Innovative ThermoOptical Measuring

Devices (TOM) for high-temperature

testing of refractories

Refractories are the key for the development of new energy efficient thermal processes. Existing deficiencies in their high-temperature characterization are closed by a new generation of ThermoOptical Measuring devices (TOM). Using the new methods enables the characterization of thermochemical and thermophysical material behavior under defined conditions up to temperatures of 1800 °C. By that, new refractories and thermal processes can be developed more purposefully.

1 Challenges for new refractory products

A large proportion of all energy consumed in the manufacturing industry goes for heating processes: In 2016, some 1700 PJ (1 PJ = 1015 J) of process heat was expended in the Federal Republic of Germany. More than half of that total served for driving thermal processes involving temperatures beyond 1000 °C. That alone accounts for approx. 20 % of Germany’s total rate of end-use energy consumption [1]. Of course, numerous other heating processes are also involved, most notably in terms of power generation and private heating systems. If the climate...

1 Challenges for new refractory products

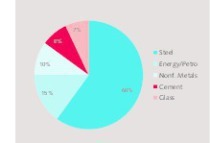

A large proportion of all energy consumed in the manufacturing industry goes for heating processes: In 2016, some 1700 PJ (1 PJ = 1015 J) of process heat was expended in the Federal Republic of Germany. More than half of that total served for driving thermal processes involving temperatures beyond 1000 °C. That alone accounts for approx. 20 % of Germany’s total rate of end-use energy consumption [1]. Of course, numerous other heating processes are also involved, most notably in terms of power generation and private heating systems. If the climate protection targets of the Paris Agreement are to be implemented in accordance with EU requirements, i.e., to reach a 40 % reduction in greenhouse gas emissions by 2030 compared with 1990, the energy efficiency of thermal processes will have to be drastically improved.

Refractories are making a significant contribution toward that goal. In the form of thermal insulation, they prevent the undesirable loss of process heat, and, as shaping and firing aids, they serve to separate and hold the material being heated. As kiln linings, refractory materials must display particularly low thermal conductivity, despite the need for good dimensional stability to prevent the occurrence of thermal leakage in long-term service. Shaping and firing auxiliaries, in turn, require both low heat capacity and low weight, because their cyclic heating consumes additional energy each time around. Moreover, refractory materials often need high resistance to thermal shock, corrosion and creep. Those properties prolong the service life of refractory products and, hence, contribute significantly to reducing the CO2 footprint of refractory materials. Since most refractories are produced in energy intensive thermal processes, the optimization of corresponding refractory manufacturing processes also makes a major contribution toward higher energy efficiency [2].

2 Criteria for high-temperature measuring

systems for refractory materials

The development of new, more energy efficient thermal processes requires more than merely refractories with improved properties. For the design of the corresponding thermal processing equipment, precise knowledge of the working properties of the employed refractory materials is also required.

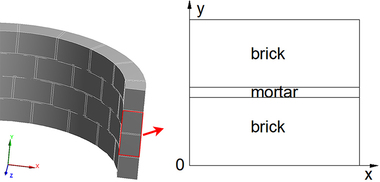

Increasingly, such design efforts are being based on computer simulations – e.g., by way of Finite-Element (FE) or Finite-Volume (FV) processes (Figure 2). Computer simulation relies on exact input variables representing the material properties of the subject refractories. In contrast to materials used at ambient temperature, many high-temperature properties of refractory materials still defy sufficiently accurate measurement. Conventional methods of thermal analysis tend to involve small measuring volumes [3]. Refractory materials, however, are very heterogeneous in structure (Figure 3) and therefore require large measuring volumes in the range of several 10 cm³ in order to obtain results that are sufficiently representative. Consequently, special standardized test methods are used for large-volume refractory samples. They allow direct comparison of different materials of identical geometry under identical test conditions. However, they do not yield the exact material properties required for computer simulation.

For example, thermal shock properties are measured by heating clay refractories to a defined temperature and then quenching them in a cold medium (water, gas flow) [4]. Their so-called thermal shock resistance is then derived from the observed decrease in strength or other parameters correlated with strength, e.g., ultrasonic velocity. The latter is well suited for the direct comparison of different clay refractories, but it does not enable the prediction of how such products can be expected to behave under field conditions involving completely different time-dependent temperature fields.

Another very important requirement is that the atmosphere in which the high-temperature properties of refractory materials are measured be properly controlled. This holds particularly true for the investigation of oxidation-sensitive materials such as molten metal or carbon-containing refractory material. For in-situ measurements conducted during heat treatment in the production of refractory materials, the practice-oriented kiln atmosphere must be faithfully reproduced under laboratory conditions [5].

3 ThermoOptical measuring devices (TOM)

ThermoOptical measuring devices - referred to by their acronym as TOM – have been under development since the 1990s [6].

Such devices are based on non-contacting – optical – dimension measurement methods. The specimens are placed in measuring furnaces set to a defined temperature and atmosphere. By means of a special shadow-imaging technique and a specially developed image-analysis software, very high measurement resolution and, in particular, excellent reproducibility can be achieved [7]. The measurement resolution for simple, one-dimensional variables such as specimen height or width presently stands at approx. 0.2 µm. The level of reproducibility determined in sintering tests, at 0.013 %, is apparently limited only by fluctuations in the green density of the subject specimens. Optical dimension measurement has been shown to be combinable with other contactless measuring techniques. For example, a specially developed laser flash measuring method can be used for measuring thermal diffusivity up to temperatures as high as approx. 2000 °C without contacting the specimen and without the otherwise necessary additional coatings [8]. The use of coatings or of any process that requires contact with thermocouples or some other material leads to artefacts in laser flash measurements – particularly at very high temperatures. With conventional laser flash methods, the measurement volume is severely limited, because evaluation of the measured data requires a one-dimensional flow of heat [9]. For TOM systems, the very small measurement volume could be significantly expanded by performing an inverse FE simulation of the temperature fields. Thus, the sample size of some 10 cm³ relevant for refractory materials was reached [10].

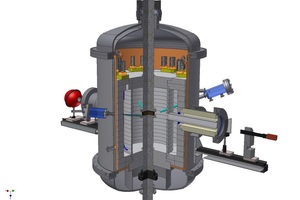

As an example, Figure 4 shows a TOM_ac ThermoOptical measurement system. The system includes a graphite-heated furnace with a maximum temperature of 2200 °C, in which inert and reducing atmospheres can be set up. The measurements are performed via an optical (telecentric) beam path and a thermal balance. If necessary, defined uniaxial forces can be applied to the sample of interest, and the resultant deformations recorded by means of optical dimension measurement. For example, in TOM_ac, wetting tests of metals against refractories can be carried out, and the pyrolysis, sintering and creep behavior of refractory materials can be investigated. The data yield serves as input for FE simulations serving to optimize process parameters [2]. Since it is not possible to realize all industrially relevant furnace atmospheres in a single furnace, four additional TOM plants have been devised for air, hydrogen and fuel gas atmospheres.

Within the scope of a comprehensive R&D project funded by the Bavarian Ministry of Economic Affairs, a new generation of thermo-optical measuring systems has been developed at the Fraunhofer Center HTL for measuring the material properties of large samples at high temperatures under defined atmospheric conditions. Entitled “Energy-efficient Thermal Processes“ (acronym EnerTHERM), the project aimed to improve the energy efficiency of industrial heat processes [11]. Launched in 2013, it was concluded in 2018. In addition to new high-temperature measurement methods, simulation methods were developed specifically for optimizing the process parameters in drying, debinding, sintering and infiltration processes [12]. Moreover, new refractory materials and composite ceramics were developed for high-temperature application (Figure 1).

3.1 The TOM_wave thermal load measuring system

Figure 5 shows the ThermoOptical measuring system TOM_wave, which was designed, built and implemented for high-temperature testing of thermo-mechanical material properties.

The system is designed for so-called hot thermal shock testing, since that can be carried out under much more closely defined conditions than an ordinary cold thermal shock test. Corresponding experiments have been published since the 1990s, first based on infrared heating [13] and later on laser irradiation [14]. So far, however, hot thermal shock testing has only been carried out with room temperature as the reference temperature, and does not reflect the typical loads to which refractory materials are exposed.

TOM_wave combines a high-temperature furnace with a 600-Watt CO2 laser, special optical beam paths and an automatic sample changer. This allows investigation of material behavior under variable thermal stress conditions. The beam path for the laser was designed to allow heating of the discoid samples from one or both sides. The diameter of the beam impinging on the sample can be altered between 2 mm and 20 mm, and the laser intensity can be ramped up between 0% and 100 % at short intervals. In addition, the laser can operate on a pulse mode and warm the samples by approx. 1000 K within just a few seconds. With irradiation on both sides, the thermal loads required for thermal-shock and thermal-cycling tests can be applied. One-sided irradiation of the samples enables both determination of their thermal diffusivity via two parameters aimed either at the back or edge of the samples and ascertainment of their natural frequencies by means of four microphones coupled onto the furnace by means of sound tubes. The thermal conductivity is calculated from the pyrometer signals by way of inverse simulation of heat propagation through the samples, using a 2½ D FE model and the aforementioned evaluation method. Interpretation of the natural vibration signals and their conversion into moduli of elasticity are also carried out using FE methods. The microphones allow time-delay filtration of the acoustic signals emitted by the sample. This is important for suppressing noise from the furnace or the surroundings. Since the noise to be identified as coming from the sample occupies a frequency range extending up to 40 kHz, the microphones must have high data acquisition rates. Accordingly, the acoustic emission measurements produce very large amounts of data. The requisite filtration is based on transit-time differences established by means of cross-correlation functions calculated in pairs for two microphones each. The data is processed by highly parallel processors.

TOM_wave also has an optical beam path for measuring thermal expansion coefficients, which are needed, inter alia, for calculating the thermal stresses that arise in the course of thermal shock tests. The moduli of elasticity and thermal diffusivity, all of which can be measured as functions of temperature on the same system, are also needed for the corresponding FE simulations. Initial experiments conducted on TOM_wave show good agreement between the measured and simulated thermal shock behavior findings [15]. Finally, an IR spectrometer is flanged onto TOM_wave for measuring the spectral emissivity of refractory materials up to very high temperatures. though spectral emissivity is an important parameter for use in calculating heat transfer in thermal processing plants, it is frequently not determined with sufficient accuracy.

3.2 The TOM_chem corrosion measuring system

The new ThermoOptical measuring system TOM_chem (Figure 6) serves for measuring the high-temperature corrosion behavior of materials under application-oriented atmospheres.

Thanks to TOM_chem’s extensively corrosion-, erosion- and heat-resistant inner lining made of nitride-bonded silicon carbide, sample material can be exposed to highly aggressive media over extended periods of time. The samples are placed in a controlled-velocity stream of hot gas, into which carefully dosed corrosive vapors can be introduced via an evaporator and abrasive dust particles via a particle injector. The latter is able to feed particles of dust ranging in size from 20 to 250 µm at mass flow rates between 0.1 g and 104 g per hour.

Weight changes taking place in the sample material are detected by means of a non-contact magnetic suspension balance with gas-tight decoupling of the sensitive weighing electronics from the recipient. The balance offers a weight resolution of 10 mg for a maximum sample weight of 50 g. During weighing, the flow of gas is automatically detoured away from the sample through a bypass line. The gas composition, volume flow and temperature are also monitored. The gas measurements are carried out by means of a measuring lance with a 3D-printed sensor tip of the type developed in the EnerTHERM project. A fan in the exhaust line serves to generate the volume flow, and a cyclone separator enables advance segregation of the particles to protect the fan against abrasion. TOM_chem can handle operating temperatures up to 1,450 °C and gas-flow velocities as high as approx. 20 m/s.

3.3 The TOM_mech mechanical high-temperature measuring system

Figure 7 shows the new TOM_mech ThermoOptical test bench for mechanical high-temperature testing that was developed within the scope of the EnerTherm project.

By coupling a high-temperature optical-axis furnace with a universal testing frame, TOM_mech enables investigation of the mechanical behavior of large specimens under different mechanical loads: bending, compression and tensile tests as well as tribological trials at temperatures up to 1750 °C. The maximum force of pressure is 150 kN, and the maximum torque 500 Nm. An integrated muffle and separate gas ducts leading to the heaters allow measurements under non-oxidic atmospheres. Special specimen mounts were designed for TOM_mech to enable load application via solid refractory push rods with simultaneous transfer of variable loads onto the specimens. The resultant deformations are measured by means of optical metrological devices situated in the hot zone of the furnace, so that, in contrast to conventional high-temperature testing systems, distortions due to temperature gradients in the push rods are excluded. The optical measurement of dimensions in connection with uniaxial compression tests has an additional advantage, i.e., the simultaneous detection of axial and transverse strain. Hence, both the uniaxial viscosity and the viscous Poisson’s ratio can be determined. Both of those parameters are required in FE simulations in order to calculate the high-temperature deformation behavior of components.

4 Conclusion

Within the scope of the EnerTHERM project, a new generation of ThermoOptical measuring techniques has been developed for establishing the high-temperature properties of refractory materials. The new methods offer the respective prerequisites in terms of adequate measuring volume, a defined atmosphere and defined temperatures. They establish and document the thermo-physical and thermo-mechanical material properties of relevance to the use of refractories: thermal-shock and thermal-cycling resistance, thermal diffusivity and conductivity, heat capacity, thermal expansion, emissivity, Young’s moduli, creep resistance, high-temperature strength and corrosion resistance. In particular, they were designed to provide input variables for FE simulations of high-temperature processes. All this serves to facilitate the more closely targeted design of new thermal processes and the selection of appropriate materials for them. Initial successful measurements performed on the new TOM systems underscore their potential for use in the development of energy efficient thermal processes.

//www.htl.fraunhofer.de" target="_blank" >www.htl.fraunhofer.de:www.htl.fraunhofer.de

First published in Prozesswärme 01|2019

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.