New DeCONOx system now in operation

at Kirchdorfer Zementwerk

On September 29, in the presence of numerous distinguished guests from the realms of politics, industry and commerce, as well as customers, staff and suppliers, Kirchdorfer Zementwerk officially inaugurated its new DeCONOx system.

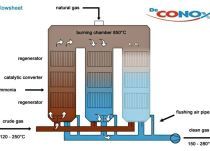

Built by Scheuch, the new DeCONOx system combines the advantages of a selective catalytic reduction (SCR) process with those of regenerative thermal oxidation (RTO) technology. The arrangement employs those two well-proven technologies to ensure high NOx, VOC and CO separation efficiency. Its main merits also include a modest space requirement, low operating costs,...

On September 29, in the presence of numerous distinguished guests from the realms of politics, industry and commerce, as well as customers, staff and suppliers, Kirchdorfer Zementwerk officially inaugurated its new DeCONOx system.

Built by Scheuch, the new DeCONOx system combines the advantages of a selective catalytic reduction (SCR) process with those of regenerative thermal oxidation (RTO) technology. The arrangement employs those two well-proven technologies to ensure high NOx, VOC and CO separation efficiency. Its main merits also include a modest space requirement, low operating costs, low energy consumption thanks to waste-heat utilization, and meagre maintenance requirements. The residual energy is returned to the production process and removed by a heat recovery setup. This way, waste heat of the order of 20 GWh per year becomes available for distribution to more than a thousand households in Kirchdorf and the surrounding area via the EnergieAG Wärme Oberösterreich district heating plant.

Stressing the fact that environmental protection does not come for free, Managing Director Mag. Erich Frommwald states that, “Over the past 15 years, we have invested more than € 23 million in environmental protection. The DeCONOx system is the latest highlight in a long series of measures that we have taken to become the lowest-emission cement factory of all, not only in Europe, but in the entire world! This novel technology enables us to completely do without fossil fuel sometimes. We are proud of the fact that the new system went right to work with no initial difficulties and is already setting new standards for cement production.”

For his part, Dipl.-Ing. Anton Secklehner, plant manager at Kirchdorfer Zementwerk Hofmann GmbH, expressed his thanks to the system’s supplier, Scheuch GmbH, for all the good cooperation. This new, very visionary technology of a kind never seen before was jointly developed in the course of a shakedown process lasting for many years. The limited space available for all the requisite equipment amounted to one of the major challenges.

On the occasion of an Open Door event on October 1, 2016, the new system was available for scrutiny by anyone interested.

//www.kirchdorfer.eu" target="_blank" >www.kirchdorfer.eu:www.kirchdorfer.eu

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.