The new Siemens MultipleDrive

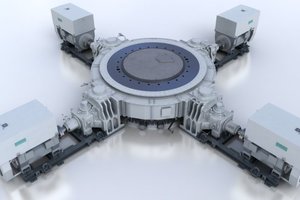

Siemens MultipleDrive is an innovative drive system for vertical roller mills focusing on availability.

The drive train

The drive train

The mill

The MultipleDrive system

Frequency converters

Electric motors

Couplings

Gear units

Mill support

Condition monitoring system

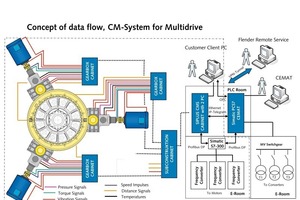

Overall integration of the MultipleDrive in the Plant Control System

Load distribution between the drive modules is taken care of by controls which are part of the frequency converters. The frequency converter also allows adjustment of the speed of the grinding table to optimize the throughput for the particular material being ground.

The mill support carries the grinding bowl. Forces coming from the grinding process are transmitted by the mill support into the foundation via slide bearing segments just as in a conventional drive. However, the drive modules themselves only have to transmit torque and do not carry any forces coming from the grinding process, because they are located outside the mill support.

Especially with raw meal, an uninterrupted flow of material is important, since the kiln requires continuous feeding. If one of the drives requires maintenance, a drive module can be pulled out of mesh with the mill support while the mill can still be operated with the remaining drives. In this way, the grinding process can continue with slightly reduced power even with major components removed.

The drive system is composed of highly standardized components: for the entire power range there are five mill supports and three drive module sizes. These are combined to match the required mill size and mill power. Spare part management is made easier and lead times are reduced since the parts used are of an easy manageable size.

A drive system for a 6600 kW mill with four drive modules of 1650 kW each for example uses modules of only 22 t in weight (Fig. 2). Compared to a conventional drive, these modules are much easier to handle.

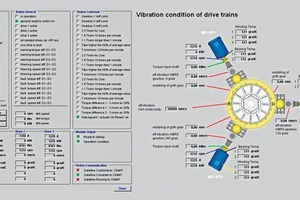

Condition Monitoring System (CMS)

Earlier failure detection

Shorter repair times

Planned spare parts procurement

Prevention of unscheduled downtimes

Improved planning and throughput

Minimization of on-site visits

Higher system availability

Better utilization of the system potential

Overall integration of the MultipleDrive in the

Process Control System Cemat based on Simatic PCS7

In a state-of-the-art controlled plant, only a few operators are responsible for smooth operation of the production. This means that they need a system at a higher level to collect general information from all existing sub-systems and make it available to the operators.

Cemat, the leading Process Control System from Siemens for the cement industry controls the whole grinding plant in Val de Seine. Cemat is much more than just a database with a few cement-specific modules. It contains a complete philosophy on how to operate cement or grinding plants, and how to make diagnostics to keep downtimes to a minimum in the event of a plant problem. Special function blocks and faceplates are designed to manage all kinds of operation, interlocking and supervision functions that are typically required. The main functions included in the Cemat system are as follows:

Supervision and control of all users involved, such as hydraulic pumps, bucket elevators, blowers, conveyors etc. and sub-control systems such as CMS, frequency converters, weighing feeders and so on.

Operator support during start-up and stop sequence as well as during regular operation, set points of control loops etc.

Optimized message functionality to reduce the operator load and to display only relevant information

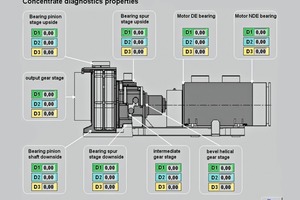

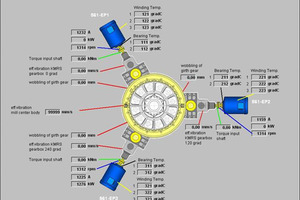

In the cement industry well known “diagnosis pictures” (Fig. 4) from Cemat are specially adapted to the MultipleDrive functionality. The diagnostic dialog shows the inputs and outputs of the block, including status information, interlocking conditions, and faults. It also permits the modification of process parameters. The operator receives comprehensive information about the MultipleDrive system in one picture and thus he is informed at first sight.

Drive mode selection (all three, or two out of three)

Welding mode selection (preselecting of a very slow speed for maintenance)

Status of all drives

Status in general for start-up or in operation

Status of CMS

Status of the communication with the sub-systems

Operating experience

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.