Image-based analysis of multi-fuel burners in industrial combustion processes

Due to fluctuating properties, high proportions of alternative fuels are a major challenge for multi-fuel burners used in industrial combustion processes. This article presents a new, camera-based measurement system that allows the online extraction of parameters concerning the flight and, hence, combustion behavior of the fuel. Based on these parameters, the combustion process can be analyzed and optimized, thus ensuring consistent product quality despite high proportions of alternative fuels.

1 Introduction

In today’s world, the conservation of natural resources, e.g., fossil fuels, is of central importance. This topic is particularly significant in energy-intensive sectors such as industrial combustion processes, where it takes enormous amounts of fuel to provide the required thermal energy.

Increasingly in such processes, lignite and other fossil fuels are being substituted by so-called alternative fuels, including processed plastic waste and used tires. In cement clinker production, for example, many rotary kilns are now equipped with multi-fuel burners designed to combust...

1 Introduction

In today’s world, the conservation of natural resources, e.g., fossil fuels, is of central importance. This topic is particularly significant in energy-intensive sectors such as industrial combustion processes, where it takes enormous amounts of fuel to provide the required thermal energy.

Increasingly in such processes, lignite and other fossil fuels are being substituted by so-called alternative fuels, including processed plastic waste and used tires. In cement clinker production, for example, many rotary kilns are now equipped with multi-fuel burners designed to combust different types of alternative fuels in specific proportions to fossil fuels.

Figure 1 traces the time history of the alternative fuel fraction consumed by a typical multi-fuel burner under actual operating conditions for several days running at a cement plant. The observed fluctuations in the proportion of alternative fuel, ranging between 40 % and 90 %, show that steady operation with a high proportion of alternative fuel is unachievable. The fluctuations in question are due to the pronounced irregular properties of alternative fuels, e.g., their moisture content or particle size, depending on the quality purchased. These properties have a major influence on the flight behavior of the alternative fuel, which in turn affects the residence time of the fuel within the burner flame. Ultimately, they affect the conversion of the fuel and alter the energy input. Changes occurring in the properties of the alternative fuel cannot be detected online by means of currently available in-plant measurement systems, such as laboratory analysis of cement clinker specimens or via cameras operating in the visual and near-infrared spectral range. Consequently, when problems occur in connection with high proportions of alternative fuel, the only option a plant operator has is to switch to a larger proportion of fossil fuel that allows better control of the combustion process. Avoiding such situations, then, requires the introduction of new measurement methods that promptly provide the necessary information on parameters such as the flight behavior of the alternative fuel.

At the Karlsruhe Institute of Technology (KIT), Institute for Automation and Applied Informatics (IAI), a camera-based measurement system developed in cooperation with ci-tec GmbH now allows explicit evaluation of the flight behavior of alternative fuels. The process is based on a special-purpose infrared camera system and subsequent image analysis. This makes it possible to calculate flight-behavior parameters online [1,2].

2 Camera system

The employed camera system measures in the mid-infrared range (MIR) with a spectral filter at 10.6±0.1µm. The selected spectral range is marked by high transmission for combustion gases and soot, hence providing a nearly interference-free view through the flame to the unburned fuel.

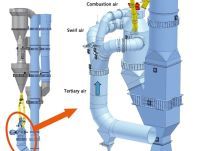

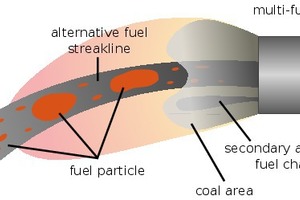

Compared to cameras operating in the visual or near-infrared spectral range, which only permit the body of the flame to be analyzed, this arrangement enables analysis of the flight behavior of individual fuel components. Figure 2 shows the installed attitude of such an MIR camera system on a cement rotary kiln. The camera’s water-cooled probe is introduced into the hot kiln atmosphere through the refractory lining at a lateral offset angle to the multi-fuel burner mounted at the end of the rotary kiln. Figure 3 shows an example of an MIR camera image taken under such conditions. The bright image areas corresponding to high grey values indicate high temperatures, while the darker areas mark regions of lower temperature. The lance of the multi-fuel burner can be seen at top right. The line of sight from the camera’s mounting position extends along the burner flame deeper into the rotary kiln. The dark area at the tip of the lance is unburned fuel. Close to the tip, the fuel still appears very dense and smoky. With increasing distance from the tip, it gradually breaks down into agglomerations and individual particles. The different manifestations depend on the types of fuel in use. The area near the tip of the burner contains mostly fossil fuel, usually in the form of pulverized coal with a characteristically short, dusty mode of combustion. With increasing distance from the burner tip, the alternative fuel becomes more conspicuous in its natural, particulate state. Figure 4 summarizes this situation as a schematic diagram. The use of an MIR camera assures the visibility of unburned fuel components, especially of the alternative fuel, hence providing a basis for the analysis and monitoring of fuel flight behavior.

3 Image analysis

The automated analysis of MIR camera images requires an appropriate image processing system [3] that, first of all, enables detection of the alternative fuel and which also provides substantive information about the flight behavior of the fuel.

The image processing procedures must be online-capable, comprehensible for the plant operator and, above all, robust. Robustness is a particularly important issue in difficult industrial environments. Especially in the production of cement clinker, various application-specific disturbances can occur. On the one hand, visibility can be negatively impacted by pronounced dust formation in the rotary kiln as well as by material adhering to the inside of the kiln wall. On the other hand, any kiln outage or maintenance performed on the multi-fuel burner can result in the position of the burner tip being altered, in turn causing previously defined image areas of interest to lose their validity. This newly developed form of image processing based on appropriate automated image preprocessing procedures takes due account of such disturb-ances. The system first checks the quality of each camera image obtained and sorts out any in which the fuel zone looks too dusty. Next, the position of the exit point of the alternative fuel is checked against the detected location of the burner tip. If any change is observed, the areas of interest are adjusted accordingly. Also, any adherent material found to be obscuring the fuel zone is ignored in the further course of analysis.

By way of various preprocessing steps, a nearly interference-free view of the alternative fuel is ensured, thus enabling robust fuel detection.

In connection with detection, it is important to keep in mind that different manifestations of the alternative fuel can appear in the camera. Near the tip of the burner lance, the fuel is still closely bundled, but the further it moves away from the tip, the more it fans out and allows individual particles of fuel and agglomerations to appear. Just when fanning begins is unknown and can vary as a function of the type of fuel in use. Consequently, image processing involves two approaches: detection of the bundled fuel fraction, and detection of the fuel particles. Depending on the observed occurrence, the two methods are automatically weighted together within the image analysis. The information gained regarding the location of the fuel can then be used to obtain, among other things, the streakline of the alternative fuel. Additional characteristics such as the throw distance and dispersion of the fuel can be derived from the streakline. Ultimately, these parameters serve to describe the flight behavior of the alternative fuel.

4 Evaluation

No alternative measurement methods are currently available for recording fuel flight behavior. That is why new reference data were created using two different approaches to evaluate the newly developed image processing methods. They are referenced to the streakline of the alternative fuel.

First, reference data were generated on the basis of human perception. Several experts evaluated various MIR camera sequences to determine, in their opinion, the most favorable streakline. The experts’ streakline situated in the middle of the individual sequences then served as a point of reference for the evaluation. In addition, the average deviation between the individual experts’ streaklines can also be used as a reference for comparison in the evaluation.

Also, a 3D simulation model (Figure 5) of a multi-fuel burner in a rotary kiln environment was generated in Blender. The streakline of the alternative fuel is freely selectable in the model taking account of the physical boundary conditions and therefore serves as a known factor for subsequent evaluation.

For both reference datasets, evaluation revealed that the streakline detected via automatic image analysis always shows only slight deviation from the reference streakline. In comparison with human perception, the deviation does not exceed the average expert deviation described above. With the aid of the MIR camera system and automatic image analysis, reliable, innovative description of the flight behavior of alternative fuel is enabled.

5 Implementation in an industrial measurement

system

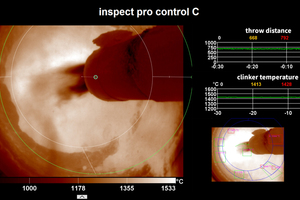

The newly developed processes were integrated into the existing inspect pro control system from ci-tec GmbH for use under real industrial process conditions at cement rotary kiln plants.

ci-tec GmbH engineered this thermal-process optimization system in close cooperation with the Karlsruhe Institute of Technology and is continuously refining it in constant contact with industrial partners and by virtue of accrued practical experience.

The inspect pro control system is used in diverse industrial combustion processes that are difficult to access for direct measurements by means of, e.g., thermocouples due to challenging in-kiln environments. With its combination of infrared camera and software for analysis and evaluation of the captured image data, inspect pro control offers a reliable, high-performance alternative: The determination of characteristic parameters for specific combustion processes from image data opens up a whole new range of options for process monitoring. In addition to modules for image acquisition and image (pre)processing, inspect pro control offers a number of other modules that can be connected up to the process control system to enable, for example, using the obtained characteristics for optimizing the control of combustion processes. The calculated parameters and the camera image can be visualized via a graphical user interface (Figure 6) and displayed in the control room. Also, various other modules are available for archiving the data and images.

Emanating from the aforementioned new developments in image processing, inspect pro control C is tailored for use in cement rotary kiln plants. Even in cases involving a high proportion of alternative fuels and for a wide variety of fuel fractions, it enables calculation of the required combustion parameters and, hence, determination of the requisite process control parameters. This makes it possible to monitor the combustion process online and to continuously optimize it in the interest of stable combustion and defined temperature profiles, thus maintaining high product quality despite widely fluctuating fuel quality. The parameters that inspect pro control C extracts from the infrared camera images for that purpose include, in particular, the throw distance and the clinker temperature.

The throw distance, which characterizes the flight behavior of the alternative fuel, is derived from the shape of the central streakline, which in turn is determined on the basis of the pre-processed images, as described above. The wider the throw distance, the longer the residence time of the alternative fuel within the burner flame, thus helping to improve its conversion. Continuous determination of this variable in the course of operation permits flexible reaction to any change in the composition of the fuel, for example by accordingly adjusting the pressure of the pneumo-deflector.

In order to determine the temperature of the clinker at the time of discharge into the cooler, the corresponding zone at the end of the rotary kiln is identified in the infrared images, and an averaged temperature is derived from the temperature data from that range. This approach is equivalent to monitoring the throw zone with a number of pyrometers or temperature sensors. The constant stream of information concerning the momentary clinker temperature allows, for example, continuous adjustment of the burner output to ensure that the process always yields high-quality clinker at minimized fuel consumption.

The inspect pro control C system from ci-tec GmbH has already found good acceptance in production plants operated by leading cement manufacturers. Initial insight into the substantive significance and utility value of the new image-based information has been drawn from operation of the measurement system under actual process conditions on a cement rotary kiln. The system is retrofittable on all conventional plants and enables significant savings on energy coupled with high product quality and extended plant longevity.

6 Results under authentic process conditions

Routine laboratory determination of the free lime content of cement clinker samples provides an essential parameter for real-time assessment of the combustion process in cement clinker production. The actual availability of such laboratory data is a major problem, since sampling only occurs at half-hour intervals, while subsequent evaluation takes between 30 and 45 minutes.

The camera-based measurement system presented here has the requisite potential for continuous online monitoring, in connection with which the temperature dependence of the free lime content in the clinker bed can be exploited. That temperature, in turn, is largely dependent on the energy input from the multi-fuel burner, any change in which is quantified by the freshly obtained, image-based parameters. This correlation is illustrated in Figure 7 by a diagram showing both the time history of temperature within the clinker bed and the throw distance of the fuel on several consecutive days at a cement rotary kiln plant. The clinker-bed temperature can also be treated as an output parameter derived from the MIR camera images. A wide throw distance means a high flight trajectory and, hence, longer residence time of the fuel within the burner flame, i.e., better conversion of the fuel and higher temperatures within the rotary kiln. The two processes therefore show high intercorrelation, and, commensurate with the aforementioned causality concept, it takes roughly 30 minutes for a change in throw distance to manifest itself in the temperature of the clinker bed. Thus, the newly obtained image-based parameters provide meaningful information on the current state of the combustion process and enable an approximately one-hour advanced prediction of the free lime content of the cement clinker material for purposes of laboratory measurement.

7 Conclusion and outlook

The subject measurement system comprising an MIR camera system feeding into an innovative image-analysis assembly gives plant operators the means to obtain up-to-the-minute information about the combustion process in general and the alternative fuel fraction in particular. Until now, that has not been feasible. This enables optimization of the combustion process, particularly when high proportions of alternative fuel are involved, and it ensures less fluctuation in the combustion process. In future, the extracted parameters can also be used for setting up an automatic control system for multi-fuel burners. Initial approaches make use of the data regarding fuel throw distance and clinker-bed temperature.

Acknowledgement

This research project was funded by KIC InnoEnergy within the scope of the COMFEB project.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

![3 MIR camera image of a multi-fuel burner in a rotary kiln environment [1]](https://www.zkg-online.info/imgs/1/4/6/9/6/6/8/tok_88bc1c10d4e0541c12c11eff5a412921/w300_h200_x600_y450_Bild3-e2dc98596776c538.jpeg)

![5 Example of a 3D simulation model of a multi-fuel burner in a rotary kiln environment in Blender [1]](https://www.zkg-online.info/imgs/1/4/6/9/6/6/8/tok_6c26889dbe8bfda6a90a92a12f741226/w300_h200_x384_y288_Bild5-69bf28001674efd5.jpeg)

![7 Comparison of clinker-bed temperature and throw distance of alternative fuel over several consecutive days of monitoring at a cement rotary kiln plant [4]](https://www.zkg-online.info/imgs/1/4/6/9/6/6/8/tok_b3f18d187dfc1f18ff09e256f113cead/w300_h200_x358_y249_Bild7-14aca0f62f0f336f.jpeg)