Material recyclable share of solid recovered fuels for co-incineration in Germany

To obtain information on the ash composition of solid recovered fuels (SRF), initial investigations have been carried out in production plants for quality assured SRF. Results of these investigations are shown in this publication. For this, the status quo of co-incineration in cement plants with regard to the legal context and the development of alternative fuels in Germany will be described first. Then, the solid recovered fuels are specified. Finally, the element contents of the ashes of SRF samples from different origins are presented with regard to a recycling quota and to savings in carbon dioxide emissions.

1 Introduction

In general, the cement production process offers different possibilities for the utilization of alternative fuels and raw materials, which lead to savings of natural resources and environmentally friendly disposal of wastes [6]. Due to the fact that ash from solid recovered fuels has valuable constituents for cement production, such as SiO2, CaO, Al2O3, Fe2O3 etc. which are incorporated into the clinker, primary raw materials can be saved (see also [1], [21]). This has meanwhile been proven in various investigations, so that these constituents can technically be considered as...

1 Introduction

In general, the cement production process offers different possibilities for the utilization of alternative fuels and raw materials, which lead to savings of natural resources and environmentally friendly disposal of wastes [6]. Due to the fact that ash from solid recovered fuels has valuable constituents for cement production, such as SiO2, CaO, Al2O3, Fe2O3 etc. which are incorporated into the clinker, primary raw materials can be saved (see also [1], [21]). This has meanwhile been proven in various investigations, so that these constituents can technically be considered as recycled on a material level [2].

In addition, the calcium and magnesium oxide contained in the fuel ashes lead directly to a reduction in process-specific CO2 emissions, as the necessary use of calcium and magnesium carbonate via the natural raw materials is reduced accordingly. These CO2 savings should be seen in addition to the CO2 savings generated by the biogenic fraction in solid recovered fuels.

So, the use of solid recovered fuels e.g. in cement plants, results in both an energy and an additional material recovery of the fuel [2].

The acceptance of a materially recycled share in the energy recovery e.g. in the cement plants is currently being intensively discussed in different European countries. In Belgium France, Hungary and Portugal the materially recycled share is already taken into account (see also [21]).

2 Status quo of the co-incineration in cement plants

2.1 Legal context

The European Waste Framework Directive [10] introduced a five-stage waste hierarchy into waste management:

waste avoidance

preparation for reuse

recycling

other utilization, in particular energy recovery

disposal

At the European level, it is generally recognized that material and energy recovery can take place simultaneously (see chapter 2.2). In addition, recycling quotas have been set in the EU. The EU’s recycling package, for example, sets recycling quotas for municipal waste, which are to be implemented in national law. By 2035, approx. 65 % of municipal waste will have to be recycled [4].

In Germany, the waste hierarchy was implemented with the Closed Substance Cycle Waste Management Act (§ 6 KrWG) [14]. At the same time, recycling quotas are laid down in the Packaging Act and the Commercial Waste Ordinance. For example, the Packaging Act stipulates that 70 % of the plastics have to be recycled by 2022 [3] and the Commercial Waste Ordinance prescribes, that 30 % of non-separately collected waste up to 2020 are to be recycled [4].

Against the background of increasing recycling rates, the acceptance of a materially recycled share in the energy recovery e. g. in the cement plants is currently being intensively discussed in different European countries.

With regard to the solid recovered fuels used in the cement industry, it can be stated that their mineral content – the ash – is completely integrated into the cement clinker, so that the solid recovered fuels utilized during the cement production process. Residues such as ash or slag do not occur. So the use of solid recovered fuels e.g. in cement plants, results in both an energy and an additional material recovery of the fuel. This is also confirmed by the EU Commission in a Guidance Document on the Waste Framework Directive: “In certain production processes such as co-processing, waste can be used in an operation combining two waste management recovery options at the same time. The energy content of the waste is recovered (R1 operation) as thermal energy, thus substituting fuels, while the mineral fraction of the waste can be integrated (hence recycled) in the matrix of the product or material produced, e.g. cement clinker, steel or aluminium (R4 or R5 operation, see a list of recovery operations in Annex II to WFD)” [11]. Also in France, the French Ministry for Sustainable Development has already recognized this by accepting a 23.75 % share of material recovery for the use of scrap tyres in the clinker burning process [2]. In Belgium, Hungary and Portugal solid recovered fuels are also used in the co-processing process. This double recovery reduces energy and material consumption and thus global emissions of carbon dioxide [15]. The same principle can basically be applied to the ashes of all fuels used in such processes. In particular, the mineral components contained therein ultimately lead to a lower demand for primary resources. In addition, the calcium and magnesium oxide contained in the fuel ashes lead directly to a reduction in process-specific CO2 emissions, as the necessary use of calcium and magnesium carbonate via the natural raw materials is reduced accordingly. These CO2 savings should be seen in addition to the CO2 savings generated by the biogenic fraction in solid recovered fuels.

For the recognition of a material recyclable share of solid recovered fuels in cement plants an appropriate method of determination is necessary. Therefore, Germany and Austria (see also [1], [19]) are currently working on this. In addition, the Technical Committee ISO/TC 300 was suggested to work on a standardized method for the determination of a recycling-index for solid recovered fuels.

The relevance of alternative fuels and their contribution to climate and resource protection is given in the next subchapters.

2.2 Development of utilization of alternative fuels in the cement industry in EU-28 and Germany

Nowadays alternative fuels play an important role in the cement industry, whereby the different types of fuel can be distinguished as shown in Table 1.

Refuse derived fuels are used in the clinker burning process to a large extent in addition to and to substitute fossil fuels. The fuel substitution rate in the cement industry of the EU-28 has increased to 46 % (2017) and to 65 % in Germany (Figure 1). From the year 2000 to 2017, the substitution rate has quintupled in the EU-28 and more than doubled in German cement plants.

In 2018 this substitution rate was 67.5 % in Germany [20] and it is assumed that the substitution rate will increase to approx. 80 % by 2020 [6].

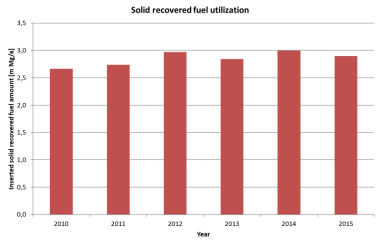

The refuse derived fuels used in the cement industry come from a wide variety of sources. For example, animal and bone meal, animal fat, waste wood, waste oil or used tyres are used as well as pretreated fractions from municipal and industrial waste. Regarding the total use of RDF in cement plants, this has risen from approx. 9.5 million Mg in 2010 to approx. 11.5 million Mg in 2017 in the EU 28 cement industry. In the same period, RDF consumption in the German cement industry has risen from approx. 2.9 million Mg per year (2010) to approx. 3.6 million Mg per year (2017), which represents about 30 % of the total amount of the RDF used in the EU-28 (Figure 2).

A part of the refuse derived fuels are the solid recovered fuels (hereinafter referred to as SRF) which, according to DIN EN 15359, are produced out of non-hazardous wastes. Due to the broad range of possible input material (industrial and commercial solid waste, municipal solid waste, construction and demolition waste or waste wood etc.) solid recovered fuel is a heterogenic group of fuels [8].

Also at national level, the term “solid recovered fuels” summarizes a broad range of different fuels, produced from non-hazardous municipal and production wastes. According to the RAL-quality mark “Solid recovered fuel” (RAL-GZ 724) solid recovered fuel is divided into “high calorific fraction” for mono-incineration (e. g. power plants for solid recovered fuels) and solid recovered fuels (SRF) for co-incineration in cement, lime and power plants (Table 2) [19]. The former are produced from municipal and/or commercial solid waste and are characterized by a lower degree of treatment, bigger grain sizes and lower calorific values. Because they are used in mono-incineration, these materials are not in the focus of the continuing explanation.

Solid recovered fuels (SRF) for co-incineration are produced by a complex and sophisticated treatment process and are characterized by a defined quality (grain size: ≤ 50 mm, higher calorific values). They are produced from production waste and/or high calorific fractions from municipal solid wastes [19] and here often the sorting residues from upstream processing of waste fractions into recyclates (e. g. residues from sorting of lightweight packaging, residues from waste paper sorting and processing, residues from mechanical processing of household waste etc.), which are not suitable for material recycling. In this respect, solid recovered fuels do not compete with material recycling, but rather complement and support it.

In Germany, approximately 2 million Mg of this solid recovered fuel (SRF) quality are used in cement plants, predominantly in the main burner. Circa 25 % of these SRF are currently quality-assured according to RAL GZ 724 with an increasing tendency.

As mentioned before, solid recovered fuels in the cement industry contribute to climate protection and resource conservation simply by using them as an energy source. For example, the use of RAL GZ 724 quality-assured SRF in Germany alone has saved approx. 2.8 million Mg of coal equivalent fossil fuels (coal, oil) and approx. 4 million Mg of CO2 so far [12]. With regard to the calcium and the manganese content in the fuel ashes, solely through the use of solid recovered fuels in German cement plants, raw materials as well as process-related CO2-emissions of a further 100 000 Mg per year can be saved [18]. This illustrates, that in co-processing, waste streams from other economic sectors can be recycled in the cement industry and thus contribute to the circular economy.

However, this requires that the ashes from solid recovered fuels contain corresponding valuable components and that primary raw materials are thus replaced. Therefore, it is necessary to have information on the ash composition. As no method has been standardized to date, investigations are currently being carried out at the Montan-universität Leoben and the Münster University of Applied Sciences as part of the RD-project ReWaste 4.0. These were supported by the BGS e. V. to the effect that various quality-securing solid recovered fuel manufacturers had their fuels tested for ash compositions.

3 Ash composition of solid recovered

fuels in Germany

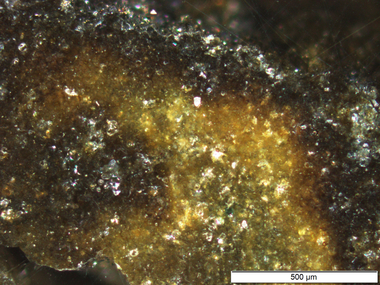

To develop information about the ash composition of solid recovered fuels, different quality assuring solid recovered fuel producers participated in investigations of the ash composition. These investigations were carried out on more than 60 samples, which were analyzed within the framework of the RAL 724 quality mark [19]. In addition to the quality assurance parameters, the composition of ash from the determination of the ash content according to DIN EN 15403 [9] at an ignition temperature of 550 °C was investigated by RFA or ICP-OES. For this purpose, the Gütegemeinschaft Sekundärbrennstoffe und Recyclingholz e. V. (BGS) (Quality Association for Solid Recovered Fuels and Recycled Wood) has defined a procedure and described it in a brief guideline.

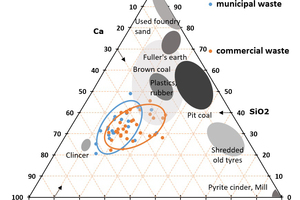

In accordance with the chemical composition of cement raw meals (Figure 3) the regarded parameters were silicon, aluminium, iron, calcium, magnesium, sodium, potassium, titanium, phosphorus, sulphur (given as oxides).

In the following, the results of the ash composition investigations are presented according to their area of origin. The ash content of SRF samples from municipal waste and from commercial waste investigated here is about 8 - 17 mass-% and nearly the same for both types of waste. In the individual samples, the ash content and the sum of the individual ash characteristics often correspond comparatively well. The main elements (CaO, SiO2, Al2O3, Fe2O3) form a proportion of 6 - 15 mass-% in SRF from commercial waste and 6 - 12 mass-% in SRF from municipal waste.

The comparison of the mean raw meal composition [16] with the average ash compositions of the solid recovered fuels shows that these contain relevant proportions of the value-giving components (Figure 3). The slightly lower CaO quantities in the SRF ashes (mean: about 35 %) are accompanied by higher proportions of SiO2, Al2O3 and Fe2O3. In addition, the ashes of the solid recovered fuels presented here show hardly any origin-related differences in their composition.

In the ternary diagram, the solid recovered fuels are located between clinker and brown coal or plastics. This speaks accordingly for a high CaO content with a lower aluminium, iron and silicium content. It also shows that solid recovered fuels from municipal or commercial waste can substitute brown coal and raw meal in certain proportions (Figure 4).

On the basis of the CaO contents of the ashes and the ash contents in the SRF, the savings in raw meal by the use of SRF only in German cement plants (approx. 2 million Mg/a) were estimated at approx. 170 000 - 330 000 Mg/a.

As already mentioned, the ashes of the solid recovered fuels presented here, were determined at an ignition temperature of 550 °C. This results from the current EN standard for the ash determination of solid recovered fuels, in which the lower temperature of 550 °C has been specified due to possible proportions of ingredients with low melting temperatures. As part of the revision and internationalization of the European standards, the ash content will (again) be determined at 815 °C in the future. This ignition temperature again complies with other standards, such as DIN 51719 for determination of ash in solid fuels and with which the ash contents of coal are also investigated.

Aldrian et al. [1] and Viczek et al. [21] have carried out investigations into the effects of different ashing temperatures. Therefore different solid recovered fuel samples from Austria, Croatia, Slovenia and Slovakia were ashed at temperatures of 550 °C, 815 °C and 950 °C. In order to get an impression of the effects of different ashing temperatures, the data of this investigation of the solid recovered fuels for the main burner (heating value 18 - 25 MJ/kgos and grain size < 30 mm) were exemplarily summarized (Figure 5).

It becomes obvious, that the median value for the ash content declines with increasing temperature (22 mass-% [500 °C], 18 mass-% [815 °C], 17 mass-% [950 °C]), wherein the relative difference between the ash content measured at 550 °C and 850 °C of about 15 % is significantly greater than that measured at 815 °C and 950 °C (about 5 %). Furthermore, the ash content at 550 °C shows a wider range than at 815 °C or 950 °C. The effects described here could also be demonstrated for other substitute fuel qualities. In addition, Viczek et al. [21] were able to show that the unknown proportions between the ash content and the sum of the measured elements can be reduced by a higher temperature in the ash content analysis.

These results also support the approach of increasing the temperature to 815 °C for ash content determination. For the quality assurance of solid recovered fuels according to RAL-GZ 724, the ash content will therefore be determined again at 815 °C in future.

4 Summary and prospects

In some EU countries the simultaneous material and energy recovery of solid recovered fuels in certain industrial processes is already recognised. In France and Belgium, for example, this has already been implemented for certain fuels. The acceptance of a materially recycled share in energy recovery e. g. in the cement plants is currently being intensively discussed in further European countries.

For the recognition of a proportionate material recycling of SRF in cement plants, an appropriate method of determination is necessary. To develop information about the ash composition of solid recovered fuels additionally, initial investigations have been carried out in production plants for quality assured solid recovered fuels. In advance, a procedure for the analysis of the ash composition has been defined by the BGS e. V., which was used for the investigations.

All in all, the obtained results show the potential of alternative fuels from the waste sector for material recycling in the cement industry. Ash contents in the investigated quality assured SRF for co-incineration were determined at an ignition temperature of 550 °C and are between 10 and 20 mass-%. The ash consists of elements that are also required in cement clinker production. In particular, the main components of cement raw meal (calcium, silicon, iron and aluminium) also form the essential components of the ash. As temperatures of 815 °C are used for solid fuels like coal, an analysis of the ash content at higher temperatures can be regarded as more praxis-oriented than an ignition temperature of 550 °C and will be used in the standard for the determination of ash contents in SRF (again). For this reason, further investigations on the ash composition of quality assured SRF, determined at an ashing temperature of 815 °C are planned.

Material recycling in the cement industry could also contribute a share to the material recycling quotas to be observed in the commercial, packaging and municipal waste sectors, if it can be proved that SRF ashes are provided with corresponding valuable components and can thus save primary raw materials in cement production. It was estimated (based on CaO contents), that the use of SRF at German cement plants (approx. 2 million Mg/a) results in savings in raw meal of approx. 170 000 - 330 000 Mg per year.

In the future, corresponding information on the ash composition of SRF and a corresponding determination method will be available. This can and will support the recognition of a proportionate recycling in the use of SRF in the various European countries.

In Germany the quality assurance according to RAL GZ 724 will in future be extended to the material recyclable share. Therefore, the Gütegemeinschaft Sekundärbrennstoffe und Recyclingholz e. V. (Quality Association for Solid Recovered Fuels and Recycled Wood) has defined a method for the determination of the ash composition which will be made available to the quality assurance laboratories. In addition, the quality assurance test reports will in future be extended to include this.

http://bgs-ev.de | //www.fh-muenster.de" target="_blank" >www.fh-muenster.de:www.fh-muenster.de

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

![1 RDF substitution rates in the EU-28 and German cement industry [17] [20]](https://www.zkg-online.info/imgs/1/5/2/9/8/4/1/tok_90ccbb11841388cb732c565d9e02ccd0/w300_h200_x600_y315_1_Fuel_substitution_rates_in_the_eu-28_and_german_cement_industry-e8636d19b4fd8117.jpeg)

![2 Quantities of RDF used in the cement industry, the EU-28 (EU) and in Germany (G) [17] [20]](https://www.zkg-online.info/imgs/1/5/2/9/8/4/1/tok_3c5b8c81ee5506d495dd7b9f73e55642/w300_h200_x600_y391_2_Quantities_of_refuse_derived_fuels_used_in_the_cement_industry_in_the_EU_and_Germany-2ed299dee8a7bc3a.jpeg)

![3 Comparison of the mean ash compositions of the solid recovered fuels from municipal waste and commercial waste with the mean raw meal [16] composition](https://www.zkg-online.info/imgs/1/5/2/9/8/4/1/tok_36d478095edcf00f4db35aa219ed4366/w300_h200_x564_y338_3_Comparison_of_the_mean_ash_composition_with_the_mean_raw_meal_composition-998bfaa4870dc743.jpeg)

![5 Distribution of ash content with different temperatures (according to [21])](https://www.zkg-online.info/imgs/1/5/2/9/8/4/1/tok_6148eb9e0758b7b97512ad04023d04d9/w300_h200_x564_y373_5_Comparison_of_the_ash_content_of_srf_determined_with_different_combustion_temperatures-9d2e5c2d464ee26d.jpeg)