First DeCONOx system up & running nicely at Kirchdorfer Zement

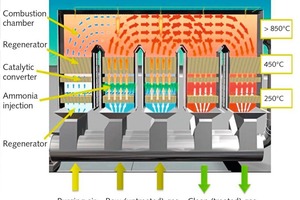

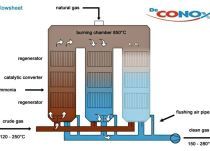

On 29.09.2016, Kirchdorfer Zementwerk officially inaugurated its new DeCONOx system. Built by Scheuch, the new DeCONOx setup combines the advantages of selective catalytic reduction (SCR) with those of regenerative thermal oxidation (RTO). The arrangement employs those two well-proven technologies to ensure high NOx, VOC and CO separation efficiency. On the occasion of its commissioning, we spoke with the CEO of Kirchdorfer Zement, Mag. Erich Frommwald, and with Plant Director Dipl.-Ing. Anton Secklehner about the investment and the company’s environmental commitment.

FROMMWALD: We have been producing cement here in Kirchdorf for nearly 130 years, and we have been engaged in environmental protection for many decades. Our management has implemented numerous measures designed to minimize potentially negative impacts on the environment. The first impetus, of course stemmed from the fact that our...

Kirchdorfer Zementwerk counts as the world’s first industrial-scale plant of its kind, making you a pioneer in the use of this technology. What made you decide to go for this new process, and how high was the overall investment?

FROMMWALD: We have been producing cement here in Kirchdorf for nearly 130 years, and we have been engaged in environmental protection for many decades. Our management has implemented numerous measures designed to minimize potentially negative impacts on the environment. The first impetus, of course stemmed from the fact that our plant is located very near the downtown area of Kirchdorf/Krems. With the passing of time, however, we developed an implicit awareness of the need to treat the environment and its resources with care. Then, in the year 2010, our owners and managers announced Kirchdorfer Zementwerk’s vision for the future. We want to become the most resource-efficient, most non-polluting cement producer with the highest safety standards in all of Europe.

In the course of the past 15 years, we have invested more than € 23 million in environmental protection. Our new DeCONOx system is the latest highlight in a long series of such measures. The DeCONOx process not only cleans up the raw exhaust gas, but also recovers heat for use in breaking down other pollutants such as nitrogen oxide and organic compounds. The residual energy is reintroduced into the production process and coupled out across a heat recuperator. As a result, waste heat of the order of 20 GWh per year becomes available for distribution to more than a thousand households in Kirchdorf and the surrounding area via the district-heating plant operated by EnergieAG Wärme Oberösterreich.

This investment did not come cheap! Environmental protection costs money and, in this case, electricity, too, of which we are now using up to 10 % more. Still, we consider ourselves responsible for our environment with the support and encouragement of our stakeholders.

SECKLEHNER: Well, while a pregnancy lasts nine months, it took us and our partner Scheuch seven years in all to design and implement the big system. That was a long time, of course, but we were looking for a solution that would count as the best available technology both now and well into the future. So through the year 2013 we gathered experience, tested out pilot plants and started planning and building the full-scale plant. With this DeCONOx system, we broke new ground by engineering a whole new kind of process. Our initial planning was confined to merely scrubbing the exhaust air. But then, we were so impressed by Scheuch’s idea of exploiting the off heat from the post combustion of carbon monoxide for reducing nitrogen emissions, that we called off construction of the already approved plant, instead deciding to install a pilot plant to find out how well the new idea would work.

For good implementation, we needed a visionary partner, and that we found in Scheuch. The ensuing teamwork can definitely be referred to as thoroughly positive.

SECKLEHNER: Our first pilot plant in 2009 was a clean-gas SCR. In addition to the catalytic reduction of NOx, it also reduced CO emissions via oxidizing catalytic converters. Consequently, at the end of its accumulated time in service, the NOx separator still had produced no waste material. Six oxidizing catalytic converters were tested, but all of them showed only minimal CO separation after the first 24 hours: from 80–90 % down to <10 % separation.

The second pilot plant (2011) was a clean-gas SCR plus RTO, i.e., a DeCONOx system. At the end of its first year in operation, it was still displaying high availability, separation efficiencies of 97.5 % for CO and 85 % for NOx, and NH3 slip amounting to less than 5 mg/Nm³. The catalytic converters had suffered no mechanical damage, and we were able to identify one of them as the most suitable choice. The plant also proved capable of autothermal operation with CO > 4000 to 5000 mg/Nm³.

Finally, we injected all the insights gleaned into the DeCONOx project to achieve simultaneous reduction of nitrogen oxides, CO and organic constituents.

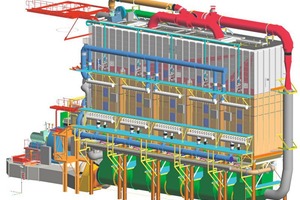

SECKLEHNER: Right. The spatial constraints were very challenging. There was no millimetre to spare in any direction. Getting everything to fit was like doing high-precision surgery. The very compact system consists of five towers: two for raw gas, two for clean gas and one for scrubbing. We had to tear down an old kiln line to make room for all of them. Even then, we only had about 30 m in length and barely 9 m in width at our disposal. Scheuch, though, did an outstanding job with this. In order to minimize pressure losses and consequentially high operating costs, it was especially important to optimize the pipe runs and to ensure good accessibility for maintenance. Again, Scheuch came up with a good solution. Nevertheless, some parts of the system had to be preassembled for positioning with a tower crane, because there was too little room for in-situ assembly. All in all, the installation work took only six months.

Actually, I tend to be rather strict with our suppliers – but in this case I could only say “Well done!”

SECKLEHNER: We implemented the project in two stages. First, in September 2015, we started up the RTO without the SCR. Then, in November, we installed the catalytic elements (29,000 in all). Commissioning of the RTO and SCR together followed in December, and that was a genuine highlight. While we were still discussing with Scheuch the best sequence for running up the plant, one of the technicians just pushed the ON button. After all the exhaustive planning, that was a special moment. The plant immediately ran up to full capacity and delivered the desired results. In March 2016, after the winter inspection, the kiln-cum-DeCONOx campaign began, and final acceptance took place in June.

FROMMWALD: The new technology lets us completely dispense with fossil fuel from time to time, and we can save valuable raw materials by substituting recycled sand, crushed brick or some other suitable recyclate.

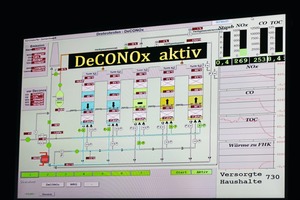

SECKLEHNER: We registered the following average emission levels between January and August 2016: dust: 0.7 mg/Nm³, NOx: 141 mg/Nm³, CO: 69 mg/Nm³, TOC: < 1 mg/Nm³, NH3 slip: 3 mg/Nm³. Our results all remain well below the Austrian averages.

In the course of 5½ months, from early March to late August, we achieved separation efficiencies of 77 % for NOx, 99 % for CO and 99 % for TOC. Plant availability hovered at 99.9 %.

SECKLEHNER: Well, our plant is no off-the-rack solution and therefore can hardly be copied on a 1-to-1 basis, but we do find the technology quite convincing and naturally recommend it to our colleagues, some of whom have already dropped by to take a look for themselves. Ultimately, everyone has to find their own most suitable solution. Scheuch has a mobile test unit for installation as a decision-making aid.

FROMMWALD: Right now, we are working on a milling project geared to reducing the consumption of electricity while feeding heat into the local district heating grid. After all, milling is our main driver of electricity consumption. In order to optimize both of our mills, we plan to invest a double-digit million euro sum by the year 2020. We have put some very good in-house mill specialists in charge of the project, and Scheuch will help us to optimize the filters.

//www.kirchdorfer.eu" target="_blank" >www.kirchdorfer.eu:www.kirchdorfer.eu

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.