How refractory technologies can reduce costs and CO2 emissions

Cement production would be impossible without refractories. However, the potential for saving CO2 emissions through the selection of refractory material and design aligned to each kiln system is often underestimated. Optimal refractory solutions can extend operating times and prevent unscheduled kiln stops.

1 Introduction

Cement making was and is all about costs. Massive investments to set up production facilities and huge amounts of costs for energy, including expenses for CO2 emissions, have to be paid back by an economic product. Growing environmental concerns linked to climate change and the depletion of fossil fuel reserves put cement and lime producers additionally in a challenging situation. Besides the main targets of producing high-quality products at low production costs, they must deal with strict environmental regulations worldwide which usually require additional investments and...

1 Introduction

Cement making was and is all about costs. Massive investments to set up production facilities and huge amounts of costs for energy, including expenses for CO2 emissions, have to be paid back by an economic product. Growing environmental concerns linked to climate change and the depletion of fossil fuel reserves put cement and lime producers additionally in a challenging situation. Besides the main targets of producing high-quality products at low production costs, they must deal with strict environmental regulations worldwide which usually require additional investments and further expenses.

According to the International Energy Agency and the Cement Sustainability Initiative (CSI), the cement industry represents about 7 % of the carbon dioxide (CO2) emissions globally. The current technology roadmap of the CSI, called Low-Carbon Transition in the Cement Industry, was updated in 2018. Its vision is based on an energy system pathway and a CO2 emissions trajectory of limiting the average global temperature increase to 2° C by 2100 and reducing its direct CO2 emissions by 24 % below current levels by 2050 [1]. A significant reduction of CO2 can be achieved by reducing the clinker content in cement and substituting binding additives, e.g. composite cements, and deploying innovative technologies like carbon capture and storage (CCS). Further reduction can be achieved by improving energy efficiency and fuel switching to carbon neutral alternatives, for example biomass fuels [2].

Refratechnik Cement GmbH has been providing high quality products and innovative engineering solutions for its clients for many years. A special focus is set on the increased utilisation of alternative fuels and reduction of thermal energy losses in order to minimise the numbers of unplanned kiln shutdowns that thus reduces CO2 emissions in the cement and lime industries. The following article gives an overview of potential CO2-saving refractory solutions.

2 Current challenges

Cement kilns can be operated with up to 100% of waste or biomass fuels, but the utilisation of alternative fuels in rotary kilns is still progressing. While in some kilns 100% substitution rates have been achieved, in others local waste management and permitting conditions are not mature yet. However, the utilisation of alternative fuels involves certain technical and environmental restrictions, such as the calorific value and concentration of trace elements or chlorine in these wastes. It should be ensured that no detrimental change in the emission situation occurs and that the product quality does not suffer. Therefore, the utilisation of waste fuels requires the adaptation of the combustion process and refractory lining concept, as the burning behaviour can change significantly. It becomes more obvious that, although the quality of refractory materials is highly important, its lifetime also depends on the process conditions. Even the best quality refractory material might not meet the expected performance targets. Its design and quality must be aligned to process-related factors. The influencing factors of the conventional burning process on the refractory lining become more serious with the increase of substitution rates of waste fuels [3]. Consequently, the degradation of refractory materials appears at earlier stages due to the high concentration of alkali vapour, sulphur oxides, and other volatile components, as well as local temperature peaks and local reducing atmospheric conditions.

As alternative fuels are usually inhomogeneous in terms of their physical and chemical properties, such as calorific value, water content and particle size distribution, these materials may cause process instabilities [4]. Moreover, due to the retarded combustion of the alternative fuels, especially while using 3D fuels and fuels with coarse particle sizes at the main burner, the flame becomes “lazier” which leads to a decrease of the burning temperature in the sintering zone. The coarser particles are being pulled by the process fan and burn out later in the upper transition zone resulting in a shift of all reaction zones including the coating towards the kiln inlet and a temperature increase up to the cyclone stages.

A further serious issue of alternative fuel utilisation is the presence of the undesirable volatile components in the kiln system. The input of these components at high concentrations involves further operational issues, as these elements do not leave the kiln system via the flue gas and remain, creating circulation phenomena which promote cyclone blockages, build ups, and ring formation [5]. Most of the time, if poking efforts do not help during operation, the kiln must be stopped frequently in order to clean the cyclones. Moreover, high concentrations of sulphur components in the kiln system create corrosion issues and failures of anchors in monolithic blocks and castables due to the formation of sulfuric acid. Internal calculations indicate that an unplanned kiln stop for a reference plant with 3000 t/d clinker costs approximately € 600 000 for one day of maintenance. This amount includes fuel costs and costs for CO2 certificate fees for the heat-up period as well as the loss of production for one day. For the cooling down of the kiln system 36 hours and for the heating up 42 hours have been assumed. This calculation shows that a loss of production and additional fuel costs for unplanned kiln stops is much more expensive than the costs for aligned quality equipment including refractory products and designs that could prevent, or delay kiln stops.

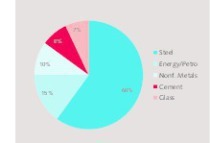

In order to overcome all aforementioned issues, the refractory lining concept for each kiln has to be adjusted to the actual burning conditions taking into account the environmental issues and production costs. The most CO2-producing sectors, fuel and electrical power, account for 42 % of the total costs of cement production (Figure 1).

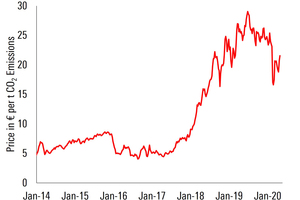

Refractories only account for about 2 % of total costs. However, if their lifetime decreases and more refractory material is required due to the use of alternative fuels, not only the costs but also the CO2 emissions per ton of clinker increase. Therefore, the selection of refractories can score twice in terms of CO2 savings. Fuel and thus CO2 can be saved through new technologies that e.g. reduce heat conduction and allow shorter heat-up periods. Since CO2 costs are expected to rise significantly further soon, these beneficial aspects become even more important (Figure 2). Further, higher quality refractory materials usually result in longer operating times and fewer unscheduled kiln stops. The cheapest refractory material is the one that lasts the longest.

3 CO2-reducing refractory technologies

The increasing use of alternative fuels can lead to a more intensive wear of the refractory lining which is why the potential to improve profitability and reduce CO2 emissions cannot be fully exploited. Higher concentrations and circulation of volatile components such as alkalis, sulphur, or chlorine in the kiln gas atmosphere have enormous effects on the lifetime of the refractory lining. Depending on the concentrations themselves and their ratio, corrosion and salt precipitates in basic refractory materials appear [7]. As a result, the structure as well as the mineralogical and physical properties of the products are impaired, and cracks and spalling can occur. Internal studies show that more than 60 % of all wear cases are due to effects generated using alternative fuels. To solve this problem, Refratechnik Cement has developed a series of basic bricks with cutting-edge concepts characterized by the AF-technology (Alternative Fuel). By modifying the structure’s decisive parameters, the mechanical and infiltration resistance is significantly increased. Due to the unique combination of high mechanical resistance and high elasticity that counteracts the loosening of the structure due to infiltrations, previously unattainable service times are now achieved, even under extreme conditions.

In non-basic refractories from the system Al2O3-SiO2 feldspars and feldspathoids form in the presence of excess of alkalis. This is accompanied by a significant volume increase which leads to a structural weakening and facilitates spalling at the brick’s hot face side. Refractory products with implemented AR concept (Alkali Resistant) show a higher resistance to chemical wear. Besides SiC, the addition of ZrO2 compounds significantly increases the resistance to alkalis by forming a protective layer on the hot face. Furthermore, Refratechnik Cement is working on less reactive but cost-efficient refractory concretes with a basic composition.

The adverse impact on the refractory material in the calciner due to the use of alternative fuels also strongly affects the calciner and cyclone steel structures. Volume expansion of the lining due to the reaction with alkalis raises the entire heat exchanger and endangers its stability (Figure 3). There is reason to assume that a great amount of damage to the calciner and cyclone constructions, which can also be attributed to alkali growth of the refractory material, remains unreported. If for example a cyclone stage is replaced then, costs for steel construction of a typical cyclone size on the German market of about € 300 000 to € 500 000 plus refractories and installation can quickly be incurred.

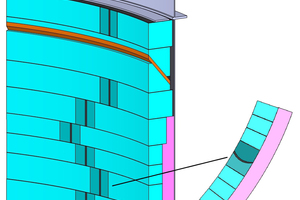

Leading engineering solutions to combat critical volume expansion of refractory materials in the preheater and calciner are the friction and radial compensators in combination with acidic Kronex® 20 bricks and Refraclay ® 25 concrete. In both materials, the proportion of acid components have been increased so far that during alkali attack only real feldspars with reduced volume increase compared to feldspathoids are formed. Although the alkali growth is strongly slowed down when using Kronex 20 and Refraclay 25, it cannot be completely prevented. In order to control the volume expansion of the refractories and to avoid an unexpected kiln shutdown, a constructional solution for measuring the expansion is necessary. The friction compensator transfers the vertical movement of the working layer caused by expansion into a horizontal movement towards the steel shell (Figure 4) [8]. The radial volume expansion is compensated by convex-concave shaped Kronex 20 bricks, the so-called radial compensator (Figure 5). With this concept of refractory design and product innovation for the first time predicative and preventive maintenance on linings in vertical parts of the plant during operation has been achieved. In addition, there is the possibility of external insulation of the calciner in order to keep the dew point of various alkaline compounds away from the steel shell and to reduce the heat radiation.

Solving the problem of alkali growth in refractories in the preheater and calciner is an example of how various departments and experts work together to optimize processes. Starting from discussions between producer and our sales department, solution alternatives are created. Behind every solution, there is a group of highly qualified and experienced professionals from the Research & Development (R&D) and Technical Engineering departments. With the friction and radial compensator, the maintenance can be planned in a detailed and optimised way and negative effects regarding alkali growth in the preheater are avoided.

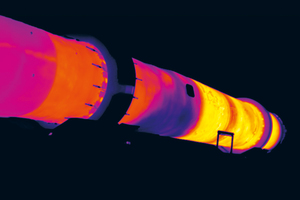

Apart from the use of alternative fuels there are further possibilities to reduce CO2 emissions. A reduction of waste heat losses and a higher energy efficiency of the fuels used are equally important (Figure 6) [9]. The ES series (Energy Saving) has become the key refractory technology to minimize heat losses through the lining and kiln shell. Because of a higher porosity but at the same time low permeability, these products show less thermal conductivity without compromising the properties necessary for a magnesia-spinel brick. This leads to lower shell temperature and reduces mechanical problems due to high temperatures in the tyre area. The experiences obtained with this product have shown a good thermomechanical and thermochemical resistance. The ES series is available for basic bricks (Almag® ES as an evolution of Almag® 85) and non-basic bricks (Refralusit® ES, an evolution of Refralusit® 63) to allow improved energy efficiency in wide areas of the rotary kiln in the cement and lime industry.

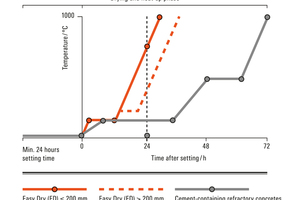

In addition to bricks of the AF and ES series, sophistically developed refractory concretes also contribute to higher energy efficiency. During the heating of a cement-bonded refractory concrete, water vapour is released from the cement hydrate phases, causing high pressure in the lining. Only by applying time consuming and technically defined heating-up procedures can vapour pressure be prevented from causing damage and risks to health and safety. To reduce these heat-up periods, two cement-free technologies were developed: ED (Easy Dry) and Nanobond.

While Nanobond requires two components, ED concretes are based on a single-component technology that does not require an additional binder, only water must be added during mixing. Due to this one-component technology, these materials can be stored for up to two years without the risk of losing their properties. They can be installed with any of the currently existing methods and in all static areas. Nevertheless, the most important advantage of these products is the reduction of heat-up periods by around 60 %, which leads to considerable savings in time and energy (Figure 7).

The story does not end with installation and use of refractories in the kiln system. The key to a successful use in the future lies in understanding the interplay of process conditions and installed material. Here, the post-mortem analysis is a powerful tool to analyse the wear influences on the lining and to make a connection between process and refractory condition. Experienced mineralogists use methods such as XRD, XRF, or optical and electron microscopy to investigate the condition of the refractory material. The causes of damage range from thermal or mechanical influences to chemical reactions caused by compounds of alternative fuels to a multi-parameter damage pattern. Knowing the cause of wear helps in the next step to find an optimal refractory solution for longer service times. Further information regarding process conditions and chemical influences can be obtained from clinker data analysis which is also informative with a focus on wear analysis.

4 Knowledge transfer and research activities

The key goal of the industry is to maintain knowledge over generations. Many of our experts have been working for Refratechnik Cement for over 30 years and got the chance to meet people from different generations. The Refra-Academy ® [10] combines a wide range of training opportunities for our industry professionals, from classic seminars via training units directly on site in the cement plant to colloquia with hundreds of participants. The annual Refra-Training International imparts theoretical and practical knowledge regarding the selection and correct installation of refractory materials and offers a unique platform to exchange with colleagues from around the world: Two weeks in a group of 40 people fully packed with know-how regarding refractories, installations, and latest trends. Every four years, Refratechnik Cement invites customers to its colloquium held in Berlin, where international speakers provide an overview of the global market situation, perspectives as well as innovations from the refractory and process engineering sectors. The Refra-Training on site concept enables a larger number of employees working in the cement and lime sector to receive targeted training in theory and practice directly at the customers’ plants (Figures 8 and 9). Knowledge of refractory materials and designs is always essential to find optimally aligned solutions for different process conditions.

In order to be able to offer optimal technical solutions also in the future, research is indispensable. Refratechnik Cements research activities are guided by the aim to tailor refractory products to the latest technologies of the cement and lime industry and at the same time to preserve the ecological balance. Important CO2 saving developments such as CCS or optimal thermal insulation of high temperature processes are just as much in the focus as the endeavour to continuously extend the refractories’ service life. In cooperation with universities and technical colleges the technology of tomorrow is supported.

Not completely new but still up to date is the oxyfuel burning technology, which is based on a combustion using oxygen instead of ambient air. Nitrogen is being removed to simplify gas separation for further utilization and sequestration of CO2. Since the flame temperature is rising with higher oxygen contents in the combustion air, flue gas must be recirculated to keep a constant oxygen level. As a result, the amounts of CO2 and volatile components, such as Cl- and SO3-, increase significantly with considerable effects on the clinker burning process and refractory lining. Together with the ECRA (European Cement Research Academy), Refratechnik Cement has conducted a study on the effects of oxyfuel combustion on the refractory lining [11]. It turned out that especially the non-basic lining shows increasing thermochemical reactions with the clinker material, which may require a shift towards a basic brick lining in the calcining zone.

Whether basic or non-basic, the replacement of refractories often comes unplanned. Refatechnik Cement’s new veneering concept allows an easy repair on worn out lining with refractory concretes. Research is still ongoing to evaluate the influence of different wear characteristics, such as infiltration of clinker melt and salts or mechanically shattered surfaces, on adhesion. However, field tests have shown promising results. The veneering concept is available for basic and non-basic refractories and suitable for static and rotary kiln areas. The biggest advantage: a faster restart of clinker production decreases the CO2 emission per ton of clinker.

Insulation has always been an effective means of reducing heat loss and therefore CO2. Producing carbon neutral insulation material from renewable resources makes it even greener. Prolite® insulation bricks, which are not fired but only dried below 200° C, are based on biogenic silica and withstand high operating temperatures. They can be used as insulation lining in heat exchangers of the cement industry, are easy to install and applicable to any geometry.

Together with experienced partners in the fields of refractories and materials science, such as TU Freiberg and IKTS Dresden, Refratechnik Cement worked on two BMBF (Bundesministerium für Bildung und Forschung) projects (IKOSEZ) [12]. Within these projects, solutions were found to improve wall structures in static aggregates of cement and lime plants with increased input of alternative fuels. Furthermore, austenitic steel anchors alloyed with cost-effective elements such as Si, Al, and N instead of Cr and Ni for enhanced alkaline corrosion resistance and with an optimized shape have been developed. The refractory concrete Refrazirkon Z AR was proven to stay almost volume-stable under alkaline loads. The combination of anchors and refractory concrete successfully reduces cracking, spalling, and breakage of anchors.

5 Conclusion

The use of alternative fuels is the core opportunity in the cement industry today. Not only because everyone is committed to reduce the CO2 footprint, energy, and therefore costs, but also to tackle the increasing emissions worldwide. Refractory materials and concepts can and should make their contribution to a less disruptive production and lower fuel consumption. As Refratechnik Cement, we provide refractory solutions for cement and lime plants in more than 120 countries worldwide and understand the daily challenges in these industries of staying competitive and meeting strict environmental regulations. Our goal is the optimization of refractory-relevant processes in the cement and lime industry through continuous development and in close cooperation with our customers and experts from science and research: today and tomorrow.

//www.refra.com" target="_blank" >www.refra.com:www.refra.com

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

![1 Cost breakdown in cement production [6]](https://www.zkg-online.info/imgs/1/5/9/1/5/9/0/tok_ba2b17ab51cd28e586a04848bb795165/w300_h200_x524_y274_Process_Refratechnik_Refractory_technologies_Figure_1_Cost-breakdown-fb321803e416f3a6.jpeg)

![4 Design and functionality of the friction compensator. During the expansion of the green coloured brick ring vertically upwards in the direction of the arrow, the orange coloured brick ring moves horizontally. The horizontal movement pushes out a metal pin (not visible) and the volume expansion inside becomes visible [8]](https://www.zkg-online.info/imgs/1/5/9/1/5/9/0/tok_5439fba8d439f718d0aa5f3cdacdd9c7/w300_h200_x600_y619_Process_Refratechnik_Refractory_technologies_Figure_4_Radial-Compensator-0ea4dacd84706b91.jpeg)