Starter kit for using solid recovered fuel

in cement plants

In 1995, the equipment supplier Tews based in Büren/Germany tested its first system for the use of solid alternative fuels at the Kollenbach cement plant/Beckum operated by the present-day CEMEX. Pure fractions of non-hazardous, high-energy production waste was the feed material for the production of solid recovered fuel (SRF). For the initial tests, this production-specific waste was comminuted using modified agricultural equipment and then conveyed mechanically to the main burner of the rotary kiln. The results of these first tests at CEMEX were the starting point for co-processing, which...

In 1995, the equipment supplier Tews based in Büren/Germany tested its first system for the use of solid alternative fuels at the Kollenbach cement plant/Beckum operated by the present-day CEMEX. Pure fractions of non-hazardous, high-energy production waste was the feed material for the production of solid recovered fuel (SRF). For the initial tests, this production-specific waste was comminuted using modified agricultural equipment and then conveyed mechanically to the main burner of the rotary kiln. The results of these first tests at CEMEX were the starting point for co-processing, which was then to develop rapidly in the cement industry in the succeeding years. A rationally priced alternative to the feeding of primary fuels at the main burner was available with immediate effect.

By the end of the 1990s, further Tews systems had been installed for Schwenk Zement KG, firstly at its Karlstadt plant, and then in Bernburg. A mutually beneficial co-operation, under which the potentials and limitations of the use of SRF in the rotary kiln could be further tested and explored, grew up in the course of time. Other operators, including Dyckerhoff or Rheinkalk, followed later.

Nowadays, thermal substitution rates (TSR) of above 60 % are achieved on average at all German cement plants, with individual plants deploying sophisticated special methods to meet almost 100 % of their energy needs. Tews has, in the intervening period, supplied numerous unloading and metering systems to the cement industry and coal-fired power plants in Germany and the rest of Europe, all the time refining and improving the technology.

The following items were important and, indeed, decisive for the continuously rising success curve: simple system use and handling, high availability, and the lowest possible investment costs for the “starter kit”.

Even by the late 1990s, there were, indeed, many other cement plants that had considered the use of SRF, but were wary of making the high investments necessary for handling systems without approval-law certainty or guarantees of assured supplies and quality. This was a result of the fact that the origin of such fuels remained, for the cement industry, totally obscure, and that their preparation and quality, and also their use, was still in its infancy. Many important emissions, process operation and product-relevant parameters, such as calorific value, chlorine, sulphur and heavy-metal contents, average ash and water contents, and the effects of these on the process, on clinker composition and on waste-gas flows, were entirely unknown, and harboured corresponding risks.

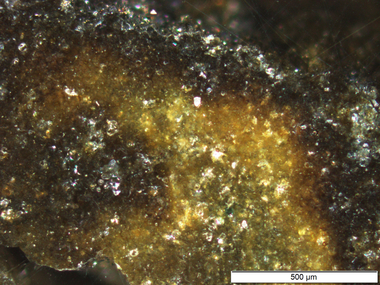

The equipment systems available from Tews thus provided an easy-to-operate, pragmatic solution at rational cost levels. The basic principle has now been replicated numerous times, and can even be found in large commercial-scale plants: the solid recovered fuel is supplied in a moving-floor semi-trailer (Fig. 1) and automatically unloaded using one or more docking stations (Fig. 2). The tractor unit is not needed for unloading, since the trailer unloading process is controlled by means of filling level sensors and runs totally automatically, using fixed hydraulic systems.

This means that the moving-floor trailer delivering new SRF can be swapped upon arrival for the empty trailer. The “incoming” trailer then remains at the cement plant’s external hydraulic installation, acting as a mobile storage unit, and discharges its approx. 90 m3 (around 20 tonnes) of SRF hydraulically, via the movement of the trailer floor.

In the Tews system, the material is transferred via the trailer floor to the docking station, and then discharged by means of metering screw feeders into the metered conveying system. The station is available with two or three metering screws, depending on the required conveying capacity (Fig. 3). Specially developed internals prevent bridging and assure continuous extraction. The SRF is then conveyed pneumatically via a Tews lock hopper (Fig. 4) and meter-fed directly to the burner of the rotary kiln. This system typically achieves conveying rates of between 0.5 and 5.0 t/h, with maximum capacity essentially determined by the internal diameter of the conveying pipes, which are used for pneumatic transport to the cement kiln.

All metering screws are frequency-controlled and can therefore be used to regulate the SRF feed rate. The density of the SRF is determined, and an individual calibration curve for metering screw frequency referred to conveyed volume is generated, in order to calibrate this volumetric feed system. This principle has proven its worth in numerous series of tests in the most diverse range of cement plants, and demonstrates that volumetric metering achieves the necessary accuracy, and actually offers significant advantages over gravimetric feed systems.

Operators are concerned to achieve the most constant possible thermal feed using fuels of a relatively constant energy content, which must be fed continuously to the combustion points, in order not to disrupt the clinker burning process. At such an early stage, one supplier alone will not be able to meet all these fuel needs, and a large range of different grades, with corresponding quality fluctuations, is thus used. The risk of underburning is therefore obvious.

In the case of gravimetric metering, an SRF with an elevated water content would import proportionally more water - and less energy - into the kiln per unit of volume, due to the constant feed weight. The experience gained by Tews indicates that volumetric metering very largely eliminates precisely this problem, since energy input per unit of volume then remains constant - only the conveyed fuel weight changes.

Tews has commissioned more than thirty such systems in cement plants and coal-fired power-generating plants throughout Europe since the installation of the first patented systems in 1995. This robust solution is also arousing increasing interest overseas, however, where SRF markets are also gradually developing, with the international cement industry pleased to benefit from tried and proven technological experience.

//www.recycling-solutions.de" target="_blank" >www.recycling-solutions.de:www.recycling-solutions.de

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.