The influence of complex additives

on the endurance strength of concrete

How does a new and complex additive, consisting of polycarboxylate ether as a water-repellent impregnation and a setting accelerator, effect the durability of concrete? The article discusses the influence of this additive on the shrinkage, swelling and sulphate-resistance of the cement mixture, and on the frost resistance, water resistance and porosity.

The development of high-performance superplasticizers (SP) has created the opportunity to utilize them in the creation of complex additives in order to manufacture high-strength and high-quality concretes with a low water-to-cement ratio while reducing the capillary porosity, which determines the durability of the concrete.

We have developed a complex additive consisting of an SP, a setting accelerator and a water-repellent impregnation (WR). The selected SP was the additive odolite-K, which is based on polycarboxylate ether (“service group”), the setting accelerator used was so-dium sulphate (So), and the WR was an insoluble silicone oligomer PVS-50 (Tscheboksary Chimprom) [2].

The optimum dosage of the additive components was determined on the basis of statistical test planning. This dosage was: SP 1 %, setting accelerator 15 %, WR 0.1 % of the weight of cement.

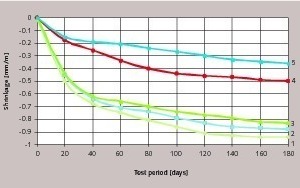

The study determined the effect of the optimum content of the additive mixture and its components on the kinetics of the shrinkage deformation of the 1:3 cement/sand mortar mixture. The results of the study show that, compared to a mortar without the additive, the addition of SP reduced the shrinkage of the 180-day mortar by a factor of 1.8 (Fig. 1). Mortar samples of the same age with the addition of So and WR showed a respective shrinkage of 0.89 and 0.81 mm/m and did not differ significantly from the control sample. The optimum content of the components of the complex additive significantly reduces the shrinkage of 180-day mortar by a factor of 2.5 compared to the control group.

It is a known fact that attack on cement, particu-larly when it is exposed to aggressive liquid media, takes the form of dissolution of cement components or creation of new compounds in the cement paste matrix caused by the interaction of hydrates and aggressive media. These new compounds have a greater volume than the sum of the volumes of the original cement compounds. The resultant increase in volume due to the hydrated new compounds causes internal stresses and the formation of cracks, leading to the destruction of the concrete [3].

Against this background, we investigated the effect of additives on the sulphate-resistance of a cement/sand mortar mixture of 1:3. Table 1 contains the test results, showing the effect of the additives on the strength and chemical resistance of cement/sand mortars.

The selected criterion for the evaluation of sulphate-resistance was the so-called sulphate-resistance coefficient SRC, which represents the ratio of limit flexural stress in samples with a size of 4 x 4 x 16 cm, which had been immersed for 180 days in a 5 % So solution to the flexural strength of reference samples which had been immersed for 180 days in tap water.

As Table 1 shows, the additive with all its components increases the sulphate-resistance of cement/sand mortar. As expected, the highest sulphate-resistance of 78 %, compared to the formulation without the additive, was achieved with the addition of the complex additive.

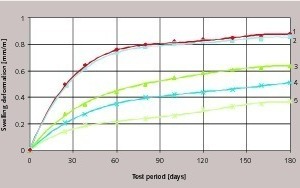

In order to ascertain the effect of the additive and its components on the swelling deformation in a corrosive environment, the kinetics of the swelling deformation of a 1:3 cement/sand mortar were determined in a 5 % solution of sodium sulphate (Fig. 2). It was found that the swelling deformation of the cement/sand mortar with the complex additive was 2.2 times smaller than the deformation of a mortar without the additive. All the components of the complex additive contribute to the reduction of deformations at all stages of the test, smaller deformations being determined when SP 1.7 was added and when WR 1.3 was added than occurred in the sample without additive. The smaller amount of swelling in the samples with additive compared to the samples without additive is explained by the reduced capillary porosity of the cement/sand mortar. This reduction in capillary porosity is obtained through the 32 % decrease in water/cement ratio.

It is known that a reduction in the water/cement ratio increases the density and reduces the total porosity of concrete, which has an inevitable effect not only on the absorption but also on the modification of physical and mechanical properties, cold strength and water resistance. In order to determine the effect of the additive and its components on the porosity and the frost and water resistance, we carried out the following experiment: using concrete mixes differing in the content of Portland cement, we determined the porosity parameters in accordance with national standard 12730,4-78. The frost resistance was determined using sample cubes of 10 x 10 x 10 cm in accordance with national standard 10.060,3-95 with the aid of the “Concrete-Frost” device. The water resistance of concrete was determined in accordance with annex 4 of the national standard 12730,5 on the “Agama-2RM” device by means of the air permeability test. The results of the experiments are depicted in Table 2.

The data in Table 2 shows that the check sample of concrete without additive characteristically displays the highest porosity. Such concrete is characterized by a high water/cement ratio, which leads to a higher capillary porosity in the hardened concrete. The change in capillary porosity takes place in its entirety through the increase in the degree of cement hydration and the amount of calcium hydrosilicates C-S-H [4], which is confirmed by the X-ray analysis [5]. The very low porosity and the small proportion of capillary pores, the increase in closed porosity at the expense of less capillary porosity, leads to a significant increase in frost- (F) and water resistance (W) of the concrete. In such pores the water freezes at temperatures significantly lower than -20 °C.

The specific consumption of cement in concrete has a significant influence on the formation of the pore structure of the concrete. Addition of the complex additive to the concrete with a cement consumption of 300-600 kg/m3 reduces the total porosity by 40-45 % compared to the formulation without the additive. At a cement consumption of 600 kg/m3, the proportion of capillary pores decreases by 52 %. The decrease is as high as 57 % in the case of a cement consumption of 450 kg/m3 and is 51 % at a cement consumption of 300 kg/m3, while the proportion of capillary pores in concrete without additive is, on average, 55 % of the total porosity. The additive raises the proportion of relatively closed pores in the concrete by 14 % in the case of a cement consumption of 300 kg/m3, by 16 % at a cement consumption of 450 kg/m3, and by 18 % at a cement consumption of 600 kg/m3, compared to the formulation without the additive.

In order to confirm the results of the concrete pore structure determination, the following experiment was carried out: it is aimed at assessing the effect of the complex additive and its components SP and WR on the water absorption due to capillary suction in accordance with national standard 31.356-2007. The results are presented in Table 3.

These results show that the water absorption due to the capillary suction WCS is 80 % lower with the complex additive than it is in the formulation without the additive. The greatest contribution towards the reduction in capillary porosity is made by WR (30 %), followed by SP (22 %).

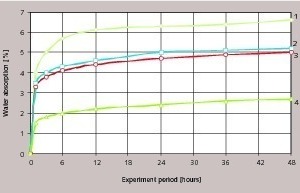

The samples for determination of the capillary suction were also used for measurement of the water absorption after 48 hours. The diagram shown in Figure 3 depicts the increase in weight due to water absorption of cement/sand mortar with the additive and its components.

The data show that the complex additive reduces the water absorption of the cement/sand mortar after 48 hours by 60 %, compared to the formulation without the additive. It should be noted that WR makes the greatest contribution of all the components of the complex additive to the reduction in water absorption.

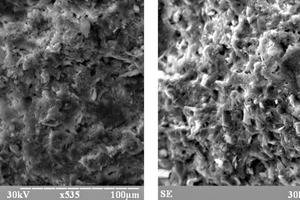

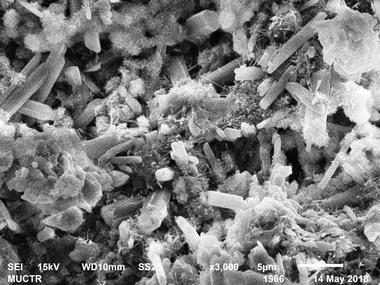

The setting of Portland cement takes place in the initial phase through the reaction of calcium aluminate, with gypsum as a crystallization process to form calcium sulphoaluminate with a simultaneous increase in volume. The addition of sodium sulphate in the complex additive causes the formation of colloidal gypsum, which causes a more intensive formation of calcium sulphoaluminate and is more capable of participating in the reactions than gypsum in the form added to Portland cement clinker (Fig. 4).

The following conclusions are to be drawn from this study:

Addition of the complex additive reduces the shrinkage of cement mortar by a factor of 2.5;

The sulphate-resistance of cement mixtures with the complex additive is 78 % higher than in cements without the additive. In a 5 % solution of sodium sulphate, deformation by swelling is reduced by a factor of 2.2 compared to a mortar without the additive;

Modification of the concrete by adding the complex additive significantly raises the frost resistance (up to 800 F) and the water resistance (up to W20). This is primarily due to a 51-57 % reduction in capillary porosity, and a 40-45 % reduction in total porosity, as well as an increase of 14-18 % in closed porosity;

In formulations including the complex additive, the water absorption due to capillary suction is 80 % less and the weight-related water absorption is 60 % less than they are in mixtures without the additive.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.