Aspects of gypsum dihydrate crystallization in the artificial aging of gypsum binder

The present paper investigates aspects of the crystallization of gypsum dihydrate during the artificial “aging” of calcined gypsum binder. On the basis of these data, it then describes the technological parameters of artificial “aging” of gypsum binder. The building and technical properties of artificially “aged” gypsum binder were significantly higher than those of non-“aged” binder.

1 Introduction

The search for effective technological operations to stabilize technical characteristics used in producing gypsum binders has received a great deal of attention in recent years owing to the instability of calcined gypsum properties [1]. Gypsum hemihydrate is a material used in the building industry and produced by means of calcinating gypsum. Calcined gypsum has a wide range of possible uses in many areas of the building industry and has also been investigated to improve its building and technical properties. However, it has been found that the investigation of the microstructure...

1 Introduction

The search for effective technological operations to stabilize technical characteristics used in producing gypsum binders has received a great deal of attention in recent years owing to the instability of calcined gypsum properties [1]. Gypsum hemihydrate is a material used in the building industry and produced by means of calcinating gypsum. Calcined gypsum has a wide range of possible uses in many areas of the building industry and has also been investigated to improve its building and technical properties. However, it has been found that the investigation of the microstructure of calcined gypsum enables a search for effective technological operations to improve its properties. One way to determine an effective operation is to investigate phase content, specific surface area, external and internal structural defects of calcined gypsum [2]. For example, Greg et al. and Melikhov. studied the influence of different air humidity on the technical properties of gypsum binders. However, although the effectiveness of humid air was demonstrated over two years ago [4], little attention has been paid to the investigation of the action of the adsorbed water molecules from the humid air on the surface of calcined gypsum.

2 Experimental

The current investigation involved analysis of aspects of the crystallization of gypsum dihydrate during the artificial “aging” of gypsum binder. The samples were selected from the Chelyabinsk gypsum plant, located in the Chelyabinsk region of Russia. The samples were gypsum binders of β-modification of G4 grade. A total of four samples were collected in separate 25-kg bags. The bags containing the samples were shipped from the plant directly to the laboratory at Nosov State Technical University. The artificial “aging” of the samples was performed separately during 14-day storage in exsiccators at a temperature of 20 °C and relative air humidity of 60 %, 80 % and 100 % (φ = 0.6; 0.8; 1.0). Each sample was analyzed to define the specific surface area, water consumption initially, and then after 3, 7 and 14 days of storage.

3 Results and Discussion

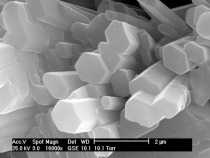

Data obtained in previous studies using the technological operation of artificial “aging” indicated that keeping gypsum binder at different relative humidity affected its building and technical properties. According to [2], the hydration of gypsum binder and the soluble anhydrite with formation of gypsum dihydrate could be considered as a criterion for assessment of the rate of “self-healing” defects. In our study, the parameters of water consumption and change in specific surface area during artificial “aging” storage were measured. Figure 1 shows the microdefects of calcined gypsum particles. As can be seen, calcination of gypsum raw material led to formation of soluble anhydrite, internal and external structural defects, which is consistent with results obtained in previous studies (Figure 1).

However, the water consumption capacity of calcined gypsum was high at the level of 56 % owing to the presence of soluble anhydrite. Although the obtained results were in line with Melikhov’s findings [4], a striking difference was noted when the technological process of artificial “aging” at different air humidity was applied.

The essence of this process is maintaining the gypsum binder at different relative air humidity. During this process, the hydration of the gypsum binder and the soluble anhydrite with formation of dihydrate gypsum takes place. In addition, it is accompanied by a process of “self-healing” of defects. It is worth noting that the artificial “aging” reduces the water consumption capacity of gypsum binder and increases its compressive strength.

Two features characterize the process of artificial “aging”:

hydration of the hemihydrate with the lack of liquid phase;

gypsum dihydrate is crystallized in a confined volume of the original binder micropores.

Artificial “aging” of gypsum binder is accompanied by the adsorption of water molecules on the surface and on the defects of gypsum binder particles, and also with condensation of water vapor in ultrathin pores (cracks). It should be stressed that the thickness of a liquid film depends on the relative humidity of the air.

For example, at high relative humidity (φ = 1) the thickness of the liquid film is about 90 microns. In this film, the water is in a droplet liquid state (bulk water). At the same time, at φ = 0.8, the film thickness is in the range of 5.6 to 8.1 µm, and at φ = 0.6, the liquid film has a thickness of 3 μm. According to [2], water films formed on the surface of gypsum particles at φ ≤ 0.8 have anomalous properties. In particular, the films exhibit high strength of about 25 MPa. The water in these films has properties similar to those of a solid body, i.e. it differs from the bulk liquid, and this can lead to a change in the mechanism of gypsum binder hydration during the artificial “aging” process.

It can be assumed that the topochemical or mixed mechanism of hydration takes place at a relative humidity less than 80 %. At 100 % humidity, the quasi-rational hydration mechanism will predominate. Changing of the hemihydrate hydration mechanism during the artificial “aging” process can form different modifications of the calcium sulfate hydrate. The formed modifications differ from each other primarily by the lattice parameters and the chemical composition [3]. Melikhov reports that lamellar crystals of calcium sulfate are formed during the gypsum aging, the composition being CaSO4 · nH2O with n = 1.86 ± 0.05. It is worth noting that such a variable chemical composition of hydration products determines their morphological heterogeneity and multiple stages of crystallization both in the micropores and on the surface of the initial hemihydrate particles [4].

According to the conventional notion, the crystallization process consists of two stages: the formation of nuclei and growth of crystals. The formation of nuclei becomes possible at a certain (critical) degree of supersaturation of the substance solution, the molecules being involved in the new phase formation. Severin et al. established experimentally that the rate of crystal growth of CaSO4 · 2H2O from aqueous solution is an S-shaped dependence on the supersaturation [5]. The speed of crystal growth with increasing supersaturation progresses to a limit, which can be interpreted as the adsorption inhibition of growth. It should be stressed that such inhibition to a certain degree is manifested only at high supersaturation, which is typical for small systems: micropores and micro-cracks. Consequently, such a phenomenon may take place in relation to the process of artificial aging at a relative humidity less than 80 %.

The formation of new phases can occur via the heterogeneous mechanism, when the substance is condensed on pre-existing surfaces (walls of the pores and micro-cracks, foreign inclusions, condensation nuclei). As mentioned above, both the composition and structure of crystals change in the growth process. Each growing crystal captures the non-equilibrium amount of impurities, and in its volume are formed by the growth of structural defects. The growth of gypsum microcrystals is followed by the formation of two-dimensional clusters and then by merging of the clusters in multi-molecular layers. If the surface of the crystals has a relief in the form of steps and “hills” of growth, then approximation of the crystal hillocks and steps can provide local molecular contact of the crystals. Designated contacts can be active centers of outgrowth formation, linking the crystals to agglomerates (crystal bridges) at any environmental supersaturation. Owing to the deposition of the substance on the walls of micropores and cracks, a concentration gradient develops, with the concentration maximum at their entrance. It allows formation of outgrowths, which stick to each other and lead to bridge crystallization [4].

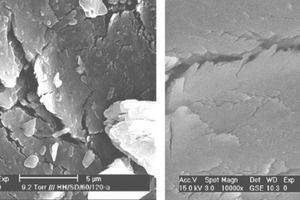

The growth of gypsum crystals through the accession of the two-dimensional nuclei becomes energetically unfavorable with the decrease of supersaturation degree. In this case, the growth of crystals develops in a dislocation mechanism [3, 6]. The dislocation growth mechanism allows from one center of crystallization the formation of a few crystals for embedding particles of crystallizing substance in a lattice of growing crystal. This phenomenon is known as splitting crystals [6]. It is due to the fact that secondary nuclei occur on the surface of the primary dihydrate gypsum nucleus, formed on the walls of microfractures, i.e. it is two-dimensional nucleation on their own substrate. The primary nucleus of calcium sulfate crystals converted to a solution at the side (-111), because this side grows based on the mechanism of two-dimensional nucleation [7]. The secondary gypsum nuclei form and grow on the surface of the primary crystals until they completely cover the entire surface of the cracks and fill its volume (Figure 2).

Figure 2 presents the crystals of gypsum dihydrate in the cracks of the particles of the initial gypsum binder.

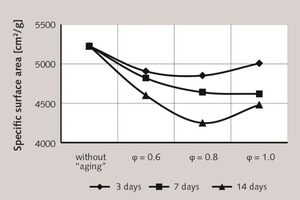

The self-healing process of microdefects particles is naturally accompanied by both a decrease in the specific surface of the gypsum binder (Figure 3) and water consumption capacity (Table 1).

A quantitative analysis to evaluate the effectiveness of artificial “aging” was applied, based on the theoretical hypothesis of the “aging” mechanism. Based on this approach, the theoretical prediction for this study was confirmed in experiments. Nevertheless, these results suggest that experimental data obtained may provide more sensitive information for assessing the impact of the artificial “aging” process on the gypsum binders.

4 Conclusion

Prior work has documented the effectiveness of using artificial “aging” in improving building and technical properties and reducing water consumption capacity. Melikhov, for example, reports that the gypsum forms lamellar crystals of calcium sulfate containing CaSO4 · nH2O at n = 1.86 ± 0.05 during artificial “aging”. However, these studies have either been short-term studies or have not focused on the mechanism investigation of artificial “aging”. In this study, we investigated the process of gypsum dihydrate crystallization in micro-pores of gypsum binder during artificial “aging”. We found that in comparison with the control sample, the water consumption capability of the sample artificially “aged” at 100 % air humidity during three days was associated with formation of gypsum dihydrate.

These findings extend those of Melikhov, confirming that the artificial “aging” enables an improvement in the technical characteristics of gypsum binder. In addition, the results obtained in our study confirmed that artificial “aging” changed the technical properties of gypsum binders. This study therefore indicates that the benefits gained from artificial “aging” may improve building characteristics. Most notably, this is, to our knowledge, the first study to predict the effectiveness of artificial “aging” of gypsum binders. Our results provide compelling evidence for using artificial “aging” and suggest that this approach appears to be effective in improving the properties of gypsum-containing binders. However, some limitations are worth noting. Although our theoretical hypotheses were supported experimentally, the conditions selected should be assessed. Future work should therefore include follow-up work designed to evaluate whether the other new gypsum-containing materials are confirmed with our theoretical hypotheses and also whether the properties of the new gypsum-containing materials may be changed by means of artificial “aging”.

The article is based on a paper presented at the 3rd Weimar Gypsum Conference in Weimar, 14.03.-15.03.2017.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

![2 The dihydrate gypsum crystals in the microcracks of the particles of the initial gypsum binder [1]](https://www.zkg-online.info/imgs/1/2/3/3/5/1/9/tok_c3fe6bce6f86f845735069fb5766b454/w300_h200_x400_y260__800_520.-f460471644b491fe.jpg)