Status quo of co-incineration of solid recovered fuels in Germany

The status quo of co-incineration in Germany and the production of quality assured solid recovered fuels (SRF) is as well described as the normative requirements for the production of SRF, which actually develop to international standards. Finally, the contribution of co-combustion to the climate and resource protection is illustrated.

1 Introduction

In Germany, co-incineration of solid recovered fuels in industrial combustion plants like coal-fired power plants and cement plants is an inherent part of modern closed loop recycling management, because this allows high-class utilization of materials with a high heating value. Thereby, solid recovered fuels are defined as a variety of fractions for energetic use, which are produced from non-hazardous wastes [14].

Solid recovered fuels are mainly used in cement, lime and coal-fired power plants. The total amount of solid recovered fuels used in these industries is about 2.75 - 3...

1 Introduction

In Germany, co-incineration of solid recovered fuels in industrial combustion plants like coal-fired power plants and cement plants is an inherent part of modern closed loop recycling management, because this allows high-class utilization of materials with a high heating value. Thereby, solid recovered fuels are defined as a variety of fractions for energetic use, which are produced from non-hazardous wastes [14].

Solid recovered fuels are mainly used in cement, lime and coal-fired power plants. The total amount of solid recovered fuels used in these industries is about 2.75 - 3 million Mg/a; main customer is the cement industry. In comparison, the use of solid recovered fuels in coal-fired power plants is at a lower but constant level, because it depends on the firing technology and a modified application regime in coal-fired power plants [15].

2 Status quo of the co-incineration in Germany

From a national point of view, the term “Solid recovered fuels” summarizes a broad range of different fuels, produced from non-hazardous municipal and production wastes. According to the so-called RAL-quality mark “Solid recovered fuel” (RAL-GZ 724) solid recovered fuel is divided into “high calorific fraction” for mono-incineration and solid recovered fuels for co-incineration in cement and lime plants and in coal fired power plants as well (RAL, 2012). The former is produced from municipal and/or commercial solid wastes and is characterized by a lower degree of treatment, bigger grain sizes and lower calorific values. Because they are used in mono-incineration, these materials are not in the focus of the continuing explanation.

In the following, only solid recovered fuels for co-incineration are regarded, i.e. finally assembled fuels with a defined quality, which are produced from production waste and/or high calorific fractions from municipal solid wastes [14]. They are produced by a sophisticated treatment process and are characterized by a smaller grain size (max. 50 mm) and higher calorific values.

2.1 Development of the amounts of solid recovered fuels in Germany

Solid recovered fuels (SRF) are mainly used for co-incineration in cement plants, coal-fired power plants and lime plants. In recent years, the inserted solid recovered fuel amounts have a constant high level of about 3 million Mg/a, with tendency to rise (Figure 1).

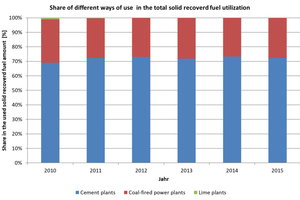

The share of the solid recovered fuel amount used per way of utilization slightly varies (Figure 2). In recent years, the SRF use in the lime industry has a maximum share of 1 % and therefore is irrelevant. In 2015 the co-incinerated solid recovered fuel merely amounts to about 600 Mg [2].

With co-incinerated SRF amounts of about 0.8 million Mg/a, the coal-fired power plant industry had a share of about 30 % in the past years. With about 0.6 million Mg/a, the predominant amount was co-incinerated in lignite-fired power plants [7, 8, 9].

With shares of 70 to 73 % of the total SRF amounts, the cement industry is the main consumer of these fuels. This can be traced back to the fact that alternative fuels are used to a high degree for the very energy-intensive process of cement clinker production. The rate of substitution for the primary energy carrier rose in the last years up to more than 64 %. Due to the fact that cement plant operators are interested in a further increase of the substitution rate up to 100 %, a further rise in SRF use in cement plants is to be expected. Even now, besides alternative fuels like meat-and-bone meal or used tyres, assembled fractions of industrial, commercial and municipal waste are predominantly used [11, 12]. Because higher substitution rates require adequate SRF of a constant quality, it is also to be expected, that an increase of substitution rate will lead to higher amounts of quality assured SRF.

2.2 Quality assurance of solid recovered fuels in Germany

A well-established quality assurance system in Germany is the quality assurance of the Gütegemeinschaft Sekundärbrennstoffe und Recyclingholz e. V. (Quality Assurance Association for Solid Recovered Fuels and Recycled Wood, BGS e. V.) including the RAL-quality mark 724, which has been awarded since the year 2001. It comprises periodical sampling and analytic monitoring during the production process for SRF and represents continuous process control. Furthermore established reference values for heavy metals guarantee an application of the SRF as substitute for primary fuels, that is high-graded and harmless for humans and the environment. Solid recovered fuels can be awarded the quality mark, if they fulfill the requirements of the “General and specific Quality and Testing Specifications Solid Recovered Fuels” („Allgemeine und Besondere Güte- und Prüfbestimmungen für Sekundärbrennstoffe“) [14] and prove the fulfillment regularly. In this case, they are named with the trade mark SBS.

The quality assurance system is based on a self-monitoring of the SRF producer and an external control conducted by independent consultants and test laboratories (see Figure 3).

It is relevant that the input material corresponds with the waste types in the Quality and Testing Specifications and that the produced SRF meet the reference values for heavy metals, shown in Table 1. The procedure of sampling, sample preparation, analysis and assessment in the context of the quality assurance is also determined in detail [3].

Besides the heavy metal contents described here, the content of copper and further parameters like calorific value, water content, ash and chlorine content also have to be analysed and documented. For the last-mentioned, specific reference values do not exist, because they are process-specific parameters, which depend on the utilization and are fixed in bilateral arrangements between contractual partners. Typical calorific values are e. g. 20 MJ/kg for the use in cement plants, >25 MJ/kg for the use in lime plants and hard coal-fired power plants and 13 - 16 MJ/kg for the use in lignite-fired power plants.

The growing importance of the quality assurance is reflected in the rising amounts of quality assured solid recovered fuels (SBS). From the year 2014 up to the end of the year 2017, they almost double and have achieved an amount of more than 500 000 Mg/a (Figure 4) which represents nearly 1/5 of the total inserted solid recovered fuel amounts per year. A further increase is expected for the next years – for 2018 it is expected, that the quality assured solid recovered fuels in Germany will reach an amount of 550 000 Mg/a.

In particular, this increase can be traced back to an increased demand for quality assured solid recovered fuels, which corresponds to the higher substitution rates in cement plants. The use of a trade mark provides evidence of a high fuel quality, which is requested during the approval process as well as for contract negotiations and as a part of accounting.

2.3 Normative requirements for the production of solid recovered fuels

Since 2011 normative requirements for the production of solid recovered fuels also exist at a European level. The Gütegemeinschaft Sekundärbrennstoffe und Recyclingholz e. V. (BGS) was significantly involved in the development of these standards. The production of solid recovered fuels is i. a. regulated in DIN EN 15359. The European regulations comprise a broader range of non-hazardous wastes than the Quality Mark RAL-GZ 724, because next to process and commercial solid waste, municipal solid waste, construction and demolition waste, mono-fractions like waste wood or sewage sludge are covered by the DIN EN 15359. Therefore, solid recovered fuel is a heterogenic group of fuels, which needs specification and classification, which are also regulated in DIN EN 15359. The classification of solid recovered fuels is based on the fuel characteristics calorific value, chlorine and mercury. For the specification, this means that the documentation of characteristic solid recovered fuel properties, physical and chemical properties (like ash, water and heavy metal contents) is mandatory (DIN, 2012). The regulations for sampling, sample preparation and analysis methods also developped during the European standardization process have been adjusted with the RAL-GZ 724 and the regulations of the latter have been adapted to the European requirements, as far as necessary and reasonable.

Presently the classification and standardization system, developed in the European Union is going global. In 2016 a mandate was accorded to an appropriate technical committee to develop international standards for solid recovered fuels. For the development of ISO-standards, the following six working groups have been set up, the BGS is also involved in this work:

WG 1 – Terminology and quality assurance

WG 2 – Specification and classes

WG 3 – Sampling and sample reduction

WG 4 – Physical/mechanical tests

WG 5 –Chemical tests and determination of

biomass content

WG 6 – Safety of solid recovered fuels

3 Relevance of the co-combustion for climate and

resource protection in Germany

Attributed to the biomass content of solid recovered fuels, the co-incineration in industrial combustion plants contributes to climate protection, because CO2-emissions from renewable resources are classified as carbon neutral and are therefore not charged when balancing the greenhouse effect. As a result, the energy-efficient use of solid recovered fuels with a high share of biogenic carbon (from 20 to 75 %) makes an important contribution to global CO2-reduction. Above all, the specific CO2-characteristics, i. e. the CO2-savings per mass of used solid recovered fuel, depend on the input material, the expenses for the treatment and the utilization. Due to the regarded boundary conditions, a qualified production of solid recovered fuels and the subsequent co-incineration in the above-mentioned combustion processes, result in a CO2-reduction potential between 350 and 1000 kg CO2-eq./Mg SRF.

Only the German cement industry avoided in 2014 fossil fuel specific CO2-emissions of about 1.5 million Mg by using suitable solid recovered fuels. Simultaneously, about 2 million Mg hard coal equivalents of fossil primary energy carriers were saved. Besides, the solid recovered fuels are completely utilized during the cement production process, because the mineral part of the ashes becomes part of the cement clinker directly. Due to the calcium and the manganese in the fuel ashes, raw materials as well as process-related CO2-emissions of further 100 000 Mg/a can be saved [13].

4 Summary and prospects

The co-combustion of solid recovered fuels in industrial combustion plants is an inherent part of a modern closed-loop recycling management, because this allows a high-class and low-emission utilization of materials with a high calorific value.

A precondition for this use is that the solid recovered fuels constantly meet the demands of the particular recovery process given for the physical and chemical quality. Solid recovered fuels, that i. a. are characterized by low grain sizes (< 50 mm) and high calorific values, are produced from non-hazardous wastes by a sophisticated treatment process. For years, the amount of solid recovered fuels for co-incineration is at a constant level of about 3 million Mg/a.

Even in the future and under the expected changing boundary conditions (e. g. increase of recycling, the phasing out of coal-powered electricity) the co-incineration of solid recovered fuels will play a decisive role for the high-grade use of waste fractions. For instance, higher amounts of sorting residues occur during treatment processes for material recycling of waste streams, which then require an energy recovery. Furthermore, new waste streams are to be expected (POP-containing wastes, fibre-reinforced plastics), for which co-incineration might also be a reasonable disposal procedure in future.

Because a high-grade energetic use is facilitated by the proof of a constant and reliable good quality (e. g. according to RAL GZ 724), it is to be expected, that in addition to an increase of the total amount of used solid recovered fuels, the amount of quality assured solid recovered fuels will rise.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.