Reduced costs and increased safety: New fully automated storage system enhances cement plant operations

The new polysius storage system from thyssenkrupp is a fully automated solution designed for storing the bulk materials required in cement production lines in a healthy, safe and more efficient manner. Its successful operation demonstrates how industry-leading know-how can be deployed to deliver operational efficiency benefits to cement manufacturers while at the same time reducing the occupational health and safety risks to operating personnel.

1 Introduction

Cement is one of the most widely used substances worldwide. Factors such as increasing urbanization and industrialization as well as continuously rising global populations are further stimulating the growth of the market. Amid this, the need to address vital issues – such as sustainability, environmental protection and social responsibilities – is more and more challenging for conventional cement production technologies.

Ensuring healthy and safe working conditions for employees is of primary importance for cement manufacturers. This is not just due to stricter regulations but...

1 Introduction

Cement is one of the most widely used substances worldwide. Factors such as increasing urbanization and industrialization as well as continuously rising global populations are further stimulating the growth of the market. Amid this, the need to address vital issues – such as sustainability, environmental protection and social responsibilities – is more and more challenging for conventional cement production technologies.

Ensuring healthy and safe working conditions for employees is of primary importance for cement manufacturers. This is not just due to stricter regulations but also an economic necessity – a company’s human resources are its most valuable assets. thyssenkrupp has developed a fully automated storage system which not only reduces the occupational health and safety risks for the operating personnel but enhances the logistical efficiency of the bulk storage operations as well. The system has now been installed for the first time in a cement plant in Halimoru/Turkey.

2 Fully automated storage system

for the cement industry

Calling on its extensive know-how in the automation of machines and systems, thyssenkrupp Industrial Solutions tackled the challenge of finding the best possible automated storage solution for the cement industry – with particular consideration given to occupational health and safety requirements. As a company certified to OHSAS 18001, the international standard for assessing occupational health and safety management systems, thyssenkrupp was determined that the same high standards it applies internally should be reflected in this bulk storage system as well.

The outcome of thyssenkrupp’s research and development efforts can now be seen at a cement plant in Halimoru in Turkey. Here, the new polysius bulk storage system started operation in mid-2017. As one of the first-ever fully automated solution, it was a technical breakthrough.

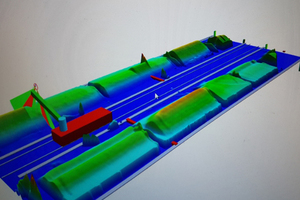

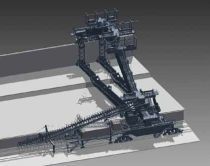

Correctives for raw meal grinding are stored on one side of the facility and additives for cement grinding on the other. A 180° slewing belt stacker installed in the middle runs up and down on rails to stack the additives and correctives into piles. Two portal scrapers, one on each outer side, reclaim the materials as required. For cement plant operators the fully automated, longitudinal storage system offers a number of operational benefits: more precise, efficient and above all health-friendly stockyard management in production plants.

3 Minimizing occupational health risks

Operator health is a key issue with conventional storage solutions for the bulk additives and correctives required for cement production. Every time the equipment that stacks the raw materials into piles has to be moved to a different pile, somebody has to enter the dust-filled storage facility to operate the machine. The same is true for the reclaimer, the machine used to remove the required quantity of the raw material for cement production. The dust levels in a conventional facility can be a health risk, and in many countries the relevant occupational health and safety regulations have become much stricter in recent years. Furthermore, conventional storage solutions have two drawbacks: they are relatively labor-intensive, which is a disadvantage in countries with high labor costs; and the equipment is often insufficiently reliable. The fully automated polysius storage system developed by thyssenkrupp ensures that operators no longer need to breathe in the dusty air inside the storage facility. In other words, this high-tech solution not only eliminates the health risk to operators, but also reduces labor costs as well as enhancing both reliability and efficiency.

4 Automation is safer and more precise

Tasks that are carried out automatically are naturally safer than manual operations. The new bulk storage system from thyssenkrupp enables four key tasks to be carried out automatically: moving the stacker from pile to pile; moving the reclaimer from pile to pile and precisely undertaking the first cut; avoiding any collisions between the stacker and the two reclaimers; and determining the respective pile volume. With conventional systems the first cut is always tricky to perform because after stacking, the pile surfaces are not at all even. But as the system software precisely knows the height and shape of each pile, it automatically directs the reclaimer to exactly the right position.

5 Smart software for safe operations

Designing an automated solution for bulk storage was only possible by means of a smart software solution. Intelligent software tools ensure safe operation of the equipment at the plant in Halimoru. Operation, handling and interaction between the machines are fully automated. One key factor for the success of this fully automatic operation was the development of an ACM (anti-collision module). By collecting and evaluating all necessary information on the position of the stacker and reclaimer, the ACM monitors internal and external collision safety independent of the technological processes and thus protects the machines in any operating mode. Communication between the stacker and the reclaimer takes place via a fixed ACM interface, which was specially developed to ensure safe and collision-free passing of the machines.

To this end, different situations have to be taken into account by the ACM. The task in developing the software was to ensure no collisions occur between the stacker and the reclaimer while including a solution and preference for crossing and passing. One particular challenge resulting from the parallel storage design was to protect the belt stacker on both sides during rotation and also to take the intermediate walls into account.

6 Design challenges

The Halimoru project presented the thyssenkrupp specialists with a number of significant challenges. Space was very limited in the longitudinal storage facility at this plant. With correctives stored on one side and additives on the other, 9-meter-high intermediate walls had to be installed to separate the various bulk materials and achieve the required storage capacities. That in turn resulted in unusually short stockpile lengths. In partitioned storage facilities the damp bulk material tends to stick to the walls. This makes it difficult to collect up all the material and reduces the amount of ‘live’ material that can be removed from the storage facility. For this reason, thyssenkrupp developed a special application for an integrated wall cleaning system. This feature, consisting of a specially designed reclaimer and a suitable software tool, ensures no ‘dead’ material sticks to the intermediate walls. As a result, the facility’s ‘live’ capacity is no less than its overall storage capacity.

7 More precise material management through

intelligent radar sensors

Another key aspect of this state-of-the-art storage solution is the intelligent radar sensor technology, which collects reliable data on the pile shape and positioning of the equipment. The polysius belt stacker is equipped with two radar sensors for 2-D scanning and one radar sensor ensuring its precise positioning. The stockpile management software then converts the data transmitted from this radar system into 3-D models of the piles. For the first cut after stacking of the material, it is indispensable to know the pile shape in case there are any unexpected material accumulations on the surface. To avoid any collision between these accumulations and the stacker, the software determines the optimized position for the first cut based on the 3-D module. Additionally, the 3-D module can be used to obtain the volumetric data of each pile after it has been scanned. This data enables an overview of the storage system and, at the same time, makes raw material management more precise.

8 Significant savings for cement manufacturers

The manpower savings achieved by using this fully automated system are a key factor in high-wage economies, for example. Another advantage is that by scanning and creating 3-D models of the stockpiles, the software also allows the volume of the piles to be determined with previously unattainable accuracy. This makes stockyard management more efficient. Being able to determine the volume of each pile is particularly useful because it provides an overview of the used and remaining quantities of additives and correctives, thus facilitating the forecasting of future demand. Last but not least, the compact design of this automated storage system saves space, which also helps to reduce bulk storage costs.

//www.thyssenkrupp-industrial-solutions.com" target="_blank" >www.thyssenkrupp-industrial-solutions.com:www.thyssenkrupp-industrial-solutions.com

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.