Chloride permeability of concrete applied with basalt fiber and nano-SiO2 modified mortar coatings

The influence of nano-SiO2 (NS) and basalt fiber (BF) modified cementitious coatings on chloride permeability in concrete and the influence mechanism explored by differential scanning calorimetry thermogravimetry (DSC-TG), X-ray diffraction (XRD), scanning electron microscopy (SEM) and mercury intrusion porosimetry (MIP) was studied. Results show that the chloride penetration resistance was significantly improved in the concrete applied with special mortar coating as compared to the non-coated variety, especially in concrete applied with 5 % NS and 0.5 % BF in a 6 mm modified mortar coating. Moreover, the mechanism analysis reveals that, all together, the heterogeneous nucleus effect, the high pozzolanic activity and micro-aggregate filling effect of NS, the inhibiting effect of BF on connected cracks and pores, and their grading advantage and synergy, improved the ability of concrete to counter chloride diffusion.

1 Introduction

Marine environment can seriously corrode and destroy the concrete structure. Chloride ion erosion, sulfate erosion, carbonation, microbiological corrosion, dry and wet alternation, and wave erosion and abrasion caused by storm are major causes of corrosion damage to marine concrete [1-3]. Among them, corrosion damage caused by chloride ions is especially prominent and seriously harmful to the safety and durability of marine engineering concrete [4-6]. Therefore, the investigation and modification research of the durability of concrete structures in marine environment are a...

1 Introduction

Marine environment can seriously corrode and destroy the concrete structure. Chloride ion erosion, sulfate erosion, carbonation, microbiological corrosion, dry and wet alternation, and wave erosion and abrasion caused by storm are major causes of corrosion damage to marine concrete [1-3]. Among them, corrosion damage caused by chloride ions is especially prominent and seriously harmful to the safety and durability of marine engineering concrete [4-6]. Therefore, the investigation and modification research of the durability of concrete structures in marine environment are a valuable and important endeavor.

Costa and Appleton’s [7] study of docks, bridges and other buildings in a Portuguese marine environment showed that the steel corrosion caused by chloride ion erosion is very serious, resulting in major damage to the concrete structure within a short service time. Via the investigation of 103 concrete seaports, the Ministry of Transport in Japan [8] found that every beam and column used for years displays considerable cracks along the rebar, all in need of repair. According to a survey of over 700 ordinary concrete structures along the British sea coast, Normand [9] discovered that the concrete durability damage is mainly related to the severe corrosion of reinforcement in the splash zone. In the past ten years, according to a survey of coastal buildings in China, all wharfs, culverts, brakes and seashore power plants exhibited damage caused by chloride erosion. Da et al. [10] surveyed the current durability status of concrete structures in port projects along the coast and found that, sometimes, it takes only 15~20 years for the concrete reinforcement to sustain corrosion damage. Therefore, domestic and international scholars do much to prevent the corrosion of reinforcement and, hence, maintain the durability of marine concrete structures by various means, including high performance concrete (HPC) [11], steel anticorrosion coatings [12, 13], electrochemical protection [14, 15], corrosion inhibitors [16, 17] and surface protection [18, 19]. However, the high brittleness, low ductility, high cost, high elastic modulus, cracking and spalling caused by alkali-aggregate reaction expansion and other constraints of HPC, limit its application [20]. The use of coated reinforcements will result in ineffective corrosion protection due to coating damage stemming from collisions in connection with transportation and working operations and to a gradual decrease in the binding force between steel and matrix [21, 22]. The cathodic protection method employing sacrificial anodes not only increases the construction costs, but also is inconvenient in construction and detection [23, 24]. The common corrosion inhibitor becomes increasingly restricted due to its disadvantages in terms of strict operating conditions, extensive use and toxicity to humans [25-27].

Concrete surface protection technology makes the concrete structure and external environment form a reliable physical and chemical isolation layer, hence preventing corrosion media such as excess water, chloride ions, carbon dioxide and dissolved oxygen from coming into contact with concrete [28] and extending the service life of concrete and reinforced concrete structures [29]. In addition, it can also serve as a specific part of maintenance systems to prolong the life even of concrete structures that are in seriously deteriorated condition [30]. Concrete surface protection technology is being applied more and more extensively because of its remarkable effects and high economic efficiency. So far, various surface coatings are being used to prevent chloride ions from penetrating into the internal part of concrete [31-33]. Most such coatings consist of organic materials including a volatile organic compound. However, such organic coatings could have the decisive drawback of causing air pollution both during their manufacturing process and when they are applied. Moreover, in a natural environment, the aging resistant performance of polymer coatings cannot meet the requirements of durability. Especially under conditions of dry-wet circulation and exposure to ultraviolet light, the cracking and peeling phenomena are much more likely to occur, thus severely reducing the protective effects and causing the coating to need continuous repair. This causes numerous practical difficulties in ocean engineering construction projects.

As research continues, more and more scientists are becoming dedicated to the use of superfine powders for cement-based materials, especially over the past decade. The pores of hardened cement pastes can be filled with fly ash microspheres, which could efficiently improve the stacking density and decrease the pore volume [34]. Silica fume, as a highly active pozzolanic material, can not only refine the pore diameter, but also react with CH to generate C-S-H, densify the matrix and optimize the interface transition zone (ITZ) between cement and aggregates [35]. Nanoparticles, which have a very good nucleation and filling effect due to their fine grain size, can obviously accelerate the hydration process and make the microstructure and ITZ of hardened pastes much denser, leading to a lower permeation coefficient [36]. Moreover, cement pastes mixed with nanosilica exhibiting high volcanic ash activity possess much higher durability, thanks mainly to an increased amount of high-stiffness C-S-H gels in the pastes, a fact that has been well proven [37-39]. To date, much work has been invested in superfine-particles-modified cementitious materials. However, a lack of definite results regarding the effect of nanomaterial modified cementitious coatings on concrete durability leads to the necessity of studying the performance measurement of surface protection materials. It can be concluded that a layer of compact surface mortar cannot only obviously reduce the chloride diffusivity of concrete, but also make up for the weakness of organic coatings. In addition, adding some fiber to cementitious material yields higher compactness while avoiding the increased brittleness caused by the addition of nanomaterial, thereby obtaining cementitious material with high strength, low brittleness and good durability [40].

This paper intends to study the resistance to chloride ion diffusion of concrete applied with basalt fiber and nano-SiO2 modified mortar coatings. X-ray diffraction (XRD), differential scanning calorimetry-thermogravimetry (DSC-TG), scanning electron microscopy (SEM), and mercury intrusion porosimetry (MIP) are used to conduct a preliminary exploration of the corrosion prevention mechanisms of NS- and BF-modified coatings.

2 Experiments

2.1 Raw materials

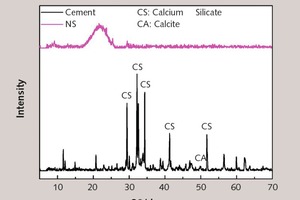

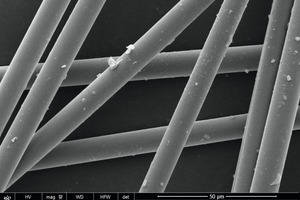

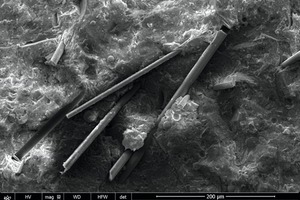

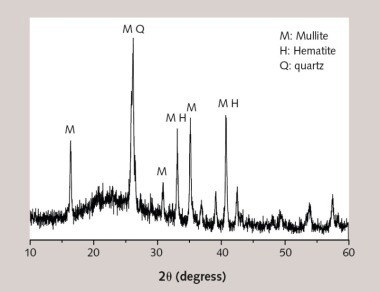

Ordinary Portland cement (OPC) CEM I 42.5 with a specific gravity of 3.13 and a surface area of 350 m²/kg, produced by Huaxin Cement Co., Ltd in China, was used. Nano-SiO2 (NS) with an average particle size of 20 nm and a special surface area of 130 m2/g was purchased from the Degussa Company. Chopped basalt fibers (BF) of 6 mm and 12 mm were selected in the experiments. These have an essentially circular cross-section and an equivalent diameter of 14 μm. The chemical composition of OPC is listed in Table 1. XRD spectrums of OPC and NS are shown in Figure 1. The dispersive X-ray diffraction peak of NS indicates that it is amorphous in structure. The surface morphology and performance parameter of BF are shown in Figure 2 and Table 2, respectively. It can be seen from the SEM image that BF has a relatively smooth surface.

Medium sand with a fineness modulus of 2.5 and a maximum size of 5 mm used in the concrete stems from the Xiangjiang River of Hunan Province in China, and the limestone rubble in the range of 5~25 mm used in the concrete was obtained from the China Construction Third Engineering Division Co., Ltd. The fine silica sand used in the mortar coatings has a fineness modulus of 1.5 and all of it was able to pass a 40 mesh size sieve. Liquefied SDS (sodium dodecyl sulfate)-type polycarboxylate superplasticizer with a solids content of 10 % was admixed to secure entrained air and reduce the specific volume of water.

2.2 Mix proportion and sample preparation

Concrete specimens used in the experiment reflect a uniform mixture ratio, i.e., the binder, water, sand and stone have a mass ratio of 1: 0.47: 2.28: 2.89. The binder includes fly ash (FA) and cement at a mass ratio of 0.29. The admixture accounting for 1.4 % of binders was used to control the slump loss. The detailed mixing ratio is shown in Table 2.

Cement mortars were mixed at a sand-binder ratio of 1.5 and a water-binder ratio of 0.35. Different dosages of NS (3 wt% and 5 wt% of binders) and BF (0.5 wt% and 1 wt% of binders) were added to the mixes. When NS and BF were mixed together, the content of NS was fixed at 5 wt% of binders. Liquefied SDS-type polycarboxylate superplasticizer was used to ensure that the different mortars had the same fluidity. Prior to mortar preparation, NS was added to deionized water, stirred and dispersed by an ultrasound device at 325 W for 30 min to obtain the uniform suspensions, whereas the BF and sand need to be mixed well. Their detailed mix proportions are listed in Table 3. For preparing SEM and MIP samples, small fragments obtained from the middle part of mortars at a certain age were placed in an acetone solution for 3 days and then dried at 80 °C for 8 h.

For the purposes of XRD and DSC-TG testing, the cement specimens were molded in steel molds with a size of 40 x 40 x 40 mm, and the proportions of cement pastes are also given in Table 3. After curing for 28 days, the hydration of the pastes was stopped by submerging the centre part of the crushed specimen in acetone solution, then drying them at 80 °C for 4 h in an oven and, finally, powdering them in an agate mortar so as to pass the 100 mesh size sieve.

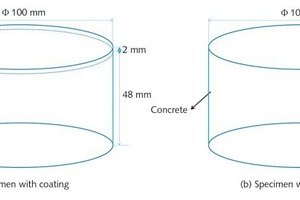

Regarding the rapid chloride migration (RCM) test, the control sample was made of pure concrete, Ø 100 x 50 mm. For the other samples, the concrete thickness was 48 mm, and the mortar coating was 2 mm, as shown in Figure 3.

2.3 Test procedure

2.3.1 RCM test

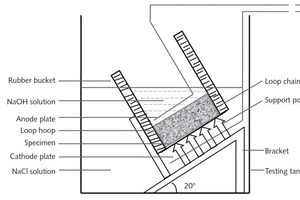

At present, the most commonly employed methods of evaluating concrete resistance to chloride ion permeability are the RCM and electric flux methods. The RCM method, because of its simple operation and short duration, has been widely used in the global scope. The test was carried out according to GB/T 50082-2009 “Standard for test methods of long-term performance and durability of ordinary concrete”, using the RCM method to determine the chloride ion penetration coefficient of the concrete. The instrument applied was an RCM-DAL chloride ion diffusion coefficient tester. The corresponding schematic is shown in Figure 4.

Before the RCM test, concrete under 28 days standard curing age was treated by water retention under vacuum for 24 hours. Then, the excess water on the surface was removed with a dishcloth. After that, the specimen was affixed to the testing tank with an anode bath of 0.3 mol/l NaOH solution (300 ml) and a cathode bath of 10 % (mass fraction) NaCl solution (12 l). During the experiments, the ambient and solution temperatures were held between 20 °C and 25 °C, and the voltage controlled at 30±0.2 V. The initial current was recorded, and the electrolytic time was determined according to Table 4. At the end of the trial period, the specimen was cut along the axial direction and the 0.1 mol/l AgNO3 solution sprayed onto the concrete surface as a color indicator. A clear dividing line appeared between the areas with and without chlorine. The area with chlorine was gray and white, while the area without chlorine was taupe. The time-dependent depth of infiltration can be measured based on the dividing line position, and the chloride ion diffusion coefficient (DRCM) can be calculated using the following formula [41-43]:

DRCM = 2.872 x 10-6 Th (Xd-α√ Xd)⇥(1)

t

α = 3.338 x 10-3√Th⇥(2)

Where T is the average values of initial and final temperatures of the anode solution, h is the height of the specimen, Xd is the chloride diffusion depth, t is the electrolytic time and α is the instrumental variable.

2.3.2 Characterization methods

The phase composition of the sample was analyzed by XRD with a Cu kα X-ray source at 40 kV and 40 mA, and the data were collected with a step-length of 0.02 °. The scanning rate of 2 °/min and 2θ ranged from 5 ° to 70 °.

The paste sample was thermally analyzed by DSC-TG at a heating rate of 15 °C/min from 20 °C to 800 °C in a nitrogen atmosphere.

The morphology of the hardened cement mortars was determined by SEM with 10 mm working distance in low vacuum mode.

The pore structure of the cement mortars was characterized by mercury intrusion porosimetry (MIP) with a measurable aperture range of 3 nm to 360 μm, a maximum pressure of 300 MPa and a contact angle of 130 °.

3 Result and discussion

3.1 Effects of NS modified mortar coating on the resistance to chloride ion permeability of concrete

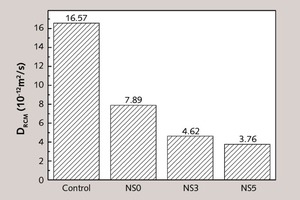

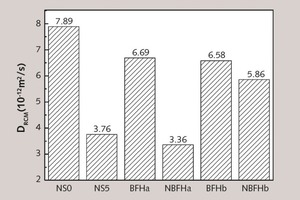

According to the parameters of average chloride ion penetration depth and electrolytic time, the chloride ion diffusion coefficient of the sample can be calculated by formulae (1) and (2). The DRCM results of concrete with and without NS modified mortar coatings are shown in Figure 5.

It can be seen that DRCM of the sample without coating was 16.57 x 10-12 m²/s, which was the highest of all samples. While the covered protective coatings markedly decreased the DRCM of concrete – specifically, the DRCM of samples NS0, NS3 and NS5 were 7.89 x 10-12 m²/s, 4.62 x 10-12 m²/s and 3.76 x 10-12 m²/s, respectively, thus being 52.4 %, 72.1 % and 77.3 % lower than that of the control sample. Obviously, the concrete with coatings applied had much stronger chloride penetration resistance than that of the control sample, mainly because the compactness of the coatings with a fairly low water binder ratio exceeded that of the concrete. As for the enhancement function of NS modified coatings on the resistance to chlorine ion corrosion of concrete, the influence mechanism is analyzed and discussed by XRD, SEM, DSC-TG and theoretical analysis.

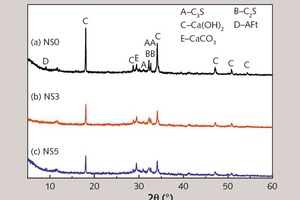

The influence of an NS modified cementitious coating on the resistance to chloride ion permeability of concrete can be explained by the altered microstructure and hydration outcome composition of the coating. XRD patterns of NS modified cement pastes at 28 days are shown in Figure 6.

It is easy to see that the diffraction peak intensity of CH decreased distinctly with the addition of NS, and that of C3 S and C2 S showed a similar tendency. Actually, this was closely associated with the pozzolanic reactivity and heterogeneous nuclei effect of NS. More specifically, the nanomaterials provided many heterogeneous nucleation sites to accelerate the pace of cement hydration to some extent, and the high pozzolanic reactivity of NS promoted the secondary hydration reaction so that much CH was consumed, while, correspondingly, the amount of C-S-H increased, all of which accelerated the depletion of clinker and cut the level of C3 S and C2 S. The greater amount of hydration products made the paste become denser, effectively preventing chloride penetration and improving the concrete’s resistance to chloride ion permeability, this being consistent with the result shown in Figure 5.

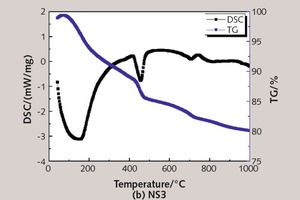

Normally, quantitative analysis of C-S-H is not directly provided by XRD, because amorphous C-S-H is impossible to be reflected by the XRD spectrum. Therefore, DSC-TG analysis was employed to intuitively obtain information on the major hydration product C-S-H. The results are shown in Figure 7.

There were two major endothermic valleys in all DSC-TG curves. The first major endothermic valley related to the bound water of C-S-H and occurred mainly in the range of 60~150 °C. The second major endothermic valley related to the decomposition of CH and occurred in the range of 420~480 °C. Obviously, the depth of the C-S-H valley increased along with the increasing NS content, indicating that NS with high pozzolanic activity and nucleation effect was favorable for C-S-H gel generation. However, the addition of NS reduced the depth of the CH valley, which is attributable to their high pozzolanic activity consuming abundant CH.

TG is a thermal analysis technique used to characterize the relationship between the sample weight and temperature. With this method, the CH amount can be calculated by thermal weightlessness between 420 and 480 °C in TG curves (Figure 7) using the following formula:

CH (%) = WLCH (%) x MWCH⇥(1)

MWH

Where WLCH is the thermal weightlessness in percent attributed to the dehydration of CH; MWCH and MWH are the molecular weights of CH and water, respectively.

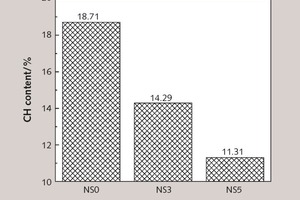

The results of CH content are shown in Figure 8. As the figure shows, the amounts of CH in sample NS3 and NS5 were 21.4 % and 39.6 %, respectively, lower than that in sample NS0. This is primarily because NS acted as potential nucleation sites for the accumulation of hydration products, and the high pozzolanic activity of NS promoted the consumption of CH. All of this confirmed the XRD results.

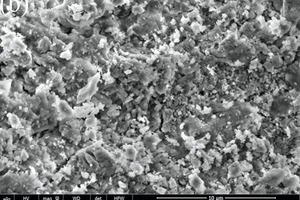

In order to intuitively observe the microstructure of samples modified with different amounts of NS, separate SEM analyses were carried out on sample NS0, NS3 and NS5 at 28 days, as shown in Figure 9.

Through comparative study, it could be seen that numerous lamellar CH crystals and some unhydrated cement particles, as well as ettringite crystals, were present in sample NS0, and that many micron-scale spaces appeared between the CH crystals. All of this decreased the compactness of the pastes. When NS was added, many gelatinous hydrates were formed, and no obvious CH crystals were found. Specifically, the gelatinous hydrates were not independent and diffusely distributed, but exhibited an integration structure, hence making the paste become more uniform and compact. Moreover, no AFt were found in Figure 9 (b) and (c), probably due to the fact that the AFt crystals in sample NS3 and NS5 were so small that they were covered with a great deal of C-S-H gel.

3.2 Effects of BF modified mortar coating on the resistance to chloride ion permeability of concrete

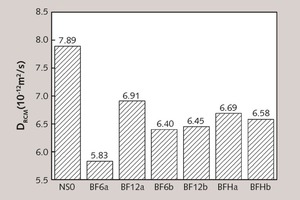

The performance of fiber reinforced mortar depends not only on its own characteristics, but also on the content, length and distribution of the fibers, all of which are decisive for the enhancement effect. In this experiment, 6 mm and 12 mm basalt fibers were selected and mixed into cement mortar. The resistance to chloride ion permeability of concrete with different amounts and different types of BF modified mortar coatings is shown in Figure 10.

As can be seen from Figure 10, mortars with different lengths of BF under different dosages have a different effect on the resistance to chloride ion permeability of concrete. However, the effect of samples with BF is better than of those without BF. When the 6 mm BF content was 0.5 % (Sample BF6a), the DRCM of concrete was at its lowest, i.e., lower by 26.1 % compared with sample NS0, which had the best permeability resistance. Once the BF content reached a certain level, any further increase in BF content was not conducive to the ability of concrete to resist chloride ion penetration. This is because excessive amounts of BF per unit volume of mortar would cause the fiber to intertwine and stack together, resulting in a poorly decentralized state, which in turn not only promotes internal defects, but also makes the fiber spacing uneven and weakens the permeability resistance of mortars to a certain extent. In addition, compared with 6 mm BF, when the length of BF increased to 12 mm or two different lengths of BF were co-doped, the chloride ion diffusion coefficient of the samples increased to a certain degree, mainly because the increase in fiber length causes more fiber-to-fiber interference and detracts from the uniformity of distribution. This generates more weakened areas and decreases the level of impermeability to chloride ions. Thus, an appropriate length and a proper admixture quantity of BF are effective in countering chloride diffusion.

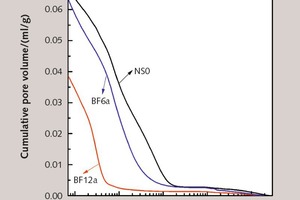

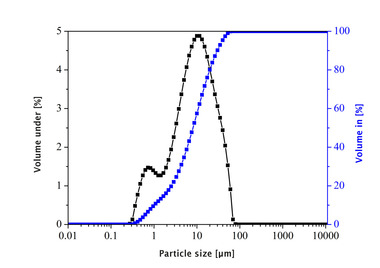

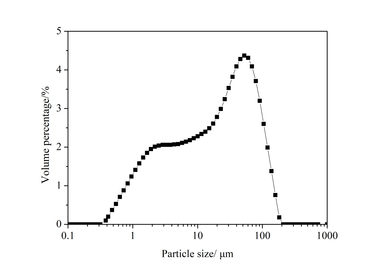

Pore structure is an important microstructural characteristic of cementitious material, with remarkable effects on its physical and permeability properties. The influence of different lengths of BF on pore structure of mortars was studied by means of mercury intrusion porosimetry (MIP). The results are shown in Table 5.

Generally, mortar with lower porosity has higher penetration resistance. From the statistics given in Table 5 it can be seen that, when the content of BF was 0.5 wt%, the porosities of mortars with 6 mm and 12 mm BF were 49.4 % and 7.6 %, respectively, i.e., higher than those without BF. Since porosity increases with increasing fiber length, excessively long fibers will have a negative impact on durability. Also, average pore size and chloride penetration resistance are strongly interrelated, showing an obviously negative correlation [44]. The addition of BF observably decreased the average diameter of pores, thus improving the mortar’s ability to counter chloride diffusion.

Figure 11 shows the integral curves of pore size distribution of hardened mortars. According to previous studies, pores with a size between 5 and 200 nm have the most adverse impact on chloride diffusivity in mortar [45], because in these pores, not only does the occurrence of capillary condensation enhance the hygroscopicity of pores, but also the generation of large capillary pressure and osmotic force increases the autogenous shrinkage stress of the mortar [46]. It also simultaneously accelerates the rate of surface and normal pressure permeation, causing an overall reduction in surface and normal pressure permeability resistance. As shown in Figure 11, the cumulative pore volume increased rapidly with the aperture in the range of 0 to 200 nm – specifically, the slope of this part of the curves increased sharply, which indicates that the apertures of the mortar were mainly distributed within that range. Compared with sample NS0, when 6 mm BF was added, the amount of capillary pores decreased significantly, which shows that appropriately sized BF could play compacting and filling roles, decrease the porosity and improve the pore size distribution of mortars, hence dramatically enhancing their ability to counter chloride diffusion. All these findings also attested to the above results of RCM analysis.

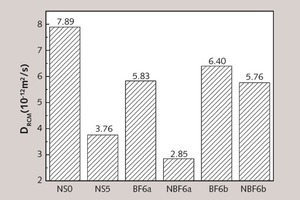

3.3 Effects of NS co-doped BF modified mortar coating on the resistance to chloride ion permeability of concrete

Introducing NS in BF reinforced mortar can give full play to the scale and performance advantages of NS and BF and enlarge the scale range of the enhancement system at different structure and performance levels, thus further improving the mortar’s performance and achieving the goal of NS and BF composite reinforcement. The effect of NS co-doped BF modified mortar coating on the resistance to chloride ion permeability of concrete were studied for a constant NS content of 5 %, and a BF content of 0.5 % or 1 %. The results are shown in Figure 12 and Figure 13.

As seen in Figure 12, compared with sample BF6a, the addition of 5 % NT made the DRCM decrease by 51.1 %, which is mainly attributable to the high pozzolanic reactivity and heterogeneous nucleation effect of NS. In addition, the mixture of micro-sized BF of three-dimensional disordered distribution and nano-sized SiO2 was able to make full use of their respective performance advantages on different scales, further strengthening the resistance to chloride ion permeability. Also, the DRCM of sample NBF6a was 10.6 % lower than that of sample NS5, primarily because the BF of three-dimensional disordered distribution blended into each other and acted as a bracket to support the aggregates, thus effectively suppressing the production of connected cracks before the mortar hardened and, at the same time, avoiding the formation of connected pores. All of these factors would improve the structure of hardened paste and eventually help improve the ability of concrete to counter chloride diffusion. Moreover, the addition of BF could prevent the growth of hot cracks caused by the rapid hydration and heat release of mortar with NS. However, when the BF content increased to 1 %, the ameliorating effect of mix BF and NS on impermeability was better than that of mix BF alone but worse than that of mix NS alone. From Figure 13, it can be concluded that the effect of mix NS and BF on the chloride ion permeability of concrete was similar to the corresponding results of Figure 12 above. Thus, within the scope of the ideal dosage, the coating co-doped with BF and NS exerted a good improvement effect on the resistance to chloride ion permeability of concrete.

Figure 14 shows the microstructure of NBFHb at 28 days using the scanning electron microscope (SEM). It was observed that the excessive fiber content and the oversized internal interface caused poor dispersion of the partial BF and cluster phenomenon, which could readily introduce additional defects. For samples with mixed BF and NS, the concrete with 0.5 % 6 mm BF and 5 % NS modified mortar coating exhibited the best resistance performance to chloride ion penetration.

4 Conclusion

In this research, on the basis of the experimental results obtained, the main findings are as follows:

As the content of NS increases, the ability to counter chloride diffusion and the amount of hydration products of C-S-H increased, while the Ca(OH)2 content decreased

More lamellar CH crystals and unhydrated cement particles were present in hardened mortar without additives, and many micron-scale spaces existed between the CH crystals. The matrix became more compact along with the dosage of NS. Especially for samples mixed with 5 % NS, the hydration products appeared to be integrated in the colloidal structure, and no evident CH crystals were found

The addition of BF was conducive to improving the ability of concrete to resist chloride ion penetration as compared to that of samples without BF, and the optimum mix amount and length were 0.5 % and 6 mm, respectively

Compared with samples without BF, when the content of BF was 0.5 wt%, the porosities of mortars containing 6 mm and 12 mm BF decreased by 49.4 % and 7.6 %, respectively. The average pore size exhibited similar changing trends. Also, the greatest reduction in capillary porosity, ranging between 0 and 200 nm, was among samples mixed with 6 mm and 0.5 % BF

The heterogeneous nucleus effect, high pozzolanic activity and micro-aggregate filling effect of NS, the inhibiting effect on connected cracks and pores of BF, and their grading advantage and synergy, together affect the resistance to chloride ion permeability of the cementitious materials. The concrete applied with 0.5 % 6 mm BF and 5 % NS modified mortar coating had the best resistance performance to chloride ion penetration.

5 Acknowledgement

The authors would like to acknowledge the 13th Five-Year Plan of National Key Research and Development (2016YFC0701003-05), the National Natural Science Foundation of China (No.51378408) and the Science and Technology Support Program of Hubei Province (2015BAA084) for supporting this research and providing the materials tested.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.