Effect of nano-SiO2 and curing temperature on the mechanical properties and hydration characteristics of cement systems containing a high volume of fly ash

In the search for an effective way of increasing the early strength of cement systems containing a high volume of fly ash (CHVFA), nano-silica (NS) was used in the CHVFA systems with two curing modes: standard curing (20 ± 2 °C, RH ≥ 95 %) for 3 days and steam curing (65 ± 2 °C, RH ≥ 95 %) for 12 h and then standard curing for 60 h. The effect of NS and curing temperature on the hydration of cement and fly ash and on the pore structure of the paste were studied in the search for the underlying mechanism.

1 Introduction

Chinese cement output has ranked first in the world continuously for 32 years, accounting for over half of the global total with 2,402,950,000 t in 2016 alone [1]. More and more attention has therefore been given to the application of supplementary cementitious materials (SCMs) that could partially replace cement. As a coal-fired country, coal is the main source of energy in China at present and will be for a fairly long period. Fly ash (FA) is the inevitable product of coal-fired power generation and every 4 t of coal consumption produces 1 t of FA. In 2015 alone it is estimated...

1 Introduction

Chinese cement output has ranked first in the world continuously for 32 years, accounting for over half of the global total with 2,402,950,000 t in 2016 alone [1]. More and more attention has therefore been given to the application of supplementary cementitious materials (SCMs) that could partially replace cement. As a coal-fired country, coal is the main source of energy in China at present and will be for a fairly long period. Fly ash (FA) is the inevitable product of coal-fired power generation and every 4 t of coal consumption produces 1 t of FA. In 2015 alone it is estimated that the FA output in China reached 620 million tons, the highest output in the world [2]. If such a large amount of solid waste is not utilized rationally it will not only represent a great waste of resources and pollute the environment but also take up a great deal of farmland and affect the sustainable development of the industry.

Using FA as SCMs in concrete engineering is one of the main ways of making highly efficient use of FA. This not only reduces the consumption of natural resources but also has advantages that other materials cannot replicate in meeting the requirements of green concrete. The advantages of FA can be summarized as follows: firstly, FA microspheres assist the advantageous distribution of cement particles and can clearly accelerate cement hydration and reduce the water/cement ratio for the same fluidity [3]. Secondly, the secondary hydration reaction of FA occurs mainly in the pores and consumes a great deal of CH, which reduces the pore volume of the cement matrix and substantially increases the compactness and durability of the cement-based materials [4]. Thirdly, any FA that does not take part in the pozzolanic reaction acts as micro-aggregate and fills the voids between the aggregate particles, thereby further improving the density of the concrete [5]. FA also can delay the rate of cement hydration, which lowers the rise in concrete temperature caused by the heat of hydration and avoids the generation of cracks [6-9].

However, a widely accepted disadvantage of cement systems containing a high volume of fly ash (CHVFA) is their poor early strength, so in some cases the use of fly ash is limited. High temperature steam curing is one common way of improving the early strength of CHVFA systems, which is largely because the high temperature curing not only obviously improves the rate of hydration of the cement but also enhances the activity of the fly ash to a remarkable extent and accelerates its secondary hydration reaction [10-13]. The addition of nano materials, including nano-SiO2 [14-16], nano-TiO2 [17], carbon nanofibres [18], etc., is another way of increasing the early strength of CHVFA systems. Nano-SiO2 has attracted significant attention during the research of its superior properties. It has been proved that nano-SiO2 not only possesses good pozzolanic reactivity and provides nucleation sites for hydration products in the early stages but also acts as a pore filler to modify the microstructure and interface transition zone (ITZ) to make the paste denser [14-16].

Single activation measures have limited influence on the early strength of CHVFA systems but composite activation measures have become an area for development in the field of activity stimulation. This paper investigates the influence of the binary system comprising nano-SiO2 and steam curing on the compressive strength of CHVFA systems in the early stages. The governing mechanisms were also studied and measured by XRD, MIP, DSC-TG and 29Si NMR.

2 Experimental

2.1 Materials

Portland cement (PC) CEM I 42.5 produced by Huarun Cement Co. Ltd was used in all the mixes. It has a density of 3 000 kg/m3 and a surface area of 345 m2/kg. Fly ash (FA) produced by the Yangluo power plant in Wuhan of China was used as SCMs in accordance with the Chinese standard GB1596-91 [17]. Nano silica (nano-SiO2, NS) with an average particle size of 15 nm produced by Aladdin Biological Technology Co. Ltd. was used. Polycarboxylate superplasticizer (PS) with a solid content of 40.0% was added to ensure the same fluidity level with the same water/cement ratio. The chemical compositions of the PC and FA are shown in Table 1.

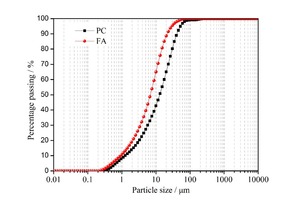

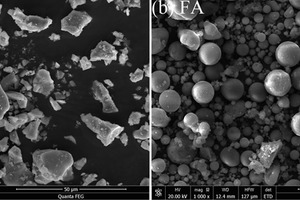

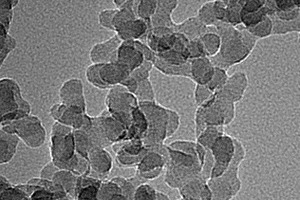

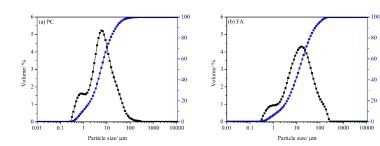

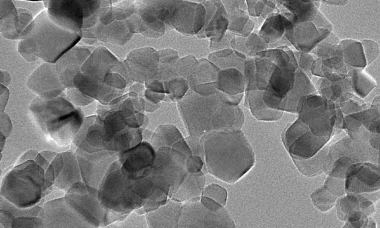

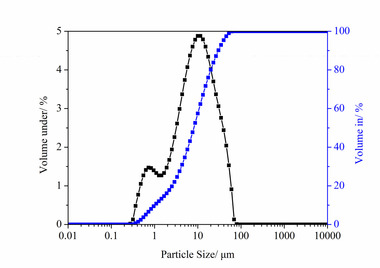

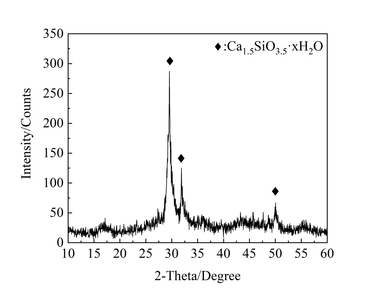

The particle size was tested with a Mastersizer 2000 laser particle size distribution instrument and the results are shown in Figure 1. The phase constitution and microstructure were studied with XRD, SEM and TEM respectively, as shown in Figure 2, Figure 3 and Figure 4. The XRD patterns indicate that the NS is an amorphous material and is relatively less crystalline than PC and FA. SEM images show that the FA particles have a perfectly spherical shape and the PC particles are somewhat irregular. The TEM image proves that the particle size of NS is about 15 nm.

Standard sand complying with GB/T14684-2011 [20] produced at Xia’men in China was used as the aggregate for the mortars. Deionized water was used for all the mixtures and experiments.

2.2 Mix proportions and sample preparation

The mix ratios of the pastes and mortars are shown in Table 2.

The mortars were moulded with a sand/binder ratio of 3 and a water/binder ratio of 0.5. The binders included PC, FA and NS. NS replacement ratios of 0 %, 1 %, 2 %, 3 % and 4 % by mass of PC and FA were used for investigating the mechanical properties, as shown in Table 2. Before the mix was prepared NS was added to the deionized water and dispersed by ultrasound at 325 W for 30 min to obtain uniform suspensions. The cement mortar samples were prepared in accordance with GB/T17671-1999 [21] in 40 mm x 40 mm x 160 mm prism moulds. Two curing modes were used in this study: standard curing (20 ± 2 °C, RH ≥ 95 %) and steam curing (65 ± 2°C, RH ≥ 95 %). Some samples were cured in the standard curing room for 3 days. Other samples with the same mix ratios were cured by rapid steam curing for 12 h and then transferred to the standard curing room for 60 h.

The paste specimens were moulded into 40 mm x 40 mm x 40 mm cubes. After steam curing the paste cubes were broken into small pieces, immersed in acetone solution to stop the hydration and then oven-dried at 60°C for 8 h. These small pieces were then ground to powder by hand, and the particles that passed the 200-mesh sieve were prepared for the XRD, TG-DSC, and NMR measurements. These small pieces were also prepared for the MIP and SEM measurements. In this paper the samples containing x% NS with standard curing for 3 days are labelled NSx-20 and the samples containing x% NS with steam curing for 12 h and then standard curing for 60 h are labelled NSx-65.

2.3 Test procedure

2.3.1 Mechanical properties

The compressive strengths of the mortars were measured in accordance with GB/T 17671-1999 [21] using a WYA-300 fully automatic test machine with a loading rate of (2400 ± 200) N/s. Six specimens of each mix were tested and the results from these six specimens were averaged In order to achieve reliable results.

2.3.2 Pore structure analysis

The pore structure of the cement paste was evaluated with a mercury intrusion porosimeter (MIP, Quantachrome AUTOSCAN–60). The measured pore apertures ranged from 7 nm to 200 μm. The highest pressure used during the measurements was 300 MPa and the contact angle was 140°.

2.3.3 XRD analysis

A Bruker D8 Advance XRD instrument with a Cu kα X-ray source at 35 kV and 30 mA was used to determine the phase compositions of the samples. During the data collection the step-length was 0.02° and the scanning rate was 8°/min over a 2-theta range from 7° to 70°.

2.3.4 DSC-TG analysis

A Netzsch STA449F3 simultaneous thermal analyzer was used for the analysis, which was carried out from 40 °C to 1000 °C at a heating rate of 10 °C/min in an atmosphere of nitrogen. The peak appearing at about 450 °C during the tests is caused by the decomposition of calcium hydroxide (CH) lime and the peak appearing at about 700 °C is caused by the thermal decomposition of CaCO3 [22, 23]. CaCO3 can be regarded here as the carbonization product of CH, so the CH content (i.e. CH (%)) can be calculated as follows:

⇥(1)

WLCH and WLCC:the weight loss in percentage attributable to the decomposition of CH and CaCO3 respectively

MWCH, MWH and MWC: the respective molecular weights of CH, H2O and CO2

2.3.5 29Si MAS-NMR analysis

The composition and structure of the Si-based substances were qualitatively analyzed by solid-state 29Si magic-angle spinning nuclear magnetic resonance (MAS-NMR, Bruker Avance III 400), with a magnetic field at 120 MHz and a rotation frequency of 6000 Hz. A 4 mm zirconia rotor with a working volume of 0.115 cm3 was used in all the tests. The samples were collected for 2000 scans, each consisting of a single pulse of width 5 μs followed by a relaxation time of 10 s. As shown in the previous study, six major peaks could be seen in the 29Si MAS-NMR spectra of the fly ash-cement system, namely Q0, Q1, Q2(Al), Q2, Q3 and Q4. The Q0, Q1, Q2, Q3 and Q4 peaks correspond to a silicon-oxygen (Si-O) tetrahedron connected to 0, 1, 2, 3 and 4 silicon-oxygen tetrahedra respectively, and the Q2(Al) peak represents two Si-O tetrahedron chain units connected to one aluminium-oxygen (Al-O) tetrahedron [24, 25]. The degree of hydration of cement (aPC) and FA (aFA) and the average chain length (ACL), representing the degree of polymerization of the C-S-H [24-27], can be calculated as follows:

⇥(2)

⇥ (3)

⇥ (4)

I0(Q0) and I(Q0): integrated intensities of the signal Q0 for the cement before and after hydration respectively

I(Q1), I(Q2) and I[Q2(Al)]: respective integrated intensities of the signals Q1, Q2 and Q2(Al)

I0(Q3) and I0(Q4): respective integrated intensities of the signals Q3 and Q4 for FA before hydration

I(Q3) and I(Q4): respective integrated intensities of the signals Q3 and Q4 for FA after hydration

For samples containing a small quantity of NS, the fraction of FA that has reacted (i.e. aFA), can be calculated as follows:

⇥(5)

I0(Q3) and I0(Q4): respective integrated intensities of the signals Q3 and Q4 before the hydration reaction

I(Q3) and I(Q4): respective integrated intensities of signals Q3 and Q4 after the hydration reaction

ωNS and ωFA: content of SiO2 in NS and FA respectively

m(FA/NS): mass ratio of FA to NS

3 Result and discussion

3.1 Compressive strength

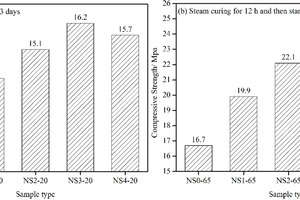

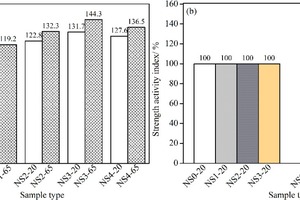

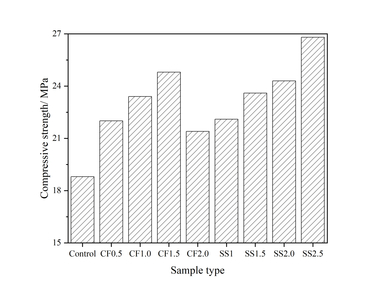

The compressive strength of CHVFA mortars containing different amounts of NS with different curing modes are shown in Figure 5.

As shown in Figure 5, the compressive strength of CHVFA mortars containing NS increases with the NS content up to 3 % (by wt.), and then decreases with any further increase in NS content (e.g. at 4 %). The greatest improvement is found in mortar containing 3 % NS, where improvements in compressive strength of 31.7 % and 44.3 % were observed with standard curing for 3 days and with steam curing for 12 h and then standard curing for 60 h respectively (Figure 6). It seems that 3 % is the optimum content of NS used in this study. The slightly lower compressive strength of mortar containing 4 % NS than that containing 3 % NS can be attributed to the agglomeration of NS. Moreover, for the same mix ratio, the compressive strength of CHVFA mortar with the combined curing modes is higher than that with standard curing alone, which is closely related to the promotional effect of high temperature on the hydration of cement and FA.

It is also noticeable that the advantages of NS occur more readily with steam curing. Figure 6 a shows that the addition of 1 % NS increases the strength of samples with steam curing for 12 h by 19.2 %, which is higher than the 11.5 % with 1 % NS for samples with standard curing. Similar results can also be found with the other samples containing 2 % NS and 3 % NS. This result shows that the promotional effect of NS on compressive strength is more marked at higher temperatures. Figure 6 b shows that steam curing also seems to play a more significant role in increasing the compressive strength in the presence of more NS – specifically, increasing the temperature from 20 to 65 °C causes the strengths of samples containing 0 %, 1 %, 2 %, 3 % NS to increase by 35.8 %, 43.2 %, 46.4 % and 48.8 %, respectively. All this clearly indicates that a cooperative effect exists between steam curing and NS and promotes the development of the compressive strength.

From what has been discussed above, it would be reasonable to assume that both the addition of NS and elevation of the curing temperature can increase the compressive strength of CHVFA mortars and that there may be a synergic effect between steam curing and NS. It has been shown that the compressive strength of cementitious composites is closely associated with their microstructure, such as pore structure, interface structure and hydration products. This will be discussed in more detail below.

3.2 Pore structure analysis

When the different effects of pore size on the performance of cementitious material were considered, the pores in concrete were classified as harmless pores (smaller than 20 nm), less-harmful pores (between 20 and 50 nm), harmful pores (between 50 and 200 nm) and more-harmful pores (larger than 200 nm) [30, 31]. In this study, the pore structure is characterized by MIP, as shown in Table 3.

It is obvious that, when compared to the samples NS0-20, there is a clear decline in porosity in the sequence: NS0-20 > NS3-20 > NS0-65 > NS3-65, due either to the addition of NS or the increasing curing temperature. Furthermore, it is clear that the addition of NS and increasing the curing temperature increases the quantity of harmless pores, mainly because NS and steam curing can promote the hydration reactions of cement clinker and enhance the activity of fly ash, thereby accelerating the secondary hydration reaction of CHVFA paste. This would produce more hydrated calcium silicate and hydrated calcium aluminium gel, causing a large increase in gel pores. Table 3 also shows that for samples with added NS, steam curing can increase the amount of harmful pores and more-harmful pores, and also the average pore diameter. The specific reasons for this can be summarized as follows: firstly, high temperatures can accelerate the migration of water within cement-based materials, causing large quantities of connecting holes; secondly, although increasing temperature would accelerate the hydration process of cementitious materials, the crystalline hydration products are usually bulky and unevenly distributed, which causes more pores to be formed. It can therefore be concluded that the addition of NS makes the pore structures shift from harmful, more-harmful and less-harmful ones to harmless ones. While increasing the curing temperature increases the less-harmful, harmful and more-harmful pores and decreases the harmless ones.

The changes of compressive strength can be explained to some extent by the variation in porosity and pore size distribution, but not completely. The widely accepted theory shows that a greater porosity and a greater quantity of large pores result in a lower strength. With respect to porosity, the strengths of the CHVFA mortars in a descending order would be: NS3-65 > NS0-65 > NS3-20 > NS0-20, which is consistent with the results in Figure 5 and Figure 6. Different conclusions would be drawn from the pore size distribution and average aperture. The reported differences in compressive strengths are the result of a complex function of multiple factors, such as hydration products, pore structure and microstructure, which will be discussed below.

3.3 XRD and DSC-TG analysis

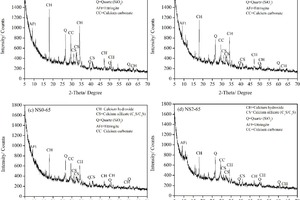

Figure 7 shows the XRD patterns obtained from cement pastes containing HVFA and combined HVFA and NS that were tested after three days curing.

Analysis indicates the predominance of portlandite (CH), calcium silicate (C2S/C3S), ettringite (AFt), calcium carbonate (CC) and quartz (Q), CH being formed in appreciable amounts in all the samples. As a product of cement hydration, CH reacts with the silica in the supplementary cementitious systems and forms C-S-H, resulting in improved mechanical properties of the mortars. In the XRD diagram the CH has a strong peak located at a 2-theta angle of 18.05. The CH peak is considered to be the main indicator of performance in cement paste samples.

The beneficial effect of adding NS to CHVFA pastes is also confirmed in the XRD analysis. From a comparison of Figure 7a with Figure 7 b it is clear that the addition of NS is accompanied by an obvious decrease in the intensity of the CH peak. This result may be attributed to the consumption of CH by pozzolanic reactions - not only the secondary hydration of NS but also the promotional effect of NS on the early hydration of FA. In another curing mode (i.e. steam curing at 65 °C for 12 h and then standard curing for 60 h) the effect of NS on the intensity of CH peak has a similar tendency, as shown in Figure 7 c and Figure 7 d.

Figure 7 a and c, and also Figure 7 b and d show that increasing the curing temperature could make a marked improvement in the hydration of CHVFA systems. More specifically, the intensity of the CH peak decreases significantly with rising temperature from 20 °C to 65 °C. As shown by previous studies, the higher temperature assists the hydration of cement and the reaction of FA.

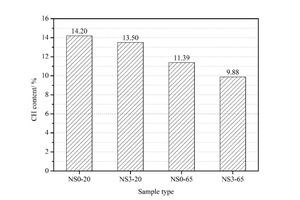

DSC-TG analysis was used to obtain a better idea of the variation in the amount of CH in the hydration products of different CHVFA pastes. The results are shown in Figure 8.

The loss in mass between 400 and 500 °C found in this study is thought to be caused by the dehydration of CH, and that between 500 and 750 °C by the decomposition of calcium carbonate. This means that the CH content can be calculated by Equation (1) and the results are illustrated in Figure 9.

As indicated by the bar graph, the sequence of CH content from high to low is as follows: NS0-20 > NS3-20 > NS0-65 > NS3-65, which is in agreement with the results of the XRD. Most interestingly, the addition of 3 % NS at 20 °C lowers the CH content by 0.7 % (from 14.20 % to 13.50 %) but when steam curing is used the addition of 3 % NS lowers the CH content by 1.51 % (from 11.39 % to 9.88 %), showing that NS promotes the pozzolanic reaction for consumption of CH more readily at the higher temperature. For samples without any NS the use of steam curing only decreases the CH content by 2.81 % (from 14.20 % to 11.39 %), while for samples containing 3 % NS the CH content is decreased by 3.62 % (from 13.50 % to 9.88 %) when steam curing is used, suggesting that steam curing can promote the pozzolanic reaction more effectively in the presence of NS. All this confirms the existence of a synergistic effect between curing temperature and NS on the pozzolanic reaction in CHVFA systems.

From the above results it can be seen that both increasing the curing temperature and the addition of NS can promote the hydration of CHVFA systems. What is particularly interesting is that NS has a greater effect on promoting the hydration of CHVFA at higher temperatures and steam curing plays a more positive role in promoting the hydration of CHVFA in the presence of NS. However, no direct experimental proof has been reported for the synergistic effect between curing temperature and NS in spite of some indirect evidence.

3.4 NMR analysis

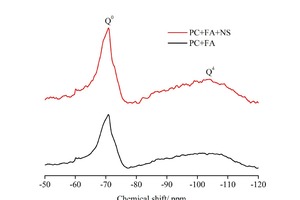

29Si MAS NMR was used to characterize the raw materials and hydrated pastes, as shown in Figure 10 and Figure 11 respectively, to provide a further illustration of the problems discussed in the preceding sections and find the direct proof mentioned above.

The 29Si NMR components were assigned in accordance with the previous studies [34-36]. The Q0, Q1, Q2(Al), Q2, Q3 and Q4 units correspond to the peaks at approximately -71, -78, -81, -84, -99 and -107, respectively. Figure 10 shows that two distinct peaks can be observed with both the PC+FA sample and the PC+FA+NS sample. The sharp peak is centred at -71 ppm and the gentle one presents a wide asymmetric signal centred at -107 ppm. Literature researches [34-37] indicate that Q3 and Q4, which represent the existence of Si-O tetrahedra in FA and NS, are difficult to distinguish because of the overlap of the peaks, while the Q0 peak indicating the existence of Si-O tetrahedra in cement is very easy to identify.

It is impossible to distinguish each peak in the 29Si NMR spectra in CHVFA pastes as shown in Figure 11 so computer analysis and peak-fit processing were carried out on the spectra shown in Figure 9. The integral intensity of the Qn (n=0~4) peaks is shown in Table 4. Based on these results, the key parameters of interest, including the degree of hydration of PC and FA and the average chain length of C-S-H gels, can be calculated from Equation (2), (3), (4) and (5) respectively. These are also shown in Table 4.

It can be seen from the above results that either the addition of NS or increasing the temperature can promote the hydration of cement and FA and increase the ACL of C-S-H, but the effect of increasing the curing temperature is more obvious. It should be noted that the addition of NS under standard curing conditions only increases the degree of hydration of cement and FA by 3.4 % and 1.0 % respectively but for samples with steam curing for 12 h and then standard curing for 60 h the addition of NS increases the degree of hydration of cement and FA by 9.1 % and 6.2 % respectively. It is clear that the promotional effect of NS on cement and fly ash hydration is more pronounced at the higher temperature. For samples containing NS the degree of hydration of cement and FA is increased by 19.5 % and 18.9 % respectively by using steam curing. This is higher than for the samples without NS (13.8 % and 13.7 %, respectively), indicating that increasing the curing temperature can promote the hydration of cement and FA more effectively in the presence of NS. All this provides direct evidence, based on the results of the mechanical properties and analysis of the hydration products, for determining the synergistic effect between NS and curing temperature on the acceleration of the hydration of cement and FA.

4 Conclusion

The following results can be concluded from this study:

Addition of NS and increasing the curing temperature can promote the hydration of cement and FA, decrease the porosity and the amount of CH in the hydration products and increase the degree of polymerization of the C-S-H gels, thereby improving the strength of the mortars.

High temperature accelerates the migration of water within cement-based materials and causes the crystalline hydration products to become larger and more unevenly distributed, so the quantity of harmful pores and more-harmful pores, and also the average pore diameter, are increased. However, the increased quantity of hydration products causes a large increase in gel pores, leading to a decrease in harmful pores. NS has much stronger effect on refining the pore structure due to the high activity of the pozzolanic reaction and the filling and nucleation effects. This means that more harmless pores are generated and there is a decrease in the quantity of less-harmful pores, harmful pores and more-harmful pores.

Clear synergistic effects have been identified between NS and temperature in CHVFA systems. Specifically, the advantages of NS occur more readily at higher temperatures and steam curing also seems to play a more significant role in increasing the compressive strength of CHVFA mortars in the presence of NS. Similar effects can be found in decreasing the amount of CH and increasing the degree of hydration of cement and FA.

Acknowledgment

The financial support from the Open Fund of the State Key Laboratory of Silicate Materials for Architecture (SYSJJ2018-14) (Wuhan University of Technology), the National key R&D program of China (2016YFC0701003-5) and the State Key Laboratory of Solid Waste Recycling and Energy Saving of Building Materials (SWR-2016-002) are gratefully acknowledged.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.