NOx separation

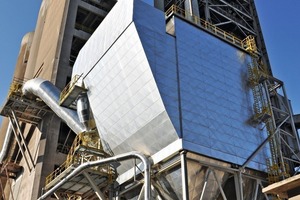

The new SCR process – “semi-dust raw gas circuit” – for NOx separation was successfully implemented by Scheuch for Lafarge Perlmooser GmbH in Mannersdorf/Austria.

With extensive experience spanning several decades and this comprehensive knowledge of dust separation in the cement process, Scheuch addressed the separation of harmful substances at an early stage. Different plant concepts are used for the specific respective requirements, from simple to high-end solutions, designed according the amount of emissions, which, in turn, varies with the kind of raw material or with the properties of the fuel being used.

Reduction of NOx emissions

“Semi-dust switching” technology

The world’s first semi-dust industrial plant

for NOX separation

With production in excess of one million tons, Lafarge Perlmooser GmbH is the largest cement plant in Austria. Thanks to the close collaboration between Lafarge and Scheuch, the on-schedule turnkey handover of the overall plant for NOx separation, including the necessary modification for the integration of the SCR semi-dust systems in an existing heat exchanger tower, was made possible.

The kiln line of the cement plant was constructed during the energy crisis of the 1970s and designed with energy-optimisation according to the state-of-the-art technology of the time. This means low kiln exhaust temperatures in the range of 290 °C to 340 °C. A unique feature of this oven is a dust content of 180 g/Nm³, which is why after careful analysis the decision was ultimately made to install the world’s first industrial SCR semi-dust system for NOx separation.

Plant concept

During the commissioning – performed on-schedule in March after a construction phase of several months – a great emphasis was placed on plant safety and fault-free kiln operation. The plant then went into continuous operation.

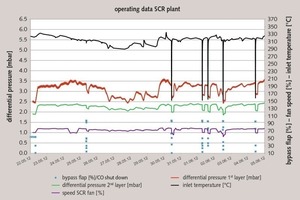

The catalytic converter was observed in regular intervals in order to check the effectiveness of the cleaning system and to ensure the functionality of the start-up and shut-down procedure.

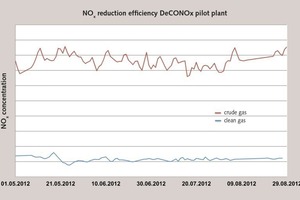

After the positive results in this phase, the planned performance test could be performed over a period of two weeks. In the process, the adherence to the contractually specified parameters was to be checked. The specified value of 200 mg/Nm³ for the NOx separation was permanently met, and from an operational costs perspective, the values with respect to energy and harmful substance consumption were even undercut (Fig. 2).

Plant and process-specific parameters bring about difficult dust properties (e.g. very high dust resistance) and diminish the performance of the pre-separation through the electrostatic precipitator. As a consequence, the dust load for the catalytic elements increases and the effectiveness of the cleaning is reduced. The availability of the plant is currently still not at a satisfactory level, therefore additional steps are required for optimisation and the initial approaches to a solution are being worked out.

Due to the good degree of separation of the SCR plant (fine denitrification) – the requisite clean gas value is achieved with this plant alone – the existing SNCR plant for the preliminary denitrification is no longer necessary. The result is additional, considerable savings in operational costs.

Initial catalytic converter analyses indicate a relatively low activity loss, however more specific statements can only be made after extended periods of operation. A positive side-effect of this semi-dust circuit: Any existing organic compounds are simultaneously broken down (Fig. 3).

NEW: Combined denitrification and VOC separation

The DeCONOx process from Scheuch

Simultaneously reducing nitrogen oxides and

carbon compounds

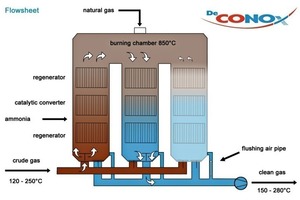

Functional principle

Laboratory plant at the technical centre

Test plant: Two-tower version

A crucial finding was made with respect to the catalytic converters used by Scheuch. They can boast the claim of withstanding constant temperature changes without any noticeable mechanical stability loss. The separation of VOC corresponds to that of a regenerative, thermal afterburning, and the NOx separation performance is identical to that of a low-dust SCR. This was verified in tests conducted over a two-year period (Fig. 4).

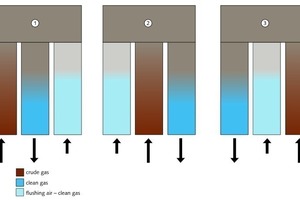

Outlook: Multiple-tower version

For the elimination of the peaks of harmful substances, the additional third tower of a three-tower version for example is flushed with clean gas. The exhaust gas present and not cleaned in the flushing tower is forced into the combustion chamber through the flushing process and the remaining organic compounds are oxidised there. This flushing tower assumes the function of a clean gas tower after the next switch-over, the crude gas tower becomes the flushing tower and the former clean gas tower assumes the function of a crude gas tower (Fig. 5 and 6).

This DeCONOx three-tower version will be available as a pilot plant from January 2013 on and will provide additional findings and operational experience for large industrial applications.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.