Large volume bulk storage

Manufacturers of building materials need to store large quantities of raw inputs and fuel. Limestone is the major raw material for cement manufacturing, while quarried materials such as clay and chalk provide the silicon, aluminum and iron oxides required in finished products. Coal is often the preferred fuel, and its efficiency depends on its moisture content and proper handling. All these are prone to affecting process efficiency and environmental compliance when not covered. Geometrica, a Texas based company with manufacturing facilities in Mexico, specializes in materials storage solutions for these sensitive stockpiles.

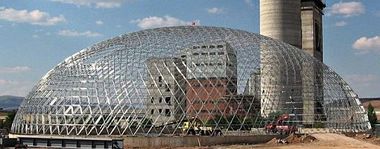

Until a few decades ago, it was not economical to cover the large circular piles of material used in automated stacking/reclaiming or preblending stockyards. Conventional buildings were too costly to build, despite that fact that uncovered raw material is potentially dangerous and can expose people, livestock and vegetation to hazards. Geometrica’s Freedome technology is an increasingly preferred solution, offering dome covers for stockpiles larger than several football fields arrayed together.

Below are examples of domes and barrel vaults that have been designed and constructed for cement...

Until a few decades ago, it was not economical to cover the large circular piles of material used in automated stacking/reclaiming or preblending stockyards. Conventional buildings were too costly to build, despite that fact that uncovered raw material is potentially dangerous and can expose people, livestock and vegetation to hazards. Geometrica’s Freedome technology is an increasingly preferred solution, offering dome covers for stockpiles larger than several football fields arrayed together.

Below are examples of domes and barrel vaults that have been designed and constructed for cement manufacturers around the globe.

Clay and limestone in Mexico

In the case of quarried materials, Freedomes are usually built in stockyards close to extraction processes. Geometrica designed two circular eco-friendly Freedomes for Cemosa in Apazapan/Mexico – one for clay storage structure spanning 61 m, and the other spanning 86 m over a limestone stockpile. The barrier-free interior allows the full use of space, while accommodating the free flow of traffic, personnel, equipment and raw materials handling.

Geometrica also constructed a 70 m coal dome and a 39 x 200 m clear-span space frame for bags and pallets at Cemosa’s Cerritos facility. The company has provided the construction industry with cement of the highest quality for more than 70 years. In 1978 they also began providing concrete, and now have 50 concrete plants and 370 mixing units nationwide.

Limestone in South Africa

Freedomes have been installed in 30 countries to date, including South Africa. Geometrica designed and installed “twin” limestone storage Freedomes for Lafarge Cement in Lichtenburg, each spanning 113 m. Lafarge manufactures and markets cement, readymix concrete, aggregate and gypsum products. Notably, Geometrica was recognized with a Safety Certificate by Lafarge Cement and Bateman for 50 000 man hours without lost-time incidents on the project.

Limestone, additives and coal in Tunisia

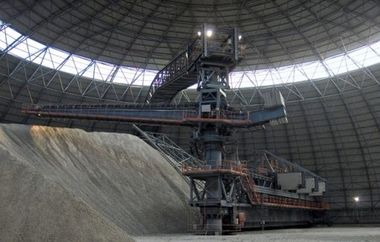

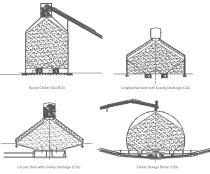

One common way to store large volume bulk materials is by stacking them in long, prismatic piles. The material is loaded with a side stacker, or with a tripper car from above. Reclaiming is done with a bridge or side scrapper reclaimer or with front end loaders. There is no better example than the domes of Carthage Cement in Tunisia.

Geometrica supplied three bulk handling structures for Carthage Cement’s Djebel Ressas cement works, Tunisia’s largest and newest cement facility. The additives and coal longitudinal buildings are 200 m and 300 m long, respectively, and similar in span (50 m). The limestone building is a 90 m circular dome.

The longitudinal domes were assembled in half-arch segments on the ground, then lifted into place and stitched into the growing structure. “This minimized the amount of time workers had to spend working at heights,” said Fernando Gracia, Geometrica’s lead designer for the project. “Oval hubs in the bottom chord of the domes’ ribs allowed us to use two rectangular bars in parallel, reducing the overall arch count, and increasing structural efficiency.”

Limestone in the United Arab Emirates

The United Arab Emirates is well known for its trend-setting construction sector, including cement production. In the Ras Al Khaimah (or RAK) cement producing region, Star Cement’s plant has a processing capacity of 7000 t/d of clinker.

One huge challenge was, literally and figuratively, the limestone stockpile. A week’s worth of limestone – the raw material for cement production – amounts to 34 000 t and has a diameter of 92 m. Star Cement’s civil and structural consultant, FLSmidth Designs Pvt Ltd, India, drafted a performance specification that included all dimensional and loading requirements for the stockpile cover. It was required to allow ample clearance for the stacker-reclaimer system, provide an opening for the incoming conveyor as well as four entrances for off-road vehicles, and include space for a traffic lane inside the dome around the ring rail of the reclaimer.

Crucial to the schedule was Geometrica’s ability to accommodate the installation of the stacker-reclaimer and the conveyor gallery concurrently with building the structure. Using Geometrica’s perimeter-up construction method, this was achieved without problems. Once the structure was complete, the second pour of the concrete edge beam was completed and the cladding installed. The cladding used for this structure consists of simple rectangular panels laid out in a 12-slice arrangement.

//www.geometrica.com" target="_blank" >www.geometrica.com:www.geometrica.com

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.