Quality assurance of solid recovered

fuels (SRF)

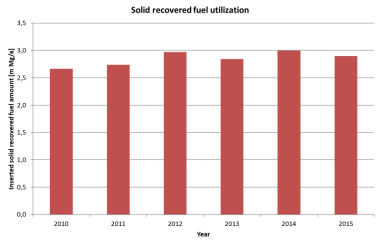

The utilization of solid recovered fuels for energy recovery has established itself and has been increasing steadily in recent years in Europe. A permanent availability in the area of solid recovered fuels can only be achieved with a fuel of constant quality that is appropriately matched with the combustion technology. In this case, it is necessary to define quality standards and introduce targeted quality assurance measures.

1 Introduction

The terminology for treated wastes used either in mono-incineration or co-incineration application varies. In Germany, waste for energy recovery is generally subdivided into solid recovered fuels and high-calorific fractions. A solid recovered fuel is a specially prepared fuel made of production-specific or municipal waste that has been treated adequately for co-incineration. Solid recovered fuels that comply with a defined quality standard according to RAL-GZ 724 [RAL, 2012a] are known by the protected brand name SBS®. By contrast, high calorific fractions have undergone a...

1 Introduction

The terminology for treated wastes used either in mono-incineration or co-incineration application varies. In Germany, waste for energy recovery is generally subdivided into solid recovered fuels and high-calorific fractions. A solid recovered fuel is a specially prepared fuel made of production-specific or municipal waste that has been treated adequately for co-incineration. Solid recovered fuels that comply with a defined quality standard according to RAL-GZ 724 [RAL, 2012a] are known by the protected brand name SBS®. By contrast, high calorific fractions have undergone a lesser degree of treatment and consist simply of selectively separated portions or fractions of waste whose calorific value is significantly higher, due to their composition and characteristics, than that of a normal waste mixture. As SBS® and other solid recovered fuels are an input material for co-incineration plants, for instance cement and coal-fired power plants, the quality requirements the fuel needs to satisfy are stricter.

Regardless of its application in mono-incineration or co-incineration systems, SRF must fulfil general quality requirements in order to be efficiently utilized. These requirements include:

A predefined calorific value and low chlorine content

Defined grain size and bulk density

Few impurities

Low heavy metal content (for co-incineration)

Availability of sufficient quantities with the required quality

Technical, legal and regulatory as well as economic requirements determine the specific set of boundary conditions for each plant, calling for the individual adaptation of the fuel to ensure they are all satisfied. Therefore, it is indispensable to define a standard procedure in order to guarantee that all contracting parties define the quality parameters unambiguously and in analogy to each other.

The establishment of the Gütegemeinschaft Sekundärbrennstoffe und Recyclingholz e.V. (BGS e.V.) in 1999 was the first step on the way to certifying quality-controlled SRF. BGS e. V. brings together representatives of SRF manufacturers, users and other stakeholders. In its quality and monitoring rules, the RAL quality assurance system defines both heavy metal limits and boundary specifications for the verification of fuel quality. Furthermore the many years of BGS e.V.´s experience in the quality assurance of solid recovered fuels is integrated in the European Standardization by CEN/TC 343 [CEN, 2012].

2 Quality standards according to RAL GZ 724

Several boundary conditions have to be considered when defining quality standards for SRF. The influencing factors for the determination of the waste components, the choice of the quality parameters and, if applicable, the definition of the corresponding guidance values call for a differentiated consideration. The assessment of SRF by analytical values is an integral part of permitting procedures and contracts. Consequently, it is necessary to rely on meaningful data. In view of the fact that waste composition is normally rather heterogeneous, various factors must be considered for analysis. These include:

Sampling

Sample treatment

Analytical method

Interpretation of data and

Choice of quality parameters

In the following the above-mentioned factors were described for the RAL-GZ 724.

2.1 Sampling

Solid wastes such as municipal, industrial or construction waste are normally heterogeneous mixtures with variable composition, distribution, shape and size of components. The sample should be taken in the output stream of a treatment plant, ideally direct from the conveyor and across the entire material stream. To take into account variances between output periods, it is necessary to take a proportional number of individual samples. These can then be combined to form mixed samples and be prepared as the laboratory sample. Within the framework of the RAL GZ 724 the sample is taken according to a predefined sampling schedule. The samples are taken to be proportional to quantity, directly from the falling stream of the conveyor belt. A mixed sample is made up of 25 separate 5-L samples. In a monitoring procedure, the plant operator must prepare 21 mixed samples.

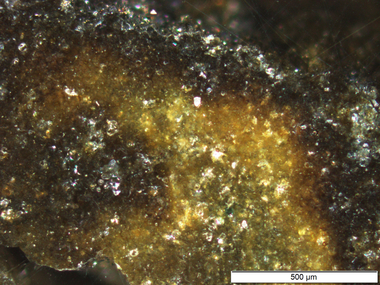

2.2 Sample treatment

To determine heavy metals in the laboratory samples, the largely heterogeneous laboratory sample must be converted into a homogeneous one, comprising approximately 1.5 g with a grain size of less than 1 mm. The waste components are determined from this mix. Intermediate grinding steps and repeated divisions of the sample are necessary to achieve this. Several steps are required for sample treatment: the removal of extraneous materials, partitioning of the sample, comminution, drying, and sample preparation. The Sampling, Sample Treatment and Analysis Guidelines [BGS, 2012b] of BGS e.V. provide a detailed description of these procedures and the subsequent analysis.

2.3 Analytical method

Once converted into analysis samples, the waste usually goes through digestion before the analysis can be performed. Digestion serves to turn as much analyte as possible into a solution. As a result of several round robin tests, BGS e.V. stipulated that the pressure digestion method with aqua regia should be used for the determination of heavy metal content of SRF. This decision was based on the fact that plastics in particular are difficult to bring into solution when using just the classic open aqua regia digestion. Other methods for determination of heavy metal content can be used if their equivalence has been proven. Precise instructions for the performance of the method and the limits of determination are given in the Sampling, Sample Treatment and Analysis Guidelines of BGS e. v. [BGS, 2012b]. At this point it must be mentioned that the definition of guidance values is based on the data interpretation of the digestion method above.

2.4 Interpretation of results

The composition of high calorific fractions and SRF for co-incineration frequently presents considerable deviations in spite of predefined sample pre-treatment. For instance, if a polyvinylchloride (PVC) or metal piece makes it into the analysis sample, it will affect the analysis result. However, this result does not reflect the quality of the original volume of the fuel from which the sample was taken. Consequently, waste analysis should never consider individual values and compare them with the guidance value. Such a comparison must always and exclusively be based on data sets. The link between the type of distribution and the rather small number of data for an assessment, led to the introduction of recurring monitoring intervals for the purpose of RAL quality assurance. In any one monitoring interval, 24 samples (21 for internal control + 3 for external control) must be produced. Out of these 24 samples, 10 samples (including the three samples for external control) are analysed. The median value of all 10 samples must not exceed the guidance value defined in the quality and monitoring rules. This also applies to eight of the ten values that are not allowed to exceed the 80th percentile (application of the “four-out-of-five rule”).

The stipulation of the “four-out-of-five”-rule for the upper concentration band was given preference over the stipulation of a 80th percentile, because the deviations that occur in waste analyses can be very large due to non-representative sub-samples, when only a small number of data is considered. In concrete terms, this means for the RAL quality assurance, that out of ten values analysed, the median as well as the 80th percentile are calculated and compared with the guidance values. This manner of interpretation is recognized in Germany and has found its way into the permitting procedures for SRF co-incineration plants and the contracts entered into with respect to them.

2.5 Choice of quality parameters

The choice of parameters is based upon consideration of the following aspects:

Emission limit values

Process technology

Fueltechnology

From the chosen parameters, it must be possible to infer the impact on the environment and process technology. Often, these parameters are already defined in the permitting documentation and contracts. In order to avoid a negative environmental impact, RAL quality assurance uses the same parameters for which emission limit values have been defined. At the time of development of the quality label, these definitions were stipulated in TA-Luft (2002) (Technical Instructions on Air Quality Control). For the co-incineration of SRF, they were subsequently superseded by the 17th Federal Immission Control Decree [17. BImSchV, 2003]. The selected parameters are consistent with the parameters in Directive 2010/75/EU of the European Parliament [European Parliament, 2010] on industrial emissions. Therefore the determination of the following parameters are required according to RAL-GZ 724: humidity, net calorific value (NCV), ash content, chlorine content, cadmium, mercury, thallium, arsenic, cobalt, nickel, antimony, lead, chromium, copper, manganese, vanadium, and tin.

No limit value was set for chlorine. As a parameter with relevance to the process technology, chlorine is subjected, individually in each case, to specifications that depend on the incineration plant. There are also no guidance values for calorific value, moisture content, copper and ash content. However, all parameters must be documented within the scope of RAL quality assurance.

Due to the emission trading boundary conditions, the biomass content must also be determined. The Gütegemeinschaft Sekundärbrennstoffe und Recyclingholz e.V. adopted a test method to determine the biomass content in SRF from the work in CEN/TC 343, which has been approved by DEHSt (the German Emissions Trading Authority). This method is laid down in the quality and monitoring rules of RAL-GZ 727 [BGS, 2012a]. As previously mentioned, the portions of biogenic carbon in the SRF are decisive for the calculations of emission factors. The test report discloses the following parameters:

Total carbon TC [% DS]

Carbon of biogenic origin [% DS]

Carbon of fossil origin [% DS]

Percentage of biogenic carbon content related to total carbon content of the sample [%]

Percentage of fossil carbon content related to total carbon content of the sample [%]

3 Implementation of quality assurance

under RAL-GZ 724

In the area of SRF, the guidelines of BGS e. v. are an established means to achieve quality assurance. Previous sections have described individual measures and implementation – they are defined in the quality and monitoring rules and in the Sampling, Sample Treatment and Analysis Guidelines of BGS e.V. [BGS, 2012b]. The implementation of these measures through the system of internal and external control within the framework of RAL quality assurance will be explained in the following section.

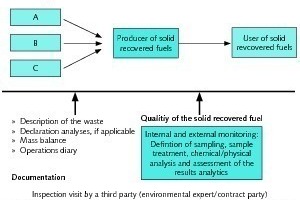

Figure 1 shows a concept for a comprehensive quality assurance system in an SRF production plant. The quality assurance system for SRF in a production plant needs to consider the operation and organization of the plant (personnel, plant technology, waste input, documentation), but also must ensure that the product quality is monitored.

Both internal and external control is required within the framework of RAL quality assurance. The plant operator usually takes charge of internal controls. In terms of the input, it is stipulated that waste must be documented with reference to the applicable waste code numbers; additionally a mass balance and declaration analysis must be prepared. For the purpose of internal control, samples are constantly taken from the output stream every 10 or 20 Mg (depending on the SRF volume produced). A monitoring interval is complete when 21 mixed samples are available, and when the test laboratory takes an additional three mixed samples on three different days. The sample mix obtained represents the throughput of the plant. For process control purposes all mixed samples are subjected to a short analysis. A short analysis comprises the following parameters:

Moisture: [weight-% OS]

Net calorific value (NCV): [MJ kg-1 DS]

Net calorific value (NCV): [MJ kg-1 OS]

Chlorine content: [weight-% DS]

Two relevant heavy metals.

The information gained from internal control measures help both the producer of SRF and the operator of the incineration plant control their respective processes. External control measures must be carried out by an independent expert and a test laboratory approved by the quality association. In the recognition procedure and subsequently once per year, the expert must carry out an on-site audit to verify the conditions for the manufacturer of SRF. The auditor must also subject the results of the internal control and those of the test laboratory to a plausibility check.

The mixed internal control samples are sent to the test laboratory, thereby becoming samples for external control. This closes the link between internal and external control, and continuity with respect to a large number of samples (at least 20 samples, see chapter 2.4) within the framework of the external control interval is accomplished.

The monitoring intervals for external control depend on the quantity of SRF manufactured. If a plant produces less than 30 000 Mg per year two monitoring points per year should be realised. 30 000 to 40 000 Mg/a mean three monitoring points, 40 000 to 60 000 Mg/a mean four monitoring points, and more than 60 000 Mg/a six monitoring points per year have to be realised.

During each monitoring interval, the test laboratory must analyse the samples from internal control in addition to three samples taken by the laboratory itself. It must send the results to the quality association within 20 days of receipt of the samples.

For the recognition procedure, continuous sampling of every 10 Mg is demanded, irrespective of throughput, so that the analysis net is denser during the approval phase of the manufacturer.

4 Conclusion

The production of high quality SRF for energy recovery in industrial plants such as cement works, power plants, and steel works is a part of this. SRF will be increasingly used and therefore also traded. This means that consistent quality standards and a reliable quality assurance are needed.

The RAL quality assurance is accepted in Germany and integrated in the administrative approval procedure. The quality and test instructions of RAL quality assurance are conform to the European Standardization by CEN/TC 343 [CEN, 2012] However, contrary to RAL quality assurance, there is no obligation to obtain certification and impose external controls. RAL quality assurance is a closed system because all the rules are interlinked and based on each other with the aim of achieving high fuel quality. The work of the BGS e. v. is based on the experiences of more than 15 years of quality assurance in the field of SRF. In principal, consistent methods of determination are necessary to obtain comparable results for SRF. In each the influence of sampling, sample preparation, but also grain size on the digestion and data interpretation must be taken into account.

All in all, the efficient production and utilization of SRF needs fixed boundary conditions. These general frameworks are guaranteed by quality assurance according to the RAL-GZ 724.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.