back pressure of all conveyors: pG ≅ 1.0 bar. Conveying gas: ambient air with a relative humidity of φ = (50 - 60)%. Operating temperature = solids/gas mixing temperature: TB ≅ 20 °C.

The particle size distributions of the conveyed bulk materials were checked for changes at regular intervals. If there were any deviations from the original distribution that affected the conveying behaviour, the bulk material was replaced with fresh product. The measured values relevant for the evaluation were always recorded under stable, fully developed operating/flow conditions. All measuring devices are integrated into a data acquisition and evaluation system.

2.2 Analysed bulk solids

The two analysed bulk solids are limestone chippings (LSC) and a limestone powder (LSP) ground from the LSC in a ball ring roller mill. Table 1 compares some characteristic values of these two solids. The limestone powder LSP has an extremely broad particle size distribution, while that of the limestone chippings LSC is relatively narrow.

As the relatively high gas velocities, vF,A > 10 m⁄s, required to convey the coarse limestone resulted in considerable grain destruction, the LSC had to be replaced after every two bulk material cycles. This considerably limited the number of test runs possible with this material (limited amount of bulk material available).

2.3 Test evaluation

From the definition of the solid/gas velocity ratio, the velocities at the C measuring point are calculated as follows

(1)

The local gas empty pipe velocity vF,C is calculated as:

(2)

with: .MF,tot - total gas mass flow fed to the conveyor system, .MF,O - top gas mass flow, which replaces the bulk material volume displaced from the feed vessel and keeps the feed vessel pressure constant,

ϱF,C - gas density at the C measuring point.

The following applies for the displacement gas flow:

(3)

with: ϱF,B - gas density in the feed pressure vessel.

The gas densities ϱF,C and ϱF,B are calculated using the ideal gas law from the local absolute pressures pC and pB. The relative gap volume εF,C at the C measuring point that is required to solve equation (1) can be determined from the continuity equations of the two phases : .MS = (1 - εF,C) ∙ AR ∙ ϱS ∙ uS,C and .MF = εF,C ∙ AR ∙ ϱF,C ∙ uF,C = AR ∙ ϱF,C ∙ vF,C. In dimensionless form, this results in:

(4)

When inserted into equation (1) and solved according to C the result is:

(5)

rV,C = .MS / .MF ∙ ϱF,C ⁄ ϱS = .VS ⁄ .VF,C is the volume flow ratio of the two phases at the C measuring point and is better suited to describe the gas/solid interactions, especially at high loads, than μ, compare section 3. It must be noted that in all of the above-described measurements the evaluations were based on mean values over the cross-section of the conveying pipe and mean values over a limited observation period, usually ∆tmess ≅ (1...2)min.

3 Measurement results

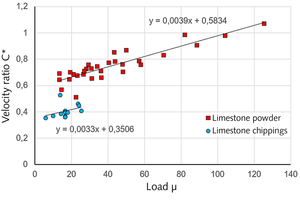

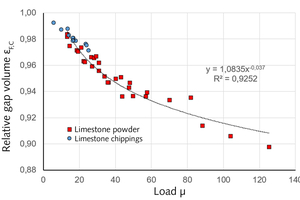

Due to the fact that in practice only the empty pipe gas velocities vF and the load μ are used, Figure 2 first depicts the approximation C* = uS,C ⁄ vF,C instead of C = uS,C ⁄ uF,C over the load μ. For both bulk materials, C* can be described in each case by a linear dependence of μ. In the case of the limestone powder LSP, this exceeds the physically non-achievable value of C = 1 at μ ≅ 100. Comparison with Figure 3, which describes the C values calculated with equation (5) dependent on μ, shows that C asymptotically approaches the value C = 1 in infinity. The potency functions depicted in Figure 3 only describe the course of C in the analysed measurement range. The correspondence of C* and C is sufficiently accurate for practical tasks in the range of smaller loads μ, in the case of the limestone powder for example in the range μ <~ 40.

Since the load μ contains absolutely no information regarding the spatial density of the gas/solids mixture ϱb,C at the measuring point, i.e. regarding the relative distances of the bulk material particles, it appears to make sense to plot the measurement results in the form C(rV,C), as rV,C takes into account the pressure dependence of the measured values, see Figure 4. This likewise does not lead to a reduction in the bandwidth of the measurement results determined. The same applies to the plotting of C against other characteristic values determined from dimensional analyses of the problem.

Evidently, the measured C fluctuations are caused by a different formation/stability of the flow patterns between the 90° elbow at the base of the vertical section and the C-measuring point. In the 90° deflection, the conveying gas and solids become segregated. A pronounced bulk solids strand forms on the outer wall of the pipe, which appear to be more stable in the case of high loads μ or volume flow ratios rV,C in the further course of the flow than it is in the range of lower values of these characteristic values. At lower loads/volume flow ratios, this strand disintegrates into balls/dunes etc. during the re-acceleration of the bulk material that had been decelerated in the 90° bend, which leads to the measured fluctuating C values. Some calculations for this are presented in the following.

The limestone powder LSP is considered here: its strand thickness at the outlet from the 90° base point elbow is to be evaluated. The two-phase flow is assumed to be incompressible in the conveyor line area under consideration (inlet of base manifold to C measuring point). The solids volume content in a pipe element is calculated from the relative gap volume of the conveying gas to εS = (1 - εF). In the deflection at the base of the vertical section, the solids are slowed down to half their entry speed (realistic value for fine-grained bulk solids): uS,U,out = uS,U,in ⁄ 2 = uS,C ⁄ 2. Its re-acceleration takes place on the way to the C measuring point. For the volume content of the solid at the manifold outlet, the value εS,U.out = 2 ∙ εS,C is derived from its continuity equation .MS ⁄ (AR ∙ ϱS) = εS,U,out ∙ uS,U,out =

εS,U,out ∙ uS,C ⁄ 2 = εS,C ∙ uS,C. Since both the sought εS,U,out and the εS,C back-calculated from the measurement results are mean values over the conveying pipe cross-section, the εS,U,out must be further divided into a dense strand portion εS,Str and a low-solids portion εS,0 outside the strand in order to determine the strand thickness. From the continuity equation .MS ⁄ (ϱS ∙ uS,U,out) = εS,U,out ∙ AR = εS,Str ∙ AStr + εS,0 A0 and εS,Str ≅ k ∙ εS,SS with εS.SS = ϱSS ⁄ ϱS, ϱSS = loosely piled bulk density, k = correction factor for the strand density, the following is the result, taking into account εS,U,out = 2 ∙ εS,C for the share of the strand cross-section in the total conveying pipe cross-section:

(6)

Table 2 compares the relevant calculations for two LSP tests with very different loads μ. For εS,0 = 0 and k = 1 the strand cross-sections listed in Table 2 are obtained. These decrease for εS,0 > 0 and increase for k < 1. Along the vertical conveying section between the foot point bend and the C measuring point, it is evident that considerable changes in the flow characteristics with corresponding effects on the C measurement are possible.

Additionally, Figure 5 shows the course of the dependence of the relative gap volume εF,C of the conveying gas at the C measuring point plotted against the current load μ.

The back-calculated εF,C measured values of the LSC fit in well with the measured values of the LSP shown in the diagram and, as required, run at μ 0 into the value εF,C 1. A simple potency equation therefore does not adequately describe the behaviour of εF(μ) in the range of low loads μ.

4 Settling velocity of particle swarms

For the settling velocity wT,ε of a particle accumulation/particle swarm relative to the conveying gas, the following derives from equation (1) with

(7)

By definition, the determination of wT,ε requires a temporally and spatially constant flow condition in the measuring section. In the tests presented here, this is only guaranteed with the fine-grained limestone powder LSP. For this reason, only results with this bulk material are presented below. Results of comparable measurements are represented in the literature, e.g. in the form of

⇥(8)

(9)

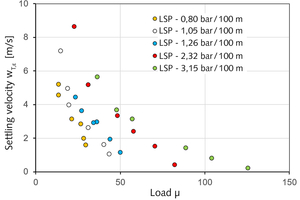

Other approaches are possible and are known in the literature. Figure 6 shows the back-calculated settling velocities wT,ε of the LSP as a function of the load μ. These show significant differences in the curves of the measurement series carried out with respectively different constant pressure loss/length unit ∆p ⁄ LR i.e. with different pressure pC at the C measuring point.

The reason for this is that the forces from particle flow, weight and buoyancy that have to be taken into account for their effect on the particles in the case of the single particle settling velocity wT,0 must be supplemented by the particle/particle and particle/pipe wall forces/interactions in the case of the particle swarm. These are usually modeled summarily as frictional resistance (λS,ε∝∆pR ⁄ LR ).

It follows from the above calculation approaches for the swarm settling velocity wT,ε that wT,ε in accordance with the function

(10)

is dependent on the size of the delivery pipe diameter. A larger pipe diameter leads to a lower settling velocity wT,ε under comparable operating conditions (μ,...), as this results, among other things, in a reduced number of wall and particle impacts. All LSP measurements carried out here are therefore only valid for the analysed pipe diameter DR = 82.5 mm.

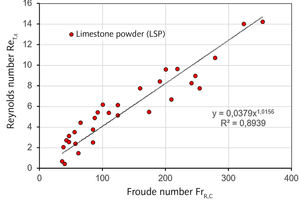

In Figure 7, the LSP measurement results are plotted non-dimensionally in the form

Reynold-No ReT,ε = wT,ε ∙ dS,50 ∙ ϱF ⁄ ηF = f (FroudeNo FrR,C = u2F,C ⁄(g ∙ DR)). This results in a linear dependency ReT,ε(FrR,C). The ReT,ε number is thereby formed with the median value dS,50 of the LSP particle size distribution, while the FrR,C number is formed with the gas velocity uF,C at the C measuring point.

The relatively wide range of measuring points encompasses their different loads μ and also the influences of the different flow forms along the measuring section. The advantages of the representation depicted in Figure 7 are, firstly, that the FrR,C number already contains the wT,ε-dependence on the conveying pipe diameter, DR, equation (10), i.e. Figure 7 can also be applied to other pipe diameters (investigations in this regard on a DN 50 vertical section are currently underway), and secondly, that even when using the easily determined empty pipe gas velocity vF,c instead of the true velocity uF,c it is possible to make a simple/rough estimate of the swarm settling velocity wT,ε.

Comparisons with other bulk solids are possible, inter alia, via the dimensionless characteristic values Ar or (wT,ε ⁄ wT,0), e.g. equations (8) and (9).

It must once again be emphasised that the measuring method described here can only be used to determine averaged C or wT,ε values over the cross-section of the conveying pipe, which although reflecting the influences of the respective flow patterns, but do not describe these conditions quantitatively. In order to determine the effects/characteristic values of different flow forms, e.g. of balls, strands etc. of solids, flow-specific calculation models are required, the characteristic values of which must be determined in tests with the specific flow forms occurring in the conveying pipe, compare e.g. [7, 8].

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.