Investigation of the influence of crystal morphology on the strength development of various a-hemihydrates by use of an in-situ ultrasonic technique and complementary methods

An efficient method to measure definite properties is the in-situ ultra-sonic wave measurement to characterize the hydration process of inorganic binding materials. A direct characterization of the chemical reactions taking place during the hydration process and the creation of the structure of the hydration product during the hydration is now possible because of the new interpretation technique of ultra-sonic results. In addition to the in-situ ultra-sonic wave measurements different other methods were used to verify the results of the ultra-sonic measurements.

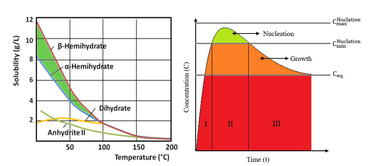

The hydration of calcium sulphate hemihydrate is a dynamic process composed of various chemical reaction steps that take place in parallel. These reaction steps influence the utility properties of the gypsum stone created by the hydration of hemihydrate. The determination of technically relevant properties of modern, inorganic materials, e.g., workability, initial set, hydration progress and mechanical properties, involves the use of various time-consuming, conventional methods requiring substantial human-resource inputs. One efficient method of obtaining information on many such parameters...

The hydration of calcium sulphate hemihydrate is a dynamic process composed of various chemical reaction steps that take place in parallel. These reaction steps influence the utility properties of the gypsum stone created by the hydration of hemihydrate. The determination of technically relevant properties of modern, inorganic materials, e.g., workability, initial set, hydration progress and mechanical properties, involves the use of various time-consuming, conventional methods requiring substantial human-resource inputs. One efficient method of obtaining information on many such parameters for the in-situ characterization of inorganic binding material hydration processes is the ultrasonic wave measurement technique, which serves as a sophisticated, state-of-the-art method of interpreting ultrasonic data. As such, it enables direct characterization both of the chemical reactions taking place during the hydration process and of the associated microstructural formation of the hydration product. In addition to in-situ ultrasonic wave measurement, the systems of interest were also investigated by means of scanning electron microscopy (SEM), in-situ optical microscopy (OM) and mechanical property determination. All this enabled interpretation of the ultrasound findings via independent reference methods and demonstrated that information on reaction kinetics, the progress of the setting process and the formation, growth and transformation of the hydration products can be derived from the results of ultrasonic measurement.

Conventional methods are only able to characterize a certain material property, while the in-situ ultrasonic technique constitutes a promising method for investigating several material properties at once. The aim of this work is to characterize the hydration of hemihydrate by way of ultrasonic wave measurement.

1 Introduction

As applied to hydrating systems, acoustic theory should be able to establish a relationship between such measured macroscopic acoustic properties as acoustic velocity, noise reduction, acoustic resistance, frequency and integral energy on the one hand, and the microscopic properties of heterogeneous systems (composition, structure, microstructure, etc.) on the other. Despite the efforts of numerous renowned scientists, there is still no theory available that could explain all of the above phenomena. The best-known theory for explaining particle size distribution is the ECAH theory (acronym indicating the names of its inventors: Epstein, Carhart, Allegra and Hawley) [1, 2].

Investigation of the hydration process by means of ultrasonic measuring technology has been the subject of numerous publications. Until now, however, there has been no satisfactory correlation between the specific values of UT parameters and the material properties. Also, the applied techniques of measurement and analysis were still inadequate for the targeted test purposes. Not all of the required, relevant ultrasonic characteristics were recorded and analysed. For example, the examined frequency range was not sufficiently broad, and the measurements either did not commence until well after the onset of hydration or were too insensitive to register changes in sound-wave propagation during the initial stages of hydration [3-16].

So far, the interpretation of ultrasonic results has been very superficial, and only a minor share of the abundant findings has been well understood. Phenomena registered in connection with ultrasonic findings that defied explanation were either simply ignored or went unmentioned. Also, the findings have been interpreted on the basis of unsuitable theories. The BIOT theory [18], for example, serves to explain the propagation of elastic waves in dilute systems and cannot be applied to hydrating binder systems due to their particular compositions and consistencies. Until now, no set theory has allowed the correct description of ultrasound propagation in hydrating materials or, accordingly, the interpretation of ultrasound test results.

2 Results and discussion

Hydration of the hemihydrate plaster is less complex than that of Portland cement. Consequently, plaster, as a system of calcium sulphate and water, makes a perfect reference system for investigating the phenomena observed in the results of ultrasonic wave measurements.

In this first part of the subject work, we investigated various engineered α-hemihydrates and their hydration processes by means of different analytical methods. The morphology of the thusly created dihydrate crystals was investigated using in-situ optical microscopy and scanning electron microscopy (SEM). The one-day strength values (flexural and compressive strength) of the gypsum were measured, as no substantial change in the strength of gypsum takes place within a single day. The hydration process and strength development were characterized by the in-situ ultrasonic wave measurement technique. By correlating the results of different employed methods, it was attempted to characterize the crystal morphology, strength development and packing density on the results of ultrasonic wave measurements. The results obtained for four different systems are discussed below.

In the results of UT conducted on α-hemihydrate (1), the energy and velocity levels are seen to be rising slowly after 10 minutes and steeply after 20 minutes. The absolute value of relative energy calculated from the squared amplitudes is situated at 0.4, and the maximum acoustic velocity amounts to approximately 3500 m/s. A narrow frequency spectrum of relatively low magnitude extending from 45 to 55 kHz was registered. While the crystal morphology, the formation and dissolution of intermediate phases and the evolution of the micro-and nanostructure proved detectable via changes in ultrasonic energy and in the frequency spectrum, the structural properties and strength evolution can be characterized as functions of ultrasonic wave velocity (Fig. 1 and 2).

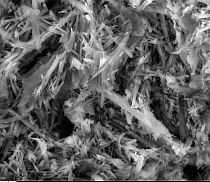

Figure 3 shows the results of optical microscopic examination of hemihydrates (1) after one minute of hydration (top right) and after 30 minutes (top left), 60 minutes (bottom right) and 240 minutes (bottom left). The in-situ microscopic investigations were performed using an elevated W/αHH value, which in preceding work was shown to have no major effect on crystal morphology (3). The first hydration products were detected after about 30 minutes. The α-hemihydrate forms branched, acicular crystals that influence both the microstructural genesis and the development of mechanical properties.

The UT findings for α-hemihydrate (2) show a sharp increase in ultrasonic wave energy after the first two minutes. By contrast, the velocity only began to rise after about four minutes, and to accelerate steeply after ten minutes. The absolute value of the relative energy computed from the square amplitudes came to 20, while the maximum acoustic velocity amounted to approx. 3200 m/s (Fig. 4). A broad spectrum of frequencies ranging from 20 to 70 kHz was registered, and the magnitude was relatively high (Fig. 5).

Figure 6 shows the light-optical micrographs plotted for different periods of hydration (1 minute at top right, 30 minutes at top left, 60 minutes at bottom right and 240 minutes at bottom left). The first hydration products appeared after 10 minutes. The α-hemihydrate was seen to form small, splintery crystals that determine the nature of the microstructure and of the mechanical properties.

In this case, the UT findings for α-hemihydrate (3) show that the energy begins to increase steeply after two minutes. The velocity starts to rise slowly after three minutes, not accelerating steeply until after about seven minutes. The absolute value of the relative energy computed from the squared amplitudes was situated at 20, and the maximum acoustic velocity was 3100 m/s (Fig. 7). The registered frequency spectrum was broad (15 to 75 kHz), and the magnitude was also relatively high (Fig. 8).

Figure 9 shows the in-situ light-optical micrographs obtained for hydration times of one minute (top left), 30 minutes (top right), 60 minutes (bottom left) and 240 minutes (bottom right). The first hydration products were detected after 10 minutes. The α-hemihydrate was seen to form splintery, somewhat branched crystals that influence formation of the microstructure and strength of the α-hemihydrate.

In this case, the UT findings for α-hemihydrate (4) show a slow gain in energy after 5 minutes and steep acceleration after about 25 minutes. The velocity began to increase sharply after 25 minutes. The absolute value of relative energy computed from the square amplitudes was situated at 0.1, and the maximum acoustic velocity came to approx. 3500 m/s (Fig. 10). A narrow frequency spectrum extending from 50 to 60 kHz was registered, and the magnitude was relatively low (Fig. 11).

Figure 12 shows the in-situ light-optical micrographs obtained after hydration times of 1 minute (top right), 30 minutes (top left), 60 minutes (bottom right) and 240 minutes (bottom left). The first hydration products were found after 10 minutes of hydration. The α-hemihydrate formed large, branched crystals.

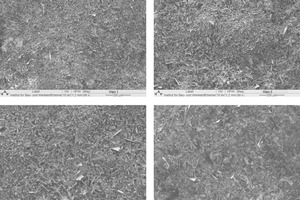

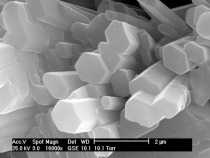

The results of SEM investigation of α-hemihydrate (1) (top right), α-hemihydrate (2) (top left), α-hemihydrate (3) (bottom right) and α-hemihydrate (4) (bottom left) are shown in Figure 13. The α-hemihydrates were seen to form a wide diversity of crystal morphologies with influence on the technical properties and strength formation of the plaster.

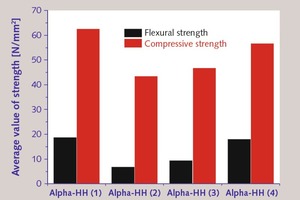

The results of flexural and compressive strength measurements are charted in Fig. 14. As shown, the strength increased quickly as a function of crystal branching and less steeply in dependence on how densely packed the microstructure was. These properties have effects on the results of ultrasonic examination.

The micrographs of α-hemihydrate specimen (1) reveal that the plaster formed long, multi-branched, acicular needles (Fig. 3 and 13). The needles matted together like felt, hence achieving high strength (Fig. 14). The packing density of the product, however, became looser as a result, as attested to by a number of acoustic parameters (energy and magnitude). Due to the low density of the plaster in combination with cavities caused by felting, the material exhibited high acoustic absorption, and the registered acoustic energy and intensity levels were accordingly low. The ultrasonic velocity, which is more dependent on mechanical properties than on recrystallization and microstructuration processes of the hydration products, reached its maximum at 3500 m/s (Fig. 1).

By way of comparison, α-hemihydrate (2) tended to form small, splintery, unbranched crystals (Fig. 6 and 13). While it did achieve high packing density, it exhibited little strength (Fig. 14), because the crystals were unable to matt together. This attenuated the acoustic signal. Consequently, the acoustic energy and intensity values registered for this plaster were higher because of the higher density. The ultrasonic velocity reached its maximum at 3200 m/s (Fig. 4).

The crystals of α-hemihydrate (3) were somewhat longer than the splinters of α-hemihydrate (2), and its crystals were somewhat larger (Fig. 9 and 13). They were, however, unbranched and therefore more apt to slide against each other. Consequently, their strength values were only marginally higher than those of α-hemihydrate (2) (Fig. 14). Their density was somewhat lower than that of α-hemihydrate (2), because their crystals were somewhat larger. As anticipated, the UT findings (acoustic energy and intensity) for this type of gypsum were somewhat lower than in the case of α-hemihydrate (2), but higher than those of α-hemihydrate (1). The ultrasonic velocity reached its maximum at 3100 m/s (Fig. 7).

The subject α-hemihydrate (4) displayed extensively branched, acicular crystals in addition to a number of very flat but large swallowtail crystals (Fig. 12 and 13). As expected, it exhibited high strength thanks to extensive ramification of the crystals (Fig. 14). Also as anticipated, its density, acoustic energy and acoustic intensity were lower. Its ultrasonic velocity peaked at 3500 m/s (Fig. 10).

3 Summary

Within the scope of this work, an in-situ ultrasonic measuring station based on a commercial-type ultrasonic measuring instrument was devised in conjunction with specially accommodated, advanced methods of interpretation. The subject interpretation technique for the measuring process in question is able to efficiently and leanly provide a data pool of information for the characterization of modern, inorganic, nonmetallic hydraulic building materials. The described procedure yielded information on attendant physicochemical processes and documented their correlation to kinetic parameters and to the physical properties of the thusly investigated systems.

In summary, the described ultrasonic technique provides a capacity for detecting time-dependent changes in process kinetics. Like data can also be collected according to other conventional methods. Conclusions regarding material strength as a function of packing density, crystal matting and crystal morphology can be drawn from changes observed in the UT signals. During the acoustic measurement process, the density of the material impacts sound attenuation and influences the degree of crystal matting in connection with strength measurements. The more closely matted (felted) the crystals, the more the subject plaster tends to display intercrystalline cavities. The resultant gain in damping capacity explains the relatively low levels of acoustic energy and acoustic intensity. Apparently, smaller, splintery crystals enable better compaction. This reduces the acoustic damping effect while amplifying the registered acoustic energy and amplitude levels.

The ultrasonic wave measurement technique is the only method with the capacity to provide information on the kinetics of the hydration reactions, the development of mechanical properties and the evolution of the microstructure from the beginning of the reaction to any arbitrary point in time.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

![1 Temporal change in ultrasonic energy and velocity of a-hemihydrate (1) [W/aHH-ratio: 0.33, Temperature: 23 °C]](https://www.zkg-online.info/imgs/tok_fb5032201bcd5fd22616eb1d6bb46780/w300_h200_x400_y308_101549230_4e7a5c3132.jpg)

![2 Temporal change in ultrasonic frequency of a‑hemihydrate (1) [W/aHH-ratio: 0.33, Temperature: 23°C]](https://www.zkg-online.info/imgs/tok_99a2a56504c824bf80c92cae1e796091/w300_h200_x400_y308_101549225_166152f723.jpg)

![3 Results of in-situ optical microscopy on hydration of a-hemihydrate (1) [W/aHH-ratio: 0.8, Temperature: 23°C]](https://www.zkg-online.info/imgs/tok_b88ae76a474d8555153a820e482a5cb6/w300_h200_x400_y319_101549215_5a9274436a.jpg)

![4 Temporal change in ultrasonic energy and velocity of a-hemihydrate (2) [W/aHH-ratio: 0.33, Temperature: 23°C]](https://www.zkg-online.info/imgs/tok_7d004005640214989a746383cb78109b/w300_h200_x400_y308_101549191_70b99a6a63.jpg)

![5 Temporal change in ultrasonic frequency of a‑hemihydrate (2) [W/aHH-ratio: 0.33, Temperature: 23°C]](https://www.zkg-online.info/imgs/tok_fc41ff8ba47c4c2ec916b1ec434b6230/w300_h200_x400_y308_101549219_ea0ff15e73.jpg)

![6 Results of in-situ optical microscopy of hydration of a-hemihydrate (2) [W/aHH-ratio: 0.8, Temperature: 23 C]](https://www.zkg-online.info/imgs/tok_7f1e78c7746a74541d65399dbe102db5/w300_h200_x400_y285_101549205_ddb076041f.jpg)

![7 Temporal change in ultrasonic energy and velocity of a-hemihydrate (3) [W/aHH-ratio: 0.33, Temperature: 23°C]](https://www.zkg-online.info/imgs/tok_19dae4ac497d7992a0021cdc8bbed9ed/w300_h200_x400_y308_101549187_f584d1ba60.jpg)

![8 Temporal change in ultrasonic frequency of a‑hemihydrate (3) [W/aHH-ratio: 0.33, Temperature: 23°C]](https://www.zkg-online.info/imgs/tok_14c01b3effc66bc4c16d1f093c0f39e7/w300_h200_x400_y308_101549226_73ec7b44ee.jpg)

![9 Results of in-situ optical microscopy on hydration of a-hemihydtrate (3) [W/aHH-ratio: 0.8, Temperature: 23 C]](https://www.zkg-online.info/imgs/tok_13022ba208025bded2385ee41b5ca7ba/w300_h200_x400_y319_101549188_8fe2f32d0f.jpg)

![10 Temporal change in ultrasonic energy and velocity of a-hemihydrate (4) [W/aHH-ratio: 0.33, Temperature: 23°C]](https://www.zkg-online.info/imgs/tok_6e5aaf1805a6faf112051e9e36d0f2ba/w300_h200_x400_y308_101549197_7b9b18851b.jpg)

![11 Temporal change in ultrasonic frequency of a‑hemihydrate (4) [W/aHH-ratio: 0.33, Temperature: 23 C]](https://www.zkg-online.info/imgs/tok_0834e4491325e9d5a00d25e38b3574f3/w300_h200_x400_y308_101549203_83335f6c48.jpg)

![12 Results of in-situ optical microscopy on hydration of a-Hemihydrate (4) [W/aHH-ratio: 0.8, Temperature: 23 C]](https://www.zkg-online.info/imgs/tok_e7b393e912a678be05317c948ed2e0e0/w300_h200_x400_y286_101549194_be8f3b6aca.jpg)