The influence of triisopropanolamine on the hydration and microstructure of cement/fly-ash systems during steam curing

A study was made of the effect of triisopropanolamine (TIPA) on the compressive strength and hydration microstructure of cement/fly-ash systems during steam curing. The results show that the compressive strength of cement/fly-ash paste increased with increasing quantity of appropriate amounts of TIPA (0~0.10%). The addition of TIPA can significantly accelerate the hydration of cement and the pozzolanic reaction of fly ash, increase the degree of polymerization of C-S-H gels, reduce the pore volume of hardened cement paste and decrease the amount of harmful and very harmful pores. This all improves the early compressive strength of cement/fly-ash systems and the findings provide some guidance for the application of TIPA in cement/fly-ash systems.

1 Introduction

Fly ash (FA) is a by-product of coal-fired power plants. As a commonly used supplementary cementitious material for concrete it has the advantages of improving workability, reducing heat of hydration and inhibiting shrinkage [1-3]. The use of FA instead of cement can also lead to cost savings and reduced carbon emissions, with significant social, economic and environmental benefits. However, the mechanical properties of cement-based materials are affected if too much FA is used. In particular, the mechanical properties in the early stages are greatly reduced, which is not...

1 Introduction

Fly ash (FA) is a by-product of coal-fired power plants. As a commonly used supplementary cementitious material for concrete it has the advantages of improving workability, reducing heat of hydration and inhibiting shrinkage [1-3]. The use of FA instead of cement can also lead to cost savings and reduced carbon emissions, with significant social, economic and environmental benefits. However, the mechanical properties of cement-based materials are affected if too much FA is used. In particular, the mechanical properties in the early stages are greatly reduced, which is not conducive to improving production efficiency. The application of large quantities of FA in precast concrete is therefore greatly restricted and any improvement of the early strength of concrete containing large volumes of fly ash would be highly significant.

Steam curing is one of the effective means of improving the early strength of cement/fly-ash systems. The increase in curing temperature not only promotes the hydration of cement but also accelerates the pozzolanic reaction of FA [4, 5]. Triisopropanolamine (TIPA) also has a positive effect on improving the compressive strength of cement/fly-ash systems as it can accelerate the rate at which the Fe in C4AF dissolves on the surface of cement particles, thus shortening the induction period and speeding up cement hydration. Furthermore, the accelerating effect of TIPA on cement hydration can generate more calcium hydroxide (CH) to stimulate the pozzolanic activity of FA [6, 7]. It is predicted that the early compressive strength of cement/fly-ash systems can be significantly improved under the synergistic action of steam curing and chemical excitation.

This paper therefore first studies the influence of TIPA on the early compressive strength of cement/fly-ash systems during steam curing. The mechanism by which TIPA improves the early mechanical properties is then explained by analyzing the influence of TIPA on the hydration characteristics and microstructure of cement/fly-ash systems. The research results provide a practical engineering reference for improving the early strength of precast concrete containing large quantities of fly ash.

2 Experimental

2.1 Raw materials

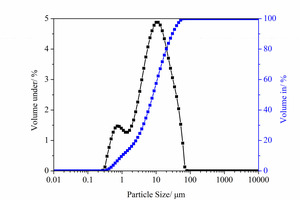

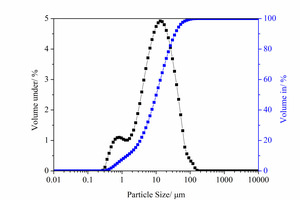

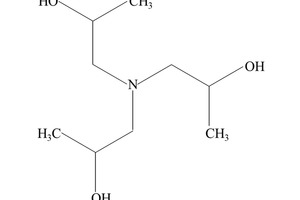

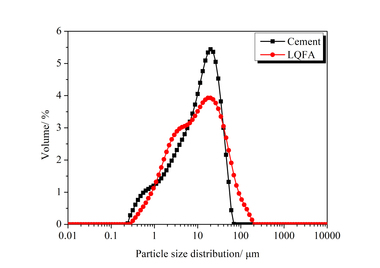

A Portland cement (P·I 42.5) complying with the requirements of Chinese standard GB175-2007 and a secondary fly ash (FA) complying with the requirements of Chinese standard GB/T 1596-2005 were used. The chemical compositions and particle size distributions of the cement and FA are shown in Table 1 and Figure 1 respectively. The triisopropanolamine was reagent grade and its molecular structure is shown in Figure 2.

2.2 Sample preparation

Cement/fly-ash pastes with different TIPA contents (0%, 0.03%, 0.06%, 0.10%, 0.13%) were prepared (the mass ratio of cement to fly ash was 7:3) with a water-binder ratio of 0.50. Before the pastes were prepared the TIPA was dissolved in water and then mixed with the cement/fly-ash and stirred thoroughly. The fresh pastes were cast in 40 mm x 40 mm x 40 mm stainless steel moulds. These specimens were then steam cured for 12 h at a temperature of (60±1) °C and a relative humidity greater than 95%, after which the compressive strengths were measured.

The specimens were then broken into small pieces and immersed in anhydrous ethanol in order to stop the hydration; after three days they were oven-dried at 40 °C for 12 hours. Some of these small pieces were prepared for measurement of the pore structure; the other specimens were ground to powder by hand and those particles that passed the 200 mesh sieve were prepared for the XRD, TG-DSC and NMR measurements.

2.3 Testing method

2.3.1 Compressive strength

The compressive strengths of the samples were tested in accordance with the requirements of Chinese standard GB/T 17671-1999 using a YAW-300C series fully automatic test machine at a loading rate of (2.4±0.2) kN/s. Six specimens of each mix were tested and the average was used as the final result.

2.3.2 Pore structure

The pore structures of the samples were determined using a Poremaster GT-60 mercury intrusion porosimeter (MIP) at a contact angle of 140° and a maximum pressure of 30000 psi.

2.3.3 XRD

The sample phase was analyzed with a Bruker D8 Advance X-ray diffractometer (XRD) at a scanning rate of 8°/min with a step size of 0.02° and a 2-theta range of 5~70°.

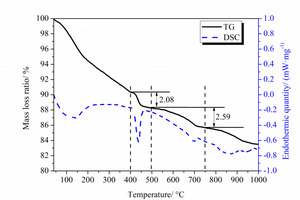

2.3.4 DSC-TG

An STA449c/3/G simultaneous thermal analyzer was used for the DSC-TG test, which was carried out from 40 °C to 1000 °C at a heating rate of 10 °C/min under an atmosphere of N2.

2.3.5 29Si-NMR

The composition and structure of the 29Si based substances were analyzed using a Bruker Advance III400 NMR spectrometer at a magnetic field frequency of 79.5 MHz and rotor rotational frequency of 5 kHz.

3 Results and discussion

3.1 Compressive strength

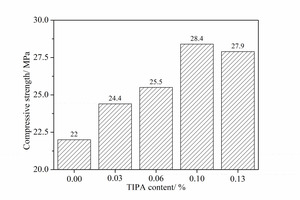

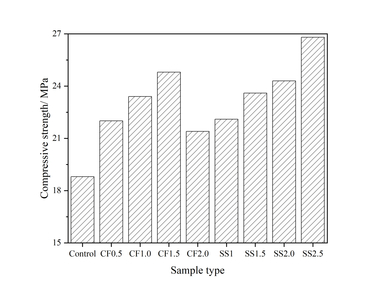

The influence of TIPA on compressive strength is shown in Figure 3. It can be seen that the compressive strengths increased with rising TIPA content up to 0.1%. Relative to the control sample, the strengths increased by 10.91%, 15.91% and 29.09% with the addition of 0.03%, 0.06% and 0.10% TIPA respectively. However, any further increase of TIPA reduced the strength slightly. Specifically, the addition of 0.13% TIPA gave a much higher (26.82%) compressive strength than that of the control sample but a slightly lower strength than with 0.10% TIPA. The optimal addition level for TIPA found in this study is therefore 0.10%.

There are two apparent aspects of the influence of TIPA on compressive strength of cement/fly-ash systems. Firstly, the incorporation of TIPA can accelerate the rate at which the Fe in C4AF dissolves on the surface of cement particles, thus shortening the induction period and accelerating cement hydration. Simultaneously, the accelerating effect of TIPA on cement hydration can generate more CH to stimulate the pozzolanic activity of FA [6, 7]. The TIPA may also chelate with Al3+ and Fe3+ in the FA and induce the dissolution of the FA. All of these are conducive to promoting the hydration of cement/fly-ash systems, so within a certain addition range (≤0.1%), the strength increases with rising addition of TIPA. Secondly, TIPA has a certain air-entraining effect [6], which is not conducive to the improvement of strength. This means that the strength decreases when the addition level of TIPA is too high (0.13%).

3.2 Pore structure

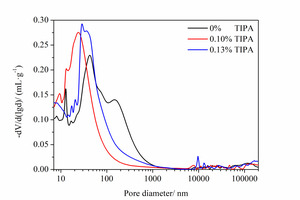

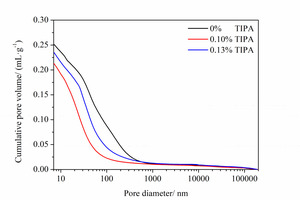

Pores in cement-based materials can be divided into four types on the basis of their influence on strength: harmless pores (<20 nm in diameter), less harmful pores (20 nm-50 nm), harmful pores (50 nm~200 nm) and very harmful pores (>200 nm) [8, 9]. The pore structure was characterized using mercury intrusion porosimetry (MIP), and the most probable aperture (MPA), the pore size distributions and the total pore volume were obtained from the results of the MIP, as shown in Figure 4 and Table 2.

As can be seen from Table 2, both 0.10% TIPA and 0.13% TIPA reduce the total pore volume of the sample when compared with the sample without TIPA. However, the total pore volume of the sample with 0.13% TIPA is higher than for the sample containing 0.10% TIPA. The influence of TIPA on the pore structure of cement-based materials depends mainly on two aspects: on one hand, the addition of TIPA can promote the hydration of cement-based materials and the filling effect of the hydration products can reduce the porosity [10, 11]. On the other hand, the air entrainment characteristics of TIPA can increase the porosity [4, 12]. When the TIPA content is 0.10%, its promoting effect on hydration is dominant and leads to a decrease in porosity; however, when the TIPA content is 0.13%, its air entraining characteristics lead to an increase in porosity.

Furthermore, the addition of TIPA can significantly increase the quantity of pores smaller than 50 nm, decrease the quantity of pores larger than 50 nm and significantly reduce the most probable aperture (MPA), suggesting that the incorporation of TIPA can transform the harmful and very harmful pores into harmless and less harmful pores. This is mainly because TIPA enhances the ionic dissolution of cement and FA, thereby accelerating the formation of the hydration products and nanoscale precipitates that fill the pores and refine the pore structure. When the TIPA content was increased from 0.10% to 0.13% the volume of less harmful pores, harmful holes and very harmful pores all increased, even though the volume of harmless pores decreased slightly, and there was also a significant increase in the MPA, which was related to the air entraining effect of TIPA.

The conclusion is that incorporation of TIPA has an air entraining effect on cement/fly-ash systems, which may adversely affect their mechanical properties. The best enhancement effect of TIPA on cement/fly-ash systems can therefore only be achieved with appropriate addition levels that are consistent with the results of compressive strength tests.

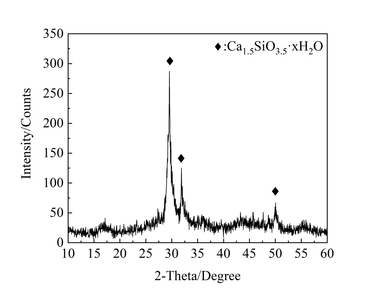

3.3 XRD and DSC-TG analysis

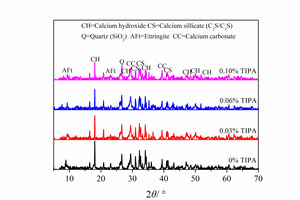

The XRD patterns of cement pastes containing different levels of TIPA (0~0.10%) are shown in Figure 5.

Figure 5 shows that the main phases in the hydrated cement/fly-ash pastes are CH, calcium carbonate (CC), quartz (Q), ettringite (AFt) and unhydrated cement clinker (CS: C2S/C3S). Comparison of the characteristic peaks of the four samples shows that there is a clear decrease in the intensity of the CS and CH diffraction peaks with increasing addition level of TIPA. This is mainly because the addition of TIPA promotes the hydration of cement and the pozzolanic reaction of fly ash, and the pozzolanic reaction of fly ash gradually consumes CH and promotes further cement hydration. The addition of TIPA therefore weakens the strength of the CS and CH characteristic peaks.

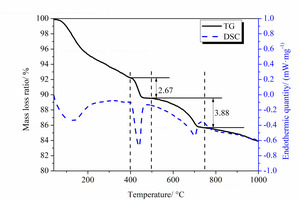

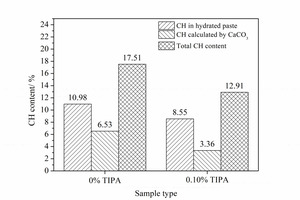

DSC-TG analysis was carried out on samples without TIPA and with 0.10% TIPA, as shown in Figure 6, for further quantitative analysis of the CH consumption caused by the pozzolanic reaction of fly ash. It can be seen from the diagrams that all the DSC curves have three main endothermic peaks and the corresponding TG curves indicate a clear decline in mass. The first endothermic peak is located at about 100~200 °C and is caused by evaporation of free water and dehydration of the C-S-H gels and AFt. The second endothermic peak lies at about 400~500 °C and is caused by dehydration of the CH. The third endothermic peak is located at about 700 °C and is caused by the decomposition of the CaCO3 generated by the carbonization of CH during the sample preparation. The quantities of CH in the hydration products were calculated in this study through the mass loss due to CH dehydration and CaCO3 decomposition, as shown in Formula (1)

⇥(1)

and the results of the calculation are shown in Figure 7, where M1 is the mass loss due to CH dehydration, M2 is the mass loss due to CaCO3 decomposition. 74, 18 and 44 represent the respective relative molecular weights of CH, H2O and CO2.

Figure 7 shows that 0.1% TIPA reduces the CH content from 17.51% to 12.91%, primarily because TIPA can promote the pozzolanic reaction of FA, thus consuming a large amount of CH, which is consistent with the XRD analysis results. It is generally true for cementitious systems containing FA that the lower the CH content the greater is the quantity of C-S-H gels produced and the higher is the compressive strength [14-16].

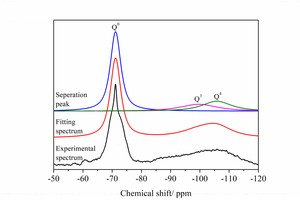

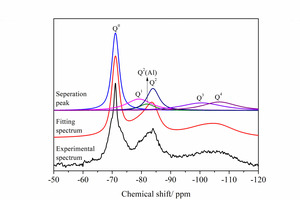

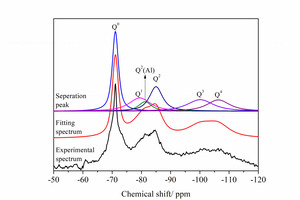

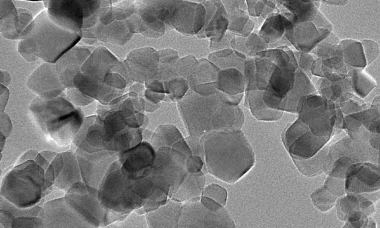

3.4 29Si-NMR analysis

For further analysis of the influence of TIPA on the hydration of cement/fly-ash systems the raw materials and hydration products were characterized by 29Si NMR, and the results are shown in Figure 8 and Figure 9. The degree of hydration of cement clinker (αPC), the degree of the pozzolanic reaction of fly ash (αFA), the average chain length of the C-S-H gels (ACL) and the ratio of Al to Si (Al/Si) can be calculated by the following formulae [17-20]:

⇥(2)

⇥(3)

⇥(4)

⇥(5)

where I0(Q0) and I(Q0) represent the respective relative integral intensities of the Q0 peaks before and after cement hydration. I(Q1), I(Q2) and I[Q2(Al)] represent the respective relative integral intensities of the Q1, Q2 and Q2(Al) peaks, I0(Q3) and I(Q3) represent the respective relative integral intensities of the Q3 peaks before and after the secondary hydration of fly ash and I0(Q4) and I(Q4) represent the respective relative integral intensities of the Q4 peaks before and after the secondary hydration of fly ash.

The peak fitting data in Figure 8 and Figure 9 were substituted into Equations (2) ~ (5) to obtain the quantitative analysis results shown in Table 3. This shows that TIPA can significantly improve the hydration of cement and fly ash. 0.10% TIPA increases the degree of hydration of cement from 48.5% to 54.6% and the degree of secondary hydration of fly ash from 17.0% to 20.6%. This confirms the XRD and DSC-TG test results and also provides a quantitative explanation of the strength improvement in cement/fly-ash systems caused by incorporation of TIPA. The addition of TIPA can also improve the average chain length of the C-S-H. The compressive strengths of cement-based materials are generally positively correlated with the degree of C-S-H gel polymerization; the larger the ACL the higher is the degree of gel polymerization [18]. The change of ACL explains another aspect of the strengthening effect of TIPA in cement/fly-ash systems. As far as the Al/Si ratio is concerned the TIPA can significantly promote the pozzolanic reaction of fly ash with a higher Al/Si ratio, so the addition of TIPA can enhance the Al/Si ratio of the hydration products.

4 Conclusion

When the TIPA content is lower than 0.10%, the strength of cement/fly-ash systems increases with increasing percentage of TIPA. The strength decreases slightly when the addition level is higher than 0.10%, so this study finds that the optimal TIPA addition level is 0.10%.

At the appropriate addition level, the addition of TIPA can improve the degree of the hydration of cement, the degree of the pozzolanic reaction of fly ash and the average chain length of C-S-H gel, and thus improve the compressive strength of cement/fly-ash systems.

There are two main aspects of the influence of TIPA on the strength of cement/fly-ash systems during steam curing. Firstly, TIPA promotes the hydration of cement and fly ash, which is beneficial to the strength development; secondly, the air-entraining effect is adverse to the development of strength. When the content of TIPA is lower than 0.10%, the former plays a dominant role, whereas at higher levels the latter plays the dominant role.

5 Acknowledgement

The financial support from the Innovation and Entrepreneurship Training Program of Hubei University Students (S202010488037) and the Science and Technology Research Program of Hubei Province Education Department (Q20191706) is gratefully acknowledged.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.