Structural parameters and properties of fine-grained concrete on Portland cement, activated with plasticizers in vortex layer apparatuses

This article presents data on the effect of Portland cement treatment in a vortex layer apparatus. The treatment of Portland cement in a vortex layer apparatus provides an increase in the strength of both cement stone and fine-grained concrete. A synergistic effect in increasing the strength is observed when processing compositions consisting of Portland cement and plasticizer in a vortex layer apparatus. The revealed increase in strength correlates with changes in the structural parameters of the cement stone and demonstrates the activation of Portland cement, associated not only with the geometric factor (increase in specific surface area), but also with a change in the structure of the surface layer of Portland cement particles.

1 Introduction

At present, the specific fuel costs per ton of cement clinker produced in the Russian Federation count among the highest in the world (about 120 kW/h). The fuel costs are determinative of the high price of cement clinker [1]. However, the building and technical properties of Portland cement remain largely unimproved.

One of the current issues of modern construction is to increase the strength of all types of concrete while reducing the consumption of Portland cement. There is a worldwide tendency to switch to a high-strength type of concrete called “High Performance Concrete (НРС)...

1 Introduction

At present, the specific fuel costs per ton of cement clinker produced in the Russian Federation count among the highest in the world (about 120 kW/h). The fuel costs are determinative of the high price of cement clinker [1]. However, the building and technical properties of Portland cement remain largely unimproved.

One of the current issues of modern construction is to increase the strength of all types of concrete while reducing the consumption of Portland cement. There is a worldwide tendency to switch to a high-strength type of concrete called “High Performance Concrete (НРС)” [2].

A traditional and efficient solution to improve the physical and mechanical properties and durability of construction materials is to activate their components. These methods can be classified as chemical (when the effect is caused by a chemical substance) or physical (the effect being exerted by various physical fields: mechanical, electromagnetic and their varieties). Each of these methods has advantages and disadvantages. In particular, for chemical methods, the advantage is the repeatability and stability of the result, and the disadvantages are chemical contamination (introduction of an additional agent), which can change the conditions for structure formation, and more stringent requirements for labor protection. Physical methods introduce a lesser degree of contamination in the material (the most polluting variety being grinding with grinding bodies). The advantage is the technological simplicity of this method, and the disadvantage is the rapid leveling of the effect of modification due to the physicochemical processes of interaction of the modified substance with the environment.

Nowadays, various ways of activating water are known [3, 4]: ultrasonic methods for activating components and raw mixtures [5-7], chemical activation methods by the introduction of various additives, impact methods for activating binder in both dry and wet environments in mills, disintegrators, activators [8-14] mechano-activation to obtain silica cite [15], and combined activation methods [16-17].

Of the listed methods of physical activation, the most common is dry and wet milling of knitting in mills and disintegrators. When milling the binder with a plasticizer, we observe astringent low water requirements (LWR), as first developed in Russia [18-20].

This article reviews the physical method of treating Portland cement in a vortex layer apparatus, which yields not only an increase in specific surface area, but also a change in the structure of the surface layer of Portland cement. The theory and design of the vortex layer apparatus (VLA) were developed by [21]. In VLA, the binder is processed by ferromagnetic bodies, the motion of which takes place by means of a rotating electromagnetic field.

However, scientific data on the use of such devices in concrete technology are practically absent, although high efficiency and productivity of VLA are noted [22-23].

2 Methods, materials and equipment used

in the study

The studied substance was Portland cement (PC) ЦЕМ I 42.5 Б / ПЦ 500-Д0-Н from the Novotroitsk cement plant, which meets the requirements of GOST 31108-2016.

The Portland cement was processed in a vortex-type apparatus (model 297, manufacturer “Regionmetrans” LLC). A typical VLA construction detailed described in work [24].

As plasticizer, the following superplasticizers were applied (SP):

SP С-3 –chemical additive, a condensation product of naphthalene sulfonic acid and formaldehyde, is a water-soluble powder manufactured by the company Polyplast

SP Remicrete-SP10 (FM) – a chemical additive based on polyether carboxylate, is a liquid with a bulk density of 1.1 g/sm³, manufactured by Schomburg

SP Melflux 2651 F – a chemical additive based on polyether carboxylate (the polymer chain being formed of α, β- unsaturated carboxylic acids), bulk density powder 0.4-0.6 g/sm³, manufactured by the concern BASF

The strength of fine-grained concrete was determined in accordance with GOST 10180-2012, which meets the regulatory requirements for the manufacture and testing of concrete samples of European regional standard EN 12390-1: 2009 Testing hardened concrete – (Part 1 - Part 6).

Quartz sand from the Kamsko-Ustinskoye deposit, with a grain size of 2.7, which meets the requirements of GOST 8736-2014, was used as a fine aggregate.

The normal thickness and setting time of the cement paste was determined in accordance with GOST 310.3-76 and according to DIN EN 196-3(2017-03) Methods of testing cement - Part 3: Determination of setting times and soundness.

When studying the influence of various factors on the formation of strength, the porosity of the cement stone obtained from the Portland cement treated in VLA with the introduction of superplasticizers was determined. The porosity was identified by determining the average (medium) and true densities of the hydration products using a Le Chatelier instrument. The calculation was made using the formula:

Р = 100 · (1 – qmedium/qtrue) (1)

Р porosity [%]

qmedium medium density

qtrue true density

The specific surface area was determined using the air permeability method with a PSH-9(ПСХ-9) instrument. The dispersion composition was determined on a laser particle size analyzer “Horiba La-950V2”.

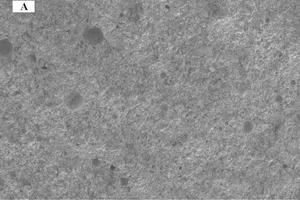

The microstructure of the cement stone was studied with a Merlin-type high-resolution field-emission scanning electron microscope by the Carl Zeiss Company. The chips of the cement stone samples were sprayed with an Au/Pd alloy at a ratio of 80/20 in a Quorum T150 ES high-vacuum unit.

3 Results and discussion

It was established in [25] that the optimal treatment regime for Portland cement in VLA is as follows: The processing time is 5 minutes, the rotation frequency of the electromagnetic field is 70 Hz, the ratio of the diameter of the ferromagnetic bodies to their length is 0.12, the ratio of the mass of the ferromagnetic bodies to the mass of the ground of the material is 0.4.

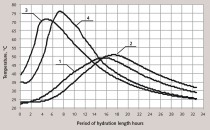

With optimal parameters of processing (hereinafter - activation) of Portland cement in VLA, the compressive strength of concrete of class B22.5 at the age of 28 days of hardening increases to 1.5 times, and on the first day of hardening – up to 2.44 times.

Activation of the compositions containing Portland cement and SP in the amounts shown in Table 1 indicates a synergistic effect. Such a high accepted dosage of SP, 3-4 times higher than optimal, is due to the increase in the specific surface area of Portland cement during activation, enabling adsorption of a greater number of SP, a fact that should help to obtain cements with qualitatively new properties [26].

Table 2 presents the results of the effect of Portland cement activation in a VLA on the flexural strength and compression of fine-grained concrete with a cement consumption of 400 kg/m3. The water-cement ratio (W/C) of the concrete mixtures studied was selected to achieve the same mobility as that of P2 grade concrete mix (the standard cone sediment being 7 to 9 cm).

The magnitude of the gain in strength depends on the type of applied SP and manifests itself in both the compression and bending strength of concrete samples. It was found that joint milling of SP and Portland cement can increase the compressive strength of fine-grained concrete on the first day of hardening by 69 %, on the 28th day by 31 % (using SP C-3); by 156 % and 11 % (using SP SP10); by 387 % and 26 % (using SP MF), respectively, compared to fine-grained concrete obtained as a result of the traditional addition of these SP into the finished concrete mixture.

The strength of fine-grained concrete during bending increases in all activated compositions, but less significantly than under compression. Within the research period, the increase in the bending strength of fine-grained concrete with joint activation of the SP C-3 and Portland cement was 27% and 9.6 %; 38% and 17 % with SP10; 77% and 22% with MF compared with compositions obtained by the traditional injection of the additive.

SP MF, the most efficient among the investigated SP, increases the strength of fine-grained concrete with the traditional introduction of additives. This SP is also the most efficient in the joint activation of Portland cement in the VLA. The activation of MF and Portland cement in the VLA leads to achieving the design strength of concrete already on the first day of hardening, and by the 28th day of hardening, the compressive strength increases up to 1.83 times in comparison with the benchmark composition.

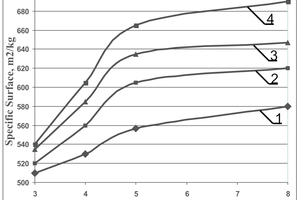

A significant increase in the strength index of fine-grained concrete is attributable to a likewise significant increase in the specific surface area of the activated Portland cement. Figure 1 shows the dependence of the specific surface area of Portland cement on the activation time and type of SP.

Also, comparison of the maximum strength indexes of activated Portland cement with and without SP shows that joint treatment of Portland cement and SP compositions allows increasing the strength of fine-grained concrete more significantly (synergistic effect). Thus, Portland cement, activated together with MF, on the first day of hardening, shows that the compressive strength increases 2.7 times (comparison of compositions No. 2 and No. 6), and when Portland cement is activated without SP, the strength increases by a factor of 2.28 (comparison of formulations No. 1 and No. 2). The same is observed after 28 days of hardening and bending.

From the data given in Figure 1, it is seen that superplasticizer MF has the greatest influence on the rate of increase in the specific surface area of Portland cement during activation. In this case, the increase in the specific surface area of Portland cement with the addition of MF during activation for 5 minutes is 1.77 times, and, for 8 minutes of activation, 1.84 times compared with the composition without activation.

The high strength of fine-grained concrete is to some extent explained by a significant increase in the specific surface area of PC when activated in VLA together with SP.

The increase in the specific surface area of the activated PC affects the setting time of the cement paste (Table 3).

The data presented in Table 3 shows that the activation of Portland cement in the VLA together with SP leads to a decrease in the normal density of the cement paste, as well as the setting time, compared to cement paste obtained by the traditional introduction of SP.

Activation of Portland cement together with C-3 additive allows shortening the setting time for the cement paste by 50 minutes, and the end of setting by 65 minutes, compared to the composition obtained by the traditional introduction of the additive. With joint activation with the addition of SP10, the start of setting begins to decrease by 35 min, and at the end by 25 min; with the addition of MF – at 110 and 50 min, respectively, compared with the composition obtained by the usual introduction of additives.

The introduction of SP additives, as well as the activation of Portland cement in VLA, significantly affects the porosity of the resulting cement.

The greatest decrease in the porosity of the cement was observed with the addition of the MF additive (porosity being reduced by 37 %). The joint activation of the MF additive and Portland cement in the VLA leads to a decrease in porosity by 40.5 %. The porosity of the cement stone obtained on the basis of joint grinding of the SP and Portland cement, compared with the traditional introduction of additives, was reduced by 4 % with the addition of the C-3 additive; by 1.5 % with the addition of SP10; and by 5.3 % with the addition of MF.

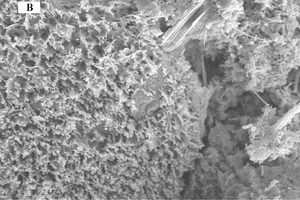

Changes in the geometric factor (the specific surface area of Portland cement), as well as in the physical and chemical properties of the Portland cement surface, affect the geometric characteristics of the hydration products (Figure 2).

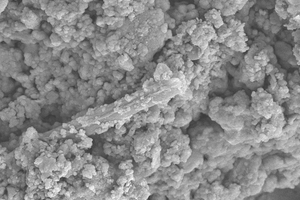

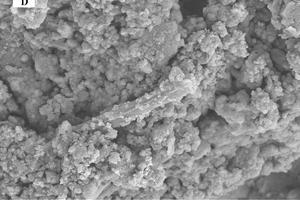

One peculiarity of the effect of Portland cement activation on the structure of cement stone is the formation of crystalline neoplasms of much less dispersity. At the same time, the emerging neoplasms crystallize in a more finely dispersed form, smaller pores and capillaries of cement stone are formed. When Portland cement is activated in a VLA, calcium hydrosilicates appear in the form of finely dispersed globules (Figure 3). This, together with a higher degree of hydration, leads to the formation of a dense structure of cement stone, naturally displaying accordingly higher strength.

It is established that mechanical and chemical activation of the cement slurry in the rotary pulsation apparatus also leads to the appearance of calcium hydrosilicates in the form of finely dispersed globules [27].

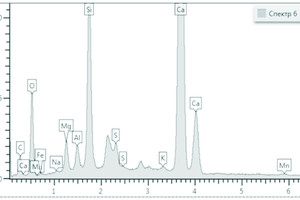

The elemental composition of the cement stone shown in Figure 2d is presented in Table 4.

4 Conclusions

The activation of Portland cement with plasticizers in a VLA is an efficient way to improve the physical and mechanical properties of building composites.

Activation of Portland cement together with C-3 additive allows shortening the time of setting the cement paste by 50 minutes, and the end of setting by 65 minutes, compared to the composition obtained by the traditional introduction of the additive. With joint activation with the addition of SP10, the start of setting begins to decrease by 35 min, and the end – by 25 min; with the addition of MF – at 110 and 50 min, respectively, compared with the compositions obtained by the usual introduction of additives.

It was revealed that the neoplasms crystallize in a more finely dispersed form, with smaller pores and capillaries of cement stone being formed in cement stone on activated Portland cement. A feature of the formation of cement stone is the formation of calcium hydrosilicates in the form of finely dispersed globules.

The greatest decrease in the porosity of the cement stone was observed with the addition of the MF additive (porosity being reduced by 37 %), and joint activation of the MF additive and Portland cement in a VLA led to a decrease in porosity by 40.5%. This, together with a higher degree of hydration, leads to the formation of a dense cement stone structure with a naturally higher strength.

It was revealed that the activation of Portland cement in a VLA allows increasing the compressive strength on the first day of hardening by 128 %, and at 28 days by 30 %. Joint grinding of the SP and Portland cement makes it possible to increase the compressive strength of fine-grained concrete on the first day of hardening by 69 %, and on the 28th day by 31 % (using SP C-3); by 156 % and 11 % (using SP SP10); by 387 % and 26 % (using the MF), respectively, compared to fine-grained concrete obtained by the traditional introduction of these SP into the finished concrete mixture.

In addition, we have established a synergistic effect of the joint activation of Portland cement in VLA with plasticizers. This effect is observed both on the first day of hardening and on the 28th, as well. The magnitude of the effect depends essentially on the employed type of plasticizer. Of the selected plasticizers, the greatest effect was observed when using Melflux 2651 F. It is also important to note that when using increased concentrations of plasticizer, no “poisoning” effect was established.

Acknowledgment

The subject work is supported by a grant from the President of the Russian Federation for young scientists (Grant Number МК-1643.2018.8)

Funding

The work was carried out within the framework of the agreement 14.578.21.0135 “Research and development in priority areas of development of Russia’s scientific and technological complex for 2014-2020”, project identifier RFMEFI57815X0135.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.