Raw materials homogenization in limited spaces

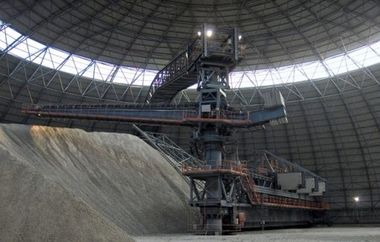

Nowadays with a growing demand for raw materials, their storage must be as environmentally friendly and without dust emissions and also with the smallest possible space requirement.

1 Introduction

Storage of great volumes of raw materials in limited spaces is an important requirement that becomes more relevant when existing plants have to be renovated. Bedeschi, a producer of a complete line of stackers and reclaimers that range from bucket wheel and scraper reclaimers for use with dry material, to bucket reclaimers that can be used with any type of raw materials, but especially with moist,...

Nowadays with a growing demand for raw materials, their storage must be as environmentally friendly and without dust emissions and also with the smallest possible space requirement.

1 Introduction

Storage of great volumes of raw materials in limited spaces is an important requirement that becomes more relevant when existing plants have to be renovated. Bedeschi, a producer of a complete line of stackers and reclaimers that range from bucket wheel and scraper reclaimers for use with dry material, to bucket reclaimers that can be used with any type of raw materials, but especially with moist, plastic and sticky ones, has developed a system named BEL C which is able to:

minimize the spaces used

provide high homogenization of materials in stock pile

claim every type of raw material especially when moist, plastic and sticky

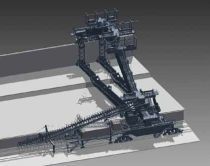

Figure 1 shows the components of the Bedeschi BEL C system.

2 The Bedeschi BEL C system

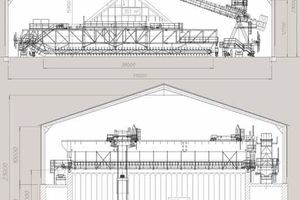

The BEL C system, based on the creation of rectangular section piles, is composed of an interconnected system with a tripper, two bridge stackers and one overhead bucket reclaimer, to provide a complete remote automatic material stacking and reclaiming process. The storage process foresees the making of two piles, one pile in stacking operation and the other one in reclaiming operation at the same time. The system has an automatic co-ordination of stacker and reclaimer to ensure safe operation without any risk of collision.

2.1 The BEL C stacking system

The stacking system is formed by a tripper and two stacking bridges (Fig. 2) running on the same reclaiming bridge rails. Installed on each stacking bridge are:

one retractable belt conveyor

one shuttle reversible belt conveyor

The tripper is motorized in order to be shifted and connected with each stacking bridge. The tripper feeds the retractable belt conveyor that feeds the shuttle reversible belt conveyor, creating the piles. Through the movement of the stacking bridge back and forth along the warehouse, the stacking cycle allows for the creation of small longitudinal chevron piles, parallel to each other.

The sequence of the storage process starts with stacking the material in longitudinal movements of the stacking bridge, followed by subsequently crosswise positioning movements of the shuttle belt to create the new pile parallel to the previous one. In this way the layer will be obtained all over the storage surface by repeating the above cycle. A series of layers, one on the top of the other will be obtained, until the pile is completely filled.

With this system, the total number of layers can easily reach 400 to 500 and even more, since the bridge stacking running speed can be adjusted up to 25 m/min.

Finally it is clear that the total number of layers can be chosen either by modifying the stacking travelling speed or modifying the pitch between the parallel layers.

A very important point for this type of piling is the fact the pile has always the constant rectangular section and consequently the layers number is always constant in any section. In this way a constant preblending factor for the whole pile is guaranteed, because there are no head or end of the pile influences, as occurs in the traditional piles with a triangular section.

2.2 BEL C reclaiming system

The reclaimer (Fig. 3) is composed of an overhead bridge, on which are installed a bucket reclaimer and a conveyor belt receiving material from buckets and feeding the longitudinal exit belt conveyor. The reclaiming cycle requires the trolley to which the bucket boom is fixed to move crosswise to the pile, so that the buckets reclaim material from the bottom up and discharge onto the transversal conveyor belt. At the end of the crosswise movement, the complete bridge draws back so that the buckets can penetrate the pile to feed the next run in the opposite direction.

It is, therefore, clear that with the stacking and frontal reclaiming system described above, it is possible to achieve a very high blending effect, comparable to or higher than the best frontal preblending bridge reclaimer, which obviously couldn’t work with sticky material and where the end pile effect drastically influences the homogenization.

2.3 BEL C with weigh feeder on board

Considering the high mixing degree obtained, it is possible to use this BEL C system in a more sophisticated way, for regular feeding of the downstream plant and of the raw material mill without installation of any intermediate buffer hopper. This option is particularly useful and sometimes quite necessary, in case of sticky materials that, if stored in an intermediate hopper, could cause huge cloggings problems.

When this option is selected the BEL C system can be implemented with the installation of a travelling weight feeder (Fig. 4) installed on the top of the longitudinal exit conveyor belt at the transversal conveyor belt discharge as well as with frequency converters for all motors (trolley translation, chain, belt conveyor, weight feeder).

Through interconnection between the electric cabinet on board the reclaimer, frequency converters and CCR, using all the variable speed motors, a regular reclaiming capacity is achieved. The layer of discharged material is regular and constant so that reclaimer works like a dosing unit and feeds the next mill without the need for an intermediate buffer hopper.

3 Comparison between longitudinal storage with

stacker and bridge reclaimer and the BEL C system

If we assume stocking of two piles of raw materials of 25,000 m³ each and we fix a pile section of 300 m², with a traditional luffing stacker and bridge reclaimer solution (Fig. 5a) we need to engage a ground surface of about 59 m (width) and 250 m (length). This area must be covered by a steel shed of the same size which results in 14,750 m² and a height of about 23 m.

If the BEL C solution is adopted with the same volume in stock and the same pile section, a surface of only 40 x 200 m will be needed, which means that the shed in this case will have only a surface of 8000 m², with a height of the steel structure of about 15 m (Fig. 5b).

Considering that the covering sheds including roofing and cladding can have a weight of about 60/70 kg per m², the traditional storage shed will weigh about 1050-1100 t, whereas the BEL C system shed weight will be only about 50 % of that (500-550 t).

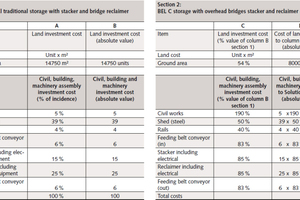

As seen for the investment costs, it is interesting to examine Table 1 and compare Section 1 with Section 2. We assume values included in Table 1 and relate them to the traditional system stacker/bridge reclaimer as an equal to 100 % of the investment.

In Section 2 the investment costs of the BEL C solution are compared to the traditional costs.

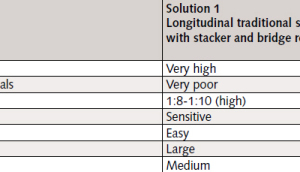

It’s quite clear by examining Table 1 in its sections that the BEL C solution, even if it requires more civil works, is economically more advantageous and presents additional important technological advantages, as summarized in Table 2.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.