Operating experience with the Pfeiffer MVR vertical roller mill and the MultiDrive®

The MVR vertical roller mill and the MultiDrive® from Gebr. Pfeiffer SE provide solutions for the cement industry that are ideally suited for meeting the requirements for ever increasing production outputs and progressively greater availabilities. Operating experience gained in more than 25 000 hours is meanwhile available for both the MVR vertical roller mill and the MultiDrive®.

In the course of time, the MPS mill has been continuously...

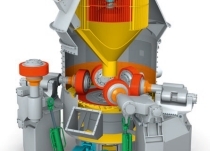

In the course of time, the MPS mill has been continuously advanced. In response to market requirements and the trend towards grinding systems with ever increasing throughput capacities, Gebr. Pfeiffer SE has developed a forward-looking concept for a new mill and a new drive. The new MVR vertical roller mill for grinding cement raw material, cement and granulated blast furnace slag has a modular design, which enables operation to be continued even if one roller module fails. The new MultiDrive® drive system, which consists of up to six identically sized drive units, incorporates the same actively redundant design principle as the mill‘s roller modules. This significantly reduces unplanned stoppage times, even in the case of main component failure.

1 Design features of the MVR mill

A roller module consists of the roller with cylindrical roller tyre, the roller axle, the roller arm, the bearing stand and the hydraulic force transmission unit. This special roller suspension design combined with the flat grinding table geometry ensures that the grinding gap between the rollers and the table remains parallel, ensuring uniform compression of the grinding bed and resultant smooth running (Fig. 2). Each pair of adjacent roller modules rests on a twin support that connects them to the foundation. This design provides more space between the supports, facilitating access and positively influencing the plant layout with regard to the arrangement of the hot gas ducts, the external material circulation and the accommodation of ancillary equipment.

Using the same hydraulic system that applies the grinding force during operation, the roller modules can be individually swung out of the mill. If the drive comprises a planetary gear unit, production can only be continued at reduced capacity after two opposing rollers have been lifted or swung out. The main advantage of the MultiDrive® with its several drive modules is that it enables operation to continue even if only one roller is lifted or swung out [1].

The trend towards higher throughputs, i.e. larger mills, is inevitably linked with the demand for larger gear units coupled with falling mill rotational speeds. The mill performance is thus determined more by the size of the torque. To avoid problems caused by using larger and larger planetary gear units, Gebr. Pfeiffer SE developed the MultiDrive® concept in co-operation with Flender/Siemens. In the MultiDrive®, two to six identical drive modules, each with installed drive powers of up to approx. 2000 kW, drive the grinding table via a girth gear located under the grinding table. Each drive module consists of an electric motor, a coupling and a combined spur and bevel gear unit mounted on a base frame to form a transport unit. It is also equipped with a frequency converter, a transformer and an oil supply station.

The load distribution to the individual electric motors is performed by a primary control system through frequency converters associated with each drive module. This design concept enables the adjustment of the grinding table speed for the purpose of process optimization. The grinding forces from the bed of material are transmitted into the foundation via a conventional plain bearing assembly. The combined spur and bevel gear units arranged around the periphery of the girth gear are not subjected to any grinding force. If one combined spur and bevel gear unit fails, it can be taken out of meshing and the MVR mill can then be operated at reduced throughput capacity.

Benefitting from the principle of active redundancy, the MVR/MPS mill equipped with a MultiDrive® is able to maintain operation even if problems occur either with the grinding rollers or with the drive. Even though the drive power range extends from 2000 kW to 12 000 kW only five roller modules and three different drive units are used for the entire mill type series [2].

2 Operating experience

The ordered MVR 5600 C-4 vertical roller mill has a grinding table diameter of 5.6 m and roller diameters of 2.83 m. It is driven via a MultiDrive® with four modules with drive powers of 1650 kW each. The guaranteed output rate for Portland fly ash cement PPC with 30 % fly ash content (corresponding to CEM II/B-V acc. to EN 197-1) is 320 t/h at a fineness of 3500 cm²/g acc. to Blaine. The guaranteed specific power requirement of the mill is 18.7 kWh/t. A second product manufactured with the MVR is Portland Cement OPC (CEM I acc. to EN 197-1) at 3000 cm²/g acc. to Blaine.

Fig. 6 and Fig. 7 show the erection of the mill housing between the preassembled supports. The swung-in rollers are shown in the top view in Fig. 8. In the subsequent erection phases, the lower and upper parts of the classifier are mounted on the lower section of the mill (Fig. 9).

In May 2012, the MVR was put into service (Fig. 10). The mill has meanwhile been in operation for more than 1000 hours, achieving an output rate of 327 t/h for PPC at a mass-specific surface of 3800 cm²/g (Blaine). The specific power consumption at the main drive of the mill is better than the guaranteed value. For OPC cement the mill has achieved an output rate of 289 t/h at 3000 cm²/g (Blaine) and a specific power consumption at the main drive of 15.2 kWh/t.

Table 1 shows the strength development of the CEM I produced in the MVR compared to other plants that also manufacture CEM I at low Blaine values.

3 Projects in hand

The mill is to be used for manufacturing five cement types with different portions of granulated blast-furnace slag at output rates of up to 450 t/h for a CEM II/B-S acc. to EN 197 at a mass-related surface of 4300 cm²/g acc. to Blaine. The hot gases required for drying purposes will be taken from the clinker cooler of the kiln line, if necessary backed-up by a hot gas generator.

The installation schedule stipulates a period of 21 months from the contract signing to production of the first cement. The various component groups are currently being manufactured, the core parts in European workshops. The first items were already shipped at the end of June 2012.

In Port Kembla, Australia, Cement Australia (a JV between Holcim and HeidelbergCement) is going to build a grinding terminal for the production of ground granulated blast-furnace slag cement and CEM I. Fig. 11 presents a visualization of the planned facility. The planned annual production is 1.1 million tonnes. To achieve this, Cement Australia has ordered an MVR 6000 C-6 to be driven by a MultiDrive® equipped with three modules of 1840 kW each.

In this case the decision for the MVR with MultiDrive® was taken on the basis of the expected shorter stoppage times due to the redundancy concept, and the lower risk of gear unit failure. A further reason was the cost-saving spare parts inventory for the gear unit modules in contrast to a conventional planetary gear unit. Like the plant in Barroso/Brazil, this project is a partnership undertaking of Cemengal and GPSE. In order to minimize work on the construction site, some plant sections, e.g. the process filter and the finished product silos are already being preassembled in Spain. Each of the silos will be delivered to the plant site in only three sections. Plant commissioning is scheduled for October 2013.

4 Summary and prospects

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.