Properties of building gypsum treated

using the vortex layer apparatus

This article describes the influence of activation of building gypsum in the vortex layer apparatus on the specific surface, setting time, heat release, change in mineralogical composition and strength of the hardened gypsum paste. A way of evaluating the efficiency of the physical effects and of defining the mechanical activation effect is proposed.

1 Introduction

It is acknowledged that the physical processing of substances is often accompanied by increased intensity of the physico-chemical processes at the interphase boundary. This is known as mechanoactivation [1].

The influence of mechanoactivation on the physico-chemical properties of mineral binders and the performance properties of the artificial hardened products obviously depends on the type of binder. Mineral binders in which the initial structure formation is attributed to the flow of both topochemical and crystallization processes (e.g. Portland cement) feature the onset of...

1 Introduction

It is acknowledged that the physical processing of substances is often accompanied by increased intensity of the physico-chemical processes at the interphase boundary. This is known as mechanoactivation [1].

The influence of mechanoactivation on the physico-chemical properties of mineral binders and the performance properties of the artificial hardened products obviously depends on the type of binder. Mineral binders in which the initial structure formation is attributed to the flow of both topochemical and crystallization processes (e.g. Portland cement) feature the onset of mechanoactivation and significant positive effects when treated using a vortex layer apparatus [2]. This is mainly due to the increase in the intensity of interphase interactions, which naturally affects the parameters of a structure (yielding a finely crystalline structure of the artificial hardened product with a large number of contacts) and the properties of the hardened cement paste [3].

The determination of how the vortex layer apparatus treatment affects the properties of mineral binders where the initial structure formation occurs by the Le Chatelier crystallization mechanism (e.g. gypsum) is of scientific and practical interest both for establishing the advantages of mechanoactivation and for determining the operating modes of apparatuses that improve the performance properties.

The crystal lattice of gypsum has a layered structure. Water molecules are distributed layer-by-layer between bi-layer packets of CaSO4, which is characterized by perfect cleavage in this direction. Moreover, each water molecule binds the Ca2+ ion with two O2- ions, one of which is located in the next layer. The water molecules are arranged between the layers and are thus better separated from the gypsum crystals [4].

In the gypsum industry there is no need for preliminary mechanical activation of the raw materials. Mechanical treatment is used mainly for phosphogypsum [5-6] or for gypsum binders made using heat treatment [7]. The possibility of obtaining an unburnt anhydrite binder by short-term grinding of natural gypsum-anhydrite rock together with a complex hardening activator in the vortex layer apparatus has been reported [8].

This paper focuses on examining how the treatment of G-5 grade gypsum (ß-hemihydrate) by the vortex layer apparatus affects the setting time of gypsum paste and the physical and technical properties of the hardened gypsum paste.

2 Research methods

2.1 G-5 grade gypsum

BII (ß-hemihydrate) as per GOST 125-79 produced by CJSC “Samara Gypsum Combine” was used for the research.

The specific surface was determined by the air permeability method using the PSKh-9 instrument.

The setting time of the gypsum paste, the compressive strength and bending tensile strength, and the content of hydrated water were determined as per GOST 23789-79.

Optical images of gypsum samples after treatment using the vortex layer apparatus were obtained with a Levenhuk D870T digital optical microscope (8 Mp, trinocular type).

X-ray photographs were taken with an automatic D2 Phaser X-ray diffractometer (Bruker AXS GmbH). The diffraction spectra obtained were processed by the Diffrac.Suite software package. Phases were identified using the diffraction data base ICDD PDF-2 Release 2013 via the Diffrac.Eva-v3.1 software package. Quantitative calculation of the phases was carried out by the Rietveld method using the Diffrac.Topas-v4.2 software package.

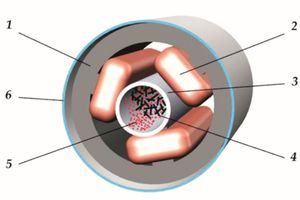

The Portland cement was treated in the vortex layer (ABC) apparatus model 297 produced by LLC Regionmetrans. Figure 1 shows a typical configuration of the vortex layer apparatus.

When a binder is ABC-treated with exposure to shock effects from ferrimagnetic bodies, not only does the specific surface of the binder increase but more defective particles occur. In this case, the degree of this transformation of the substance of the particles depends both on the ABC vortex layer energy density and on the intensity and force of the collisions between the substance particles and the ferrimagnetic bodies. The mode of grinding of building gypsum in the ABC vortex layer was taken from preliminary experimental studies. The treatment time was 3 min, the electromagnetic field rotation frequency was 70 Hz, the ratio of the ferrimagnetic body diameter to the length was 0.12, and the ratio of ferrimagnetic body weight to the weight of grinding material was 0.65 [9, 10].

3 Results and discussion

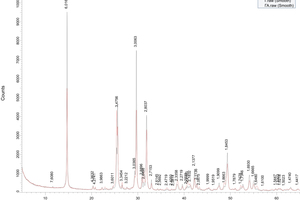

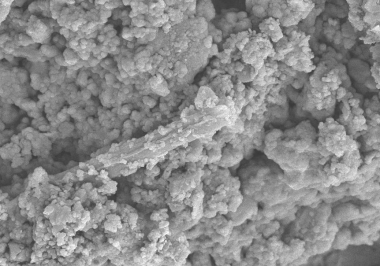

The effects of the treatment time for building gypsum in the ABC vortex layer on the geometric dimensions of the gypsum particles are given in Table 1, on the mineralogical composition of the gypsum binder are given in Table 2 and Figure 2

and on the setting time of the gypsum paste and the physical and mechanical properties of the hardened gypsum paste are given in Table 4.

A natural consequence for the ABC-treated gypsum binder is the increased specific surface Sspec. Analysis of the data in Table 1 shows that Sspec. = (t) indicates a change in kinetics of an extreme nature: the maximum Sspec. (Sspec. increases by almost 200 %) is observed after ABC treatment for 3 min.

The increasing temperature that accompanies the ABC treatment process leads to a change in the mineralogical composition of the building gypsum (Figure 2 and Table 2).

It is clear from analysis of the X-ray images that the initial gypsum and treated building gypsum are substantially different at the following intensities of diffraction peaks: d = 6.01; 3.006; 2.803; 2.1377; 1.8453 Å, which are typical for the ß-modification of the hemihydrate gypsum (CaSO4·0.5H2O) and at d = 3.74; 2.849; 2.3358; 2.223; 1.866 Å, which are typical for the anhydrite (CaSO4). The quantitative compositions of the mineral phase of the initial gypsum and treated building gypsum are shown in Table 2. This shows that the ß-hemihydrate gypsum transforms into anhydrite when treated in the ABC vortex layer. In this case the ß-CaSO4·0.5H2O content decreases by a factor of 1.5 and the CaSO4 content increases by a factor of 3.3.

The data obtained can be used to estimate the water demand for the production of CaSO4·2H2O. The amount of water need to hydrate ß-CaSO4·0.5H2O can be found using the formula:

⇥ (1)

and to hydrate CaSO4 using the formula

⇥(2)

where Q1 is the amount of ß-CaSO4·0.5H2O and Q2 is the amount of CaSO4.

The calculation made using the data in Table 2

shows that the total amount of water necessary for hydration of the initial gypsum binder is 17.1 % and for hydration of the treated gypsum is 19.1 %, i.e. the difference is 2 %. This result is very useful for calibrating experimental data on the content of hydration water in hardened gypsum paste.

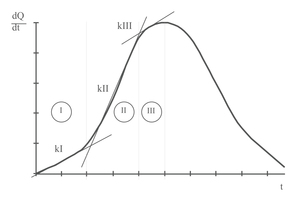

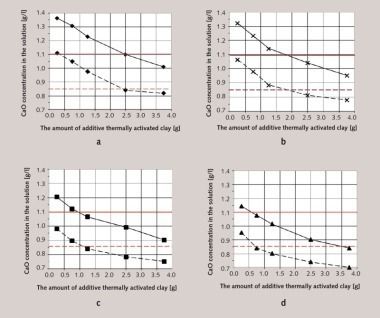

The change in the mineralogical composition leads to a regular change in the kinetics of the chemical reactions, for which the intensity can be estimated from the heat release kinetics (Figure 3a).

It is expedient to analyse the factors affecting the heat release kinetics by distinguishing individual stages. In particular, it is expedient to distinguish three sections for the factors obtained (Figure 3b). Each section is characterized by the parameters given in Table 3.

From the data for the heat emission kinetics during hydration of the gypsum binder material it can be concluded that the ABC-processed gypsum has a better water-contact performance. For each of the sections selected the values of the coefficient ki are better than those for the initial gypsum material. However, the total heat emission values in the selected areas are slightly higher in the initial gypsum, i.e. initial gypsum binder material: 1672.50 J/kg, ABC-processed gypsum: 1635.0 J/kg. This is probably caused by the differing anhydrite content in the gypsum binder materials in question (Table 2).

It is known [11] that the b hydration and modi-fication of hemihydrate gypsum results in a heat emission of 19.3 J/mol. If the heat emission and b gypsum content data (Table 2) are recalculated it will be found that hydration of the initial building gypsum results in a heat emission of 3186.8 J/mole while hydration of the ABC-processed gypsum results in an emission of 4685.3 J/mole, which is 47 % higher. This is a convincing proof of the intensification of the boundary (binder – water) physical and chemical processes caused by the ABC processing.

This change in the geometry of the gypsum binder particles has an effect on the initial structuring process and properties of the gypsum paste and hardened gypsum paste (Table 4).

Table 4 shows that the ABC processing of gypsum for up to three minutes may reduce the setting time by 2–10 min. There is also a slight increase in normal density of gypsum paste caused by the increased specific surface area of the gypsum (Table 1). A three minute (maximum) ABC processing results in a significant increase in compressive strength (44 %) and flexural strength (50 %). ABC processing of the binding material for over three mins results in balling or granulometric heterogeneity of the material. ABC processing for 5 mins led to a 30 % decrease in compressive strength and a 71 % decrease in flexural strength of the gypsum.

Also characteristic of the change of the structuring rate after ABC processing is an increase in the volume of hydration water, e.g. the hydration water content had increased by 2 % after the 3 minute ABC processing. This amount matches the value calculated in accordance with Table 2. A decreased W value resulting from the increase in ABC processing time (to more than 3 min) is likely to be caused by transformation of the anhydrite into the insoluble modification.

Unlike the situation with Portland cement [3], the boundary physical and chemical processes have a great impact due to the high level of impurity of hemihydrate gypsum. It is therefore not correct to assess the impact of physical processing (ABC) solely on the basis of property (especially strength) increment rates due to boundary area modification. This requires modification of the methodology. Suppose that the material property subject to structural parameters (e.g. strength) depends on two overall factors:

intensity factor to evaluate the impact of boundary process intensification

extensiveness factor E to evaluate the impact of boundary surface area changes

It is clear that the said factors are interrelated but having different units of change. In this respect the form of a general equation to describe the impact of these factors on the property F will be as follows:

⇥3)

where m, n are coefficients to evaluate the input sensitivity of the said factors and kI, kE are adjustment factors to reduce the units of factor change to a property unit of measurement F.

Conversion of the above formula with respect to the initial property value F0 results in:

⇥(4)

In this last formula, in addition to the relative modification of properties or factors, it is also important to note the values of coefficients m, n that indicate the efficiency of solutions under assessment:

the value of coefficients m and/or n = 1 is indicative of an equal contribution of factors to the property change

values of coefficients m and/or n > 1 are indicative of a synergistic effect

values of coefficients m and/or n < 1 are indicative of a disproportionate contribution of factor modification to the property change.

The latter may not only be indicative of a non-efficient solution proposal (e.g. in the physical processing of materials) but can also provide evidence of their specific structuring. To find the key reason it is important to conduct an analysis of the value change rate F/F0 with both an extensive factor and an intensive factor:

⇥

⇥

and⇥(5)

⇥

According to the above equations the property change rate for m and/or n < 1 should be decreased depending on the factor under consideration. A symbatic change in the function rate as calculated using the experimental and statistic model, and in the function rate as calculated using the above formulas, is indicative of non-efficient proposal solutions; otherwise, it is indicative of specific features of the structuring process in the material in question.

The ABC processing efficiency is evaluated by using the proposed methodology (for gypsum binder material) based on the data in Table 1 and Table 4 and on the results of the analysis of kinetics for heat emission during the hydration of the gypsum binder material. The factor used for evaluating extensive properties is the specific surface area of the gypsum binder material:

⇥(6)

where Sud is the specific surface area of the gypsum binder material and t is the ABC processing time.

At this stage, it is recommended that a heat emission value for the hydration of the gypsum binding material is chosen as a factor for evaluating intensive properties:

⇥(7)

where Qud is the specific heat emission during hydration of the binder material and t is the ABC processing time.

The compressive strength of the hardened gypsum paste will be the reference property (Table 4):

⇥(8)

The calculation of the coefficient values m and n is carried out at t = 3 min: a relative strength increase (F/F0 = 1.44) at the relative increase in an extensive (E/E0 = 1.99) factor and an intensity (I/I0 = 1.47) factor is needed to reach m = 0.25 and n = 0.5.

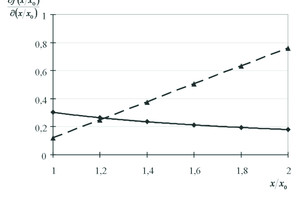

The analyzed rates of changed interrelation of strength and specific surface area of the gypsum binder material along with the dependency factor

demonstrate that they do not change symbatically (Figure 4).

This type of function change rate is indicative of specific structuring of the gypsum binder material, namely, of the formation of the hardened gypsum paste by crystallization from a supersaturated CaSO4· 2H2O solution, due to the dissolving and hydration of CaSO4 · 0.5H2O. In this regard, the much greater impact of a factor I and a correspondingly higher value of the coefficient n as compared to the value of the coefficient m seem to be normal.

4 Conclusions

It has been found that the processing of gypsum binder material in a vortex layer apparatus results in its mechanical activation which (assuming optimum processing conditions) results in a 200 % increase in the specific surface area of the gypsum, as well as in a 47 % increase in heat emission during hydration. The latter is caused by the change in the content of minerals in the gypsum binder material. It was been found that the ß-CaSO4·0.5H2O content decreased by a factor of 1.5 and the CaSO4 content increased by a factor of 3.3.

Assuming the optimum ABC processing conditions, there is a 44 % increase in compressive strength and a 50 % increase in the flexural strength. The gypsum paste setting time is reduced by 2-10 min. It has been found that the 3 minute ABC processing results in a 2 % increase of hydration water. A decreased W value caused by an increased ABC processing time (to more than 3 min) is probably due to transformation of the anhydrite into the insoluble modification.

A way of evaluating the efficiency of physical effects and defining the mechanical activation effect has been proposed. The method involves evaluation of contributions to the change of a property typical of the quality of the structure, an extensive factor (changes in the border area) and an intensive factor (change in intensity of boundary physical and chemical processes). The results of an analysis performed using the proposed method show that the changed rate of strength dependence on the specific surface area of the gypsum binding material and the rate of change in the value of F / F0 due to the extensive factor do not change symbatically. This is indicative of the dominant effect of the intensity factor I on the structure of the hardened gypsum paste.

Funding

This research was supported by the President of Russia’s Grant for Young Scientists (No. 14Z56.18/1643).

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.