Effect of nano-SiO2 on the strength and hydration characteristic of low quality fly ash-cement system

Generally, low quality fly ash (LQFA) is a kind of micron industrial by-product which seriously affects the strength of cement-based materials, and in order to explore a method to improve this disadvantage, the effect of LQFA and nano-SiO2 (NS) on compressive strength were investigated. To reveal the mechanism behind this, the influence of LQFA and NS on hydration characteristics and microstructure of the cement matrix were also studied by XRD, DSC-TG, SEM and MIP. Results show that when the content of LQFA is more than 10%, the early strength of hardened cement paste decreases significantly, and the larger the dosage, the greater the reduction. Further addition of NS can improve the strength drop caused by LQFA incorporation due to its micro-filling effect, crystal nucleus effect and chemical activity. In the hydration process of the LQFA-cement system, NS can not only consume a lot of CH to generate compact C-S-H, but also play a role of filling effect, leading to the improvement of pore structure, an increase in compactness and uniformity, and an enhancement in compressive strength. The results can provide a reference for the application of LQFA and NS in cement-based materials.

1 Introduction

Fly ash (FA) is a micron industrial by-product, which can cause a waste of land resources and environmental pollution when piled up in large quantities. However, its chemical composition is similar to cement, which means that it reacts with cement hydration products to produce a certain gelling property. Therefore, its incorporation into cement can not only adjust the mixing ratio of binding materials and reduce the amount of cement, but also reduce the carbon emission in the production process of cement clinker. In addition, the incorporation of FA into cement can also reduce...

1 Introduction

Fly ash (FA) is a micron industrial by-product, which can cause a waste of land resources and environmental pollution when piled up in large quantities. However, its chemical composition is similar to cement, which means that it reacts with cement hydration products to produce a certain gelling property. Therefore, its incorporation into cement can not only adjust the mixing ratio of binding materials and reduce the amount of cement, but also reduce the carbon emission in the production process of cement clinker. In addition, the incorporation of FA into cement can also reduce the hydration heat [1, 2], reduce shrinkage [3] and creep [4], and improve the durability of cement-based materials [5]. Therefore, the addition of FA into cement can kill multiple birds with one stone. However, mixing in FA often significantly reduces the early strength of cement hardened paste [6], which is extremely unfavorable to its engineering application.

Studies have found that nano-silica (NS) has excellent micro-filling effect, nucleation and chemical activity [7], and the incorporation of NS can promote the hydration of cement clinker [8] and improve the compactness of cement-based materials [9], so it is helpful for improving the early strength and has a good application prospect in cement-based materials. The research of Flores et al. [10] found that the use of NS was helpful for refinement of the porous structure and for an increase in compressive strength of the paste, due to its role on heterogeneous nucleation and pozzolanic reactivity. Wang et al. [11] investigated the synergistic effects of NS and fly ash on properties of cement-based composites and pointed out that NS can promote cement hydration in the early stage and provide favorable hydration conditions for the later hydration of fly ash. Moreover, the synergistic effect of NS and FA significantly optimizes pore structure in the hardened paste. The study of Seifan et al. [12] indicated that the fly ash based geopolymer mortar with a dosage of 5% NS shows optimum results in workability and mechanical properties, mainly because of the pozzolanic and filling effects of large surface area nanosized particles on the cementitious matrix.

So far, the effect of NS on cement-based materials blending with fly ash has been widely studied, and especially its effect on the common fly ash system, many results having been obtained [11-14]. However, there has been rather little research on the influence of NS on the low quality fly ash system, which posesses the characteristics of many impurities, large firing loss, high water demand and low activity index. In this paper, low-quality FA and NS were added to study their influence on the strength of cement-based materials, and the mechanism of NS in improving the strength of low-quality fly ash-cement system is revealed through XRD, comprehensive thermal analysis, scanning electron microscopy and pore structure analysis. The results have certain reference significance for promoting the efficient utilization of high volume low quality fly ash and the engineering application of NS.

2 Experiment

2.1 Raw materials

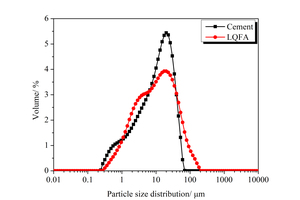

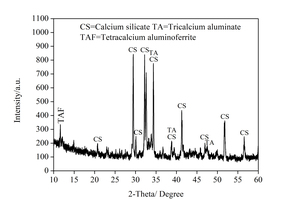

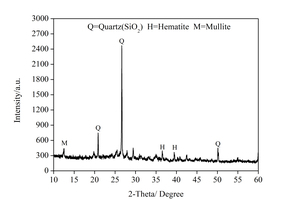

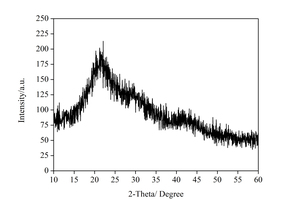

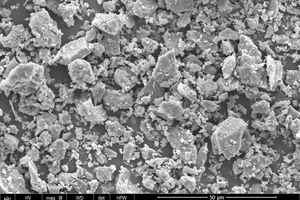

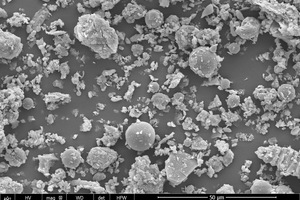

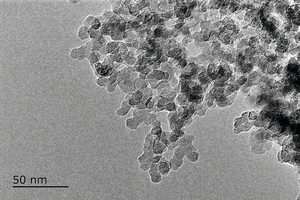

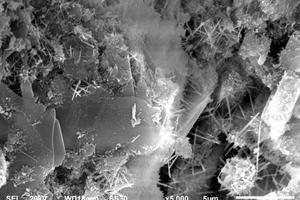

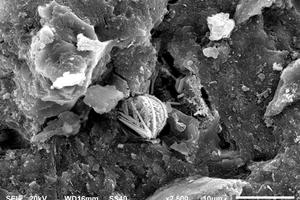

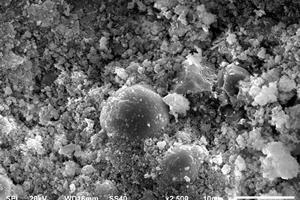

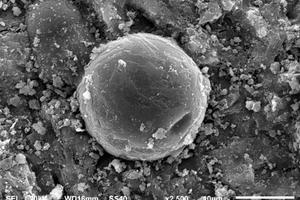

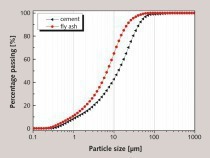

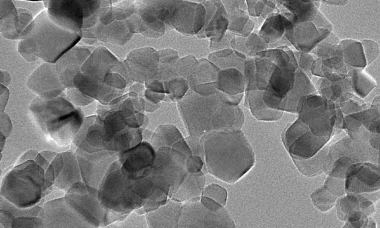

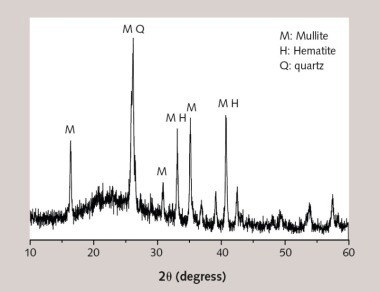

42.5 ordinary Portland cement, low quality fly ash (LQFA), ISO standard sand, and polycarboxylate superplasticizer (PCE), nano-silica (NS with a surface area of 300 m2/g and a particle size of 7-40 nm) and tap water were used to prepare mortar and paste. The chemical composition and particle size distribution of cement and LQFA are shown in Table 1 and Figure 1, respectively. The XRD patterns and the morphology images of cement, LQFA and NS are shown in Figure 2 and Figure 3, respectively. Nearly 10% ignition loss and rough surface appearance confirms that the fly ash used is of low quality. XRD patterns show that NS is an amorphous substance with a poor degree of crystallization. TEM imagary proves that the particle size of most NS is no larger than 20 nm.

2.2 Specimen preparation

The mortar specimen was prepared according to the mix ratio in Table 2. The water-cement ratio was controlled as 0.5 and the cement sand ratio was 1:3. LQFA was used as the supplementary cementitious material, which was 10%~30% replacement of cement. With a fixed ratio of 30% FA, 1%, 2%, 3% and 4% NS were added to study the synergistic effect of NS and LQFA on performance of the mortar. In order to ensure the uniform dispersion of NS in cement paste, nanoparticles were added into water and ultrasonically dispersed for 10~15 minutes before the sample preparation.

The mix ratio of the pastes for microanalysis is the same as that of the mortar except sand, and the stirring method is referred to GB/T1346-2011 [15]. When curing to a certain age, the samples were broken into small pieces and the middle parts were picked out to soak in anhydrous ethanol to stop the hydration. Parts of the small pieces are used for SEM and MIP analysis, and the remaining part is ground into powders for XRD and DSC-TG analysis.

2.3 Testing method

The compressive strength of the mortars cast in molds of 40 mm×40 mm×160 mm at 1 d, 3 d and 28 d was determined according to GB/T17671-1999 [16]. The phase of cement pastes was characterized by a Bruker D8 Advance X-ray diffractometer (XRD). DSC-TG analysis was carried out by STA449C/3/G synchronous thermal analyzer with the protective atmosphere of N2 and a temperature rise range of 30~1000 °C. The surface morphology of cement paste was observed by JSM-6610 scanning electron microscopy (SEM) with an acceleration voltage of 20 kV and a magnification of 2500 times under vacuum environment. The pore structure of cement pastes was measured by the AutoPore V 9600 mercury intrusion porosimeter (MIP).

3 Results and discussion

3.1 Compressive strength

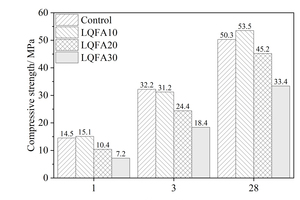

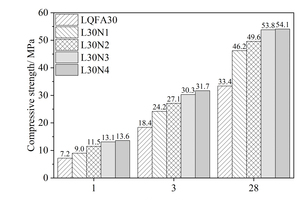

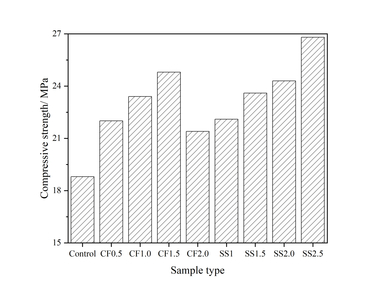

The influences of LQFA and LQFA-NS on the compressive strength of mortars at 1 d, 3 d and 28 d were measured, and the results are shown in Figure 4.

As can be seen from Figure 4 (a), when LQFA content is 10%, the strength of the sample is close to or even slightly increased compared with the control sample, mainly because the compactness improvement of cement-based materials caused by the filling effect and morphologic effect of fly ash at a lower content can make up for its influence of insufficient activity. When the fly ash content is greater than 10%, the strength decreases at 1 d, 3 d and 28 d, and the higher the fly ash content is, the more obvious the strength reduction is, primarily because the activity of fly ash was lower than that of cement clinker and less hydration products were generated. Among them, 30% fly ash can reduce the strength at 1 d, 3 d and 28 d by 50.34%, 42.86% and 33.60%, respectively. Obviously, the longer the curing time is, the smaller the strength reduction due to LQFA is. The reason for this phenomenon is that with the extension of age, the activity of fly ash is gradually stimulated by sufficient alkaline hydration products, and secondary hydration occurs to generate C-S-H gels and improve the strength at late age.

As shown in Figure 4 (b), the further addition of NS can additionally increase the compressive strength of cement mortar, and the higher the NS content is, the more obvious the improvement is. The strength of L30N4 at 1 d, 3 d and 28 d is 88.89%, 72.28% and 61.98% greater than that of LQFA30, respectively, and the strength of L30N4 at 28 d is even slightly higher than that of the control sample. This is largely because, first of all, the pores of the fly ash-cement system can be refined due to the nano filling effect of NS, making the structure more compact; On the other hand, NS can react quickly with calcium hydroxide (CH) to form C-S-H gels [17], which can be used as seeds to reduce the nucleation barrier of hydration products [18] and promote crystal growth. More hydration products are generated and the pores continue to be filled, making the structure denser and greatly improving the early strength. Simultaneously, previous studies [13, 14] have shown that NS can promote the secondary hydration of fly ash to a certain extent, so at 28 d, NS still significantly improves the strength of fly ash mixed samples.

The above results show that a certain amount of LQFA in cement has an adverse effect on the strength of cement-based materials, and the higher the LQFA content is, the more obvious the reduction is. However, after the incorporation of NS, the problem of early strength reduction caused by the incorporation of LQFA can be remedied, and with the extension of the age, the pozzolanic activity of LQFA is gradually stimulated and secondary hydration occurs. Therefore, when a suitable amount NS is incorporated, the late strength of the matrix with 30% LQFA would not be reduced, but increased.

3.2 XRD analysis

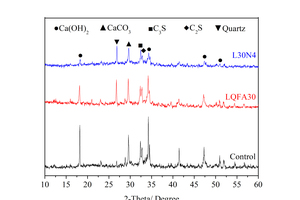

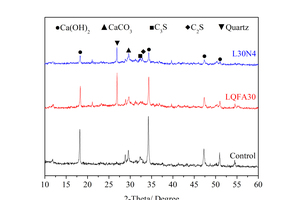

To investigate the effect of NS on hydration of the LQFA-cement system, XRD characterization was carried out on thecontrol samples, the LQFA30 and the L30N4 at 1 d and 28 d, and the results are shown in Figure 5.

By comparing the XRD characteristic peaks of each hydration sample, it can be seen that the phases in hydrated paste without LQFA mainly include calcium hydroxide (CH), calcium carbonate (CaCO3) and unhydrated calcium silicate (C3S or C2S). For samples with LQFA, in addition to the above four substances, the main phase also contains quartz, which is caused by the introduction of well-crystallized SiO2 after replacing cement with LQFA in equal amounts. As can be seen from Figure 5 (a), the CH and CS diffraction peaks of the LQFA30 sample are somewhat lower than those of the control sample, mainly because the incorporation of LQFA reduces the amount of cement clinker which can be hydrated to form CH [19]. Moreover, it is obvious that the peaks of CH and CS are much lower with addition of the LQFA-NS binary system than those with LQFA only. The reason for this phenomenon is that NS with a large specific surface area has high pozzolanic activity, which would consume a lot of CH; simultaneously, NS can be used as crystal seeds to promote the formation of hydration products, thus inducing the hydration of cement clinker [20].

From Figure 5 (b), the characteristic peaks of CH in these three samples at 28 d have the same trend: the lowest intensity of CH peak is in the L30N4 sample while the highest is in the control sample. However, the peaks of CS decrease significantly in all samples, which is due to the fact that CS is hydrated gradually as the time prolongs.

3.3 DSC-TG analysis

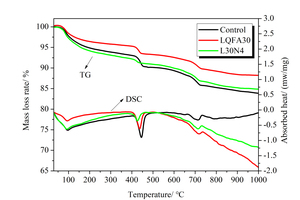

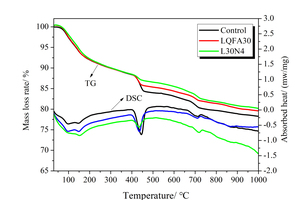

In order to explore the influence of LQFA and LQFA-NS on the hydration process of cement-based materials, DSC-TG analysis was conducted on the control sample, the LQFA30 sample and the L30N4 sample, and the results are shown in Figure 6.

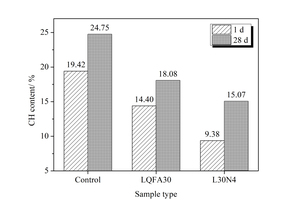

As shown in Figure 6, when the samples are heated from room temperature to 1000 °C, there are five obvious endothermic peaks in the DSC curve, corresponding to five mass losses respectively. Among them, the mass loss from 400 °C to 500 °C corresponds to the loss of crystal water from CH decomposition, and the mass loss from 500 °C to 750 °C corresponds to the decomposition of calcium carbonate (CC), which is accompanied by the formation of CO2. In General, CH can react with supplementary cementitious materials (SCMs) to produce C-S-H gels, so the degree of hydration of cement-based materials containing SCMs can be measured indirectly by the content of CH. Considering calcium carbonate as the carbonization product of CH, the following formula [20-22] can be used to calculate the content of CH in the hydration products and the results are listed in Figure 7.

⇥ (1)

Where MLCH and WLCC correspond to the mass loss percentage of CH and CaCO3 in TG curves respectively.

It can be seen from Figure 7 that the CH content of the LQFA30 sample is lower than that of the control sample no matter whether at 1 d or 28 d. On the one hand, this is because the incorporation of LQFA reduces the content of cement clinker; on the other hand, the pozzolanic activity of LQFA continuously consumes CH with the progress of hydration. However, because the content of LQFA is large and its activity is lower than that of cement clinker, the strength is also reduced by incorporation of 30% FA.

Moreover, the addition of 4% NS further decreases the CH content of the paste at 1 d, and since the pozzolanic activity of LQFA is not obvious at this time, the reason for the reduction of CH content is the consumption of CH by the pozzolanic effect of NS, which promotes the formation of C-S-H gels and improves the degree of hydration of cementitious materials. Therefore, the CH content decreases while the strength increases after incorporation of NS. With the age extended to 28 d, CH in hardened cement paste is continuously consumed by pozzolash reaction with LQFA and NS, and more C-S-H gels are generated. The lowest CH content of the sample with LQFA-NS at 28 d is the result of hydration of the cement clinker and pozzolanic reaction of NS and LQFA, and the L30N4 sample shows a highest strength level at this time.

3.4 SEM analysis

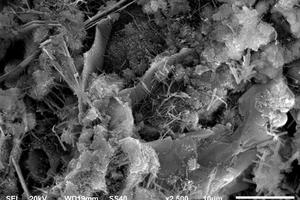

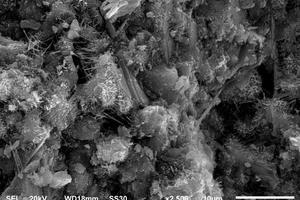

In order to confirm that the incorporation of a high volume of LQFA would reduce the strength of cement-based materials, while the incorporation of NS can make up for this shortcoming, SEM was used to characterize the micro-morphology of the control samples, the LQFA30 sample and the L30N4 sample, and the results are shown in Figure 8.

As shown in Figure 8, the degrees of hydration of all the three hydrated samples are relatively low at 1 d, and the hydration products are C-S-H gels, ettringite (AFt) and a few hexagonal sheets of CH. By comparing Figure 8 (a) and 8 (c), it can be seen that the compactness of the control sample and the LQFA30 sample is poor, which is caused by short hydration time and insufficient hydration products generation. The compactness of the hydration phase structure in Figure 8 (e) is significantly higher than that in Figure 8 (c), which is mainly because the micro-filling effect of NS and the promotion effect of its pozzolanic activity on the nucleation and growth of hydration products can make the structure denser.

At 28 d, the degree of hydration of the control sample, the LQFA30 sample and the L30N4 sample are all improved compared to that at 1 d because of the continuous hydration reaction. In addition, there are no apparent AFt and CH in Figure 8 (f), probably because they are covered by hydration products, and the structure of the L30N4 sample is significantly denser than that of the control sample and the LQFA30 sample, which also explains why the incorporation of NS can improve the strength of the LQFA-cement system, even exceeding the strength of the control sample.

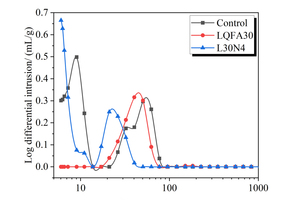

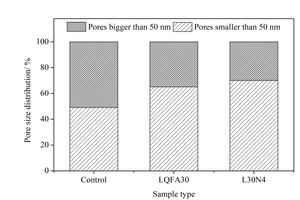

3.5 Pore structure analysis

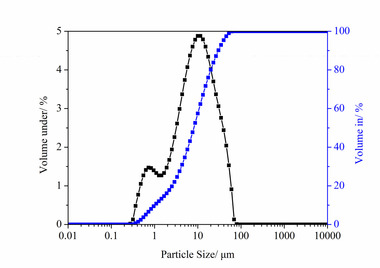

For the purpose of studying the influence of LQFA and LQFA-NS on the pore structure of cement-based materials, MIP tests were conducted on the control sample, the LQFA30 sample and the L30N4 sample at 28 d, and the results are shown in Figure 9.

Based on the effect of pore structure on strength, pores in cement-based materials can be divided into four categories, namely, harmless pores (smaller than 20 nm), less harmful pores (20 nm~50 nm), harmful pores (50 nm~200 nm), and very harmful pores (bigger than 200 nm) [23]. In general, the pore size bigger than 50 nm has a great influence on the strength, while the pore size smaller than 50 nm has less effect on the strength. The pore size distribution percentage at 28 d is shown in Figure 10.

From Figure 9 and Figure 10, for the control sample, the amount of harmful pores and very harmful pores accounts for almost half of all pores; After mixed with LQFA, the total pore volume is reduced, and the proportion of harmful pores and very harmful pores also decreases compared with that of the control sample, indicating that the filling effect and pozzolanic effect of fly ash can effectively fill the pores and make the hardened cement structure more compact. Even so, because the activity of LQFA is lower than that of cement clinker and less hydration products are generated, the strength of the LQFA30 sample is also lower than that of the control sample, showing that the strength of cement-based material is not only related to its microstructure, but also related to the amount of hydration products. When NS is continued to be added, the proportion of harmful pores and very harmful pores are further decreased, while the proportion of less harmful pores and harmless pores are increased, which is also the reason for the strength improvement of the LQFA-cement system caused by NS incorporation.

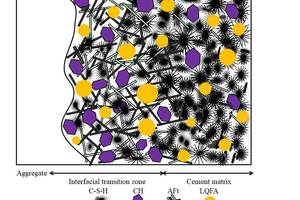

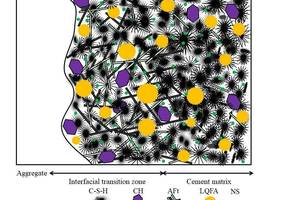

3.6 Synergistic effect mechanism

According to the above experimental results, the microstructural model of cement-based materials induced and regulated by LQFA-NS can be established, as shown in Figure 11~Figure 13.

As shown in Figure 11, in the control sample, the interfacial transition zone (ITZ) has more oriented CH crystals and AFt crystals, while the C-S-H gels have less. The porosity of the ITZ is relatively high and with the gradual transition to the cement matrix, the porosity decreases continuously until it is similar to the cement body.

As shown in Figure 12, in the sample mixed with LQFA, the amount of cement is reduced, and LQFA can react with CH crystals, effectively reducing the enrichment and preferred orientation of CH in the ITZ. In addition, the micro-aggregate filling effect of LQFA and the reduction of AFt amount make the microstructure of the ITZ more compact, and the difference between the ITZ and the cement body is narrowed. The amount of CH in the cement body is also reduced, and the overall structure develops to a more dense direction.

As shown in Figure 13, with the incorporation of nanoparticles, the enrichment and preferred orientation of CH in the ITZ are greatly reduced, due to the high pozzolanic activity of NS and its role in promoting the secondary hydration of LQFA. CH crystals are also refined to a certain extent, along with NS for the improvement of cement hydration and its excellent micro aggregate filling effect, so the density of the ITZ is significantly increased. The CH in the cement body is also greatly reduced, and the gel products are also increased. In this case, the consistency between the ITZ and the cement body is enhanced, the width of the ITZ is reduced, and the overall structure tends to be uniform, which significantly improves the mechanical properties of the sample.

4 Conclusion

When a certain amount of LQFA replaces cement in equal quantities (> 10%), the early strength of cement-based materials is significantly reduced. When the dosage of LQFA is in the range of 10%~30%, the greater the dosage, the more obvious the strength reduction. When the dosage of LQFA reaches 30%, the strength of mortars at 1 d and 3 d decreases by more than 40%, respectively.

In the case of 30% LQFA, the early strength of mortars is increased along with the rise in dosage of NS in the range of 1% to 4%. When the dosage is 4%, the strength at 1 d and 3 d can be increased by more than 70%, and at 28 d even exceeds the strength of the control sample.

Under the combined action of NS and LQFA, not only is the problem of early strength loss caused by the incorporation of LQFA offset, but also the microstructure of cement-based materials is denser and the strength is also improved in the later stage.

5 Acknowledgement

Financial supports from the Innovation and Entrepreneurship Training Program of Hubei University Students (S202210495067) and Hubei Provincial Excellent Young and Middle aged Science and Technology Innovation Team Project of Colleges and Universities (T2022002) are gratefully acknowledged.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.