Natural, modified and saturated zeolites as additives in Portland cement

The results show that cement with the addition of various zeolites (natural zeolite, zeolite modified with Fe(III) ions and zeolite saturated with Pb ions) applies as a supplementary cementitious material. The obtained results indicate that natural zeolites, Fe(III)-modified zeolites and zeolites from aqueous Pb ion extraction can be used as additives in cement.

1 Introduction

The contemporary cement industry has faced the challenge of producing more sustainable, less energy consuming and more durable products without reducing the mechanical properties of the final product. One of the most widespread developments in the conventional production process is the blending of supplementary cementitious materials or pozzolans with ordinary Portland cement [1].The replacement of a specific amount of cement clinker with pozzolans results in a proportional decrease in the economic and environmental cost of the end product. Moreover, the use of pozzolans in...

1 Introduction

The contemporary cement industry has faced the challenge of producing more sustainable, less energy consuming and more durable products without reducing the mechanical properties of the final product. One of the most widespread developments in the conventional production process is the blending of supplementary cementitious materials or pozzolans with ordinary Portland cement [1].The replacement of a specific amount of cement clinker with pozzolans results in a proportional decrease in the economic and environmental cost of the end product. Moreover, the use of pozzolans in blended cement and concrete applications has been observed to significantly improve the cement durability, especially to reduce the vulnerability to chemical attack, improve acidic and sulphate stability, and also, alkali-aggregate reaction can be mitigated [2]. Alumino-silicate materials are often used as pozzolanic materials because of their ability to combine with portlandite (Ca(OH)2) in the presence of water and forming reaction products with binding properties [1]. Among these materials are slags, fly-ashes and micro silica, and also naturally occurring materials such as vitreous pumice, diatomite earths and zeolites [2].

Application of the natural zeolite as an addition to Portland cement has been investigated by large number of researchers [3-6]. For example, Yoleva et al. have investigated the influence of the combination of the active additive trass and natural zeolites on the properties of Portland cement type CEM I 52.5 R [6]. It was observed that using natural zeolite as a pozzolanic additive caused decreasing of the specific cement mass and increasing of the specific surface area of cement. It was also established that the cement strength increased with the increasing of the natural zeolite quantity and the decreasing of the trass content. The authors also pointed out that the replacement of cement clinker with the natural zeolite in the quantity of 30 % decreased the price of the obtained pozzolanic cement.

Natural zeolites are also efficient adsorbers of heavy metal ions (Cd2+, Pb2+, Cu2+, Ni2+, Zn2+ etc.), especially lead ions from water and water solutions [7-9]. Also, a large number of investigations highlight the face that modification of natural zeolite by iron ions significantly increases the efficiency of heavy metals and other pollutants removal [10-12]. However, the storage of adsorbents (natural or modified zeolite) contaminated by heavy metal ions, which are a waste material arising during refining of polluted water, might represent a significant problem. According to the literature [13, 14], waste material containing heavy metals and other ions of elements which represent a hazard for the surrounding area can not be stored in the environment without some means of control. Such waste material has to be stabilized in order to prevent toxic leaching, which is above the upper eligible limit, in the environment even when the waste is exposed to atmospheric conditions during a long period of time.

The studies which are investigating the stabilization of the processes in the industrial waste and similar materials containing harmful ions point out the fact that these materials can be successfully stabilized if they are bonded as a component in the cement [15, 16]. There are researches dealing with the effect of adding hazardous wastes in the form of zeolite tuff saturated with Zn2+ ions on hydration processes via the solidification of cement binding composites [17, 18]. Investigations pointed out the fact that zinc concentration in elutes after the leaching test depends on the duration of solidification, quantity of saturated zeolite and duration of rinsing after cement sample solidification. Obtained low zinc concentration in elutes after leaching indicates that such wastes can be successfully stabilized by solidification processes in Portland cement composites.

Iucolano et al. [19] have investigated the stabilization of the barium ion saturated residue which contains the cationic exchangers phillipsite, chabazite, analcime and smectite for safer storing. Results pointed out that such residue can be used as an addition to cement up to mass content 75 %. The hardened compacts present quite good mechanical resistances and Ba2+ leaching is considerably under the allowed limits for discharge in a water body and can be, therefore, safely disposed in a cheap segregate, landfill.

All these investigations initiated this research into the application of saturated zeolites which are produced during the refining procedure of water with Pb ions elevated content. Therefore, in this paper the application of natural zeolite, Fe(III)-modified zeolite and zeolite saturated with Pb ions as supplementary cementitious materials (SCM) was investigated with an aim of obtaining cement with addition.

2 Experimental

2.1 Material

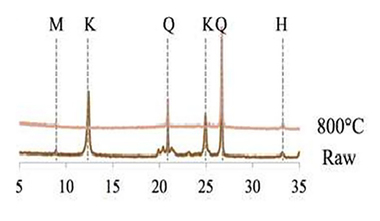

The natural zeolite-rich rock from Zlatokop deposit (Vranjska Banja, Serbia) used in this study was grinded and sieved with a final particle size <0.043 mm. The Fe(III)-modified zeolite was synthesized according to the procedure given elsewhere [12]. Fe(III)-modified zeolite was obtained by modification of the surface of previously mentioned natural zeolite. Portland cement PC 42.5R, used in this investigation, originates from the cement factory Beo´ cin, Serbia. The chemical composition of starting raw materials is given in Table 1.

The physico-mechanical characteristics of the PC 42.5B cement are given in the Results and Discussion Chapter.

2.2 Experimental procedure

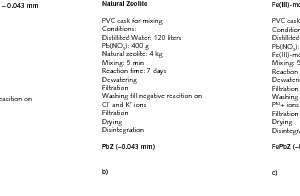

Experimental researches were conducted in two phases. The first phase implied production of the zeolite which was used during later stages of the experiment as an addition to the Portland cement:

natural zeolite with grain size 100 % -0.043 mm (labeled as Z in this investigation)

Fe(III) modified zeolite obtained from the natural zeolite Z (labeled as FeZ in this investigation)

zeolite saturated with Pb ions obtained from the natural zeolite Z (labeled as PbZ in this investigation)

zeolite saturated with Pb ions obtained from the zeolite FeZ (labeled as FePbZ in this investigation)

The second phase of the experimental investigation consisted of mixing of the obtained zeolites with Portland cement in various mass ratios with the aim of finding the level of applicability of these zeolites as Supplementary Cementitious Materials (SCM).

For obtaining saturated samples (PbZ, FePbZ), the applied initial concentrations of Pb2+ ions were equal to maximal adsorption capacities of the starting samples (66 mg/g for natural zeolite and 133 mg/g for Fe(III)-modified zeolite) [12]; while the starting pH was adjusted to the level of 4.24. In order to compare the results, investigation of influential factors on the quality of cement with all observed zeolites were conducted on natural zeolite (PbZ) and on superficially modified zeolite (FeZ).

Experimental procedure of obtaining Fe(III) modified zeolite, as well as the Pb ion saturated zeolites (PbZ and FePbZ) is schematically described in Figure 1. The parameters under which the pro-cedure of obtaining of zeolites is conducted is given in the scheme.

After obtaining of the zeolites according to the previously described procedure, their mixing with Portland cement in various mass ratios took place (second phase of the experiment). Thus, the following cements with additions are obtained:

PC+10 %-PZ = PC10Z

PC+30 %-PZ = PC30Z

PC+50 %-PZ = PC50Z

PC+10 %PbZ = PC10PbZ

PC+30 %PbZ = PC30PbZ

PC+50 %PbZ = PC50PbZ

PC+10 %FeZ = PC10FeZ

PC+30 %FeZ = PC30FeZ

PC+50 %FeZ = PC50FeZ

PC+10 %FePbZ = PC10FePbZ

PC+30 %FePbZ = PC30FePbZ

PC+50 %FePbZ = PC50FePbZ

All stated cements had a mass of 4000 g.

2.3 Method and equipment used

for the investigation

Chemical composition analysis was conducted on all investigated samples. Chemical composition was conducted by the method given in the Standards: SRPS EN 196-2:2008 Methods of testing cement Part 2: Chemical analysis of cement and SRPS B. F8.050. Loss of ignition testing was performed at a temperature of 900 oC. The testing equipment is an atomic absorption spectrophotometer “Analytic Jena Spekol 300” (AAS).

Physico-mechanical testing according to the procedures given in European Norms EN 197 was performed on the samples of cements with additions and on the starting cement PC42.5R:

EN 196-6, Methods of testing cement. Determination of fineness [20].

EN 196-6, Methods of testing cement. Determination of fineness, Blaine, cm2/g[20].

SRPS EN 196-3:2007. Methods of testing cement-Part 3: Determination of setting time and soundness [21].

SRPS EN 196-3:2007. Methods of testing cement-Part 3: Determination of setting time and soundness [21].

SRPS EN 196-1:2008. Methods of testing cement-Part 1: Determination of strength [22]

3 Discussion

Investigation of the influence of zeolite and saturated zeolite addition in Portland cement on the quality of thus obtained cements was monitored by determination of the chemical composition, and physlcal and mechanical charatcteristics. In Table 2, the results of the chemical analyses of all applied zeolites, Portland cement and obtained zeolites and Portland cement mixes are given.

The condition of sulfate content (as SO3) being ≤ 3.5 %, [23] is fulfilled by all investigated cements; the values of sulfate content is in the range from 1.58 % (PC50FePbZ) to 3.4 % (PC 42.5R).

Natural zeolite has so-called “zeolite water”, and therefore it has relatively high loss of ignition which is obtained upon heating up to 900 °C. At the same time this is the reason why cements prepared with the addition of zeolite or zeolite waste have a high percentage of LoI. Having in mind the demand that LoI for cement has to be less than 5 % [23], it can be concluded that from the group of investigated cements the following samples are completing the given request: PC 42.5R with 1.89 %; PC10PbZ with 2.75 %; PC10FePbZ (2.74 %); and PC30FePbZ (4.27 %). Cement samples which show obtained LoI at the limit value are: PC10FeZ (5.19 %); PC50FePbZ (5.82 %).

The achieved results (Tab. 2) showed that the maximal content of Fe2O3 has FeZ sample (4.04 %), and the lowest content is found in the sample PC 42.5R (1,48 %), which was expected considering the fact that this cement does not contain Fe. The content of Fe ion in the cement mixes PbZ and FePbZ was (expressed in Fe2O3 form) in the range from 1.58 to 1.53 % in the PC10-50PbZ, and 1.64 – 2.13 in the PC10-50FePbZ, which is satisfying in the competition with the pure PC (1.48 % Fe2O3).

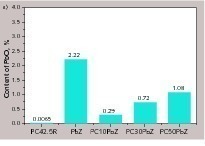

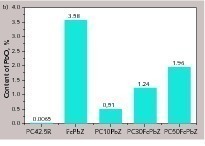

Since Pb(NO3)2 is used in the procedure of obtaining of Pb zeolites, the graphical description of the share of PbO content in the zeolite, and PbZ and FePbZ samples, based on the results given in Table 2, is showed in Figure 2.

Based on the results (Tab. 2 and Fig. 2a) it can be concluded that PbZ has 2.22 % PbO. When such zeolite is added to PC in mass ratio 10 %, the 0.29 PbO is obtained in such cement (PC10PbZ). By increasing the PbZ content in the PC, the content of PbO is also increased (which is logical). Thus, with 50 % content of Pb zeolite and 50 % PC 42.5R, there is 1.08 % of PbO in the PC50PbZ sample. In respect to that, the higher content of Pb is found in FePbZ than in PbZ, it is logical that cements with addition of this zeolite have a higher content of PbO (Fig. 2b). Thus, the content of PbO as high as 0.51 % is found in the PC10FePbZ sample, and PbO content of 1.96 % is found in the sample PC50FePbZ.

In previous researches [24] it was found that Pb ions are connected via strong forces with both natural zeolite, and Fe(III)-modified zeolite, i.e. there is no desorption of Pb ion. Therefore, the Pb leaching test has not been performed in this investigation.

In Table 3, the results of physical properties testing of PC and PC with addition of zeolite in various mass ratios are given.

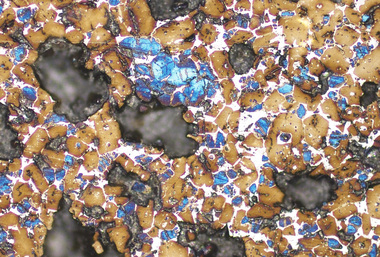

Since the initial zeolite sample had a grain size 0.043 mm, when this sample is mixed with Portland cement the specific surface area is significantly increased which can be seen from the results given in Table 3.

Standard consistency (SK, %) (Tab. 3) of all investigated cements is higher than SK of PC (29.0 %), and it is in the range of 31.6 % for PC 10PbZ up to 44.0 % for PC 50FeZ.

According to the Point 17 of the Regulation [23] which concerns cement PC 42.R and similar cements (according to the SRPS EN 196-3), initiation of setting time for cement PC 42.5 R is ≥ 60min. All investigated cements are fulfilling this condition. It can be said that (Tab. 3) the shortest setting time (initiation and ending) is noticed in the case of PC30Z (80/100 min) and PC50Z (80/130 min) samples. The longest setting time is obtained in the case of PC30PbZ (270/340 min), which is a longer time period than the PC setting time for 50 min (initiation), i.e. 70 min – end of setting.

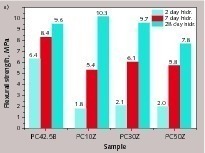

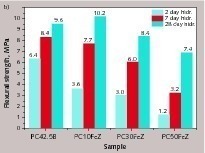

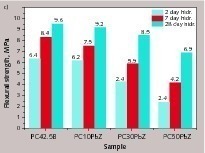

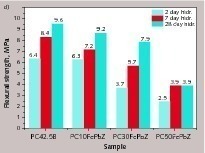

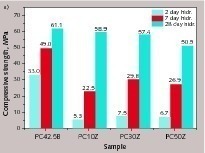

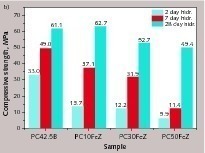

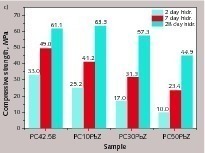

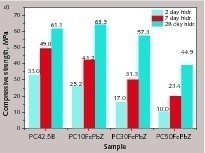

Figures 3 and 4 show values of flexural strength and compressive strength of Portland cement and cement with addition of saturated zeolite for 2, 7, 28 days of hydration. Based on these results (Fig. 4) it can be seen that values of flexural strength and compressive strength depend on the mass content of addition used in Portland cement, i.e. addition of zeolite waste to cement composite. Strengths of investigated cements are decreasing with the increase of saturated zeolite content in the PC for all investigation periods (2, 7 and 28 days). However, the decrease of the strength is at its peak after 2 days of hydration, less for 7 days, and the least for 28 days.

This is in complete accordance with the role of cement additives, reactions and interactions of contaminated zeolite in reaction system–cement and water, where characteristic properties of such zeolites perform. Namely, its aluminosilicate composition provides pozzolanic reaction with products of cement hydration [14].

When values of flexural strength (after 28 days) of Portland cement and the rest of the investigated samples with addition of zeolite and addition of saturated zeolite are compared, it can be concluded that the lowest value of flexural strength, being 3.9 MPa, is noticed for the PC50FePbZ, while this value for PC is 9.6 MPa. Since the flexural strengths (after 28 says of solidification) for the samples obtained by addition of 50 wt. % zeolite to Portland cement are in the range 7–8 MPa, they can be considered as low values.

Therefore, the optimal mass content of zeolite or previously mentioned contaminated zeolites in Portland cement should not exceed 30 %. Having this in mind, three cements with 30 % zeolite addition show high flexural strengths after 28 days of solidification: PC30Z - 9.7 MPa; PC30FeZ - 8.4 MPa; and PC30PbZ – 8.5 MPa. Cement PC30FePbZ shows the 7.9 MPa value for flexural strength, which points out that it is possible that minimal content of this contaminated zeolite is used in the Portland cement.

According to the EN 197 Standard, cement marked as CAM I should have compressive strength 42.5 MPa. Compressive strengths of newly-formed cements with addition of Pb ion saturated zeolite after 28 days of hydration are mostly above these values. Cement PC50FePbZ does not satisfy the requirements due to its compressive strength after 28 days being 38.7 MPa. It can be said that value of compressive strength for PC50PbZ is reaching the limit by being 44.9 MPa.

It can be said that all used zeolites can be applied as additives for Portland cement in the quantity up to 30 %. Namely, values of compressive strength (after 28 days of solidification) for all cements with 30 % of additive are high (PC30FeZ – 52.7 MPa; PC30FePbZ – 56.9 MPa; PC30PbZ – 58.3 MPa and PC30Z – 57.4 MPa) in comparison with the requested minimum – 42.5 MPa.

4 Conclusion

The obtained results point out that harmful zeolite waste containing Pb ions, which is obtained by absorption of lead ions from water on natural zeolite, can be used as supplementary cementitious material (SCM).

Having in mind the requirement that LoI of cements should be ≤5 %, it can be concluded that among all investigated cements, only cements which contain up to 30 wt. % of addition can be treated as satisfactory. Condition that sulfate content (in form of SO3) is ≤ 3.5 % is fulfilled by all cement, since the sulfate content is in the range from 1.58 % (PC50FePbZ) to 3.4 % (PC 42.5R).

The content of Fe ion in the cement mixes PbZ and FePbZ was (expressed in Fe2O3 form) in the range from 1.58 to 1.53 % in the PC10-50PbZ, and 1.64 – 2.13 in the PC10-50FePbZ, which is satisfying in the competition with the pure PC (1.48 % Fe2O3). A higher content of PbO was found in FePbZ (3.58 %) than in the PbZ (2.22 %).

Fineness of PC and zeolite mixture samples is a few times higher than fineness of PC. This is the consequence of the zeolite grain size being100 % - 0.043 mm.

Standard consistency (SK, %) (Table 3) of all investigated cements is higher than SK of PC (29.0 %), and it is in the range of 31.6 % for PC 10PbZ up to 44.0 % for PC 50FeZ.

Requirement regarding the beginning and the end of setting period is fulfilled by all investigated cements. The shortest setting time is noticed for the samples PC30Z (80/100 min) and PC50Z (80/130 min). The longest setting period was noticed for the PC30PbZ (270/340 min). That is 50 min (beginning), i.e. 70 min (end) longer period than setting time found for PC, and according to the Regulation of the quality of cement setting time for PC 42.5 R should not be longer than 60 min.

Strengths of the investigated cements are decreasing with the increase of the content of saturated zeolite in the Portland cement for all investigation periods (2, 7 and 28 days). However, the decrease of the strength reaches its lowest peak after 2 days of hydration, after 7 days the decrement is smaller, and after 28 days the decrease is significantly smaller. Since the flexural strengths (after 28 says of solidification) for the samples obtained by addition of 50 wt. % zeolite into Portland cement are in the range 7-8 MPa, they can be considered as low values. Therefore, the optimal mass content of zeolite or previously mentioned Pb contaminated zeolites in Portland cement should not exceed 30 %.

Since values of compressive strength (after 28 days of solidification) for all cements with 30 % of additive are high (PC30FeZ – 52.7 MPa; PC30FePbZ – 56.9 MPa; PC30PbZ – 58.3 MPa and PC30Z – 57.4 MPa) in comparison with requested minimum – 42.5 MPa, it can be said that all used zeolites (Pb ion saturated, Fe ion modified and natural) can be applied as additives for Portland cement in the quantity up to 30 wt. %.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.