Effect of calcium formate/nano C-S-H composite on early hydration

and microstructure of the GGBS-cement

system under steam curing

The influence of calcium formate (CF)/nano C-S-H (NC) composite on the early strength of the ground granulated blast-furnace slag (GGBS)-cement system under steam curing conditions was investigated, and the mechanism behind was analyzed by means of XRD, FTIR and MIP. Results show that the early strength of the GGBS-cement system can be obviously improved by the incorporation of CF, and the optimum added quantity is 1.5%; the addition of CF can enhance the hydration of cement and GGBS, promote the generation of hydration products and reduce the total pore volume and the most probable aperture of the GGBS-cement system. The addition of CF/NC composite can further improve the compressive strength, and in the range of 1%~4%, the greater the content of NC, the higher the compressive strength, which is related to the density improvement of the system by the nucleation effect and micro-aggregate filling effect of NC.

1. Introduction

Ground granulated blast-furnace slag (GGBS) is the residue formed by impurities such as SiO2 and Al2O3 and lime in the iron making process, which is collected and water quenched to obtain high fineness and high activity powder. When GGBS is applied to cement, the OH- provided by clinker hydration can stimulate the potential activity of GGBS. Compared with Portland cement, GGBS cement has the advantages of lower hydration heat and inhibition of alkali aggregate reaction. After GGBS is incorporated into cement, the microstructure is relatively loose and the strength develops...

1. Introduction

Ground granulated blast-furnace slag (GGBS) is the residue formed by impurities such as SiO2 and Al2O3 and lime in the iron making process, which is collected and water quenched to obtain high fineness and high activity powder. When GGBS is applied to cement, the OH- provided by clinker hydration can stimulate the potential activity of GGBS. Compared with Portland cement, GGBS cement has the advantages of lower hydration heat and inhibition of alkali aggregate reaction. After GGBS is incorporated into cement, the microstructure is relatively loose and the strength develops slowly in the early stage, while the strength increases rapidly in the late stage [1, 2]. In general, the compressive strength of cementitious materials with high volume GGBS is low and negatively correlated with the GGBS content [3, 4]. Steam curing is a common curing mechanism in the production of precast concrete components, which can promote cement hydration, improve the demolding strength, and speed up the mold turnover. However, when the amount of GGBS is large, steam curing alone cannot meet the need of early strength of cement-based materials in practical engineering.

Calcium formate (CF) is a kind of organic early strength agent, which is weakly acidic after ionization in water, and can reduce the pH value of the liquid phase, increase the hydration reaction rate of tricalcium silicate, and accelerate the coagulation and hardening of the paste. Moreover, CF can provide Ca2+, accelerate the precipitation of hydrated calcium silicate and calcium hydroxide, improve the solid ratio in the paste, and facilitate the construction of the cement stone structure, thus improving the strength of the specimen [5-7]. The study of Yum et al. found that the addition of CF can significantly increase the strength of the GGBS binder system by inducing the more dissolution of GGBS, greater C-S-H formation and an increase in C2AH8 formation [8]. The research of Bellmann et al. showed that it was possible to increase the strength of mortar bars produced from the pure slag from 3 MPa to 25 MPa after seven days by adding calcium hydroxide, calcium carbonate and calcium acetate because the incorporation of calcium salts is able to increase the calcium ion concentration and thus reduce the pH in the pore solution via the calcium hydroxide equilibrium [9].

Nano C-S-H (NC) in another effectively early strength agent, which has nucleation and filling effects and can provide seeds for early hydration products, reduce the nucleation barrier, accelerate the hydration reaction process, improve the pore structure and thus increase the density and strength of cement-based materials [10]. In addition, NC has a high surface free energy due to a large number of broken bonds and structural defects on the surface, so it owns a strong adsorption capacity of ions and molecules. The hydration process of the cementitious materials can be changed under the joint action of nucleation and adsorption, which has a certain effect on the shielding effect of high concentration at the interface of the original mineral, short-range crystallization and crystallization pressure caused by crystallization, which can make the hydration product grow synchronously in the whole system and obtain a dense and uniform structure of hardened cement paste [11]. Feng et al. [12] pointed out that the nucleation and adsorption effects of NC seeds can promote the reactivity of cement clinker at low temperatures, thus effectively accelerating the hydration rate of cement paste. Sun et al. [13] found that the seed effect of NC enhanced the hydration product growth in the pore space and filled the void between the clinker particles more quickly, thereby reducing the porosity. The study of Szostak et al. [14] and Kanchanason et al. [15] showed that adding NC to cement-based systems doped with supplementary cementitious materials (SCMs) can significantly accelerate the secondary hydration reaction of SCMs, mainly because NC can promote cement hydration to produce more calcium hydroxide and improve the alkalinity of the system. Therefore, it can be inferred from the above discussion that the incorporation of CF/NC compound into the high-volume GGBS cement system is expected to further improve its early strength.

In this paper, the effect of the combination of calcium formate and NC on the early compressive strength of the GGBS cement system under steam curing was studied, and the mechanism of its influence on the early hydration was explored by means of XRD, MIP and FTIR. Such results have certain guiding significance for the application of high volume GGBS in concrete.

2. Experiment

2.1 Raw materials

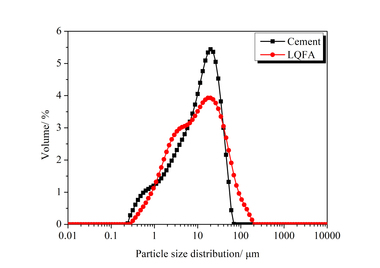

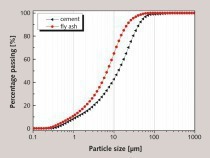

P·O 42.5 cement and ground granulated blast-furnace slag (GGBS) were used in all mixes, and their chemical compositions are shown in Table 1. Calcium formate (CF) was used as a chemical activator with a purity of 98% (mass fraction). NC was prepared by sodium silicate solution and anhydrous calcium chloride solution as raw materials, self-made in the laboratory. During the preparation process, the water-solid ratio of the solution was controlled to be 10, the molar ratio of calcium to silicon was 1.2, and the water bath was heated at 60 °C for 7 d, then the solid powder obtained was repeatedly pumped, filtered, washed, dried and ground. The XRD pattern of NC is shown in Figure 1, with semi-crystalline C-S-H (I) characteristic peaks at 29.55 °C, 31.88 °C and 50.05 °C. TEM image of NC, as shown in Figure 2, indicates that NC is mainly formed by the agglomeration of spheroidal particles.

2.2 Sample preparation

The mix ratios of the pastes are shown in Table 2. The water-binder ratio of all samples is 0.38 and the contents of GGBS, CF and NC are 40%, 0.5%~2% and 1%~4% of the total mass of the binders, respectively. The paste samples were prepared in prismatic molds of 40 mm × 40 mm × 160 mm and the compressive strength test of the pastes was carried out after they were cured by steam at 60 °C for 12 h.

After the hardened paste was broken, the central part of the sample was soaked in anhydrous ethanol for 3 d to terminate hydration, and then dried in a vacuum drying oven at 60 °C. Then some small pieces were ground into powders for XRD and FTIR tests, while other pieces were used for the MIP test.

2.3 Test procedure

The compressive strength of the cement paste was determined according to GB/T 17671-2021 [16]. In order to eliminate as much error as possible, six samples were tested for each mix, and the average is used as the final result. The phase composition and crystal structure of the sample were measured by STA449C Advance X-ray diffractometer (XRD) with the Cu target. The chemical structure of the samples was analyzed by Nicolet iS50 Fourier transform infrared spectrometer (FTIR) and the wave numbers are ranged from 4000 cm-1 to 400 cm-1. The porosity and pore size distribution of the samples were measured by PoreMaster-33 mercury injection porosimeter (MIP) with the contact angle of 140 °.

3. Results and discussion

3.1 Compressive strength

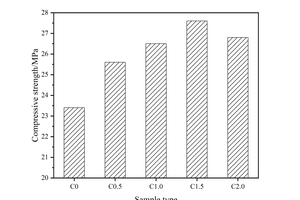

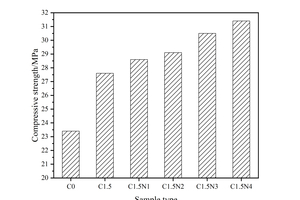

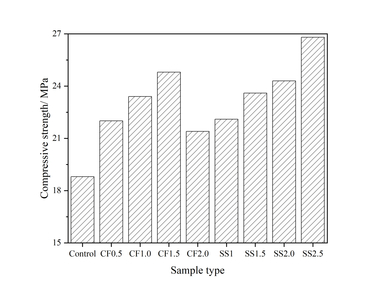

Figure 3 shows the influence of CF/NC composite on the early compressive strength of the GGBS-cement system under steam curing.

As shown in Figure 3 (a), the addition of calcium CF can significantly improve the early compressive strength of the GGBS-cement system, and with the increase of CF content, the strength first increases and then decreases, and reaches the maximum when the CF content is 1.5%, which is 17.9% higher than that of the control sample. It is clear that with the addition of 2.0% CF, 14.5% higher compressive strength than the control sample can be found in spite of a little lower strength than that of 1.5% CF. This is because CF can accelerate the hydration of the GGBS-cement system, promote the generation of hydration products, increase the solid ratio in the paste, and thus improve the early strength of the specimen [17, 18]. However, the addition of too much CF would consume a lot of water and make the paste become viscous, which is not conducive to its structural construction [19].

As shown in Figure 3 (b), when CF and NC are combined, the compressive strength of the sample is further improved on the basis of the single addition of CF, and in the range of 1%~4%, the higher the addition of NC, the greater the strength improvement. Specially, the strength of the sample modified by 1.5% CF and 4% NC composite is increased by 34.2% compared with the control sample. This is because NC not only has the filling effect and refines the internal structure of the paste, but also provides nucleation sites for hydration products, reduces the nucleation barriers [20, 21], improves the hydration rate of the GGBS-cement system, and thus forms a more compact structure and further improves the early compressive strength [22, 23].

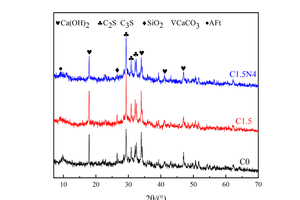

3.2 XRD analysis

Fig. 4 shows the XRD spectra of C0, C1.5 and C1.5N4 samples hydrated for 12 h under steam curing. It is obvious that, before and after the addition of CF or CF/NC, no new diffraction peaks appears in the XRD spectra of the samples, that is, no new substances are formed, and the main phases are calcium hydroxide (CH), unhydrated calcium silicate (C2S/C3S), calcium carbonate (CaCO3) and ettringite (AFt).

It can be seen from Figure 4 that the diffraction peak of CH increases after the incorporation of CF into the GGBS-cement system. The reasons for this phenomenon are: First, the diffusion rate of HCOO- in CF is faster than Ca2+, which can quickly pass through the initial hydration layer on the surface of C2S and C3S, reduce the nearby pH value, and thus improve the hydration reaction rate and promote the generation of hydration products; Second, the incorporation of CF increases the concentration of Ca2+ in the liquid phase, reduces the nucleation barrier of the CH crystals [24-26], and therefore increases the precipitation rate of CH. Although the secondary hydration of GGBS consumes some CH, the consumption amount is still lower than the production amount, so that the intensity of the CH diffraction peak of C1.5 is higher than that of C0. In addition, the hydration of C3A is enhanced by CF, forming AFt and AFm analogues, so there is no AFt diffraction peak enhancement in XRD. After further incorporation of NC, the diffraction peaks of C2S and C3S decrease, indicating that NC can further improve the hydration rate and the hydration degree of GGBS and cement. More-over, the diffraction peak of CH is the lowest in the sample with CF/NC, mainly because GGBS activity is excited under the joint action of CF and NC, and the active substance is released to undergo secondary hydration reaction with CH, which consumes a large amount of CH. Although the promotion of cement hydration can generate CH, the consumption amount is higher than the generated amount, so that the diffraction peak of the co-doped sample CH is lower than that of the single doped sample.

3.3 FTIR analysis

Figure 5 shows the FTIR spectra of C0, C1.5 and C1.5N4 samples hydrated for 12 h under steam curing.

As shown in Figure 5, the vibration peak of CO32- appears near 1360 cm-1, indicating that the system contains carbonate. The bending vibration peak and stretching vibration peak related to H2O appear around 1660 cm-1 and 3430 cm-1, respectively. The SO42- vibration peak related to AFt appears near 1084 cm-1. The stretching vibration and the asymmetric stretching vibration displacement of the Si-O bond in the silica tetrahedron of C-S-H gels reflect the change of C-S-H structure, and Q1 vibration peak and Q2 vibration peak related to C-S-H appear near 876 cm-1 and 984 cm-1, respectively. The addition of CF makes the Q2 value higher than that of the control sample, and the Q2 also migrate to higher frequency (from 984 cm-1 to 985 cm-1), indicating that the mixture of CF could increase the production of C-S-H gels, and also raise the degree of polymerization and chain length of Si-O tetrahedron to a certain extent [27, 28]. While for the C1.5N4 sample, the Q1 and Q2 vibration peaks are significantly enhanced compared with those of the C1.5 sample, and the difference in peak shape is small, indicating that the further incorporation of NC on the basis of the single doped CF could increase the generation amount of C-S-H gels, improve the polymerization degree of silica tetrahedron, and do not change the basic structure of C-S-H in the GGBS-cement system.

3.4 Pore structure

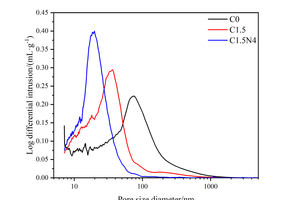

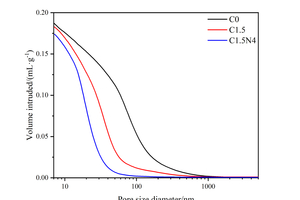

The influences of CF and CF/NC composites on pore structures of the GGBS-cement system were characterized by MIP, and the cumulative and differential distribution curves of the pore are shown in Figure 6. Based on the reports of Wu and Pang et al. [29, 30], pores in cement-based materials can be divided into four types: harmless pores (smaller than 20 nm), less harmful pores (between 20 nm and 50 nm), harmful pores (between 50 nm and 200 nm), and more harmful pores (bigger than 200 nm), and according to this division method the microscopic pore structure parameters are listed in Figure 7.

It can be seen from Figure 6 and Figure 7 that after the incorporation of CF, compared with the control sample, the quantities of the most probable aperture, total pore volume, harmful pores and more harmful pores decrease significantly, while the quantities of less harmful pores and harmless pores increase obviously, showing that the addition of chemical activators can refine the pore size of the paste and promote the transfer of harmful and more harmful pores to less harmful and harmless pores. This is because the addition of CF can promote the hydration reaction of the paste, and the products can fill the pores, making the structure more compact. When CF/NC are used together, the total pore volume and the most probable aperture of the paste are further reduced, the amount of harmful pores and more harmful pores reach a very low level, and the pore size in the paste are further refined, mainly because the nucleation effect of NC can accelerate the hydration rate, refine the pore structure and thus increase the density of cement-based materials. As a rule, the strength can be enhanced by the reduction of total pore volume and the refinement of pore structure, which can be used to explain the change of compressive strength in Figure 3.

4. Conclusion

The main conclusions of this study are as follows:

1. Under steam curing condition, the compressive strength of the GGBS-cement system first increases and then decreases with the increase of CF content, and the optimal content of CF is 1.5%. The addition of CF/NC can further improve the compressive strength, and in the range of 1%~4%, the greater the content of NC the higher the compressive strength.

2. Under steam curing condition, CF can stimulate the activity of GGBS and promote the hydration of GGBS and cement. The incorporation of NC can reduce the dissolution barrier of cement clinker, promote the formation of hydration products, and thus improve the early strength.

3. The addition of CF can reduce the total pore volume, the most probable aperture, and the amount of harmful pores and more harmful pores, increase the amount of harmless pores and less harmful pores in the GGBS-cement system, and thus improve the density of the paste. The addition of CF/NC can further reduce the most probable aperture and refine the pore size of GGBS cement system.

5. Acknowledgement

Financial support from the Innovation and Entrepreneurship Training Program of Hubei University Students (S202210495067) is gratefully acknowledged.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.