Drives for large vertical roller mills

The continuing development in the size of vertical roller mills and their corresponding increase in market share when compared to other mill types in the cement industry is only feasible with adequate drive solutions. In this article we profile the different solutions and review projects where these new drive solutions are already integrated.

1 Introduction

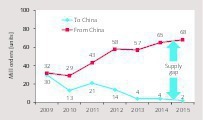

Vertical roller mills (VRM) have dominated raw materials and coal grinding for many years, and in cement and slag grinding the market share of VRM is constantly growing with larger mill sizes. In the period 2009 to 2015, of the 1209 new mills that were ordered by the cement industry outside China, 661 units or 55 % were VRM, the remaining 45 % were other types such as ball mills, high-pressure grinding rollers (HPGR) and horizontal mills. Figure 1 shows how the mill market potential developed and how the market share of VRM changed. A large quantity of mills outside China has...

1 Introduction

Vertical roller mills (VRM) have dominated raw materials and coal grinding for many years, and in cement and slag grinding the market share of VRM is constantly growing with larger mill sizes. In the period 2009 to 2015, of the 1209 new mills that were ordered by the cement industry outside China, 661 units or 55 % were VRM, the remaining 45 % were other types such as ball mills, high-pressure grinding rollers (HPGR) and horizontal mills. Figure 1 shows how the mill market potential developed and how the market share of VRM changed. A large quantity of mills outside China has already been ordered from Chinese suppliers, and the number of mills supplied to China has nearly reached zero (Figure 2). Of the 352 mills ordered from Chinese suppliers 40 % or 141 units are VRM. However, these VRM are only mills of the low and medium capacity range [1].

Figure 3 illustrates how the mill sizes for VRM have developed in the last three years. A breakdown of VRM is made by three drive sizes. Low and medium VRM are mills below 5000 kW nominal installed power. Large VRM mills are from 5000 kW to < 9000 kW and finally, very large VRM are mills of 9000 kW and above. The chart demonstrates, that small and medium VRM make up most of the market. However, the share of large and very large VRM has grown in the last three years from 29 % to 38 %. Of the 52 large and very large mills, four (8 %) had a nominal installed power of more than 9000 kW and of the 112 mills installed in the period from 2013 to 2015 with low and medium capacity, 69 % or 77 units were ordered from Chinese suppliers and only 31 % from Western suppliers. Of the large and very large VRM, all were supplied by Western manufacturers and none by the Chinese.

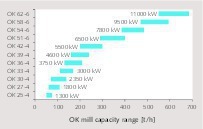

Years ago the largest VRM in the cement industry were designed and used for raw material grinding. Today, the largest VRM are designed and used for cement and slag grinding, with ever increasing capacities. As an example, Figure 4 shows the capacity range of OK cement mills by supplier FLSmidth and the related nominal motor sizes. The eleven sizes with nominal motor power of 1300 kW up to 11 000 kW cover mill capacities from 50 t/h to 685 t/h OPC cement. However, the capacity range does depend on the fineness, grindability and additives (types and proportion of mill feed). For the grinding of granulated blast furnace slag (GBFS) a 20 % bigger motor is necessary. An OK 58-6 for GBFS grinding will require an 11 000 kW motor as compared to 9500 kW for cement and the capacity of this mill will decrease to 295-420 t/h for GBFS, compared to 480-595 t/h for cement [2].

Until 2015, there were five suppliers outside China, who have delivered large VRM. Table 1 shows the number of VRM designs for motor sizes of 5000 kW and above comprising 29 mills for cement and slag grinding (CSG) and 19 mills for raw material grinding (RMG). Loesche is leading this ranking with seven mill sizes for CSG and five mills for RMG (LM mill design), followed by Gebr. Pfeiffer (GPSE) with six sizes for CSG (MPS, MVR mills) and six sizes for RMG (MPS, MVR mills). Next in the ranking is thyssenkrupp Industrial Solutions (TKIS) with six for CSG (Quadropol QMC and QMS) and four for RMG (Quadropol QMR). The other two suppliers are FLSmidth with six sizes for CSG (OK mill) and two for RMG (Atox) and UBE Machinery with four for CSG and three for RMG (UM mills). With increasing mill sizes conventional drive solutions were limited and new drives had to be developed.

2 Challenges for mill drives and new solutions

Less than ten years ago with the increase in cement, slag and raw material grinding capacities, conventional drive solutions for VRM reached their limits [3]. The limitation in the conventional drive solutions was due to the required output torque of the gearbox. In conventional drive systems with 3-stage bevel-planetary gearboxes (Figure 5) the torque is generated by the main stand-alone motor and transmitted via a first bevel gear stage and the following two planetary gear stages to the grinding table of the VRM. The gearbox reduces the high input speed of the motor to the output speed on the grinding table and changes horizontal input axes into vertical output axes. Additionally the gearbox has to absorb the grinding forces and to support the grinding table. With this arrangement, the maximum transmittable torque is limited by the max. design torque of the bevel gear stage of approximately 86 000 Nm (9000 kW @ 1000 rpm) with leads to the critical bevel gear diameter of about 2 m.

Failures in conventional 3-stage bevel-planetary gearboxes were located in the bevel stage, and also specifically in the sophisticated bearing and cooling equipment for the high speed input shaft, while the other gearbox components such as the planetary stages have proved to be technically mature. Loesche for this reason has limited the power transmission with these conventional gearboxes to 7800 kW [4]. The nominal maximum power of the most widely used gearbox for large VRM is 8000 kW in the Siemens KMPP, however there are developments with an improved bevel-planetary design which is possible with a lower gear ratio of the bevel stage and a torque split in the planetary stage. The largest 3-stage WPV gearbox by FLSmidth Maag Gear is now available up to 9000 kW, with a tested version for 8600 kW [5].

However, today’s power requirements for large VRM exceed the capacities of conventional drive systems. There are principally three different solutions. The first option is new gear concepts with integrated drives, the second option is dividing the required power into a multiple of smaller drive units and the third is a separate drive solution for each roller in the VRM. The main objectives are: achieving power requirements above 9000 kW, high operating efficiency, availability and redundancy of the drive system, avoidance of critical components and a reasonable price/performance. The price/performance is dependent on parameters such as investment costs, variable speed drive requirements, maintenance costs and lifetime. Finally, it also depends on which new gearbox solution or brand will be available for which kind of mill/brand or whether there are exclusive agreements.

2.1 Gearbox with integrated motor

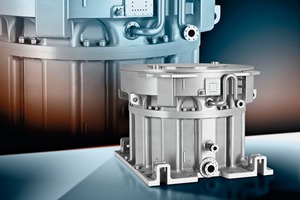

At the moment there are two solutions available on the market. In 2010 Siemens introduced the Flender EMPP drive concept (Figure 6) to the market, while FLSmidth Maag Gear introduced their CEM drive concept in 2011. Both concepts have a modular design in common with an integrated permanent magnet synchronous motor and one to two planetary gear stages. These drive systems are available up to 15 000 kW, although the Maag design was first made for 8000 kW. The elimination of a bevel gear stage and the coupling of the motor torque to the planetary gears enables the power to be optimally transferred with a high efficiency of the mechanical system and less complex components. However, this drive system requires a variable frequency converter (VFC) for the motor. The VFC allows the mill speed to be continuously adjusted, ideally matching the specific grinding requirements for blended cements.

The heart of this drive solution is the permanent magnet motor which is particularly robust and entirely wear-free with an extremely durable stator winding. The use of permanent magnets minimizes ohmic losses in the rotor, resulting in reduced energy costs. High attention has been paid to the cooling and lubrication systems. In the case of the CEM drive (Figure 7) the cooling system is simplified via only one oil circle for the motor and the planetary gear stages. The integrated motor has a number of benefits when compared to the conventional system with external motor, which needs a motor foundation, alignment and auxiliary drive for maintenance work. The mechanical part of the gearbox is well-proven. Furthermore the drive is so compact, that conventional gearboxes can be replaced. These drive systems are available for all VRM suppliers. However, up to now only a few are operational.

2.2 Multiple drive solutions

In 2012 Siemens introduced to the market a multiple drive solution for VRM. In the “MultipleDrive System” concept by Siemens up to six independent drive units power a common girth gear, which supports the grinding table of the VRM. Grinding forces are not transmitted to the gear units and the building height is low. The concept unites the benefits of a variable speed drive with the modularity of multiple standard drives. The solution is designed for large VRM up to 16 500 kW. A first system was sold by GPSE for a MVR vertical roller mill with an installed power of 12 000 kW and featured as patented “MultiDrive” system [6]. Figure 8 shows the drive system with four drive modules, each comprising a standard bevel-spur gear coupled to a squirrel cage motor with 1650 kW nominal power and active redundancy on a partial load level if a motor is unavailable. In the MultiDrive solution by GPSE a VSD is optional. The complete capacity range from 4000 to 12 500 kW is covered by four sizes.

Renk introduced their new and compact COPE gearbox design in 2013 [7]. The COPE drive system extends the planetary KPBV gearbox design and is available in four sizes to cover power ratings from 2500 to 13 000 kW. The design (Figure 9) comprises a 2-stage planetary gearbox that is driven by six to eight water jacket cooled cage induction motors as they are used for driving cutter heads of large tunnel drilling machines. The drive system is equipped with the motors and controllers. Variable speed drives (VSD) are optional but not necessary. The first COPE drive was used in a Loesche 70.4+4 cement mill, which has a drive capacity of 8800 kW, supplied by eight 1100 kW drive units. The COPE drive achieves highest drive system efficiencies and has low maintenance needs [4]. Active redundancy is also possible if one of the motors is not available. The drive development was a result of a cooperation between Renk and Loesche, with a five-year exclusivity for marketing, application and development of the drive system.

FLSmidth Maag Gear developed the MAX drive for vertical mills up to 15 000 kW. This system comprises two 3-stage spur gears, which drive a girth gear around the central part on two flanks (Figure 10) and the motors. The spur gears have a compact design due to a torque split in the gearbox and transmit the power from the squirrel cage vertical motors via the girth gear to the grinding table. The torque split between the two pinions and highly flexible couplings enable a mechanical synchronization so that the total torque is always equally distributed and that any torque imbalances are automatically equalized. Self-alignment of the pinions is achieved by a crowned toothing between pinion and pinion shaft. The central part of the system with the girth gear and a thrust bearing supports the grinding table and grinding forces. The system is designed with only two drives for mill power up to 15 000 kW. The first system will be provided for an FLSmidth OK 62-6 mill with 11 650 kW installed drive power.

2.3 The roller driven solution

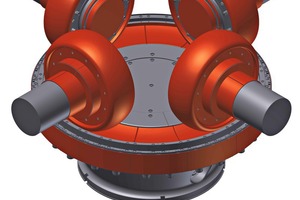

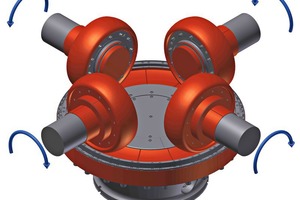

An innovative new drive concept for VRM was introduced by thyssenkrupp Industrial Solutions (TKIS) with the second generation of their Quadropol VRM [8]. The Quadropol is now available with two drive options, the TD table drive and the RD roller drive (Figure 11). In the RD version all rollers are equipped with their own drive and gear unit. In contrast to the TD version the rollers rotate faster than the table, which results in a better material intake under the roller, less vibration and a higher grinding efficiency. As there is no contact between roller and grinding table, the mill housing is completely free of grinding forces. A RD roller unit comprises the grinding roller with drive shaft, bearings and hydraulic cylinder and the drive unit consisting of a compact bevel-planetary gear and a frequency-controlled motor, which is coupled to the gear via a cardan shaft with torque sensor.

Depending on the required power capacity there are three different versions with three, four and six separate drives. Principally, the RD drive solution is another multiple drive version. The required power for the mill is divided into a multiple of smaller drive units (Figure 12). Accordingly the RD drive assures low drive torques even at high capacities. Furthermore, the standard bevel-planetary gears used are very similar to the ones of roller presses (HPGR), but with 1800 kW still significantly smaller in size, when compared to the largest HPGRs drives, which exceed 3000 kW. In mills with four and six rollers, reduced operation is possible with two opposing rollers lifted or removed. Because of the electronic synchronization of the VSD drives the mill can be adjusted to the grinding requirements.

3 VRM with new drive solutions

If Table 1 is again taken into account, then it becomes clear that firstly not all the mill designs in the table have been ordered up to now and secondly most of the mills have been supplied with conventional 3-stage bevel-planetary gears. So the cases in which new drive concepts are used are, up to now, relatively rare. FLSmidth for example has sold three OK 54-6 with up to 8000 kW installed power (Figure 13). These three mills still have conventional gears. One is already in operation producing the guaranteed 320 t/h of OPC with 3200 Blaine. The first new drive solution was sold by FLSmidth with an OK 62-6 with 8.1 m table diameter. This mill was ordered by Shah Cement for their Mukhtarpur plant in Bangladesh and will have an installed power of 11 650 kW and a MAX drive. The mill is designed for the grinding of OPC, PPC, PSC and slag with a maximum capacity of 640 t/h for cement with 3800 Blaine. Start-up is scheduled for November 2017.

Gebr. Pfeiffer (GPSE) has sold the MultiDrive solutions in combination with MPS and MVR mills. So far 5 MVR are equipped with MultiDrives. The first mill with MultiDrive was the MVR 5600 C-4 for the Balaji plant of Jaiprakash Associates in India. Here a throughput of 350 t/h for Pozzolana Cement with 4300 Blaine could be achieved [9]. The largest MVR are two MVR 6700 C-6. One is operated by LafargeHolcim in their Barroso cement plant in Brazil (Figure 14). The guaranteed production rate is 448 t/h of slag cement with 4300 Blaine. This mill has six drive units with combined power of 11 500 kW. Another mill is operated by Cilas in their Biskra plant in Algeria (Figure 15). The guaranteed production rate is 342 t/h cement with 3700 Blaine. The mill is fitted with five drive units with combined power of 9125 kW. These MVR/MultiDrive solutions are very interesting, because of the potential high redundancy of the mill and drive concept.

Although introduced in 2013, the first COPE drive solution by Renk/Loesche only recently started operation. The first mill to be equipped with this drive is a LM 70.4+4 CS cement mill (Figure 16). This mill has been in operation since October 2016 at Unicem’s new Mfamosing cement plant in Nigeria. The mill has a power capacity of 8800 kW, driven by eight 1100 kW motors. The guaranteed output of the mill is 370 t/h of cement with 4700 Blaine. Further orders include a mill LM 72.5 CS for raw materials grinding and a LM 72.4+4 CS cement mill (Figure 17), both with a grinding table diameter of 7.2 m. The installed power for these two mills are 7500 kW and 10 000 kW respectively, provided by six and eight drives, each with 1250 kW. However, the COPE drive will not only be used in very large mills. Another order is for a LM 53.3+3 CS for cement grinding. This mill has an installed power of 4600 kW, which is split by 8 drive units, each with 575 kW.

Thyssenkrupp Industrial Solutions (TKIS) has so far installed three Quadropol mills with roller driven drives. The smallest of these mills is operated by LafargeHolcim in their La Rochelle cement plant in France. The Quadropol QMC2 48/24 3RD (Figure 18) is for the production of CEMI 52.5R cement and ground granulated blast furnace slag (GGBFS) with up to 6000 Blaine. The required power of 3900 kW is provided by three drives with 1300 kW, each. The largest Quadropol QMC2 64/30 4RD (Figure 19) is for Cycna de Oriente in their Palmar del Bravo plant in Mexico. This mill has a power requirement of 7200 kW, provided by four drives with 1800 kW, providing a guaranteed throughput of 265 t/h CPC-30R cement with a fineness of 3 % < R45 µm. The mill has already achieved higher throughputs as well as reducing the specific power consumption of the mill, separator and mill van to only 28.7 kWh/t, which is about 22 % less than guaranteed.

4 Conclusion

The latest developments in drive solutions for large VRM are fascinating because of their different designs and advantages. For us it is too early to give a statement about price/performance parameters and added value of these solutions. However, some trends can be observed. Conventional drive solutions will still compete with the new drive solutions up to 9000 kW. Of the new drive solutions, most of them will mainly make sense over 5000 kW or more but will depend not only on the technical concept, but also on the mill suppliers, who will market these solutions with their mills. Clearly the preference of mill suppliers by cement customers will have a big impact. Open solutions, such as gearboxes with integrated motors compete with the preferences of the mill suppliers. Maybe more direct orders will be seen here from the replacement sector of conventional drives.

However, at the moment two concepts seem to be leading. One is the MultiDrive solution by GPSE/Siemens the second one is the COPE drive solution by Loesche/Renk. Both concepts are multi-drive solutions, each one having more advantages than disadvantages. The price/performance concept seems to be very well interpreted by Loesche/Renk. If the motor solution of this concept is as reliable as proposed, then this will be a strong point. In the GPSE/Siemens concept the strong point is that the active redundancy concept fits in very well with the MVR mills, maybe more than to any other mill. The multiple drive concepts will be completed by FLSmidth/Maag Gear’s MAX concept, which is also a very interesting solution. The TKIS concept is the most innovative of all, but price/performance is still the main disadvantage. If the roller driven solution generates added value such as a significant lower energy demand, preferences could change in the future.

//www.onestone.eu" target="_blank" >www.onestone.eu:www.onestone.eu

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.