Influence of nano-TiO2 on rheological and fresh properties of fly ash-cement systems

The influence of nano-TiO2 (NT) on the rheological parameters, fluidity, and setting time of a fly ash (FA)-cement system is studied and the influence mechanisms are investigated by hydration heat, X-ray diffraction (XRD) and differential scanning calorimetry-thermogravimetry (DSC-TG). Results show that the addition of NT with high special surface area increases the plastic viscosity and yield stress, decreases the fluidity and shortens the setting time of cement paste, and that the extent of variation is related to the content of FA. In addition, incorporating NT, which has a heterogeneous nucleation effect, promotes the hydration and hardening of cement and accelerates the formation and precipitation of calcium hydroxide (CH) at an early stage. FA substituting the same quantity of cement is unfavorable to the generation of CH. However, the perfectly spherical structure and micro-aggregate filling effect of FA improve the rheological behavior of fresh paste and restrain the setting and hardening of cement.

1 Introduction

As a kind of regulating supplementary cementing material, fly ash (FA) is widely used in cementitious composites, because it can improve the workability and durability of cement-based materials, make full use of industrial waste, effectively save resources and energy, and reduce environmental pollution, all of which conforms to the developing direction of green building materials [1, 2].

There are four main functions of FA used in cementitious composites. First of all, because FA particles are almost perfectly spherical, they can fill the clearance between aggregate particles and...

1 Introduction

As a kind of regulating supplementary cementing material, fly ash (FA) is widely used in cementitious composites, because it can improve the workability and durability of cement-based materials, make full use of industrial waste, effectively save resources and energy, and reduce environmental pollution, all of which conforms to the developing direction of green building materials [1, 2].

There are four main functions of FA used in cementitious composites. First of all, because FA particles are almost perfectly spherical, they can fill the clearance between aggregate particles and form a lubrication layer, thus improving the workability of cement-based materials with no supplemental water [3]. Secondly, FA can play a physical dispersion role and make the distribution of cement particles more uniform. Especially when the water-binder ratio of concrete is low, FA can provide water, making the cement hydrate fuller [4]. Thirdly, the pozzolanic reaction between fly ash and calcium hydroxide crystals around the aggregate particles not only generates products with characteristics of gel, but also strengthens the weak interface transition zone, significantly improving the original properties of concrete [5-7]. In addition, FA can delay the hydration rate and reduce the temperature rise caused by hydration heat, both of which are advantageous in preventing the temperature-induced cracking of concrete [8-11]. Undesirably, the early hydration of FA develops slowly, which is unfavorable to the early properties of cement-based materials, and therefore restricts its application [12, 13].

Nano-material, which displays high surface activity, can provide nucleation sites for cement hydration at early ages, all of which helps improve the early properties of cementitious composites. By far, the application of nano-material in cement-based materials focuses primarily on nano-SiO2 (NS) with strong pozzolanic activity [14, 15]. It has also been proven that NS not only plays the role of a pore filler and provides nucleation sites to accelerate the early hydration of cement, but also modifies the microstructure and enhances the pozzolanic reaction of FA [15-17]. However, because of the relatively high pozzolanic activity of NS, the Ca/Si ratio of the coating around the FA particles is lower than that of the bulk C–S–H gel. It has been reported that C–S–H gel with a low Ca/Si ratio is less permeable, thus hindering later-stage hydration [10]. As a new kind of functional material, nano-TiO2 (NT) is widely used in the field of construction materials because of its multiple advantages in applications such as sewage disposal, air purification, antisepsis, anti-fog and self-cleaning, etc., but there have been few studies of the effects of NT on the inherent performance of hardened cement pastes. The effects of NT on the physical and hydrational characteristics of cement-based material have been systematically discussed by Chen et al. [18], who found that low NT dosage could improve the early hydration of cement. But unlike nano-SiO2, NTs are inert fine powder fillers with no pozzolanic activity that simply act as potential nucleation sites to promote cement hydration. Therefore, it can be deduced that NT as additives could promote early hydration without forming a compact hydration film with low Ca/Si ratio. Thanks to the rapid consumption of Ca(OH)2 and the secondary hydration of FA at late ages, the process would not be unduly hindered, hence simultaneously guaranteeing both the early and the late properties.

In this paper, the influence of NT on the rheological parameters, fluidity, and setting time of the fly ash-cement system is studied, and the influence mechanisms are investigated by hydration heat, X-ray diffraction (XRD) and differential scanning calorimetry-thermogravimetry (DSC-TG).

2 Experiment

2.1 Raw materials

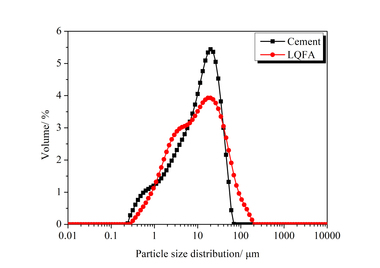

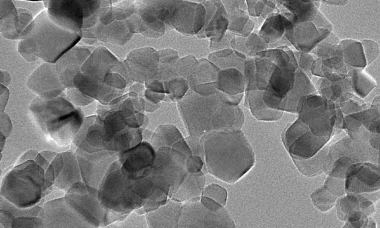

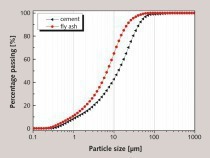

The employed sample of ordinary Portland cement (OPC) with a specific gravity of 3.1 was produced by Huaxin Cement Co., Ltd. The superfine fly (FA) ash stems from the Yangluo power plant. The white crystalline powder of nano titanium dioxide (NT) with a specific surface area of 50 m²/kg was obtained from the Degussa Chemical Co., Ltd. The chemical compositions and size distributions of OPC and FA are shown in Table 1 and Figure 1, respectively. XRD patterns of OPC, FA and NT are shown in Figure 2. A scanning electron microscope (SEM) image of FA is shown in Figure 3, where it is obvious that the FA particles are of a perfectly spherical shape. A transmission electron microscopic (TEM) image of NT is shown in Figure 4. 2651F-type polycarboxylate superplasticizer (PS) with solid content of 40 % was purchased from BASF China Ltd. The tap water accords with the level of mixing water in JGJ 63-2006 [19].

2.2 Mix proportion

and sample preparation

The mix proportions of the pastes are listed in Table 2.

Cement pastes were cast at a water-binder ratio of 0.5. The binding materials are constituted by OPC, NT and FA. NT replacement ratios of 0 %, 1 %, 2 % and 3 %, FA replacement ratios of 0 %, 10 %, 20 % and 3 %, by mass of binding material were used for all the tests. According to the mixing amount of FA, samples can be divided into four systems: F0Nx, F10Nx, F20Nx and F30Nx.

The dispersal uniformity of nanoparticles in aqueous solution is an important factor affecting the properties of nano-modified cementitious materials. Prior to mix preparation, NT was added to deionized water, stirred with a TZZT 78-1 magnetic stirrer at a stirring frequency of 600 r/min for 15 min, then dispersed in a PS40-type ultrasonic cleaner at a frequency of 40 kHz for 20 min, to obtain the uniform suspensions.

All specimens for XRD, TG-DSC were molded into a cube with a size of 40 x 40 x 40 mm using cement pastes. After curing to the test age at (20±1) °C and (90±5)% relative humidity, hydration of the pastes was stopped by submerging the center part of the crushed samples in acetone solution, after which the samples were oven-dried at 40 °C to constant weight and hand ground in an agate mortar so as to pass the 200 mesh size sieve. Finally, the powder samples were placed in a silica gel dehydrator.

2.3 Test procedure

The rheological behavior of the paste was tested with an R/S-SST2000 rheometer produced in Brookfield. The rotor rotation program is shown in Figure 5. During the viscosity test, shear action between the rheometer rotor and the paste generates a torque that translates into curves of shear stress and strain. The rheological parameters of the paste, namely, viscosity and yield stress, are obtained using the linear regression equation of the Bingham fluid mechanics equation yielding the stress-strain curve of the descending portions shown in Figure 6 and Equation (1):

τ = τ0+ μ0γ⇥(1)

Where τ is the shear stress, τ0 is the yield stress, μ0 is the apparent viscosity and γ is the shear rate.

The cement paste fluidity experiment was conducted according to GB/50448-2015 [20], and the setting time tests were carried out according to GB/T 1346-2011 [21].

The heat evolution of pastes was conducted by micro calorimeter C80 with a test temperature of 25 °C and a sample quantity of 0.5 g. The composition and chemical phase analyses were confirmed using a Bruker D8 Advance XRD device with a Cu kα X-ray source at 40 kV and 40 mA. During data collection, the step-length was 0.02°, the scanning rate was 2°/min, and the 2θ range was 5-70°. DSC-TG analysis was conducted using an STA449c/3/G apparatus at a heating rate of 15 °C/min from 50 °C to 900 °C in a nitrogen atmosphere.

3 Results and discussion

3.1 Rheological behavior

Figure 7 shows the influence of different dosages of NT on the viscosity and yield stress of fly ash cement paste.

It can be seen from Figure 7 that, for pastes without FA, the viscosity and yield stress increase along with the dosage of NT. For a paste with 3 % dosage of NT, the viscosity and yield stress increase by factors of 4 times and 2.6 times, respectively, compared to that of the control sample. In general, the changes in viscosity and yield stress are often caused by the varying degree of overlap between matrix materials and hydration products. NT, which has a huge surface area, can absorb abundant free water in mixtures, thus increasing the extent of cement particle overlap and, accordingly, also increasing the viscosity and yield stress.

In addition, the viscosity increases when fly ash is used to replace part of the cement, mainly because more free water is absorbed on the surface of FA particles due to the fact that the specific surface area of FA is larger than that of cement (see Figure 1). Studies show that the larger the specific surface area of the solid particles in paste is, the higher the viscosity will be [22, 23]. Moreover, when FA substitutes an equal amount of cement, the solid volume of the paste increases, because the density of the FA is smaller than that of the cement, which is also one of the factors leading to high viscosity. Research shows that increasing the solid volume will also increase the apparent density of the paste [24]. The decrease in yield stress caused by the addition of FA is due mainly to fact that the adhesive force between FA particles is far weaker than that prevailing between hydration products.

3.2 Fluidity

The effects of different dosages of NT and FA on the fluidity of fresh cement pastes are shown in Figure 8.

As the figure shows, the addition of NT significantly reduces the fluidity of fresh pastes. For pastes without FA, 1 %, 2 % and 3 % NT lower the fluidity by 17.7 %, 24.6 % and 28.4 %, respectively, which may be attributed to the increase in absorbed water caused by the huge special surface area of NT [25]. In addition, agglomeration occurs easily in the superfine particles with strong Van der Waals forces, thus reducing the fluidity of the fresh paste [25].

When FA is added, the weakening effect of NT on the fluidity of the fresh paste begins to decrease. In the F10Nx system, the addition of 1 %, 2 % and 3 % NT lowers the fluidity by 10.7 %, 19.1 % and 22.7 %, respectively. Similarly, in the F20Nx system, the addition of 1 %, 2 % and 3 % NT reduces the fluidity by 10.0 %, 16.3 % and 22.5 %, respectively, while in the F30Nx system, the addition of 1 %, 2 % and 3 % NT lowers the fluidity by 5.5 %, 14.8 % and 19.3 % respectively. The above results indicate that FA has an opposite, reversing effect on fluidity as compared to that of NT, and that the reverse effect is all the clearer, the higher the dosage of FA. This may be associated with the combination of surface role, filling role and lubricating role of FA particles. As Figure 1 shows, the average particle size of FA is smaller than that of cement, and the pores among larger cement particles can be filled by smaller FA particles, thereby avoiding direct contact between the angular cement grains [26, 27]. In addition, FA particles are virtually spherical (Figure 3) and have a lubricating effect on fresh paste. Thus, the negative effect of NT is offset by FA. The comprehensive effect of these FA factors is to reduce the fluidity of the fresh paste.

3.3 Setting time

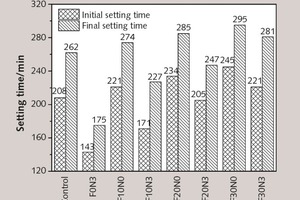

The influence of NT and FA on the setting time of fresh pastes in shown in Figure 9.

As Figure 9 shows, in the F0Nx system, the addition of NT obviously accelerates the initial and final setting, primarily because the high special surface area of NT would tend to increase the water absorption, and the rapid depletion of free water would promote the bridge connection of hydration products, thus making the viscosity increase significantly and solidification occur earlier.

When 10 %, 20 % and 30 % FA substitute equal amounts of cement, the reduction in setting time caused by NT decreases gradually. The more cement replaced by FA, the smaller the residual decrease. For example, in F0Nx, F10Nx, F20Nx and F30Nx systems, the addition of 3 % NT retards the initial setting by 31.3 %, 22.6 %, 12.4 % and 9.8 % respectively, and the final setting by 33.2 %, 17.2 %, 13.3 % and 4.7 % respectively. In addition, the setting time of paste with 20 % FA and 3 % NT is similar to that of pure paste.

3.4 Hydration heat

The influence of NT and FA on the cement hydration rate is shown in Figure 10.

As Figure 10 shows, for all samples, the peaks before 3 h are related to the hydration of C3A, and the peaks between 3 h and 20 h are related to the hydration of C3S. In addition, NT incorporation increases the exothermic peaks and accelerates their appearance time. For instance, in F0Nx, F10Nx, F20Nx and F30Nx systems, 3 % NT heightens the C3S peak values by 19.9 %, 8.2 %, 26.1 % and 20.4 %, respectively, compared to those without NT, and makes the peaks appear earlier by 157.2 min, 171.0 min, 181.8 min and 198.0 min. Prior studies suggest that inert or active ultrafine particles evidently can promote cement hydration, and that the primary role of the particles is to provide potential heterogeneous nucleation sites [28]. Accordingly, this indirectly explains the increase in plastic viscosity and yield stress, the decrease in fluidity and the shorter setting time caused by NT.

As Figure 10 also illustrates, FA has an adverse effect on hydration exothermic peaks compared with NT, namely, the addition of FA decreases the peak values and delays the appearance of the peaks. For samples without NT, 10 %, 20 %, and 30 % FA incorporation makes the peak value decrease by 4.5 %, 13.5 % and 15.5 % respectively, and delays its appearance by 22.8 min, 34.8 min and 79.8 min respectively. This is consistent with results reported in papers by Rahhal and Talero [29] and Nocuñ-Wczelik [30], according to which the hydration exothermic rate decreases along with FA because of its low pozzolanic activity.

The enhancement effect of NT and the obstruction effect of FA on cement hydration are also evidenced by their influence on the induction stage, which lasts about 2~3 h from the beginning of hydration, as shown in Figure 10. During this period, the addition of NT shortens the induction periods of all samples, indicating that NT can promote the hydration of cement. By way of contrast, for samples with FA only, the induction periods are prolonged with increasing FA content, hence implying that FA counteracts the early hydration of cement. Also, the induction period is associated with the setting time, the results of which are further verified by the content of Figure 10.

3.5 XRD and thermal analysis

of the hydrated cement pastes

XRD patterns and DSC-TG analyses of F0N0, F20N0 and F20N3 at 8 hours are shown in Figure 11.

It can be seen from XRD patterns that, at 8 hours, the calcium hydroxide (CH) diffraction peak of F20N0 is lower than that of F0N0. However, the CH peak of F20N3 increases notably compared to that of F20N0, and it is higher than that of F0N0. Similarly, DSC-TG curves show that the decalescence peak of F20N0 at 450 °C, which is related to the decomposition of CH, is lower than that of F0N0, while the F20N3 peak is the highest compared to that of F0N0 and F20N0. It can be seen from the above analysis that the result of XRD is consistent with that of DSC-TG, all of which demonstrates that FA is unfavorable for the crystallization of CH, while NT has a favorable impact on CH crystallization. This is mainly because the CaO content of FA is far lower than that of Portland cement, and accordingly, 20 % FA substituting the same quantity of cement would retard the generation of CH in the mixture. In addition, numerous network ions ([SiO4]4-, [AlO4]5-) in vitreous FA may help stabilize its microstructure, so the hydration activity of FA at early age remains relatively low. Some scholars have demonstrated that NT incorporation promotes the early hydration of cement and increases the amount of products of CH, which is mainly attributed to the huge specific surface area and the heterogeneous nucleation effect of NT [28, 31]. Portland cement coagulation mainly depends on the formation of a reticular structure in the paste and on more hydration products resulting from the addition of NT being more likely to overlap with each other and form a mesh structure. Hence, NT incorporation can make the fluidity deteriorate and shorten the setting time.

4 Conclusion

In this research, on the basis of the experimental results obtained, the main findings are as follows:

The addition of NT increases the plastic viscosity and yield stress and decreases the workability of fresh pastes. When FA replaces part of the cement, the plastic viscosity increases, while the yield stress decreases. FA can weaken the negative influence of NT on the workability of cement-based materials

NT can significantly shorten the setting time of the fly ash-cement system, but the accelerating effect decreases along with any increase in the replacement ratio of FA. The setting time of paste with 20 % FA and 3 % NT is similar to that of pure paste

The addition of 3 % NT can increase the hydration exothermic rate of cement and significantly shorten the duration of its induction period. However, FA has the opposite effect on both the hydration exothermic rate and the induction period

The addition of NT promotes the crystallization and precipitation of hydration products at early ages. The content of CaO decreases as FA substitutes the same quantity of cement. This is unfavorable for the generation of CH

5 Acknowledgement

The authors would like to acknowledge the 13th Five-Year Plan of National Key Research and Development (2016YFC0701003-05) and the Science and Technology Support Program of Hubei Province (2015BAA084) for supporting this research and providing the materials test.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.