One of the cleanest cement plants

in the world

Kirchdorfer Zementwerk describes itself as one of the cleanest cement plants in the world. Proof of this claim made by the Upper Austrian industrial enterprise is found in the world’s first DeCONOx system.

“We have invested over 23 million € in environmental protection in the last 15 years,” says Plant Manager Anton Secklehner, Kirchdorfer Zementwerk, proudly. “We feed the excess process heat into the district heating grid which is used to supply over 1000 families and businesses in Kirchdorf with environmentally friendly heat. Working together with our innovative partner Scheuch, we have now turned another milestone into reality with the world’s first DeCONOx system.” Originally, the Kirchdorf plant was only planning a new flue gas catalyst. The system was even already approved. But the idea of...

“We have invested over 23 million € in environmental protection in the last 15 years,” says Plant Manager Anton Secklehner, Kirchdorfer Zementwerk, proudly. “We feed the excess process heat into the district heating grid which is used to supply over 1000 families and businesses in Kirchdorf with environmentally friendly heat. Working together with our innovative partner Scheuch, we have now turned another milestone into reality with the world’s first DeCONOx system.” Originally, the Kirchdorf plant was only planning a new flue gas catalyst. The system was even already approved. But the idea of Scheuch’s technicians to use the energy contained in carbon monoxide (CO) to generate heat for denitrification was so popular that the managing directors stopped the existing project and decided to test the function with a pilot plant instead.

Planning began in 2008, and the pilot plant was installed on the cement plant site at the end of 2010. The results impressed the managers of the Kirchdorf cement plant so much that they commissioned Scheuch in the summer of 2014 to convert the pilot into an industrial plant.

Two solutions in one plant

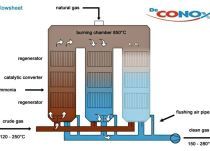

Two exhaust gas cleaning procedures are combined in the DeCONOx system. In a simultaneous process, nitrogen oxides (NOx) are reduced at the same time as carbon monoxide (CO) and organic carbon compounds (VOC). Stefan Huemer, Team Leader for Technology in the Industrial Minerals Industry division, explains how the new system works. “Crude gas flows into the system from below. It flows through the regenerator layers and is heated to 250–450 °C. Denitrification then takes place in the catalyst through the addition of ammonia. The gas is heated to the firing temperature of 850 °C with additional regenerator layers. This causes the organic carbon compounds to combust in the combustion chamber. The hot gas flows out of the other side of the system and transfers the heat to the regenerator layers on that side. Then the direction of flow is changed so that the energy just supplied by the gas can be reused.”

The results of the exhaust gas measurements send a clear signal. NOx is reduced by around 75 %. CO and VOC can also be reduced by more than 99 %. “Combined exhaust gas cleaning means that fuels and secondary fuels can be used in a much more flexible and efficient manner,” says Alois Hermandinger, Manager of the Industrial Minerals division at Scheuch, explaining a further advantage of the new procedure.

Compact design

The compact system design is also impressive. The technology can be integrated into existing operating plants without taking up a lot of space. Nevertheless, as assembly of the industrial plant began in Kirchdorf in February 2015, even the small dimensions still seemed too big. “We managed to fit the system into a trench that was scarcely 9 m wide and around 30 m long,” explains Huemer. “The pipeline routing was a particular challenge. Poor pipe routing leads to pressure loss which is reflected in the operating costs. Maintenance access during operation also had to be borne in mind. Material stress due to the temperature differences from 150 to 850 °C was another tricky problem for system engineering. But our team mastered these tasks brilliantly.” Despite the tight space, assembly was completed after just six months through the use of a revolving tower crane and many pre-assembled parts.

The new DeCONOx system was commissioned even more quickly. As the managers were still discussing the commissioning process, a plant technician anticipated the decision and simply flicked the switch. “It was as though someone had turned on the light. The system worked straight away in full operation and provided the desired results from the beginning,” says Secklehner, remembering this special moment.

Just a few weeks after it had been commissioned, the new DeCONOx system had developed into a global showcase project. Large numbers of industry colleagues and scientists from all over the world come to visit the plant in Kirchdorf. Alois Hermandinger is delighted that enquiries are coming in from many other cement plants. “Scheuch was also awarded the Energy Globe Award for this innovative technology,” says Hermandinger, who is extremely proud of his company’s idea. The new DeCONOx system from Scheuch is ahead of the industry standard and is setting new benchmarks in environmental technology.

//www.scheuch.com" target="_blank" >www.scheuch.com:www.scheuch.com

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.